sewerin EX-TEC SR5 User manual

Instructions

Operating-

102424

Measurable success by Sewerin equipment

You settled on a precision instrument.

A good choice!

Our equipment stands out for guaranteed safety, optimal output and efficiency.

They correspond with the national and international guide-lines.

These operating instructions will help you to handle the instrument quickly and

competently.

Please pay close attention to our operating instructions before usage.

In case of further queries our staff is at your disposal at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

D-33334 Gütersloh

: +49 - (0) - 52 41/9 34-0

FAX : +49 - (0) - 9 34-4 44

http:// www.sewerin.com

1

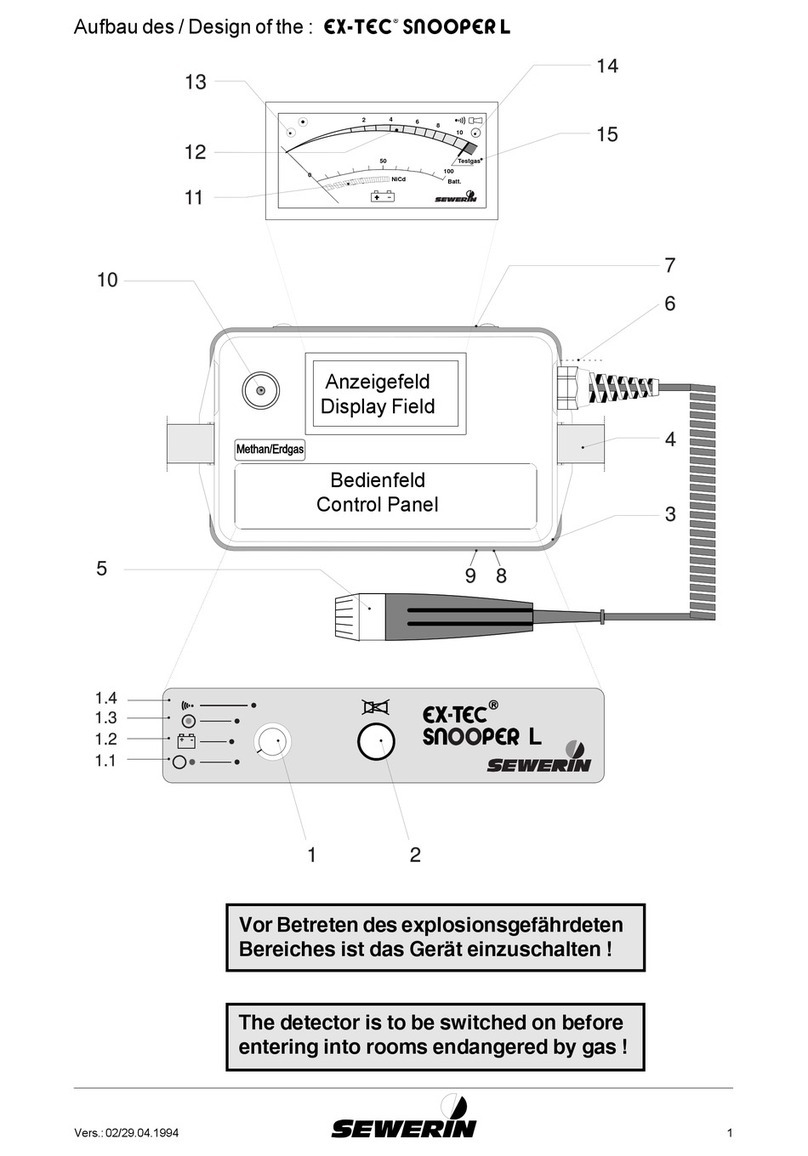

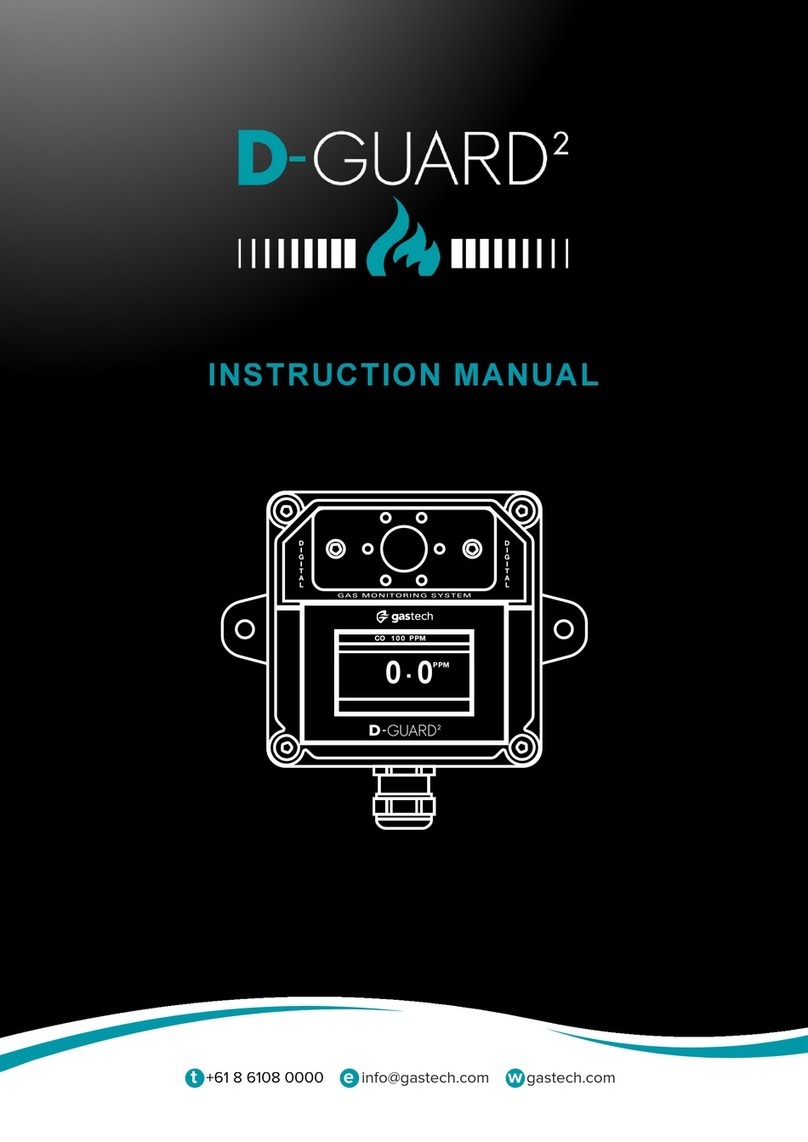

Design of the: EX-TEC® SR5

1

2

3

6

7

4

5

2

Notes

3

EX-TEC® SR 5, SR4, SR2

VARIOTEC® 8

Operating InstructionsOperating Instructions

Operating InstructionsOperating Instructions

Operating Instructions ................

................

........ pages 3 - 52pages 3 - 52

pages 3 - 52pages 3 - 52

pages 3 - 52

102424 - 04/20.08.1999

4

For your safety *For your safety *

For your safety *For your safety *

For your safety *

The law governing technical equipment (the Law on the afety of Appliances)

of 24.06.1968 (BGBl.I, page 717) as amended by the Amendment Law of

13.08.1979 (BGBl.I, page 1432) requires the following matters to be drawn

to your attention:

Comply with the Operating InstructionsComply with the Operating Instructions

Comply with the Operating InstructionsComply with the Operating Instructions

Comply with the Operating Instructions.

Before operating or adjusting the appliance you must be thoroughly familiar

with this operating manual. You must comply with it in every respect.

The appliance is designed only for the application described and for

industrial (commercial) use.

Liability for Function an /or DamageLiability for Function an /or Damage

Liability for Function an /or DamageLiability for Function an /or Damage

Liability for Function an /or Damage

Liability for the functioning of the appliance passes to the owner or operator

in all cases in which the appliance has been improperly maintained or

repaired by persons not associated with EWERIN ervice or if it has been

used for a purpose not in accordance with its designated application.

You should therefore always use original EWERIN accessories with the

EX-TEC® SR 5, SR4, SR2 and VARIOTEC® 8.

Hermann ewerin GmbH accepts no responsibility for damage due to a

failure to comply with the foregoing instructions. The guarantee and liability

terms of the Hermann ewerin GmbH terms of sale and supply are not

extended by the foregoing.

We reserve the right to make technical changes in the course of continued

development.

HERMANN EWERIN GMBH

* All references to laws, statutes and norms relate to the legislation of the Federal Republic of

Germany.

5

ContentsContents

ContentsContents

Contents pagepage

pagepage

page

For your safetyFor your safety

For your safetyFor your safety

For your safety ........................................................................................................................................................................

........................................................................................................................................................................

.................................................................................... 4 4

4 4

4

1.01.0

1.01.0

1.0 The EX-TEC® SR5, SR4, SR2 and VARIOTEC® 8

models ............. 6 6

6 6

6

1.1 Tests ............................................................................................. 8

1.2 Probe systems ............................................................................. 9

2.02.0

2.02.0

2.0 Measuring operationMeasuring operation

Measuring operationMeasuring operation

Measuring operation................................................................................................................................

................................................................................................................................

................................................................ 1 1

1 1

111

11

1

2.1 witching on ................................................................................ 11

2.2 Illumination and contrast ............................................................. 12

2.3 Pump operation .......................................................................... 13

2.4 Alarm signal and volume ............................................................ 14

2.5 Alarm threshold value ................................................................. 14

2.6 witching measuring ranges ...................................................... 15

2.7 Zero-point adjustment ................................................................ 16

2.8 Workplace monitoring ................................................................ 16

2.9 Battery alarm............................................................................... 18

2.10 witching off ............................................................................... 18

3.03.0

3.03.0

3.0 Charging techniqueCharging technique

Charging techniqueCharging technique

Charging technique..................................................................................................................................

..................................................................................................................................

................................................................. 19 19

19 19

19

4.04.0

4.04.0

4.0 Inspection, testing an maintenanceInspection, testing an maintenance

Inspection, testing an maintenanceInspection, testing an maintenance

Inspection, testing an maintenance........................................................................

........................................................................

.................................... 21 21

21 21

21

4.1 Test sets ..................................................................................... 22

4.2 Test gases .................................................................................. 24

4.3 Function testing .......................................................................... 25

5.05.0

5.05.0

5.0 A justmentA justment

A justmentA justment

A justment................................................................................................................................................................

................................................................................................................................................................

................................................................................ 26 26

26 26

26

6.06.0

6.06.0

6.0 TT

TT

Technical specificationsechnical specifications

echnical specificationsechnical specifications

echnical specifications..................................................................................................................

..................................................................................................................

......................................................... 34 34

34 34

34

7.07.0

7.07.0

7.0 TT

TT

Technical ataechnical ata

echnical ataechnical ata

echnical ata ....................................................................................................................................................

....................................................................................................................................................

.......................................................................... 37 37

37 37

37

8.08.0

8.08.0

8.0 AccessoriesAccessories

AccessoriesAccessories

Accessories............................................................................................................................................................

............................................................................................................................................................

.............................................................................. 39 39

39 39

39

9.09.0

9.09.0

9.0 Error messagesError messages

Error messagesError messages

Error messages ..............................................................................................................................................

..............................................................................................................................................

....................................................................... 40 40

40 40

40

10.010.0

10.010.0

10.0 Parts subject to wearParts subject to wear

Parts subject to wearParts subject to wear

Parts subject to wear ............................................................................................................................

............................................................................................................................

.............................................................. 42 42

42 42

42

EC-TEC-T

EC-TEC-T

EC-Type Examinations Certificateype Examinations Certificate

ype Examinations Certificateype Examinations Certificate

ype Examinations Certificate ....................................................................................................

....................................................................................................

.................................................. 43 43

43 43

43

Declarations of conformityDeclarations of conformity

Declarations of conformityDeclarations of conformity

Declarations of conformity ............................................................................................................................

............................................................................................................................

.............................................................. 47 47

47 47

47

TT

TT

Test reportsest reports

est reportsest reports

est reports................................................................................................................................................................................

................................................................................................................................................................................

........................................................................................ 51 51

51 51

51

6

1.01.0

1.01.0

1.0 The The

The The

The EX-TEC® SR5, SR4, SR2 and VARIOTEC® 8 mo elsmo els

mo elsmo els

mo els

This family of detectors consists of a total of four combined detectors

for the following uses:

EX-TEC® SR5 (Ex-protected)

•Gas etectionGas etection

Gas etectionGas etection

Gas etection

above-ground gas detection for

pipeline monitoring (ppm range)

•Interior installationsInterior installations

Interior installationsInterior installations

Interior installations

leak detection for pipelines in

buildings (ppm range)

•Workplace monitoringWorkplace monitoring

Workplace monitoringWorkplace monitoring

Workplace monitoring

monitoring proximity to the

Lower Explosive Limit (%LEL

range)

•LocationLocation

LocationLocation

Location

concentration measurement in

probe holes (vol.% range)

•Gasing an inertisationGasing an inertisation

Gasing an inertisationGasing an inertisation

Gasing an inertisation

concentration measurement in

pipelines (vol.% range)

EX-TEC® SR4 (Ex-protected)

•Workplace monitoringWorkplace monitoring

Workplace monitoringWorkplace monitoring

Workplace monitoring

monitoring proximity to the

Lower Explosive Limit (%LEL

range)

•LocationLocation

LocationLocation

Location

concentration measurement in

probe holes (vol.% range)

•Gasing an inertisationGasing an inertisation

Gasing an inertisationGasing an inertisation

Gasing an inertisation

concentration measurement in

pipelines (vol.% range)

7

EX-TEC® SR2 (Ex-protected)

•LocationLocation

LocationLocation

Location

concentration measurement in

probe holes (vol.% range)

•Gasing an inertisationGasing an inertisation

Gasing an inertisationGasing an inertisation

Gasing an inertisation

concentration measurement in

pipelines (vol.% range)

VARIOTEC® 8

•Gas etectionGas etection

Gas etectionGas etection

Gas etection

above-ground gas detection for

pipeline monitoring (ppm range)

•LocationLocation

LocationLocation

Location

concentration measurement in

probe holes (vol.% range)

8

1.11.1

1.11.1

1.1 TT

TT

Testsests

estsests

ests

Passive explosion protectionPassive explosion protection

Passive explosion protectionPassive explosion protection

Passive explosion protection

The EX-TEC® SR5, EX-TEC® SR4 and EX-TEC® SR2 models are explosion-

proof in accordance with European norms (CENELEC):

EC prototype test certificate: PTB 96 ATEX 2166

Classification: II 2 G EEx ib d IIB T4

Test institute: Physikalische-Technische

Bundesanstalt, Braunschweig

Active explosion protectionActive explosion protection

Active explosion protectionActive explosion protection

Active explosion protection

The EX-TEC® SR5 and EX-TEC® SR4 have also been tested for

functional safety in the Workplace Monitoring (WPM) field:

Test report: PFG no. 41300897

Test institute: DMT-Gesellschaft für Forschung

und Prüfung mbH, Essen

The test certificates can be found on and after page 43.

9

1.21.2

1.21.2

1.2 Probe systemsProbe systems

Probe systemsProbe systems

Probe systems

- Probes for the survey of gas istributions networks -- Probes for the survey of gas istributions networks -

- Probes for the survey of gas istributions networks -- Probes for the survey of gas istributions networks -

- Probes for the survey of gas istributions networks -

Carpet probeCarpet probe

Carpet probeCarpet probe

Carpet probe

for checking stable surfaces.

The sample is drawn into an

excrescence in a neoprene mat

in contact with the surface with no

extraneous emissions.

Bell probe,Bell probe,

Bell probe,Bell probe,

Bell probe,

telescopic bell probetelescopic bell probe

telescopic bell probetelescopic bell probe

telescopic bell probe

for checking unstable and

overgrown surfaces.

It can be used in confined

spaces, e.g. between parked

cars or in front gardens.

- Probes for localisation -- Probes for localisation -

- Probes for localisation -- Probes for localisation -

- Probes for localisation -

Search probeSearch probe

Search probeSearch probe

Search probe

for measuring concentrations in

probe holes,

with a rigid rubber cone to seal

off the probe hole,

2 different probe tips (length 245

mm or 345 mm),

carbon-dioxide filter to filter out

traces of CO2

10

- Probes for hollow spaces -- Probes for hollow spaces -

- Probes for hollow spaces -- Probes for hollow spaces -

- Probes for hollow spaces -

Floating probeFloating probe

Floating probeFloating probe

Floating probe

for measuring concentrations in

pits,

with suction vent and hose

connection

Divisible han probeDivisible han probe

Divisible han probeDivisible han probe

Divisible han probe

for the detection of leaks in pipes

installed in poorly accessible places,

measuring of concentration in con-

tainers, overall length 900 mm

- Probes for house service lines -- Probes for house service lines -

- Probes for house service lines -- Probes for house service lines -

- Probes for house service lines -

Flexible han probesFlexible han probes

Flexible han probesFlexible han probes

Flexible han probes

for the detection of leaks in

house service lines, handle with

flexible swan neck and probe

hose, overall lengths 360 mm or

660 mm

☞Except with the carpet probe , a probe hoseExcept with the carpet probe , a probe hose

Except with the carpet probe , a probe hoseExcept with the carpet probe , a probe hose

Except with the carpet probe , a probe hose

shoul always be use shoul always be use

shoul always be use shoul always be use

shoul always be use withwith

withwith

with a hy rophobic filter ! a hy rophobic filter !

a hy rophobic filter ! a hy rophobic filter !

a hy rophobic filter !

11

2.02.0

2.02.0

2.0 Measuring operationMeasuring operation

Measuring operationMeasuring operation

Measuring operation

☞Please fol out the illustration insi e thePlease fol out the illustration insi e the

Please fol out the illustration insi e thePlease fol out the illustration insi e the

Please fol out the illustration insi e the

front cover !front cover !

front cover !front cover !

front cover !

ItemItem

ItemItem

Item DescriptionDescription

DescriptionDescription

Description FunctionFunction

FunctionFunction

Function

1 alarm lamp optical warning

when alarm thresholds are

exceeded

2 LCD display display of gas

concentrations and

operating conditions

3 probe connection connection to the probes

described

4 buttonboard operating the detector

5 harness for portable systems

6 outlet for gas sample

7 buzzer acoustic warning

when alarm thresholds are

exceeded

2.12.1

2.12.1

2.1 Switching onSwitching on

Switching onSwitching on

Switching on

•press the on/off buttonon/off button

on/off buttonon/off button

on/off button (gas-

detection mode) or WPM button WPM button

WPM button WPM button

WPM button

(workplace-monitoring mode, p.

16 ff.) for approx. 2 seconds

•optical and acoustic control signal

(items 1 and 7) operate for approx.

2 seconds

12

•display of available operating

hours in the form of bars (e.g. 5

hours)

•the integral pump operates at

maximum power

•wait until the zero point has

established itself in fresh air

(approx. 2-3 minutes):

EX-TEC® SR5 and VARIOTEC® 8:

☞0 PPM0 PPM

0 PPM0 PPM

0 PPM

(after flashing stops)

EX-TEC® SR4 and EX-TEC® SR2:

☞0,0 %VOL0,0 %VOL

0,0 %VOL0,0 %VOL

0,0 %VOL

2.22.2

2.22.2

2.2 Illumination an contrastIllumination an contrast

Illumination an contrastIllumination an contrast

Illumination an contrast

•pressing the light buttonlight button

light buttonlight button

light button

switches the LCD illumination on

and off

•the illumination automatically

switches off approx. 4 minutes

after being switched on

•simultaneously pressing the light

button anan

anan

an a cursor button

increases or reduces the contrast

of the LCD display

13

2.32.3

2.32.3

2.3 Pump operationPump operation

Pump operationPump operation

Pump operation

•pressing the pump buttonpump button

pump buttonpump button

pump button

switches the pump on and off

•the corresponding symbol

appears in or disappears from

the LCD display (item 2)

•this enables the pump function to

be checked

☞Altering the pump powerAltering the pump power

Altering the pump powerAltering the pump power

Altering the pump power

(available only on the (available only on the

(available only on the (available only on the

(available only on the EX-TEC® SR5) !) !

) !) !

) !

•simultaneously pressing the

pump button anan

anan

an one cursor

button increases or reduces the

pump power

☞gas etectiongas etection

gas etectiongas etection

gas etection

for above-ground gas detection

(pipeline monitoring) always use

maximum pump powermaximum pump power

maximum pump powermaximum pump power

maximum pump power

☞house service lineshouse service lines

house service lineshouse service lines

house service lines

for detecting leaks in pipelines

inside buildings always use

minimum pump powerminimum pump power

minimum pump powerminimum pump power

minimum pump power

14

2.42.4

2.42.4

2.4 Alarm signal an volumeAlarm signal an volume

Alarm signal an volumeAlarm signal an volume

Alarm signal an volume

•pressing the signal buttonsignal button

signal buttonsignal button

signal button

switches the alarm signal on and

off

•the corresponding symbol

appears in or disappears from

the LCD display (item 2)

•this enables the alarm signal to

be checked

•simultaneously pressing the

signal button anan

anan

an one cursor

button increases or reduces the

buzzer volume (item 7)

2.52.5

2.52.5

2.5 Alarm threshol valueAlarm threshol value

Alarm threshol valueAlarm threshol value

Alarm threshol value

•when the threshol valuethreshol value

threshol valuethreshol value

threshol value

buttonbutton

buttonbutton

button is held down

•the alarm threshold value (e.g. 10

PPM) flashes in the full-range

display

15

•holding down the threshold value

button anan

anan

an repeatedly pressing

one cursor button increases or

reduces the alarm threshold value

•this value is preserved even when

the detector is switched off

2.62.6

2.62.6

2.6 Switching measuring rangesSwitching measuring ranges

Switching measuring rangesSwitching measuring ranges

Switching measuring ranges

•all detectors have an analogueanalogue

analogueanalogue

analogue

isplayisplay

isplayisplay

isplay (above, full range) anan

anan

an a

igital isplayigital isplay

igital isplayigital isplay

igital isplay (below);

both scales indicate the same

concentration (e.g. 70 PPM)

•the full rangefull range

full rangefull range

full range is a logarithmic

scale covering the range:

0 PPM ... 100 %VOL

•here the display of low

concentrations is intensified;

the measurement result can be

read off from the digital display

•repeatedly pressing the zoomzoom

zoomzoom

zoom

buttonbutton

buttonbutton

button switches between the fullfull

fullfull

full

and optimum rangesoptimum ranges

optimum rangesoptimum ranges

optimum ranges

•depending on the concentration,

switching between the following

measurement ranges is

automatic:automatic:

automatic:automatic:

automatic:

0 ... 10 PPM 0 ... 1 %VOL

0 ... 100 PPM 0 ... 10 %VOL

0 ... 1,000 PPM 0 ... 100 %VOL

•the optimum measurement range

in this example is 0 ... 100 PPM

16

•repeatedly pressing one of the

cursor buttons while holding down

the zoom button switches

manually to the required display

range

2.72.7

2.72.7

2.7 Zero-point a justmentZero-point a justment

Zero-point a justmentZero-point a justment

Zero-point a justment

•if the detector fails to reach its

zero point of

0 PPM0 PPM

0 PPM0 PPM

0 PPM or 0,00,0

0,00,0

0,0 %VOL%VOL

%VOL%VOL

%VOL

after flushing with copious fresh

air, pressing the zero pointzero point

zero pointzero point

zero point

buttonbutton

buttonbutton

button enables you to adjust it

manually

•the reading display flashes while

the adjustment is being carried

out

•measurement cannot be

resumed until afteafte

afteafte

after the flashing

stops

2.82.8

2.82.8

2.8 Workplace monitoringWorkplace monitoring

Workplace monitoringWorkplace monitoring

Workplace monitoring

☞This function is available only with the This function is available only with the

This function is available only with the This function is available only with the

This function is available only with the EX-TEC® SR5

an an

an an

an EX-TEC® SR4 etectors ! etectors !

etectors ! etectors !

etectors !

•this function is switched on by

pressing the WPM WPM

WPM WPM

WPM (ww

ww

workpp

pp

place

mm

mm

monitoring) buttonbutton

buttonbutton

button

•the detector can also be switched

on by pressing this button

17

•this measuring range is used to

monitor proximity to the LELLEL

LELLEL

LEL

(ll

ll

lower ee

ee

explosion

ll

ll

limit)

•after approx. 8 seconds' warm-

up time a stable zero point is

reached

•the pump runs at minimum power

and the acoustic operating signal

(item 7) sounds every 5 seconds

•when the pre-set threshold of

20 %LEL is exceeded

methane:methane:

methane:methane:

methane: 20 %LEL = 0,88 %VOL

(display = 0,90 %VOL)

propane:propane:

propane:propane:

propane: 20 %LEL = 0,34 %VOL

the a vance alarma vance alarm

a vance alarma vance alarm

a vance alarm is triggered

both optically (item 1) and

acoustically (item 7)

•the advance alarm is an

intermittent tone quite distinct

from the operating signal;

it ceases after a certain perioceases after a certain perio

ceases after a certain perioceases after a certain perio

ceases after a certain perio

and cannot be cleared

•if the concentration exceeds

100 %LEL

methane:methane:

methane:methane:

methane:100 %LEL = 4,40 %VOL

propane:propane:

propane:propane:

propane:100 %LEL = 1,70 %VOL

the main alarmmain alarm

main alarmmain alarm

main alarm is triggered

optically (item 1) and acoustically

(item 7)

18

•the main alarm is a continuous

tone quite distinct from the

operating signal;

it continues in efinitelycontinues in efinitely

continues in efinitelycontinues in efinitely

continues in efinitely and

cannot be cleared

•Cancelling the main alarm:Cancelling the main alarm:

Cancelling the main alarm:Cancelling the main alarm:

Cancelling the main alarm:

switch to location operation (press

the pump button for approx. 2

seconds ) or switch the detector

off

2.92.9

2.92.9

2.9 Battery alarmBattery alarm

Battery alarmBattery alarm

Battery alarm

•if the battery symbol appears in

the LCD display, at least 15

minutes' operating time remains;

after that the detector must be

recharged

•in workplace-monitoring mode

the battery alarm is accompanied

by a "double beep" to distinguish

it from the operating signal

2.10Switching off2.10Switching off

2.10Switching off2.10Switching off

2.10Switching off

•Press the on/off buttonon/off button

on/off buttonon/off button

on/off button for

approx. 2 seconds

•the optical and acoustic

monitoring signals (items 1 and

7) operate for approx. 2 seconds

•remaining operating hours are

displayed in the form of bars

This manual suits for next models

3

Table of contents

Other sewerin Gas Detector manuals