Trolex Sentro 1 TX6351 User manual

P5536.1600 rev D 1

TX6351 • TX6352

Sentro 1 Universal Gas Detector

Leading safety technology

User Manual

TX6351 • TX6352 User Manual

P5536.1600 rev D 3

TX6351 • TX6352 Sentro 1 Universal Gas Detector

Contents

1. Product Overview 4

1.1 Operating Features 4

1.2 Application 5

1.3 Product Options 5

1.4 Dimensions 6

1.5 Technical Information 7

1.6 Electrical Details 9

1.7 Sentro eModules 11

2. Certification 18

2.1 Newer Sentro 1 Models with Red

Labels (designated .35) 18

2.2 Older Sentro 1 Models with

Yellow Labels (not designated

.35) 20

3. Installation 23

3.1 Safety Precautions 20

3.2 Tools and Test

Equipment Required 24

3.3 Siting Recommendations 25

3.4 Connections 26

3.4.1 0.4 to 2 V / 2 to 10 V Analogue

Output Signal 26

3.4.2 4 to 20 mA Analogue

Output Signal 27

3.4.4 Contact Output Signal 28

3.4.5 RS485 Data Output Signal 29

3.5 Connecting in Hazardous

Areas 30

4. Setup and Calibration 31

4.1 Controls and Indicators 31

4.2 Main Display 33

4.3 Security Code Access 34

4.4 Main Menu 35

4.4.1 Calibrate 36

4.4.2 Sentro 1 Setup 39

4.4.3 Output Setup 41

4.4.4 Modbus 44

4.4.5 Module Setup 44

4.4.6 Support 47

5. Diagnostics and

Maintenance 48

5.1 Diagnostic Messages 48

5.2 Maintenance 49

5.3 Maintenance and

Calibration Log 52

5.4 Disposal 53

Disclaimers 53

Trademarks 54

Contact Details 54

Document History 54

4 P5536.1600 rev D

1. Product Overview

TX6351 3/4 wire device with separate output signal and power lines.

Can be used with any Sentro eModule

TX6352 2-wire line powered 4 to 20 mA output signal.

Can ONLY be used with electrochemical Sentro eModules

1.1 Operating Features

• Fixed sensor for detection of Toxic Gases and Flammable Gases

• Exclusive pre-calibrated plug-in gas sensing modules for many types of gas

• LCD readout and visual LED alarm indicators

• Choice of output signal format

• Heavy duty housing to IP65

• EMC compliant

• STEL and TWA monitoring for selected gases

TX6351 • TX6352 User Manual

P5536.1600 rev D 5

1.2 Application

Fixed point gas detection for safety monitoring in hazardous areas and general purpose

applications.

Underground Mining and Tunnelling

Ex ia I Ma

TX6351.01i

TX6352.01i

Supply Voltage: 12 V dc from an

approved power source

Type of protection:

Intrinsically safe. Ex ia

Category: I M1

General Purpose

TX6351.03

TX6352.03

Supply Voltage: 24 V dc

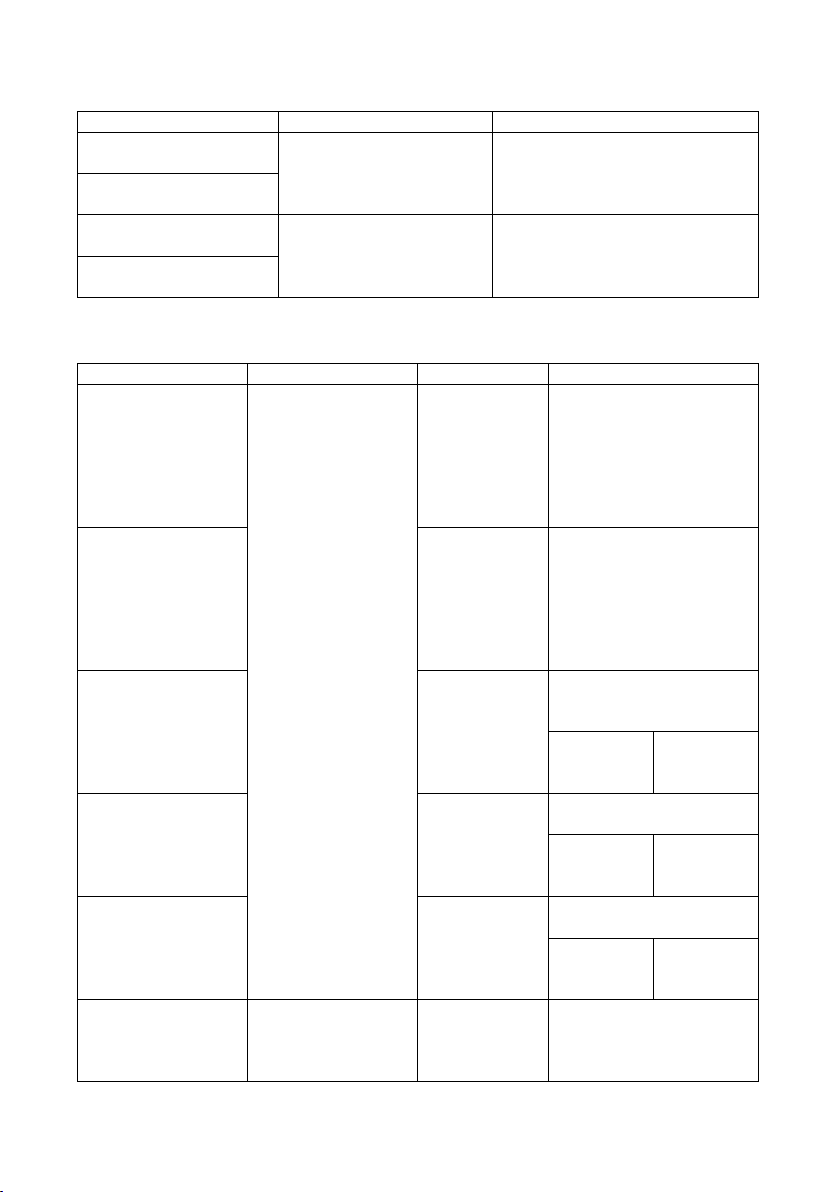

1.3 Product Options

Mining Ex ia

Certification Certification

Four-wire connection

(older models with yellow

labels)

(newer models with red

labels)

TX6351.01i

0.4 - 2.0 V dc .11 .35.05

4 - 20 mA .12 .35.19

Dual Relay NC .14

Dual Relay NO .17

IECEx (AUS) GrpI EAC GrpI ATEX/IECEx GrpI MASC GrpI

.06 MASC/IECEx GrpI

.14 ATEX/IECEx/UKEX GrpI .19

.05RS-485 .15

TX6352.01i Two-wire line powered

4 - 20 mA loop .12

General Purpose

Four-wire connection Button configuration

TX6351.03.00

4-20mA .12 Internal buttons .01

Dual Relay NC .14 External buttons .02

Dual Relay NO .17

RS-485 .15

2-10Vdc .16

TX6352.03.00 Two-wire line powered

4 - 20 mA .12

6 P5536.1600 rev D

1.4 Dimensions

TX6351 • TX6352 User Manual

P5536.1600 rev D 7

1.5 Technical Information

Ambient temperature limits -20 to +40 °C

Storage temperature -20 to +60 °C

Ambient pressure 800 to 1100 mbar

Humidity 15 % to 90 % non-condensing

Protection classification Dust and waterproof to IP65. Gas Port: IP54.

Housing material Reinforced polymer with static charge dissipation

Nett weight 530 g

Cable entries 2 x M20

Electrical connections 4 mm barrier/clamp terminals

Conductors A maximum of two per terminal

Conductor size A maximum of 2.5 mm²

Terminal torque 2.4 Nm maximum

Information display 128 x 64 dot graphic backlit LCD

Vibration limits Vibration limits (IEC 60079-29-1):

• 10 to 30 Hz - 1.00 mm total excursion

• 31 to 150 Hz - 19.6 m/s2acceleration peak

Impact limits 20 joules (housing)

Calibration and setup Digitally controlled ZERO and SPAN pushbutton

setting

Signal fix The analogue output signal of the sensor is fixed

during calibration to prevent false alarms from

being initiated

Fault indication Under range signal transmitted and fault display for:

• Loss of communications from the sensing

module

• Sensing module absent for more than 10

seconds

• Sensor over-range protect

Key coding Coding stops prevent insertion of a non-valid

sensing module.

8 P5536.1600 rev D

Alarms Programmable GENERAL alarms and HIGH alarms

with an LED indicator.

The two adjustable alarm setpoints are preset

during manufacture to default values appropriate

to the type of sensor, determined by the sensing

module being used.

STEL and TWA Automatic setting of STEL and TWA limits to EH40

standards.

STEL: Exposure over 15-minute successive periods

TWA: Exposure over a continuous rolling 8-hour

period

Output signals 0.4 to 2 V / 2 to 10 V

4 to 20 mA

Dual relay contacts. NO or NC to specification

RS485 Modbus datacomms

TX6351 • TX6352 User Manual

P5536.1600 rev D 9

1.6 Electrical Details

General Purpose

TX6351 3/4 wire. Remote powered

4 to 20 mA analogue output

Supply voltage: 18 to 28 V

Max. line load: 500 Ω at 24 V

Type of sensor: Toxic Flammable Infrared

Supply current: 40 mA 40 mA 60 mA

TX6351 3/4 wire. Remote powered

Dual output contacts NC/NO

Supply voltage: 20 to 28 V

Type of sensor: Toxic Flammable Infrared

Supply current: 35 mA 45 mA 60 mA

TX6351 3/4 wire. Remote powered

RS485 datacomms output

Supply voltage: 14 to 28 V

Line: Modbus protocol

Type of sensor: Toxic Flammable Infrared

Supply current: 40 mA 40 mA 60 mA

TX6352 2 wire. Line powered

4 to 20 mA analogue output

Supply voltage: 18 to 28 V

Max. Line Load: 300 Ω

Type of Sensor: Toxic only

TX6351 3/4 wire. Remote powered

2 to 10 V analogue output

Supply voltage: 14 to 28 V

Minimum line load: 10 KΩ

Type of sensor: Toxic Flammable Infrared

Supply current @ 24 V: 20 mA 60 mA 80 mA

10 P5536.1600 rev D

Mining and Tunnelling

TX6351 3/4 wire. Remote powered

4 to 20 mA analogue output

Supply voltage: 10 to 14 V

Max. line load: 220 Ω maximum @ 12 V dc

Type of sensor: Toxic Flammable Infrared

Supply current @ 12 V: 48 mA 70 mA 91 mA

TX6351 3/4 wire. Remote powered

Dual output contacts NC/NO

Supply voltage: 10 to 14 V

Type of sensor: Toxic Flammable Infrared

Supply current @ 12 V: 60 mA 85 mA 105 mA

TX6351 3/4 wire. Remote powered

RS485 datacomms output

Supply voltage: 10 to 14 V

Line: Modbus protocol

Type of sensor: Toxic Flammable Infrared

Supply current @ 12 V: 25 mA 60 mA 80 mA

TX6351 3/4 wire. Remote powered

0.4 to 2 V analogue output

Supply voltage: 10 to 14 V

Min. line load: 10 KΩ

Type of sensor: Toxic Flammable Infrared

Supply current @ 12 V: 20 mA 60 mA 80 mA

TX6352 2 wire. Line powered

4 to 20 mA analogue output

Supply voltage: 10 to 14 V

Max. line load: 90 Ω

Type of sensor: Toxic only

TX6351 • TX6352 User Manual

P5536.1600 rev D 11

1.7 Sentro eModules

Plug-in pre-calibrated modules with standardised output data.

• Each module stores all the necessary data about its type identification, sensing

range and specific calibration. This data is automatically recognised by Sentro when

the module is loaded into the module bay.

• The modules are pre-calibrated so can be substituted at any time by a replacement

module – usually of the same type, but an alternative may be inserted if required.

• Insert coding stops to prevent non-valid module combinations.

• The sensing module will identify itself when plugged into the sensor housing and

auto configuration will take place.

• All Sentro Modules have two output alarm signals for GENERAL alarm and HIGH

alarm. Default values are entered during manufacture and these can be changed to

preferred values.

• The alarm signals can be set to illuminate built-in flashing LED indicators.

• The signals can operate the two GENERAL alarm and HIGH alarm relays on the

CONTACT OUTPUT version of Sentro 1.

• Service replacement modules can be specified using the appropriate gas type code

from the eModule order reference table on the datasheet

• The order reference is also marked on the back of the eModules.

• The order reference may vary for some eModules dependent upon the year of

manufacture of the base unit:

12 P5536.1600 rev D

Flammable gases • Poison resistant catalytic sensor

INDICATIVE VALUES ONLY, OTHER RANGES AND CALIBRATIONS CAN BE

SUPPLIED TO SPECIFICATION

The sensor can be configured to respond to many flammable

gases and vapours. It is usual to calibrate to methane in

terms of %LEL or %volume.

TX6350 .240

.246 .244

Methane CH

4

Methane CH

4

Methane CH

4

Sensing element Poison resistant pellistor with active temperature compensation

Sensing range 0 to 100% LEL

based on 4.4%v/v

0 to 4% v/v 0 to 5% v/v

Linearity Linear up to 3% v/v 3% to 5% ±0.25%

Max. Drift @ 25°C ±0.25% CH4 v/v per month

*Response time t(63) <15 secs

*Response time t(90) <20 secs

Sensing element life >5 years in clean atmosphere

Warm up time <5 mins in air or 1% v/v CH4

Stabilisation time ≥15 mins

GENERAL alarm 10% LEL (.240) 0.40% (.246) 0.50% (.244)

HIGH alarm 25% LEL (.240) 1.00% (.246) 1.25% (.244)

* Response times are tested by owing test gas using the calibration kit referred to in section 5.2

Maintenance.

Checkpoint

Not suitable for use with the TX6352 4 to 20 mA two wire, line powered version of

Sentro.

Checkpoint

The pellistor is automatically protected against exposure to excessively high

concentrations of gas.

Section 4.4.5

TX6351 • TX6352 User Manual

P5536.1600 rev D 13

oxic gases • Electrochemical cells

INDICATIVE VALUES ONLY, OTHER RANGES AND CALIBRATIONS CAN BE

SUPPLIED TO SPECIFICATION

Selected toxic gas modules are equipped with automatic

STEL/TWA calculation in accordance with EH40.

TX6350 .250.50 .250.250 .250.300 .250.500 .251 .252

Carbon

Monoxide

CO

Carbon

Monoxide

CO

Carbon

Monoxide

CO

Carbon

Monoxide

CO

Hydrogen

Sulphide

H

2

S

Sulphur

Dioxide

SO

2

Sensing

element Electrochemical cell

Sensing range 0 to

50 ppm

0 to

250 ppm

0 to

300 ppm

0 to

500 ppm

0 to

50 ppm

0 to

20 ppm

Linearity ±2% FS

Drift 2% per month

Repeatability ±2%

*Response

time t(63) <20 secs <30 secs <20 secs

*Response

time t(90) <30 secs <45 secs <30 secs

Operating life 2 years

Relative

humidity 15 to 90% non-condensing

Operating

temperature -10 to +40°C

GENERAL

alarm 18 ppm 38 ppm 45 ppm 75 ppm 8 ppm 3 ppm

HIGH alarm 15 ppm 75ppm 90 ppm 150 ppm 15 ppm 6 ppm

STEL & TWA 200 ppm 200 ppm 200 ppm 200 ppm 10 ppm 1 ppm

30 ppm 30 ppm 30 ppm 30 ppm 5 ppm 0.5 ppm

* Response times are tested by owing test gas using the calibration kit referred to in section 5.2

Maintenance.

Section 4.4.5

14 P5536.1600 rev D

Toxic gases • Electrochemical cells - continued

INDICATIVE VALUES ONLY, OTHER RANGES AND CALIBRATIONS CAN BE

SUPPLIED TO SPECIFICATION

Selected toxic gas modules are equipped with automatic

STEL/TWA calculation in accordance with EH40.

TX6350 .254 .254.10 .257 .259 .261

Nitrogen

Dioxide

NO

2

Nitrogen

Dioxide

NO

2

Oxygen

O

2

Nitric Oxide

NO Hydrogen H

2

Sensing element Electrochemical Cell

Sensing range 0 to 20 ppm 0 to 10

ppm 0 to 25% 0 to 50 ppm 0 to

1000 ppm

Linearity ±2% FS ±0.3% vol ±5% FS ±2% FS

Drift 2% per month 10%

per year 2% per month

Repeatability ±2%

*Response time

t(63) <20 secs N/A <20 secs <30 secs

*Response time

t(90) <30 secs <60 secs <30 secs <40 secs

Operating life 2 years 2 years 2 years

Relative humidity 15 to 90% non-condensing

Operating

temperature -10 to +40°C

GENERAL

alarm 3 ppm 1.5 ppm 19% (under) 8 ppm 150 ppm

HIGH alarm 6 ppm 3 ppm 23% (over) 15 ppm 300 ppm

STEL & TWA 1 ppm 1 ppm N/A 10 ppm N/A

0.5 ppm 0.5 ppm N/A 25 ppm N/A

* Response times are tested by owing test gas using the calibration kit referred to in section 5.2

Maintenance.

Section 4.4.5

TX6351 • TX6352 User Manual

P5536.1600 rev D 15

Checkpoint

Toxic gas Sentro eModules have a very low power consumption, enabling 4 to 20 mA two wire

TX6352 line-powered version of Sentro to be used.

Checkpoint

All values listed are nominal and slight variations may occur depending upon operating

conditions.

• The natural level of oxygen available in the atmosphere is influenced by relative humidity

and temperature. The oxygen sensor will react to these changes.

• Sudden changes in atmospheric pressure will also cause temporary instability in

electrochemical sensors which may exceed 60 seconds.

• Long periods of use in extremely high or low humidity may aect the response of the

sensor and shorten the life of electrochemical sensors.

• Nitric oxide sensors must be continuously powered to maintain calibration stability. If

power has been absent for more than 10 minutes, it may take 24-48 hours for the sensor

to restore stability. Do not calibrate until the output signal is steady.

• The presence of high levels of carbon dioxide (over 5%) may have a minor eect on the

accuracy of the oxygen sensor.

Checkpoint

Periodic calibration of the gas sensor should be carried out whilst it is in service. For oxygen

and carbon monoxide gas sensors Trolex recommends that this is carried out every three

weeks. For other gas sensors Trolex recommends that this is carried out in accordance

with best practice for the industry where the gas sensor is being used, and should take into

consideration local operating conditions.

16 P5536.1600 rev D

Carbon Dioxide/Methane Gases • Infrared sensor

INDICATIVE VALUES ONLY, OTHER RANGES AND CALIBRATIONS

CAN BE SUPPLIED TO SPECIFICATION

The sensor is highly specific to the selected gas and exhibits

consistent sensing accuracy with superior long-term stability.

The linear response means that it can be calibrated for low gas

concentrations and high concentrations up to 100% by volume.

TX6350

.243 .245 .242 .278.2 .278 .279

Methane

CH

4

Methane

CH

4

Methane

CH

4

Carbon

Dioxide

CO

2

Carbon

Dioxide

CO

2

Carbon

Dioxide

CO

2

Sensing element

Infrared

Sensing range

0 to

5% v/v

0 to

100% LEL

0 to

100% v/v

0 to

2% v/v

0 to

5% v/v

0 to

100% v/v

Zero drift

±0.05% v/v

per month

±1% LEL

per month

±0.5% v/v

per month ±0.05% v/v per month ±1% v/v

per month

Repeatability

±0.1% v/v ±2% LEL ±2% v/v ±0.05% v/v ±2% v/v

*Response time

t(63)

<15 secs

*Response time

t(90)

<30 secs

Operating life

<5 years

Relative humidity

15 to 90% non-condensing

Operating

temperature

-10 to +40°C

GENERAL

alarm

0.5% v/v 10% LEL 10% v/v 0.3% v/v 0.75% v/v 15% v/v

HIGH alarm

1.25% v/v 25% LEL 25% v/v 0.6% v/v 1.5% v/v 30% v/v

* Response times are tested by owing test gas using the calibration kit referred to in section 5.2

Maintenance.

TX6351 • TX6352 User Manual

P5536.1600 rev D 17

Checkpoint - Carbon Dioxide Sensors

Normal atmosphere contains carbon dioxide which will aect the sensor signal so

nitrogen gas must be used to accurately calibrate the zero value. Power should be

applied to the sensor and the nitrogen applied for at least 5 minutes to ensure that the

sensor has stabilised.

Checkpoint

Not suitable for use with the TX6352 4 to 20 mA two wire, line powered version of

Sentro 1.

18 P5536.1600 rev D

2. Certification and Conformity

2.1. Newer Sentro 1 models with red label (designated .35)

ATEX certification for use in underground mines (Group I) in European

Union.

Complies with ATEX Directive 2014/34/EU.

Standards:

EN IEC 60079-0:2018

EN 60079-11:2012

UKEX certification for use in underground mines (Group I) in Great Britain

(England, Scotland and Wales).

Complies with UK Regulations 2016 S.I. 2016/1107

Standards:

EN IEC 60079-0:2018

EN 60079-11:2012

IECEx (International) certification for use in underground mines (Group I).

Standards:

IEC 60079-0:2017

IEC 60079-11:2011

MASC IA certification for use in underground mines (Group I) in South

Africa.

Standards:

IEC 60079-0:2017

IEC 60079-11:2011

TX6351 • TX6352 User Manual

P5536.1600 rev D 19

Product Code:

Ex Certificate Number:

Ex Certification Code:

TX6351.01i.xx.35.19

Sentro 1 CML 20ATEX2271X

IECEx CML 20.0158X

CML 21UKEX2323X

I M1

Ex ia I Ma

-20 °C ≤ Ta ≤ +40 °C

TX6352.01i.12.35.19

Sentro 1

TX6351.01i.xx.35.05

Sentro 1

MASC M/21-8496 X

IECEx CML 20.0158X

Ex ia I Ma

-20 °C ≤ Ta ≤ +40 °C

TX6352.01i.12.35.05

Sentro 1

The following Safety Description applies to the equipment listed above:

Model No.

Power Input

Output type

Output

TX6351.01i.11.35

Terminal 5 w.r.t. 6

Ui = 14.4V

Ci = 0

Li = 0

0.4V – 2V

Terminal 1 w.r.t. 2 or 3

Ui = 14.4V

Uo = 14.4V

Io = 40mA

Po = 0.135W

Ci = 0

Li = 0

TX6351.01i.12.35 4mA – 20mA

Terminal 1 w.r.t. 2 or 3

Ui = 14.4V

Uo = 14.4V

Io = 0.477A

Po = 1.72W

Ci = 0

Li = 0

TX6351.01i.15.35 RS485

Terminal 1 w.r.t. 3 (RS485 A)

Terminal 2 w.r.t. 3 (RS485 B)

Parameters for each output:

Ui = 6.88 V

Ci = 0

Li = 0

Uo = 5.88 V

Io = 66 mA

Po = 97 mW

TX6351.01i.14.35 Relays NC

Terminal 1 w.r.t. 2 (Relay 1)

Terminal 3 w.r.t. 4 (Relay 2)

Ui = 30 V

Ci = 0

Li = 0

Uo = 0

Io = 0

Po = 0

TX6351.01i.17.35 Relays NO

Terminal 1 w.r.t. 2 (Relay 1)

Terminal 3 w.r.t. 4 (Relay 2)

Ui = 30 V

Ci = 0

Li = 0

Uo = 0

Io = 0

Po = 0

TX6352.01i.12.35

Terminal 1 w.r.t. 2

Ui = 14.4V

Ci = 0

Li = 0

Loop powered N/A

20 P5536.1600 rev D

The following Specific Conditions of Use apply to the certificates listed above:

• The cable entries to the supply and output terminals shall be made via cable glands which

provide a minimum degree of protection of IP54.

• Under certain extreme circumstances, unearthed metal parts of the enclosure may store an

ignition-capable level of electrostatic charge. The equipment shall either be earthed via the

integral earthing terminal or the user/installer shall implement precautions to prevent the

build-up of electrostatic charge. When not earthed, the capacitance of the metallic label to

earth is >10pF.

2.2 Older Sentro 1 models with yellow label (not designated .35)

ATEX certification for use in underground mines (Group I) in European Union.

Complies with ATEX Directive 2014/34/EU.

Standards:

EN 60079-0:2012

EN 60079-11:2012

IECEx (International) certification for use in underground mines (Group I) in

Australia (including New South Wales) and New Zealand.

Standards:

IEC 60079-0:2011

IEC 60079-11:2011

EAC certification for use in underground mines (Group I) in Eurasian Customs

Union (including Russia).

Standards:

ГОСТ 31610.0-2014 (IEC 60079-0:2011)

ГОСТ IEC 60079-1:2013

ГОСТ 31610.11-2014 (IEC 60079-11:2011)

ГОСТ МЭК 60079-25-2012

MASC IA certification for use in underground mines (Group I) in South Africa.

Standards:

SANS (IEC) 60079-0:2012

SANS (IEC) 60079-11:2012

This manual suits for next models

1

Table of contents

Other Trolex Gas Detector manuals

Popular Gas Detector manuals by other brands

STATUS SCIENTIFIC CONTROLS

STATUS SCIENTIFIC CONTROLS FGD4 Installation, Commissioning & Routine Gas Testing Manual

Emerson

Emerson Rosemount 925FGD manual

Bionics

Bionics TX-2300KFP Guide to installation and operation

WatchGas

WatchGas AirWatch Mk 1.0 Quick reference card

Atest Gaz

Atest Gaz SmArtGas 4 user manual

ION

ION SF6 P2 user manual