Southwest Microwave INTREPID User manual

Version A

Southwest Microwave, Inc.

Security Systems Division

INTREPID™

Control Module II

Technical Manual

ALARM RELAY OUTPUT

SYSTEM CONTROLLER

2 Version A

Trademark Notice and Certifications

INTREPID™, MicroPoint™and MicroTrack™are registered trademarks of Southwest Microwave, Inc.

Copyright 1995 and 2012 Southwest Microwave, Inc. All rights Reserved.

Windows™, XP™, Vista™, Word™and Notepad™are a registered trademark of Microsoft Corporation™.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

CE Notice

This equipment has been designed and tested to EN61000-6-2:2005 and EN61000-6-4:2006 per Directive

89/336/EEC.

RoHS Compliant

Copyright Southwest Microwave, Inc. June, 2012

Southwest Microwave, Inc.

9055 South McKemy Street

Tempe, Arizona 85284-2946

Tel: (480) 783-0201

Fax: (480) 783-0401

Email: infossd@southwestmicrowave.com

Web: www.southwestmicrowave.com

3 Version A

Table of Contents

1. Introduction.............................................................................................................................................5

1.1 Limitations......................................................................................................................................... 5

1.2 Basic System Requirements ..............................................................................................................6

2. Hardware.................................................................................................................................................6

2.1 Control Module II..............................................................................................................................6

2.2 Optional Power Supplies...................................................................................................................6

2.3 Interconnections.................................................................................................................................7

2.4 Typical Configuration........................................................................................................................8

3. System Communications........................................................................................................................9

3.1 Introduction .......................................................................................................................................9

3.2 System Setup Using CST II...............................................................................................................9

3.2.1 Options .......................................................................................................................................9

3.2.2 Edit........................................................................................................................................... 11

3.2.3 Language.................................................................................................................................. 11

3.2.4 Help..........................................................................................................................................11

4. Definitions..............................................................................................................................................11

4.1 System Definitions...........................................................................................................................11

5. Programming Menu..............................................................................................................................12

5.1 CST II Programming Screens for CM II ........................................................................................12

5.1.1 Main Menu...............................................................................................................................12

5.1.2 CM II Properties....................................................................................................................... 12

5.1.3 Device Management................................................................................................................. 12

5.1.4 Zone Administration.................................................................................................................12

5.1.5 Reports......................................................................................................................................13

5.1.6 About........................................................................................................................................ 13

5.1.7 Language.................................................................................................................................. 13

6. Programming Sequence........................................................................................................................13

6.1 Main Menu ...................................................................................................................................... 13

6.2 CM II Properties Menu....................................................................................................................14

6.2.1 Restore CM II to Factory Default Settings...............................................................................15

6.2.2 Assign Site Name.....................................................................................................................15

6.2.3 Set Real Time Clock................................................................................................................. 16

6.2.4 Backup System.........................................................................................................................17

6.2.5 Restore System.........................................................................................................................17

4 Version A

6.2.6 Functional Testing and Verification......................................................................................... 17

6.2.6.1 Relay Test ............................................................................................................................ 18

6.4.6.2 RS422 External Loopback Verification............................................................................... 18

6.4.6.3 RS232 External Loopback Verification............................................................................... 20

6.3 Device Management Menu..............................................................................................................21

6.3.1 Device Discovery..................................................................................................................... 22

6.3.2 Device Name Update................................................................................................................ 25

6.3.3 Accept Device Configuration Change...................................................................................... 26

6.3.4 View Device Status.................................................................................................................. 27

6.3.4 Change Device Polling Interval................................................................................................29

6.4 Zone Administration Menu..............................................................................................................31

6.4.1 Add Zones ................................................................................................................................ 31

6.4.1.1 Assign Name........................................................................................................................32

6.4.1.2 Assign Comment..................................................................................................................32

6.4.1.3 Assign Input.........................................................................................................................33

6.4.1.4 Assign Relay Output............................................................................................................37

6.4.2 Modify Zones...........................................................................................................................38

6.4.2.1 Next Zone.............................................................................................................................38

6.4.2.2 Previous Zone ......................................................................................................................39

6.4.2.3 Select Zone...........................................................................................................................39

6.4.2.4 Edit Name ............................................................................................................................39

6.4.2.5 Edit Comment ......................................................................................................................39

6.4.2.6 Edit Input..............................................................................................................................39

6.4.2.7 Delete Input.......................................................................................................................... 39

6.4.2.8 Edit Relay Output................................................................................................................. 40

6.4.2.9 Delete Relay Output............................................................................................................. 40

6.4.3 Delete Zones............................................................................................................................. 40

6.4.4 View Zones............................................................................................................................... 40

6.4.5 List All Zones........................................................................................................................... 41

6.4.6 View Zone Status ..................................................................................................................... 42

6.5 Reports............................................................................................................................................. 43

6.5.1 View Configuration Report...................................................................................................... 43

6.5.2 Download Configuration Report.............................................................................................. 45

6.5.3 View Event Log Report............................................................................................................ 45

6.5.4 Download Event Log Report.................................................................................................... 46

6.5.5 Erase Event Log Report............................................................................................................46

6.6 About............................................................................................................................................... 47

6.7 Language .........................................................................................................................................47

7. Attachment A ........................................................................................................................................49

5 Version A

1.0 Introduction

The Control Module II (CM II) is part of the INTREPID™ family of products. Its’function as a system

controller is to be a “Poll Master” and poll all of the INTREPID Series II compatible IPP II (INTREPID Polling

Protocol II) sensor devices, relay input devices, and relay output devices that are connected to its

communications ports. It also has eight (8) relay outputs. When an alarm is detected on any device, it will send

the command to set the appropriate relay(s) on the output device(s).

As a Poll Master, the CM II communicates with other system devices using RS422 communications. This

communication can be done over 22 or 24 gauge stranded twisted shielded pair wire (max 5,000 feet [1,500m])

or fiber optic devices.

As an output device each CM II provides eight (8) form C relay outputs used to trigger camera presets, impact

lighting or any function that can be activated by a contact closure. Both Normally Open (N.O.) and Normally

Closed (N.C.) contacts are available at the terminal strip.

The CM II operates from 10.5 to 60 VDC @ 2 Watts. The operational current rating with standard power

supplies are: 12 VDC @ 150mA, 24 VDC @ 80mA and 48 VDC @ 45mA.

During installation, the CM II will automatically detect each INTREPID Series II device that is connected to its’

comports through a process called Device Discovery. This will provide a list of all possible alarm inputs and all

possible relay outputs. From this Discovery list, the installer will be able to define up to 256 Alarm Zone

Records, which defines the relationships between alarm inputs and relay outputs.

1.1 Limitations

When used in conjunction with other INTREPID Series II devices, a maximum of 16 devices can be connected

to the communications ports of the CM II as shown in Figure 1. Eight (8) to each port or sixteen (16) on any one

(1) port or any combination as long as it does not exceed sixteen (16) devices. The system can also be

configured as Fault Tolerant.

CM II

Device 8 Device 9 Device 10 Device 15

RS422-2

RS422

Com 1 RS422

Com 2 RS422

Com 1 RS422

Com 2 RS422

Com 1 RS422

Com 2 RS422

Com 1 RS422

Com 2

Device 0 Device 1 Device 2 Device 7

RS422

Com 1 RS422

Com 2 RS422

Com 1 RS422

Com 2 RS422

Com 1 RS422

Com 2 RS422

Com 1 RS422

Com 2

RS422-1

Figure 1 –Maximum Devices

The address range for these devices is limited to address 0 to address 239. The CM II has a fixed address of 254.

Regardless of configuration total length of all RS422 communications wire between devices must not exceed

5,000 feet (1,500 meters).

6 Version A

After configuration, the CM II will poll each discovered device every 125ms for alarms. With the maximum of 8

devices connected to the RS422 communications ports, any alarm will be received within a 1 second timeframe.

If more than 8 devices are on one communications port the polling time will be 150ms. Note: with the Tamper

Switch closed only the Pulse LED will be illuminated.

1.2 Basic System Requirements

A computer or laptop with Windows XP™, Vista™ or Windows 7™ operating system and a RS232 serial port

or USB port. Note; if a USB port is to be used, a USB to RS232 serial cable is required. The Windows USB

driver should be Version 1.0. A dB9 straight (not a null modem cable) male to female cable is required to

connect from the PC to the CM II. The Controller Setup Tool II (CST II) should be installed on the computer as

discussed in Section 3.0.

If copper wire is to be used, it is recommended that only stranded/twisted shielded 22 or 24 gauge wire be used

for communications between the CM II and other INTREPID™ Series II devices. The maximum distance

between any two devices should not exceed 5,000 feet (1,500m). Any variations from this schedule should

reference TIA/EIA TSB 89 - Applications Guidelines for TIA-422-B. Most RS422 fiber optic devices can be

used as well.

2.0 Hardware

2.1 Control Module II (CM II)

The CM II assigns alarm sources to alarm outputs and serves as the poll master to monitor and maintain the

communications link between other INTREPID Series II devices by RS422.

The CM II is packaged in the standard INTREPID enclosure as shown in Figure 2. The dimensions are 5.5 in H

x 13.5 in W x 5 in deep (14cm H x 34.3cm W x 12.7cm D). It weighs 2.5 lbs (1.1kg).

Figure 2 –INTREPID Enclosure for RCM II

2.2 Optional Power Supplies

12 VDC power supply: Model PS13 Power Supply operates from 85-246VAC, 47-63Hz and furnishes 13.6

VDC at up to 2.8A. Power supplies contain automatic switchover and battery charging circuitry for optional

standby batteries of up to 25AH. Temperature rated from 14° to 122° F (-10° to 50° C). UL, ETS, EMC, CE,

and RoHS compliant.

7 Version A

12 VDC power supplies: Model PS40 Power Supply operates from 120 VAC, 50-60Hz, 0.5A and furnishes

13.7 VDC at up to 1.6A. Model PS41 Power Supply operates from 220 VAC, 50-60Hz, 0.25A. Both contain

automatic switchover and battery charging circuitry for optional standby batteries of up to 25AH and are fused

on both input and output for maximum protection. Temperature rated from -40° to 150° F (-40° to 66° C).

24 VDC power supply: Model 78B1064 operates from 120VAC to provide 24VDC at 5A with 6.5AH battery

backup. Includes; indoor enclosure 15 x 11 x 4 in. (381 x 280 x 102mm). Temperature rated from -32° to 122° F

(0° to 50° C).

48 VDC power supplies: Model PS48 operates from 120VAC to provide 48VDC at 3A. Includes; indoor

enclosure 14 x 12 x 4 in. (356 x 305 x 102mm). Model PS49 operates from 220VAC to provide 48VDC at 3A.

This supply does not include enclosure. Temperature rated from 32° to 122° F (0° to 50° C). UL, CSA, TUV and

CE compliant.

2.3 Interconnections

Figure 3 shows the various connection points, programming port and diagnostic LED’s available on the CM II

circuit board assembly.

J1

1

6 9

5

P2

1

6 9

5

P1

TB2 TB3

XSW2

XSW1

F1

TB1

02D46635-A01

RELAY OUTPUTS

10.5-60 VDC

IN

GND

POWER

NO COM NCNO COM NCNO COM NCNO COM NCNO COM NCNO COM NC

NC

COM

NONCNO COM

SERVICE TOOLTERMINAL

PULSE

RX

TX RX

TX

RX

TX

RX

TX

-

RX

SHLD +

-

TX

+

RXTX

SHLD -

+

-

+

RS422-2

RS422-1

CONTROL MODULE II

-8--7--6--5--4--3--2-

-1-

-8--7--6--5--4--3--2--1-

10.5 to 60 VDC

Input Terminal

RS232 Port

for CST II RS232 Port

for UIST II

Communication LED’s

RS422 Communications

Terminals Pulse LED

Pins for External

Tamper Switch Relay Output Terminals

8 Form C Relays Alarm LED’s

Figure 3 –Control Module II (CM II) Circuit Card

Figure 4 shows the typical RS422 wiring diagram from the Control Module II (CM II) to other INTREPID™

Series II devices. In this case an Alarm Input Module II (AIM II) and a MicroTrack Processor II (MTP II)

located on the perimeter. The CM II and the Relay Output Module II-16 (ROM II-16) are located in the control

room for relay output interface to other control room devices. A maximum of eight (8) devices can be connected

to each of the RS422 communications lines. The communications is RS422 and should use a 22 or 24 gauge

twisted, stranded, shielded pair wire. Fiber optic devices can be used as well. Since this RS422 communications

format is a point to point configuration, no termination device is required for the last unit on the line. The RS422

8 Version A

communications wiring is from the transmit side of one device to the receive side of the next device with the

wiring from + to + and –to –as shown in Figure 4.

COM 2

TB1

SHLD

SHLD

RS422

TX RX

MTP II on Perimeter

JB70

TB2

TX SHLD

TX

RX

RS422-1

+-+-

RX

CM II

TX SHLD RX

COM2 RS422

+-+-

TX SHLD RX

COM1 RS422

+-+-

TX RX TX RX

ROM II-16

TX SHLD RX

COM2 RS422

+-+-

TX SHLD RX

COM1 RS422

+-+-

TX RX TX RX

AIM II on Perimeter

Control Room

Figure 4 –CM II Communications Wiring Diagram

2.4 Typical Configuration

Figure 5 shows a typical configuration using a CM II, ROM II-16, AIM II, MTP II, PM II and a Microwave

Link. The Control Room has a matrix switcher, lighting control system, paging system and an alarm panel. A

computer is shown as the configuration/programming tool to set up the CM II and communicate to the sensors

with the UIST II. The JB70A Surge/Lightning protection module is shown on the outside of the control room

and at the sensors. The ROM II-16, AIM II and MTP II are connected together with the RS422-1

communications line and the PM II to the RS422-2 communications line. The Microwave Link alarm relay and

tamper switches are wired into the AIM II. The CM II and the ROM II-16 are programmed so their relay outputs

trigger inputs on the alarm panel, lighting control system, pager system and CCTV matrix. A UPS is also shown

and is recommended for backup of the INTREPID™ products.

Matrix Switch

RCM II

CCTVCCTV

AIM II

Lighting

Controller

Audio/Paging

System

Configuration Tool

INTREPID

ROM II-16

JB70A

Control Room

MTP II

Alarm and Tamper Wiring

RS422 Wiring

RS232 Cable Alarm Panel

* Note: Power Wiring not Shown

MicroTrack Sensor Cable

UPS

JB70A

JB70A

INTREPID

MP II

JB70A

Figure 5 –Typical CM II Network Configuration

9 Version A

3.0 System Communications

3.1 Introduction

To set up alarm reporting and communications hierarchy of the CM II network, the Controller Setup Tool II

(CST II) must be installed on the computer that will be used to configure the system. The software is provided

on a CD and is a “drop”and “drag”or copy installation.

Insert the disc into the CD drive of the computer. Locate the application software and drag or copy it to the

desktop or any other location on the hard driver that is convenient for use.

Connect a RS232 serial cable between the communications port on the computer and the RS232 Terminal

communications port (P1) on the CM II.

3.2 System Setup Using CST II

Open the CST II software to launch the program to the default configuration screen as shown in Figure 6. On the

menu bar for the default screen are the Options, Edit, Languages and Help menus.

Figure 6 –CST II Default Screen

3.2.1 Options

The “Options” menu opens the “Settings”, “Forced Disconnect”and “Close” functions. Selecting “Settings” will

open the User Settings dialog box with the “Connection” and “Window” setup parameters.

The “Connection” tab will allow setting the I/O source (serial or network), the source setting (com port, telnet

port/address/IP port) and the port settings (baud rate, parity, data bits, stop bits and flow control) as shown in

Figure 7. These are default setting and should not be changed except for the Serial Port.

10 Version A

Figure 7 –CST II Connection Tab

The “Window” tab will allow setting Terminal Display Mode, Font and Color while the Scrollback will set the

Rows, Columns and no Scrollback as shown in Figure 8. These are default setting and should not be changed.

Figure 8 –CST II Window Tab

11 Version A

3.2.2 Edit

The “Edit” menu opens the “Copy”, “Paste”, “Clear” and “Form Feed” functions.

3.2.3 Languages

The “Languages” pull down menu allows selecting one of the 5 available languages to change the language of

the menu bar. The language choices are: English, Spanish, Russia, Chinese and Korean.

3.2.4 Help

The “Help” menu will list the product name, part number, build time, Southwest Microwave information,

copyright information and an OK button.

4.0 Definitions

4.1 System Definitions

Before beginning the programming process, there are a few definitions and concepts to understand.

CM II –This is the Control Module II. It has 8 relay outputs per board. Sixteen (16) INTREPID™

Series II devices can be connected to the two (2) communications ports. It is the Poll Master in the

system and has a fixed address of 254. It has communications status LED’s, Alarm LED’s and a Pulse

LED to indicate the device application is functioning.

MTP II –This is the MicroTrack™Processor II. It will monitor up to two 656 feet (200m) buried

sensor cable sets and will report Alarms, Cable Faults, Communication Failure and Tamper back to the

Poll Master on request. It has communications status LED’s, Alarm LED’s, Tamper LED and a Pulse

LED to indicate the device application is functioning.

AIM II –This is the Alarm Input Module II. It is used to bring auxiliary alarms from other sensors such

as: microwave sensors, infrared sensor and contact closures. Typically these are alarm and tamper

contacts. It can accommodate normally open (N.O.) or normally closed (N.C.) contacts. The input can

also be set as a supervised input. It has communications status LED’s, Alarm LED’s and a Pulse LED to

indicate the device application is functioning.

ROM II –This is the Relay Output Module II. It is available with 8 or 16 relay outputs. It has

communications status LED’s, Alarm LED’s, and a Pulse LED to indicate the device application is

functioning.

PM II –This is the MicroPoint™Processor II. It will monitor up to 1,443 feet (440m) of fence

mounted sensor cable and will report Alarms, Cable Faults, Communication Failures and Tampers back

to the Poll Master on request. It has communications status LED’s, Alarm LED’s, Tamper LED,

External Input LED’s and a Pulse LED to indicate the device application is functioning.

Model 330 –This is a microwave intrusion link with transmitter and receiver. It has communications

status LED’s, Alarm LED, Tamper LED, Jam LED, Wrong Channels and a Pulse LED to indicate the

device application is functioning.

12 Version A

Zone Record –The zone record consists of up to four (4) inputs that can be assigned to up to four (4)

relay outputs. This information is what is programmed into the CM II to control the alarm relay output

functions. Inputs that can be assigned are: intrusion alarms from sensors such as microwaves, infrareds,

etc., intrusion alarms from cell groupings from MicroPoint II or MicroTrack II systems, tamper

switches, cable faults, communication failures, supervised alarms, configuration change alarms, and

service alarms.

Zone Record Input / Output Assignment Matrix –In Attachment A of this manual is a matrix to list

the inputs and outputs that have been assigned for a particular Zone Record. This should be saved for

future reference.

5.0 PROGRAMMING MENU

The programming menus that will be displayed in the CST II are shown in section 5.1. A brief description of the

function is inserted after the menu. Section 6.0 will cover each menu in detail for the programming of the CM II.

5.1 CST II Programming Screens for CM II

5.1.1 Main Menu

1. CM II Properties

2. Device Management

3. Zone Administration

4. Reports

5. About

6. Language

5.1.2 CM II Properties

1. Restore CM II to Factory Default Settings (restores factory default setting into CM II)

2. Assign Site Name (allows for naming of CM II device)

3. Set Real Time Clock (sets clock to be broadcasted to all connected device)

4. Backup System (allows backing up the CM II with all programmed information)

5. Restore System (allows importing backup into CM II with all programmed information)

6. Functional Testing and Verification (tests the RS232/ RS422 communications ports of CM II)

5.1.3 Device Management

1. Device Discovery (automatically finds all devices on communications lines)

2. Device Name Update (allows for naming of other devices connected)

3. Accept Device Configuration Changes (acceptance for changes or edits to system)

4. View Devices Status (views status of all connected devices)

5. Change Device Polling Interval (ms) (allows adjustment of polling time for intranet use)

5.1.4 Zone Administration

1. Add Zones (where zone records are created)

2. Modify Zones (modification of existing zone records)

3. Delete Zones (deletes zone records)

4. View Zones (view existing zone records)

5. List All Zones (shows list of all zone records)

6. View Zone Status (shows status of zone records)

Figure 17

13 Version A

5.1.5 Reports

1. View Configuration Report (shows zone records that were created)

2. Download Configuration Report (allows saving of zone records)

3. View Event Log Report (allows viewing of all zone record activity)

4. Download Event Log Report (allows saving of event log)

5. Erase Event Log (allows for erasing of event log file)

5.1.6 About

1. List software version with build date and time

5.1.7 Language

1. Allows selecting operator language in English, Spanish, Russian, Chinese or Korean

6.0 PROGRAMMING SEQUENCE

6.1 Main Menu

NOTE! When the CM II has been programmed with a zone record the system will automatically start polling

that zone record. Any alarm activity will be displayed on the CST II and by the relay(s) assignment(s).

Selecting “ESC” will return to previous menu without saving any changes.

After the CST II has been configured and opened, all the devices communications wiring connected and verified

and power has been applied, hit any key to open the Main Menu screen as shown in Figure 9.

Figure 9 –Main Menu Screen

14 Version A

The Main Menu screen as well as all subsequent screens will have a banner as shown in Figure 9. The banner

will display:

Control Module II –A member of the INTREPID™family: product model that is connected

Copyright information

Site Name: displays user defined site name (used for reference only)

Zones Defined = 000: displays the number of Zone Records created

Zones in Alarm = 000: displays the number of Zone Records in an alarm state

Zones Secured = 000: displays the number of Zone Records in the secure state

Attached Devices = 00: displays devices found on the RS422 communications ports

Devices Compromised = 00: displays the number of devices in Configuration Change Alarm

Fault Tolerance Mode = 0: displays if the system is in or out of Fault Tolerance Mode

Devices in Service = 00: displays devices that have the UIST II programming tool connected

Devices in Comfail = 00: displays any device(s) that are not responding to the polling message

Line Break Alarm = 0: displays if the communications line has been broken in Fault Tolerance Mode

Main: this line will display what menu is currently being used

Main Menu: selection list for programming

From this Main Menu screen all programming of the CM II will be performed. Selecting the appropriate

command number (1-6) will open the various menu functions for programming and reviewing the data of the

CM II. Entering the number will open the requested menu. Selecting “ESC” will return to the previous menu.

6.2 CM II Properties Menu

Selecting “1” from the Main Menu will open the “CM II Properties” menu as shown in Figure 10. There will be

six (6) command selections available.

Figure 10 –CM II Properties Screen

Figure 17

15 Version A

6.2.1 Restore CM II to Factory Default Settings

Selecting command 1 will open the “Restore CM II to Factory Default Settings” screen as shown in Figure 11.

This menu is used to erase all data in the CM II and restore it to the factory default settings. A warning will be

displayed. Note: This will stop all alarm polling and reporting!

Figure 11 –Restore CM II to Factory Default Settings Screen

It is recommended that this function be performed for any new installation before any data entry is to be made.

This will ensure that any miscellaneous data from previous use or any factory testing data is removed and only

current data for the new installation should be found in the system.

Select “Y” for “Yes” and press “Enter”. A prompt will ask “Are you sure you want to restore default settings?

(Y/N) Select “Y” for “Yes” and press “Enter” to start the process. The screen will display “Erasing all

configuration data, please wait. When finished erasing it will state: “DONE”. Selecting “N” for “No” will end

the process.

The screen will then display “The system is restarting”. It will return to the main menu after it is restarted. All

relays on the system should reset and all LED’s should be illuminated. Select 1 to return to the CM II Properties

Menu.

6.2.2 Assign Site Name

Selecting command 2 will open the “Assign Site Name” screen as shown in Figure 12. This screen will display

a Current Name field (if there has been one given from a previous time it will be displayed otherwise it will be

blank) for reference and New Name field that is blank. This screen allows the naming of the site or CM II. Enter

an appropriate name for the CM II or site (up to 64 characters long). This name will also be displayed in the

“List All Zones” function.

16 Version A

Figure 12 –Assign CM II Site Name Screen

Once the new name has been typed, select “ENTER” to save the new name. This name will now be displayed in

the header next to the “Site Name:” field. This name is for reference only and will also be used in the

Configuration Report that will be discussed later. Select “ESC” to return to the previous menu.

6.2.3 Set Real Time Clock

Selecting command 3 will open the “Set Real Time Clock” screen as shown in Figure 13. Only the “Enter Year”

will be displayed when the screen is first opened.

Figure 13 –Real Time Clock Screen

17 Version A

The other fields (month, day, hour, minute and second) will be displayed after each entry. Press enter after each

entry. This command will set the Real Time Clock in the CM II and update the time to all devices connected to

the RS422 communications line that support a Real Time Clock function. After all fields are entered a prompt

“Set time completed successfully” will be displayed. Select any key to continue.

Daylight Savings Time is not supported by the devices. Manual adjustment of the clock is required twice per

year to maintain correct time on the devices.

6.2.4 Backup System

Selecting command 4 will open the Windows™ Directory to save a backup file of all programmed information

in a *.txt format. Select a location to save the file on the PC hard drive or other location, provide a file name and

“Save”. The bottom of the screen will state “Downloading File”. Once completed, the screen will state “File

Transfer Completed”. Press any key to continue.

An independent folder is recommended for all files associated with this CM II and the site where it resides.

6.2.5 Restore System

Selecting command 5 will open the Windows™ Directory to restore a backup file of all programmed

information. Find the location where the file was saved on the PC hard drive or other location and “Open”. The

bottom of the screen will state “Uploading File”. Once the upload is completed it will return to the Main Menu.

6.2.6 Functional Testing and Verification

Selecting command 6 will open the “Functional Testing and Verification” screen as shown in Figure 14. This

screen will allow for relay testing and testing the RS422 and RS232 communications ports of the CM II. These

tests are recommended before the CM II is put into service.

Figure 14 –Functional Testing and Verification Screen

18 Version A

The CM II will need the RS422 communications ports wired from the RS422-1 TX + / TX –to RS422-2 RX + /

RX –and RS422-1 RX + / RX –to RS422-2 TX + / TX –to test the RS422 ports communications. Transmit

plus (+) should be wired to Receive plus (+) and Transmit minus (-) should be wired to Receive minus (-).

The CM II will need a null modem cable connected from the Terminal port (dB9) to the Service port (dB9) to

test the RS232 ports communications.

Note: All LED’s should be illuminated as no programming has been done to the CM II. Selecting command 1, 2

or 3 will turn off all LED’s during these test functions.

6.2.6.1 Relay Test

Selecting command 1 will open the “Relay Test” screen as shown in Figure 15. The commands on this screen

will allow setting and clearing of a single relay or all relays of the CM II as a verification test.

Figure 15 –Relay Test

Selecting “Relay Test” command 1 will set a single relay output on the CM II. Enter the relay number to be set

and press enter. That relay and the associated LED will activate (the LED will turn on). Select “Relay Test”

command 2, enter the relay number and press enter to clear the relay output. Selecting command 3 will set all

relay outputs of the CM II. Command 4 will clear all the relay outputs.

6.2.6.2 RS422 External Loopback Verification

Selecting command 2 will open the “RS422 External Loopback Verification” screen as shown in Figure 16.

19 Version A

Figure 16 –RS422 External Loopback Verification Screen

Press any key to start the loopback verification test. The screen will display “Testing RS422-1 and RS422-2

Ports… as shown in Figure 17. The test results will display PASSED or FAILED. If connected to devices during

this test only the Fault Tolerance Mode will work as polling to all devices will continue.

Figure 17 –RS422 External Loopback Verification Results Screen

20 Version A

After testing has been completed and successfully passed, press any key to return to the Functional Testing and

Verification screen as shown in Figure 15. Press “ESC” twice to return to the Main Menu.

Disconnect the local wiring at the CM II RS422 ports and make the wiring connections to all the devices that

will be used in the system at this particular site.

If the testing failed, replace the CM II (provided all wiring was correct for the test).

6.2.6.3 RS232 External Loopback Verification

Selecting command 3 will open the “RS232 External Loopback Verification” screen as shown in Figure 18. A

null modem cable connected between the two (2) dB9 ports will be required to perform this test.

Figure 18 –RS232 External Loopback Verification Screen

Once the command has been selected, remove the dB9 serial cable from the “Terminal” port and attach a null

modem cable between the “Terminal” and “Service” ports. The relays will start to cycle. When the relays

complete the process and stop cycling, disconnect the null modem cable and re-connect the dB9 serial cable

from the PC to the “Terminal” port.

Press any key to get the test results as PASSED or FAILED as shown in Figure 19. If the testing failed, replace

the CM II (provided all wiring was correct for the test).

Other manuals for INTREPID

1

Table of contents

Popular Controllers manuals by other brands

Vestamatic

Vestamatic Touch Centre XL 4C Wired Installation and operating instructions

Vivo

Vivo DESK-V103E instruction manual

Norac

Norac UC4 Plus Rogator 64 Series installation manual

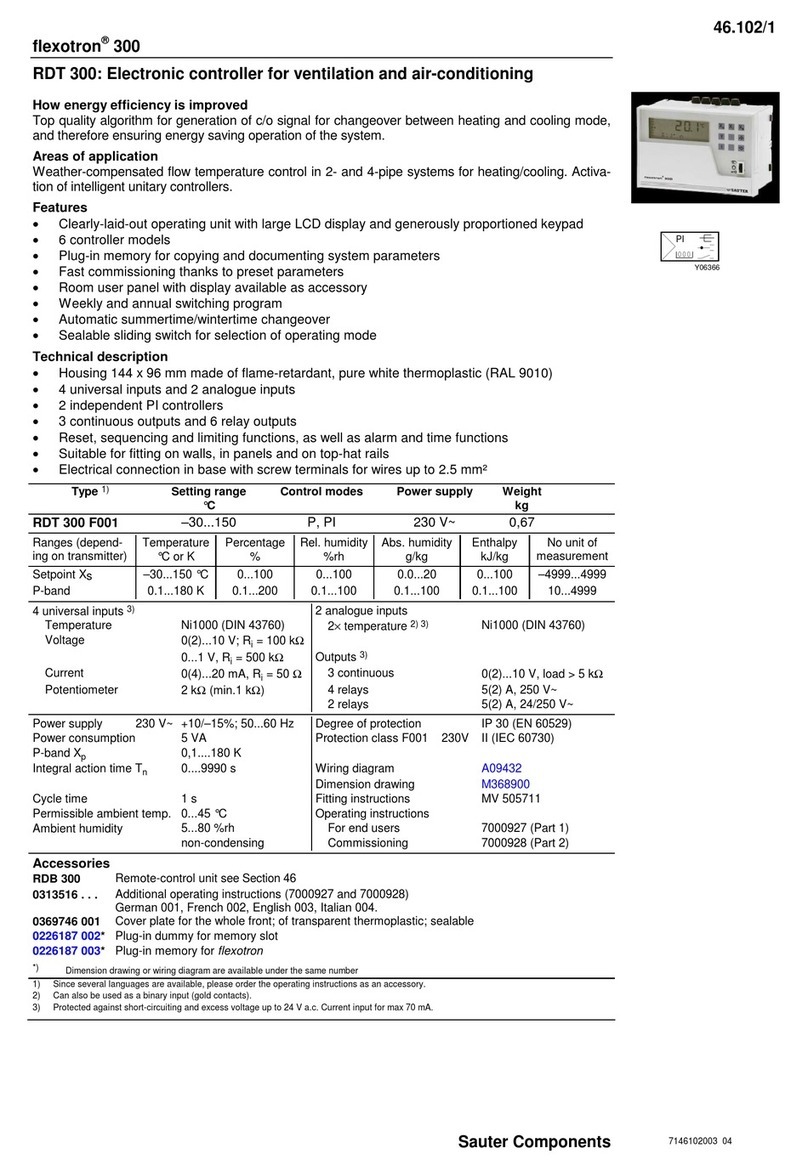

Sauter Components

Sauter Components flexotron 300 manual

Savant

Savant LCB-DMX1 Deployment guide

Automationdirect.com

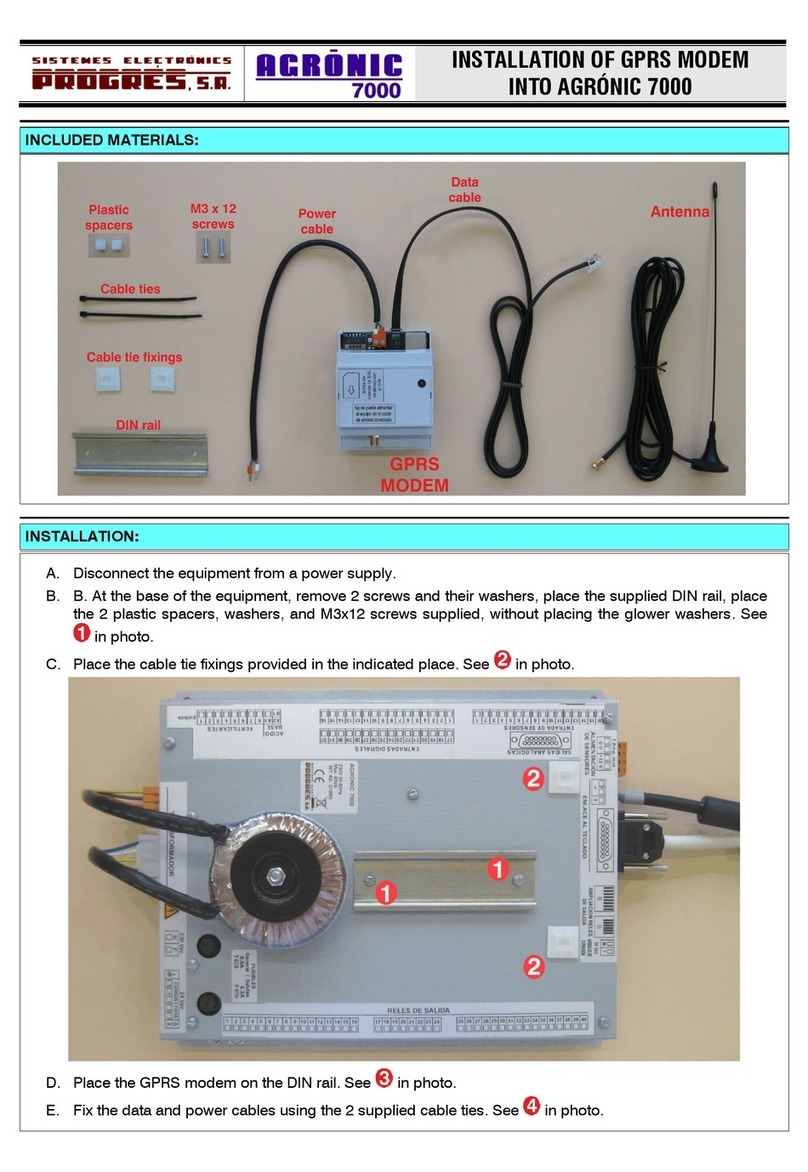

Automationdirect.com D4-454 PLC user manual