Page 5 from 6 921377000_09_007

Input for external button LAY 5-BP111

Τhe external button LAY 5-BP111 operates in

o

surrounding temperature: -25~+55 C, the rated

insulation voltage is: 600V AC (50-60Hz) and

the IP rating is: ΙΡ40. The external button can

used to mute/reset the alarm relay, Buzzer and

Red indicator as described in each section.

WARNING!!! The cable length between the

external button and the system must not

exceed three (3) meters.

System Calibration

WARNING!!! The calibration procedure of the

detector must be done by qualified personnel

that have previously read the user manual.

-The special calibration function is not available

to the user if there are faults in the system.

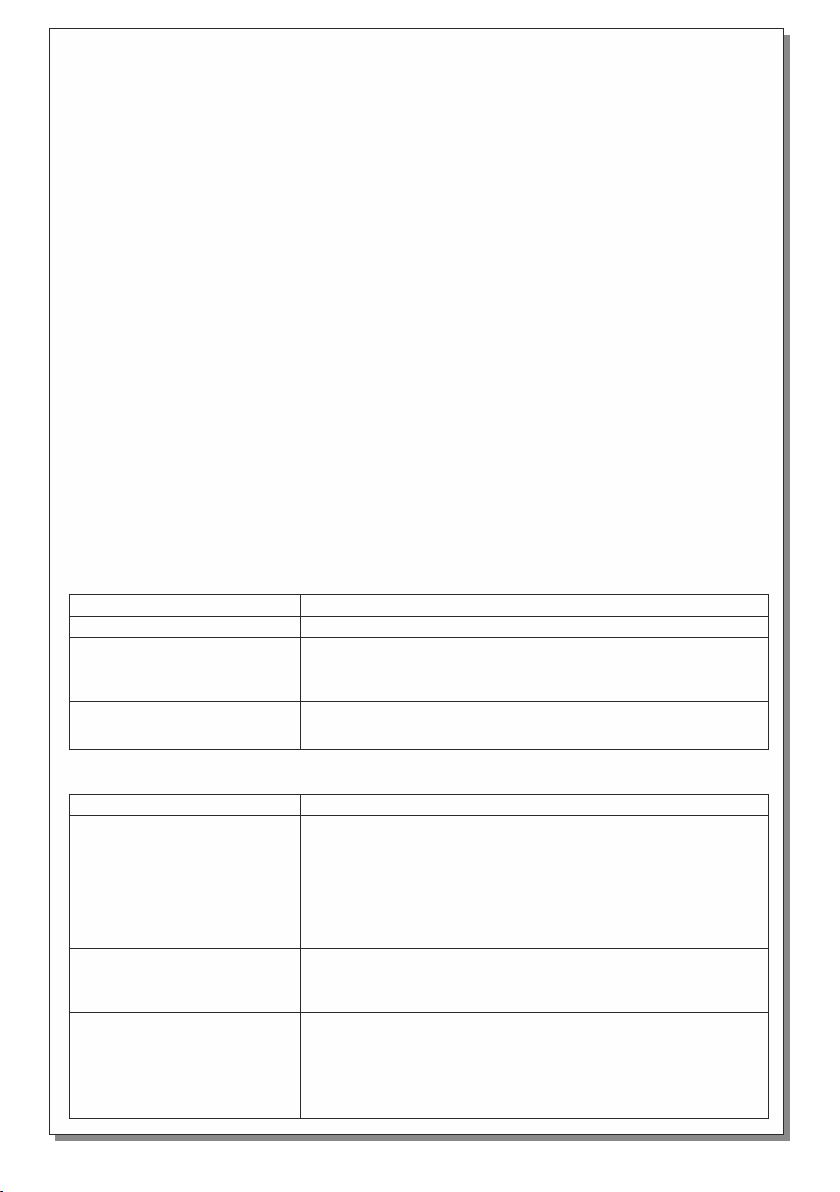

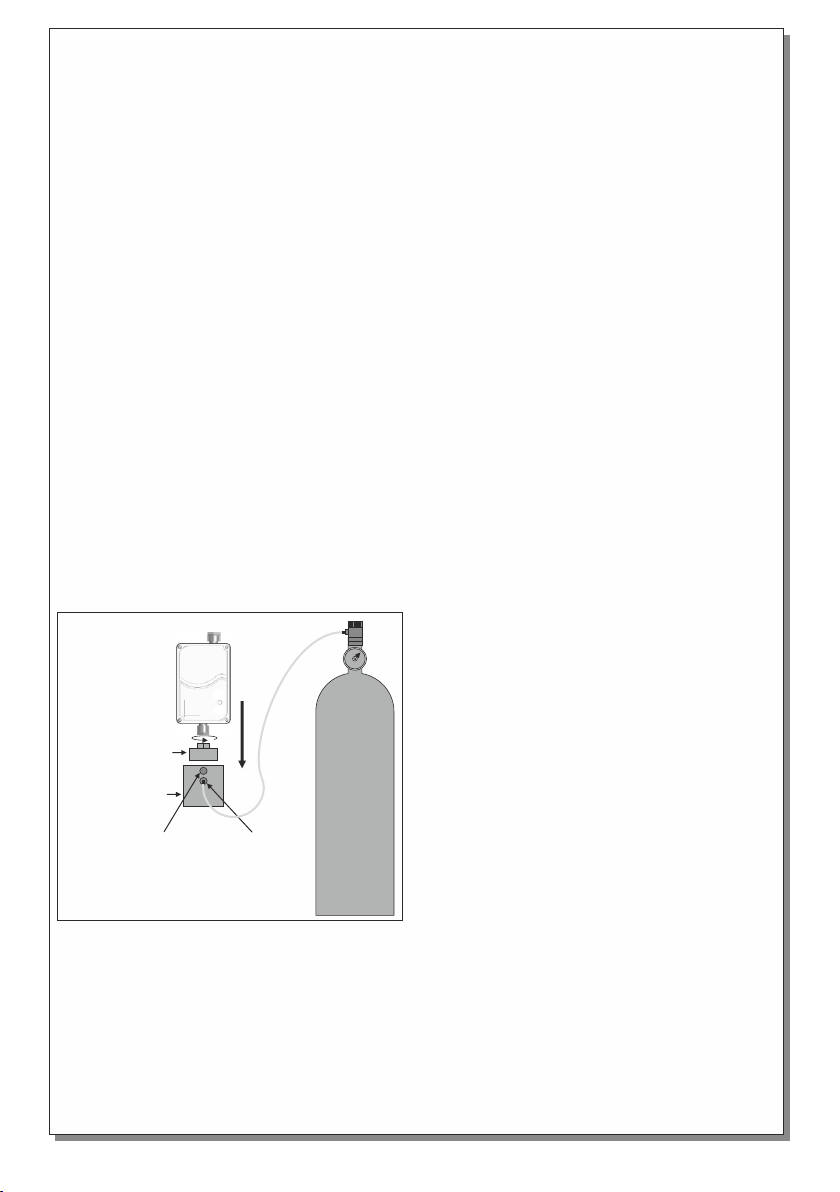

-For the calibration procedure using a reference

gas, the OL-11 calibration kit is required. (figure

4).

-For the calibration procedure using a reference

gas, a mixture 20% or 50% L.E.L. with oxygen

and nitrogen is used. The explosive gas

catalytic sensors do not operate without oxygen.

-It is suggested to conduct the calibration

test at least once every 12 months.

-During the calibration procedure, conduct a

clean air calibration and then a reference gas

calibration.

To calibrate the device, remove the 4 retaining

screws (figure 1) in order to gain access to the

interior.

Clean air calibration

Take the following steps:

1.Ensure that the environment is clean and does

not contain explosive gases.

2.Select using the switches S1 and S2 (figure 3)

the special function «Clean air calibration»

3. Press the button BT2 (figure 3) for more than

3 seconds until the 3 system LEDs(green,red

and yellow) start to blink with a one second rate.

4.Wait 4 seconds until the procedure is

completed. This step may last 60 seconds

more in some instances.

When the procedure is finished, the yellow led

a n d t h e b u z z e r o p e r a t e i n t e r m i t t e n t l y.

(intermittent brief activation every second).

At this point there are two instances:

-The green led is lit. This means that the clean

air calibration has finished with success. Press

and hold the button ΒΤ2 for more than 1 second

to exit calibration mode and to return the

detector to normal operation.

-The red led is lit. The clean air calibration

procedure did not finish successfully. Press and

hold the button BT2 for more than 1 second to

exit calibration mode and to return to normal

operation. You can repeat the process by

following the steps from the beginning.

Calibration using a reference gas

The steps for calibrating using a reference gas

are the following:

1. Ensure that the environment is clean an free

from explosive gases.

2.Remove the gland with the filter located on the

sensor head (figure 1).

3. In its position install the accessory OL-11-1 of

the calibration kit OL-11 (figure 4).

4. Install the part OL-11-2 on the part OL-11-1

(figure 4).

5. Select via the micro-switch S4 (figure 3) the

concentration of the reference calibration gas

that will be used (20% or 50% L.E.L.).

6. Select via the micro-switches S1 and S2

(figure 3) the special operation «Calibration with

a reference gas».

7. Press and hold the button BT2 (figure 3) for

more than 3 seconds until the 3 system LEDs

( g r e e n , r e d a n d y e l l o w ) s t a r t t o b l i n k

(intermittent blink once a second) and then

release the button.

8. Open the steady pressure valve (0.3L /

minute) of the reference gas canister.

9. Wait 3 minutes until the procedure finishes.

This step may last 60 seconds more in some

instances.

While waiting for the procedure to complete

you can cancel it at any time by pressing the

Bt2 button for more than 3 seconds.

When the procedure is finished, the yellow led

a n d t h e b u z z e r o p e r a t e i n t e r m i t t e n t l y.

(intermittent brief activation every second).

At this point close the flow valve on the gas

canister.

At this point there are two instances:

-The green led is lit. This means that the

reference gas calibration procedure has finished

with success. Press and hold the button ΒΤ2 for

more than 1 second to exit calibration mode and

to return the detector to normal operation.

-The red led is lit. The reference gas calibration

procedure did not finish successfully. Press and

hold the button BT2 for more than 1 second to

Gas

Canister

Detector

Adapter

OL-11-1

Outlet

port

figure 4

OL-11-2

Inlet

port