Southwestern Industries TRAK 2OP M11 Guide

Southwestern Industries, Inc.

2615 Homestead Place

Rancho Dominguez, CA 90220-5610 USA

T | 310-608-4422

F | 310-764-2668

Service Department: 800.367.3165

e-mail: sales@southwesternindustries.com | service@southwesternindustries.com | web: southwesternindustries.com

TRAKTM 2OP M11 Mill

Safety, Installation, Maintenance, Service and Parts List

Document: P/N 28170

Version: 111816

Copyright 2016, Southwestern Industries, Inc. All rights are reserved. No part of this

publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by

any means, mechanical, photocopying, recording or otherwise, without the prior written

permission of Southwestern Industries, Inc.

While every effort has been made to include all the information required for the purposes of this

guide, Southwestern Industries, Inc. assumes no responsibility for inaccuracies or omission and

accepts no liability for damages resulting from the use of the information contained in this guide.

All brand names and products are trademarks or registered trademarks of their respective holders.

i

Southwestern Industries, Inc.

TRAK2OP Installation, Maintenance, Service & Part List Manual

Table of Contents

1.0 Safety

1.1 Safety Publications 1

1.2 Danger, Warning, Caution and Note

Labels and Notices Used in this Manual

1.3 Safety Precautions

2.0 System Description

2.1 Machine Specifications 8

2.2 Maximum Spindle Torque & HP

2.3 ProtoTRAK TMX Control Hardware

2.4 Machine Major Subassemblies

3.0 Installation

3.1 Lifting the 2 OP mill 18

3.2 Uncrating the 2 OP

3.3 Shortages: Inventory Checklist

3.4 Installation Checklist

3.5 Electrical Connections

3.6 Air Connections

3.7 Cleaning the 2 OP

3.8 Leveling Procedure

3.9 Lubrication

3.10 Moving the 2 OP Around the Shop

3.11 Cutting the Euclid Test Block

4.0 Troubleshooting by Symptom

4.1 Machine Related Problems 31

4.2 Motion Related Problems

4.3 Control Related Problems

4.4 Tool Changer (Carrier) Problems

4.5 Control Input or Output Problem

4.6 Measurement Problems

4.7 Machine Tool Problems

5.0 Diagnostics

5.1 The Machine Tool & Setup 48

5.2 The Mechanical Drive Train

5.3 Computer Module

5.4 Programming Panel

5.5 Axis Motors/Servos

5.6 Spindle Motor & AC Drive

5.7 Electrical

5.8 Tool Carrier Diagnostics

5.9 Pneumatic Diagnostics

5.10 Coolant Diagnostics

5.11 Service Codes

6.0 Replacement Procedures

6.1 Axis Motor Replacement (includes setting

motor index angles) 106

6.2 AC Spindle Drive Replacement

6.3 Computer Module Replacement

6.4 Linear Guide Replacement

6.5 Ballscrew Replacement –X Axis

6.6 Ballscrew Replacement –Y Axis

6.7 Ballscrew Replacement –Z Axis

6.8 Spindle Motor Replacement

6.9 Spindle Motor Wiring

6.10 Spindle Cartridge Replacement

6.11 Spindle/Motor Coupling Alignment

6.12 Automatic Tool Carrier (ATC) Replacement

6.13 Setting ATC Locations

6.14 Coolant Pump Replacement

6.15 Bleeding Air from Tool Unclamp Cylinder Oil System

6.16 Programming Panel Replacement

6.17 Home Switch Replacement

6.18 Spindle Motor Encoder Replacement

6.19 X, Y & Z Home Switch Adjustments

6.20 Adjusting the Drawbar Bumpout

6.21 Servo Drive Replacement

6.22 Setting Spindle Orientation –Service code 510

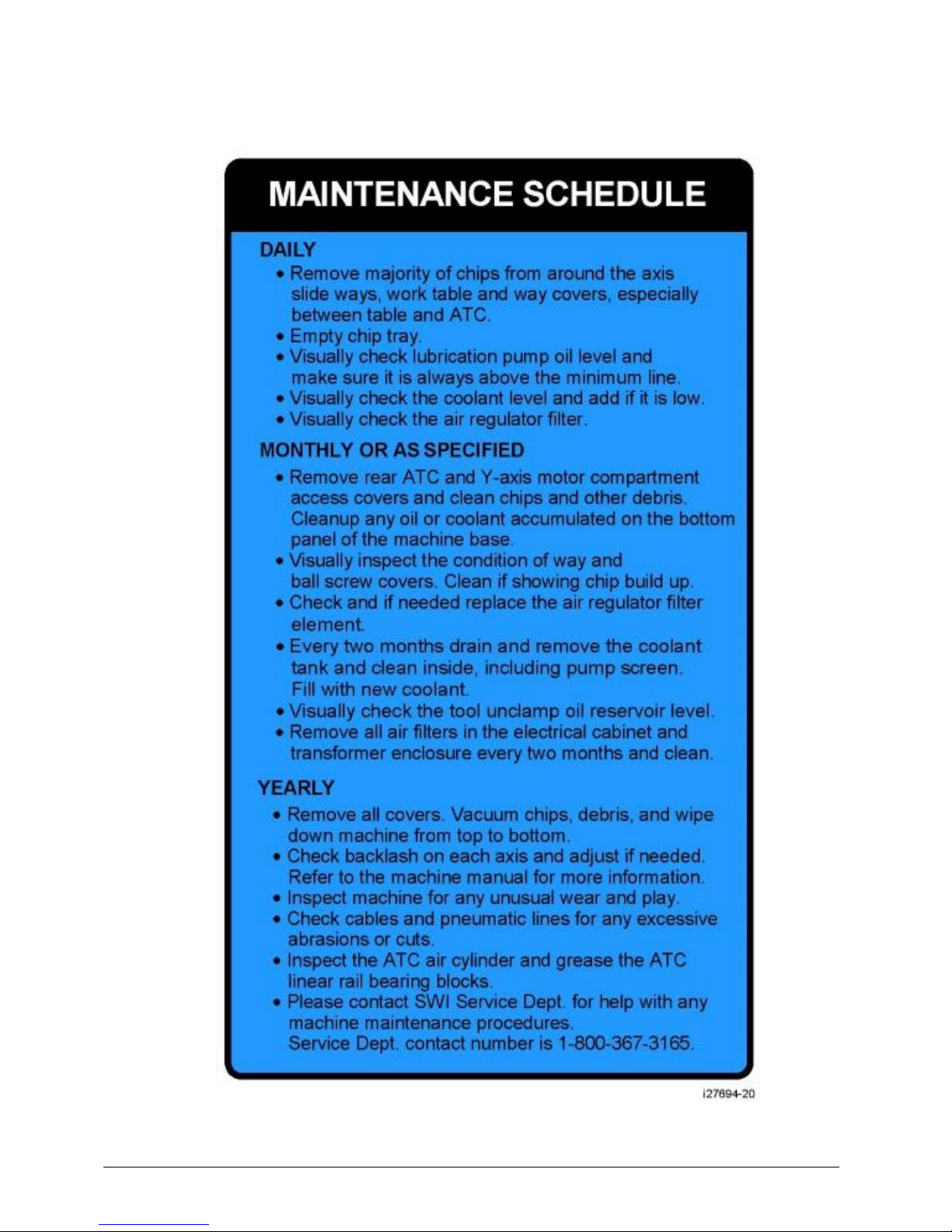

7.0 Maintenance

7.1 Calibration 136

7.2 Backlash Compensation

7.3 Periodic Maintenance

Assembly Drawings (rear of manual)

27500-1 Rev B Spindle Head Assembly

27520-1 Rev B X Axis Drive Train

27540-1 Rev D Z Axis Drive Train

27542-1 Rev B Base Frame Assembly

27557 Rev B Coolant System

27563-1 Rev D Pneumatic System

27564-1 Rev E Y Axis Drive Train

27568-1 Rev D Enclosure Assembly

27587-1 Rev A ATC Assembly

27591-1 Rev B Lubrication System

27600-2 Rev C Machine Assembly

27605-1 Rev A Single Phase Option

27621-2 Rev C Electrical Cabinet Assembly

27648-2 Rev C System Diagram

27650-2-SCH Rev F (D size) Electrical Schematic

27658-1 Rev A Home Switch Assembly

27682 Rev A Cover Assembly

27830-1 Rev C Spindle Cartridge Assembly

28091-1 Rev C 440 Volt Option

28137 Rev C Indexer Ready Option

28156 Rev A Enclosure Assembly –Servo Drives

28160 Rev B Programming Panel Assembly

1

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

1.0 Safety

The safe operation of the 2 OP Mill depends on its proper use and the precautions taken by each operator.

Read and study this manual and the 2 OP Programming, Operating, and Care Manual. Be certain

every operator understands the operation and safety requirements of this machine

before

its use.

Never run the machine with enclosure doors open

Always wear safety glasses and safety shoes.

Always stop the spindle and check to ensure the CNC control is in the stop mode before changing or

adjusting the tool or workpiece.

Never wear gloves, rings, watches, long sleeves, neckties, jewelry, or other loose items when

operating or around the machine.

Use adequate point of operation safeguarding. It is the responsibility of the employer to provide and

ensure point of operation safeguarding per OSHA 1910.212 - Machining centers.

1.1 Safety Publications

Refer to and study the following publications for assistance in enhancing the safe use of this machine.

Safety Requirements for Machining Centers and Automatic, Numerically Controlled Milling,

Drilling and Boring Machines (ANSI B11.22-2002) (R2007) & (ANSI B11.23-2002 (R2007). Available from

The American National Standards Institute, 1819 L Street N.W., Washington D.C. 20036

Concepts And Techniques Of Machine Safeguarding (OSHA Publication Number 3067). Available from

The Publication Office - O.S.H.A., U.S. Department of Labor, 200 Constitution Avenue, NW, Washington, DC

0210.

1.2 Danger, Warning, Caution, and Note Labels & Notices As Used

In This Manual

DANGER - Immediate hazards that will result in severe personal injury or death. Danger labels on the

machine are red in color.

WARNING - Hazards or unsafe practices that

could

result in severe personal injury and/or damage to the

equipment. Warning labels on the machine are orange in color.

CAUTION - Hazards or unsafe practices, which

could

result in minor personal injury or equipment/product

damage. Caution labels on the machine are yellow in color.

NOTICE- Call attention to specific issues requiring special attention or understanding.

2

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

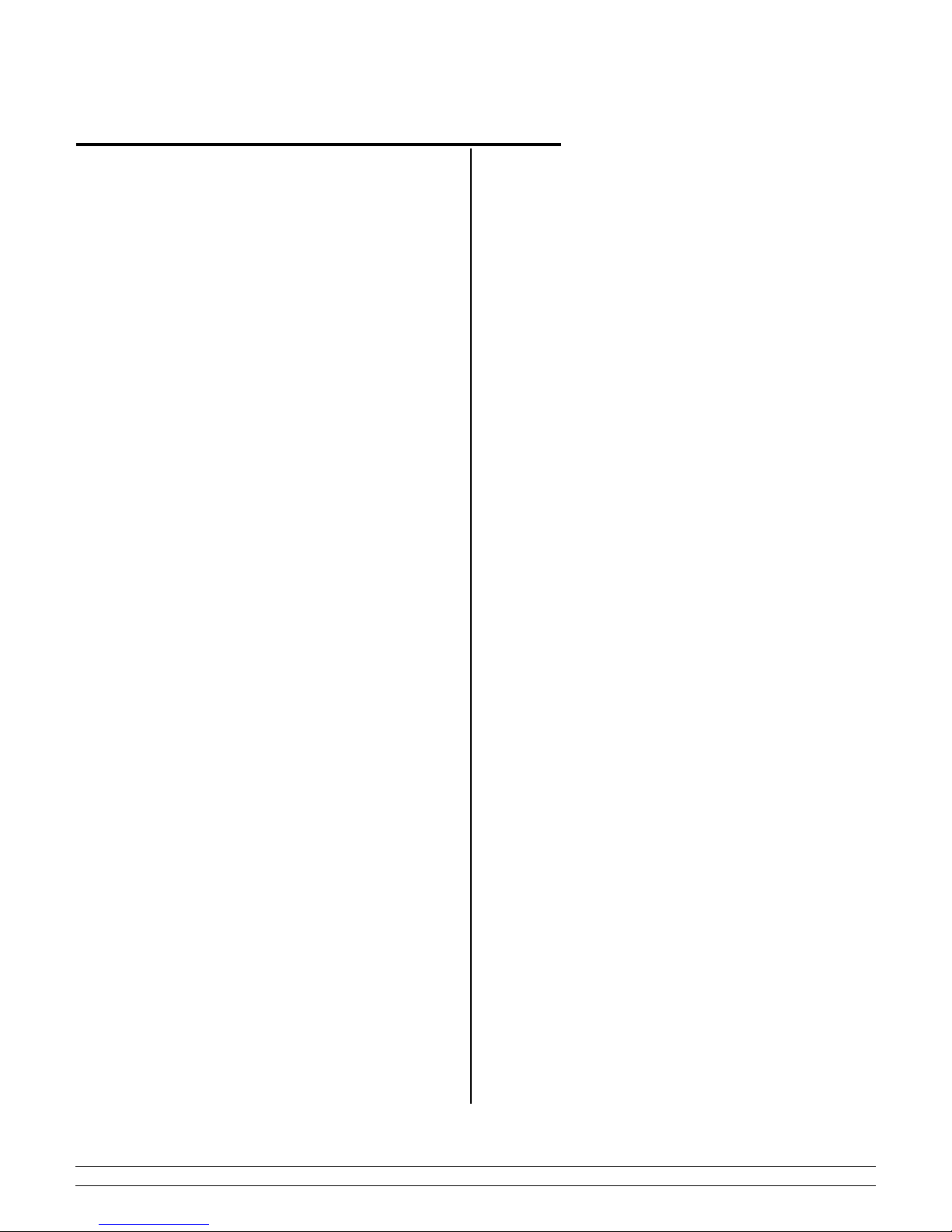

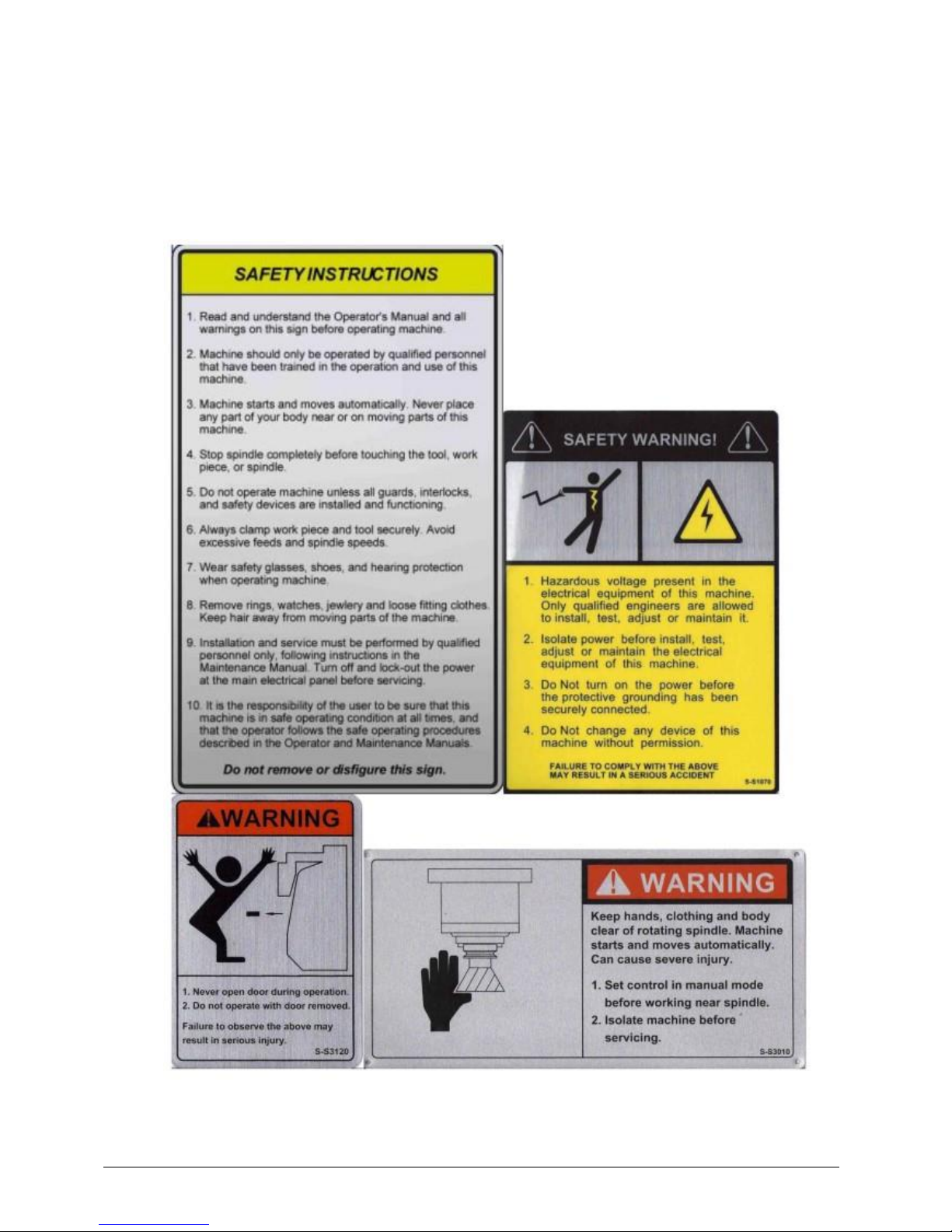

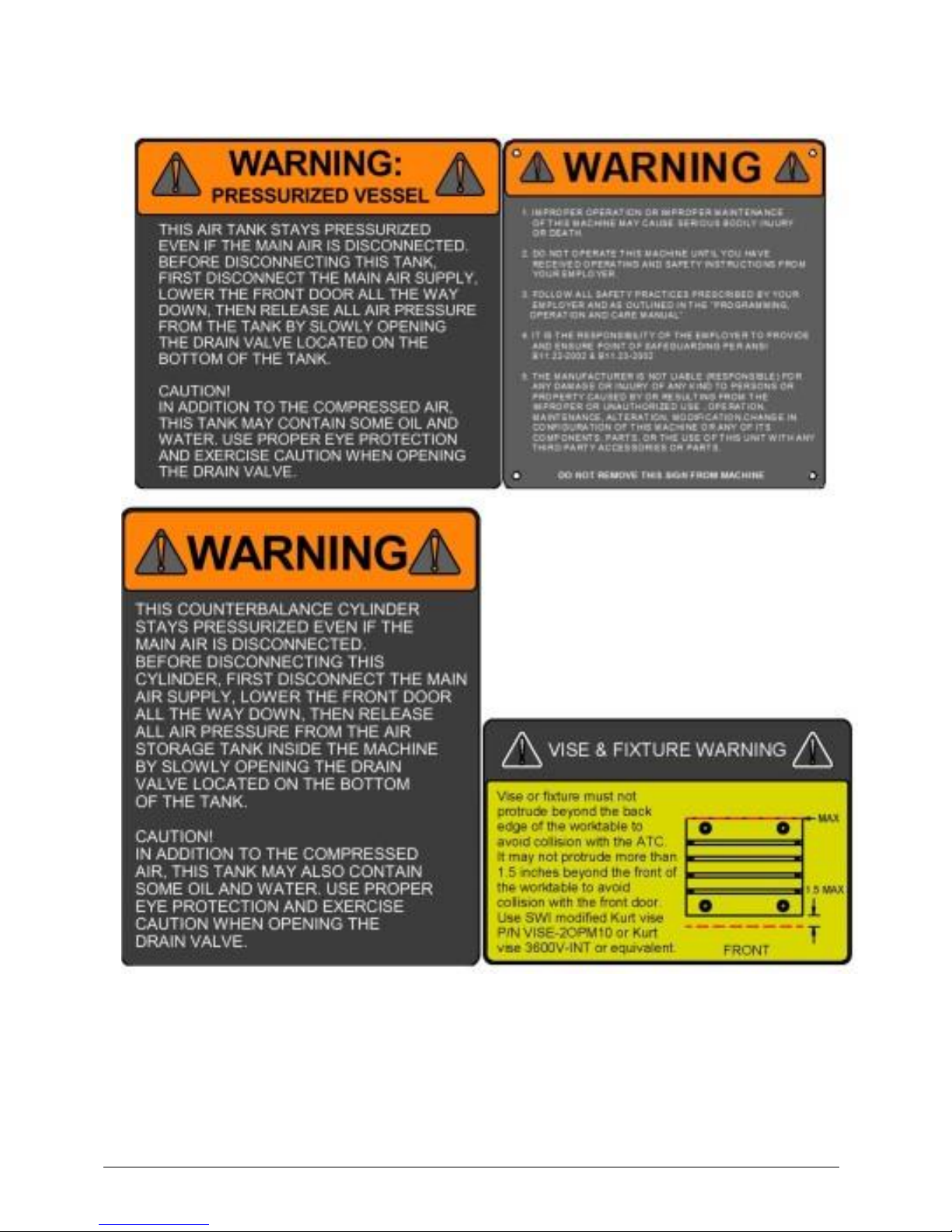

Safety & Information Labels Used On The

TRAK 2 OP Milling Machine

It is forbidden by OSHA regulations and by law to deface, destroy or remove any

of these labels

3

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

4

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

5

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

6

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

1.3 Safety Precautions

1. Do not operate this machine before the 2 OP Installation, Maintenance, Service and Parts List

Manual,Operating & Care Manual have been studied and understood.

2. Do not run this machine without knowing the function of every control key, button, knob, or handle.

Ask your supervisor or a qualified instructor for help when needed.

3. Protect your eyes. Wear approved safety glasses (with side shields) at all times.

4. Don't get caught in moving parts. Before operating this machine remove all jewelry including

watches and rings, neckties, and any loose-fitting clothing.

5. Keep your hair away from moving parts. Wear adequate safety headgear.

6. Protect your feet. Wear safety shoes with oil-resistant, anti-skid soles, and steel toes.

7. Take off gloves before you start the machine. Gloves are easily caught in moving parts.

8. Remove all tools from the machine before you start. Loose items can become dangerous flying

projectiles.

9. Never operate a milling machine after consuming alcoholic beverages, or taking strong medication, or

while using non-prescription drugs.

10. Protect your hands. Stop the machine spindle and ensure that the CNC control is in the stop mode:

Before changing tools

Before changing parts

Before you clear away the chips, oil or coolant. Always use a chip scraper or brush.

Do not used compressed air to clean the machine.

Before you make an adjustment to the part, fixture, coolant nozzle or take measurements.

Do not attempt to disable any safety interlock. Never reach around a safeguard.

11. Protect your eyes and the machine as well.

12. Disconnect power to the machine before you change belts, pulley, and gears.

13. Keep work areas well lighted. Ask for additional light if needed.

14. Do not lean on the machine while it is running.

15. Prevent slippage. Keep the work area dry and clean. Remove the chips, oil, coolant and obstacles of

any kind around the machine.

16. Avoid getting pinched in places where the table, saddle or spindle head create "pinch points" while in

motion.

17. Securely clamp and properly locate the workpiece in the vise, on the table, or in a fixture. Use stop

blocks to prevent objects from flying loose. Use proper holding clamping attachments and position

them clear of the tool path.

18. Use correct cutting parameters (speed, feed, depth, and width of cut) in order to prevent tool

breakage due to premature wear.

7

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

19. Use proper cutting tools for the job. Pay attention to the rotation of the spindle: As viewed from

above, left hand tool for counterclockwise rotation of spindle, and right hand tool for clockwise

rotation of spindle.

20. To prevent damage to the workpiece or the cutting tool, never start the machine (including the

rotation of the spindle) if the tool is in contact with the part.

21. Check the direction (+ or -) of movement of the table when using the jog feature, clockwise rotation

of the EHW moves the axis in the positive direction, counterclockwise in the negative direction.

22. Don't use dull or damaged cutting tools. They break easily and become airborne. Inspect the

sharpness of the edges, and the integrity of cutting tools and their holders. Use proper length for the

tool.

23. Inspect the retention knobs for damage or excessive wear before each use.

24. Large overhang on cutting tools when not required result in accidents and damaged parts.

25. Prevent fires. When machining certain materials (magnesium, etc.) the chips and dust are highly

flammable. Obtain special instruction from your supervisor before machining these materials.

26. Prevent fires. Keep flammable materials and fluids away from the machine and hot, flying chips.

Warning

Retention knobs come in a wide variety of designs, however they often look similar and appear to

be interchangeable, but they are not. Use only the knob that the 2 OP mill is designed to use.

The use of the incorrect knob, or the incorrect usage of a knob, may result in injury or property

damage. To ensure the correct knob is chosen, please refer to section 2.4.4, System Description

section of this manual

8

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

2.0 System Description

Read and understand this entire installation section before beginning the installation procedure.

2.1 Machine Specifications

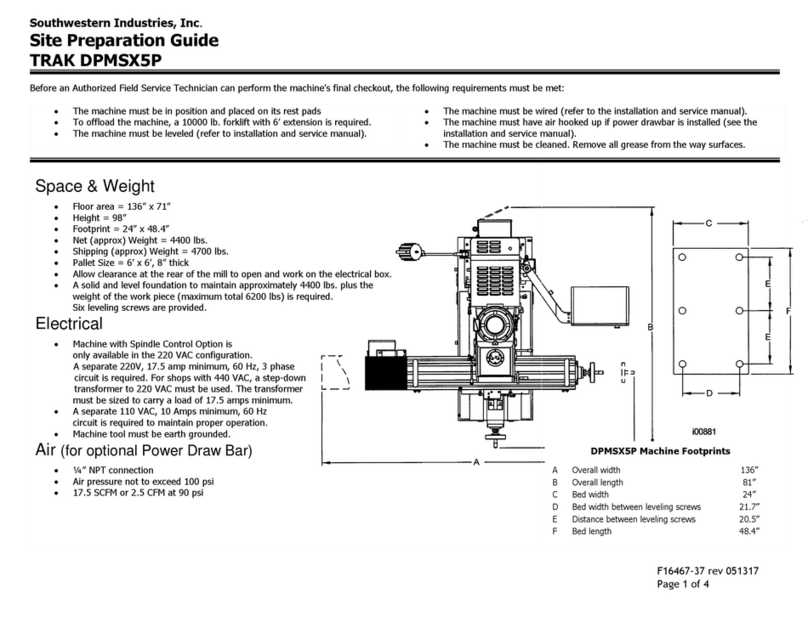

Please see the drawing on the next page for a layout of the TRAK 2OP machine.

Overall Machine Dimensions

Width of machine 30.5”

Depth of machine 52”

Height of mill with head all the way up 101”

Minimum height to fit mill through doorway 92”

(Z cable carrier collapsed, resistor cover and resistors removed)

Machine Specifications

Table Dimensions

Table size

18” x 15”

Number of tee slots and pitch

4 @ 63 mm

Tee slot width

0.630” or 16 mm

Table maximum load

500 lbs.

Ball Lock ® hold down force

2250 lbs @ 35 in/lbs of

torque

Machine Weight

~2825 lbs

Machine Shipping Weight

~3175 lbs

Travel

X-axis

14”

Y-axis

18” (12” of machining travel)

Z-axis

17”

Maximum distance from spindle nose table surface

20.25”

Minimum distance from spindle nose table surface

2.75”

Maximum swing clearance from spindle center to column

14”

Maximum Rapid speed X, Y & Z-axis, inches per minute

600

Spindle

Tool holder type

BT30

Spindle nose diameter

2.2” or 56 mm

Maximum RPM

6000

Automatic Tool Carrier

Tool Capacity

8

Maximum tool diameter

2 or ~50 mm

Retention knob

See section 3.4.4

Longest Tool that can be use in ATC –length measured from

bottom of drive dog flange on holder

6.75”

Air Requirements

Pressure

90 psi

Quality

CFM

SCFM

Air dried/filtered water

separator upstream of the

machine

2.5 @ 90 psi

18

9

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

10

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

2.2 Maximum Spindle Torque and Horsepower

The following graphs illustrate the continuous and peak torque vs RPM and horsepower vs RPM

for the 2 OP M11 machine at the spindle. Peak torque and horsepower values can only be

attained for a short period of time before the spindle drive will fault out to protect the motor.

Note - Maximum work capacities are dependent on a lot of variables that cannot be controlled by

the machine manufacturer. Each one of the following will have an impact on the above

0

2

4

6

8

10

12

14

16

0 1000 2000 3000 4000 5000

Torque (ft-lbs)

RPM

Torque vs RPM

Continuous Torque

Peak Torque

11

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

numbers: speeds, feeds, cutter, cutter sharpness, material, setup, coolant and machine

adjustments.

2.3 ProtoTRAK TMX Control Hardware

2.3.1 Programming Panel Assembly

The programming panel assembly on the 2 OP is mounted to the front right side of the machine.

The panel consists of the program overlay, electronic handwheel (EHW), 5.7” LCD and a servo on

button. There are 2 USB ports mounted on the right side of the machine next to the

programming panel. They are used to save programs and/or plug in a keyboard and mouse.

There are 6 cables that route from the programming panel to the computer module. They are

the VGA cable, 2 USB cables, COM port cable, overlay power cable and EHW cable. The VGA

cable carries video signals from the computer module to LCD controller board. The LCD interface

board gives the user the ability to modify the brightness, color and position of the image. The

USB cables extend 2 of the USB ports on the computer module up to the right side of the

machine, next to the programming panel. The COM port provides the communication between

the computer and the Overlay Interface board. The Overlay power cable provides power to the

LCD and Overlay Interface board, it also feeds back the critical keys (GO, STOP, etc) to the

computer module. The EHW cable carriers the signals from the EHW down to the computer

module.

2.3.2 Electrical Cabinet

The electrical cabinet is found at the rear of the machine. The electrical cabinet contains the

main control hardware for the machine. The main components are the computer module and AC

spindle drive. See drawing 27621-2 at the rear of the manual.

2.3.3 Computer Module

The computer module is the heart and soul of the machine. All of the inputs and outputs are fed

through this module. The computer module controls the programming panel assembly, AC

spindle drive, servo drives, motor signals and feedback and all the inputs and outputs. Inside of

the computer module is a motherboard, motion control board and an applications board along

with a power supply.

The computer module also contains 2 USB ports. Both USB ports extend with 2 cables to the

front of the machine to ease access from the front of the machine.

2.3.4 Servo Motors

The TRAK 2OP mill uses 3 servo motors with servo drives to run the X, Y and Z axes. The motors

for the X and Y axis produce 21 in-lbs of continuous torque and 63 in-lbs of peak torque. The Z

axis motor produces all produces 28 in-lbs of continuous torque and 84 in-lbs of peak torque.

The servo motors run off of 220 volt single phase power.

2.3.5 Servo Drives

The TRAK 2OP mill uses 3 servo amps that are mounted in an enclosure that is mounted to the

top of the machine. The servo amps are the same for both the X and Y axis. The Z axis uses a

larger servo amp to drive the larger Z axis motor. A separate braking resistor is part of the Z axis

servo amp circuit to dissipate heat generated when the motor is decelerating. The resistor is

mounted to the top of this enclosure.

12

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

2.4 Machine Major Subassemblies

2.4.1 Spindle

The spindle is contained within a cartridge and BT30 tool holders must be used. The spindle

bearings are permanently lubricated and require no additional attention by the user. The spindle

has an air purge system that is automatically activated during the tool change sequence; it blows

air down the spindle to prevent chips from being trapped between the holder and spindle taper.

The spindle cartridge design is also pressurized by air to prevent contaminants from getting up

inside the spindle. A spindle ring is also attached to the bottom of the spindle via the drive dogs

and prevents debris like coolant from getting up inside the spindle.

2.4.2 Spindle Motor & Drive

The spindle motor is 3 HP and directly drives the spindle via a coupling. The RPM range for this

machine is 50 to 6000 RPM.

2.4.3 Automatic Draw Bar Assembly

The automatic drawbar is an assembly consisting of an air cylinder and an actuator that

unclamps the tool. Tooling is changed by means of the Automatic Tool Changer (ATC), or can be

done manually by pressing and holding the “Unclamp” button. Tools are clamped when the

button is released. A clamping force of approximately 1000 lbs is generated to clamp the

toolholder to the spindle. The Automatic Draw Bar Assembly uses full system air and hydraulic oil

and requires no adjustment. There is an oil reservoir for the hydraulics that should be monitored

on a regular basis. If there is a leak in the system the oil in this reservoir will go down. This leak

will need to be fixed. This oil cup is found on top of the machine behind the spindle motor.

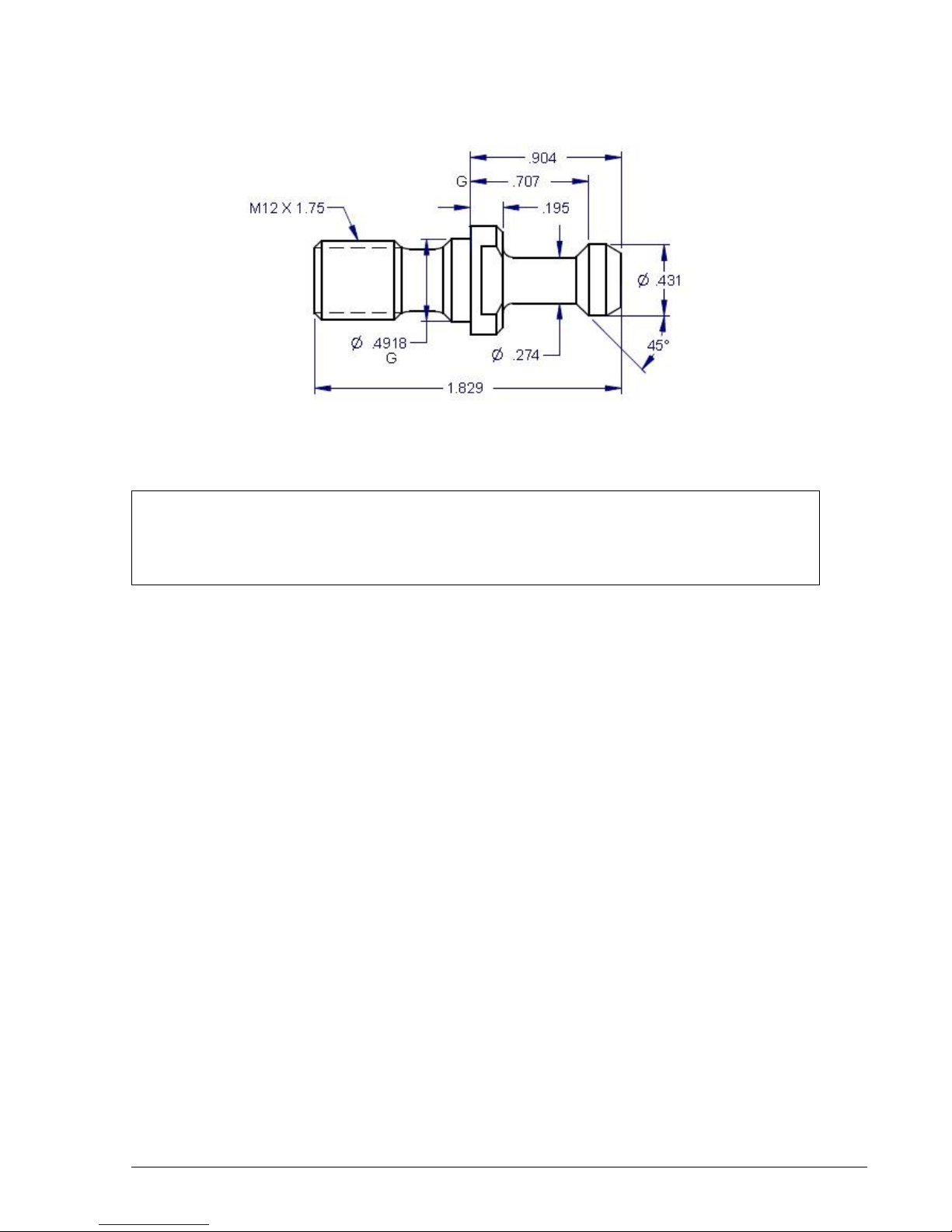

2.4.4 Retention Knobs

The TRAK 2OP Mill uses BT30 retention knobs as shown in Figure 2.4.4a. Tightening to the proper

torque value is important for all retention knobs. Please see the retention knob manufacturer for

the proper torque. You can order these retention knobs from Southwestern Industries under

part number RETN KNOB-2OPM11. Our retention knobs should be torqued to 30 ft-lbs. It should

be noted that lesser quality retention knobs will be torqued to something less than this.

Warning!

The spindle unit is not field serviceable. If the bearings go bad the entire

spindle cartridge will be replaced.

13

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

Figure 2.4.4a

Warning!

Retention knobs come in a wide variety of designs, however they often look similar and appear to

be interchangeable, but they are not. Use only the knob that the 2 OP mill is designed to use.

The use of the incorrect knob, or the incorrect use of a knob, may result in injury and/or damage

to the mechanism.

2.4.5 Tool Changer (Carrier)

The tool changer is an 8 station mechanism that is actuated along the Y axis. It is hidden from

view while the machine is cutting. The ATC mechanism slides forward on the Y axis linear guides

and is actuated via an air cylinder.

2.4.6 Drive Train, Axes

Each axis (X, Y and Z) rides on precision linear guideways, with four preloaded recirculating ball

carriages. Each axis is moved via a 6 mm pitch ballscrew. The axis motors drive each axis via a

timing belt except on the Z axis where it is directly driven.

2.4.7 Worktable

The 2 OP table utilizes Ball Lock® technology as well as conventional T-bolt construction. Each

Ball Lock mechanism has a hold-down force of 2250 lbs when 35 in/lbs of torque is applied to the

screw. The software on the 2 OP mill allows the user to save the X and Y location of your

program relative to the lower left hand corner ball lock. See the programming manual for more

information. There are 4 ball lock receivers mounted in the table and they are separated by 12”.

The front 2 ball lock receivers are to be used to locate your fixture and the rear two are for

clamping purposes.

14

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

Figure 2.4.7a

2.4.8 Home switches

Each axis has a home switch which is used to home the mill. The machine must be homed each

time the control is powered on.

Warning

It is not recommended that the position of the home switches be changed. They are preset at

the factory and should require no additional adjustments. Should any major adjustments be

done, service codes 500, 505, and 520 may need to be performed.

2.4.9 Lubrication System

The automatic lubricating system is a centralized system. It is located on the left side of the

machine. While the system is automatic, it is recommended that after long idle periods, the

machine be manually lubricated by using service code 300.Cycle the lube pump two to three

times. The lubrication reservoir should be maintained on a daily basis, filling only with high

quality lubricating oil. See section 3.9

2.4.10 Coolant and Coolant Wash System

The coolant and coolant wash system uses 1 pump to provide coolant to the work and also to

wash chip away from the area where the ATC comes out. Wash areas can be controlled by the

flexible coolant lines found at the base of the enclosure.

The coolant tank holds approximately 15 gallons of coolant.

See drawing 27557 at the rear of the manual for the coolant system.

2.4.11 Pneumatic System

The machine requires a supply of compressed air between 85-100 psi with a recommended air

supply of ½” I.D, minimum is 3/8” ID. Air pressure to pneumatic components, the ATC slide

mechanism, and air purge (internal spindle) can be controlled individually by means of the

adjusting valves located at the back of the 2 OP mill. See drawing 27563-1 for an overview of

the pneumatic system.

CAUTION!

Always Observe Low Air Pressure and Low Oil Level Warnings

15

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

2.4.12 Enclosure Doors

The front door has an electro-mechanical safety interlock that must be engaged when running a

CNC program. If the door is opened during a machining operation, the program will be shut

down. This includes the axis motors and spindle.

The enclosure is also equipped with left and right doors that are bolted in place.

2.4.13 Status Light

The machine has a status light attached to the top of the machine to give the user status of what

is going on. The lights perform as follows:

a. The green light is illuminated when the machine is running a program.

b. The green light is flashing once per second when the operator input is required, like when a

part needs to be changed.

c. The green light flashes 3 times per second when a fault condition exists.

2.4.14 Chip Removal

The chip pan is located in the front of the mill. To remove, lift up on the pan and pull forward.

2.4.15 Work Lamp

The 2 OP mill comes equipped with a fluorescent work lamp, which comes on automatically

when the power is turned on.

2.4.16 Transformer

The TRAK 2OP mill must be ordered for 200 to 240 or 400 to 480 volts. A transformer outputs

115 and 24 volts. During the installation of the machine, the wires to the transformer may need

to be moved to adjust the output voltage. From the factory the wires on the transformer will be

place on the 220 or 440 volt tap and 115 volt tap on the output side. It should be noted that the

transformer is physically different for 220 volt machines versus 440 volt machines.

Warning

The input voltage to the machine should not exceed 240 or 480 volts. The spindle

inverter is not rated for voltages higher than this. If the shop has voltages that

exceed these numbers, they will need a step down transformer to lower the voltage.

Voltages higher than this may void your warranty.

DANGER

You must turn the power off to the machine before adjusting the wires on the

transformer. Failure to do so may cause death by electrocution.

Figure 2.4.17a shows the terminal blocks where you can switch the wiring. For example, the

machine is most likely shipped from the factory with the wire in the 220 volt terminal. This wire

needs to be moved to the 200 or 240 terminal if the input voltage to the machine measures this

amount.

CAUTION!

Do not Attempt to Disable or Override the Safety Interlock.

16

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

Figure 2.4.17a –Transformer used on 220 volt machines

Figure 2.4.17b shows the terminal blocks for a 440 volt machine where you can switch the

wiring. For example, the machine is most likely shipped from the factory with the wire in the 440

volt terminal. This wire needs to be moved to the 400 or 480 terminal if the input voltage to the

machine measures this amount. The 380 volt terminal will most likely not be used on USA

machines.

Figure 2.4.17b –Transformer used on 440 volt machines

Please see drawing 27648-2 at the rear of the manual for more information.

17

Southwestern Industries, Inc.

TRAK2OP M11 Installation, Maintenance, Service, & Part List Manual

2.4.17 Single Phase Power Option

The TRAK 2OP mill has an optional single phase option for 220 volts. It needs to be noted that

running the machine on single phase power reduces the spindle power by about 40% as

compared to 3 phase 220 volt power. In other words, the spindle will not produce 3 HP. A

different style electric cord plug is used with single phase power. As part of the single phase kit,

we will provide an adaptor cable that allows the user to plug the machine into a 3 phase 220 volt

power connector. Please note that the machine will still only run on single phase power with this

adaptor. In order to convert the machine back to 3 phase power, a number of changes need to

be done to the machine. See section 3.5 for an illustration of what that plug looks like.

Table of contents

Other Southwestern Industries Power Tools manuals