Southwestern Industries TRAK VMC2 Guide

TRAK®VMC2

ProtoTRAK®RMX CNC

Safety, Installation, Maintenance, Service and Parts List

Covers Current Model:

•TRAK VMC2

Document: 31552

Version: 022521

2615 Homestead Place

Rancho Dominguez, CA 90220-5610 USA

T | 310.608.4422 | F | 310.764.2668

Service Department: 800.367.3165

Copyright ©2021, Southwestern Industries, Inc. All rights are reserved. No part of this publication may

be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, mechanical,

photocopying, recording or otherwise, without the prior written permission of Southwestern Industries,

Inc.

While every effort has been made to include all the information required for the purposes of this guide,

Southwestern Industries, Inc. assumes no responsibility for inaccuracies or omission and accepts no

liability for damages resulting from the use of the information contained in this guide.

All brand names and products are trademarks or registered trademarks of their respective holders.

TRAK Machine Tools

Southwestern Industries, Inc.

2615 Homestead Place

Rancho Dominguez, CA 90220-5610

Phone 310.608.4422 ▪ Fax 310.764.2668

Service Department

Phone 800.367.3165 ▪Fax 310.886.8029

Web: www.trakmt.com

i

TRAK Machine Tools

Southwestern Industries, Inc.

TRAK VMC2 with ProtoTRAK RMX CNC Safety, Installation, Maintenance, Service & Parts List

Table of Contents

1.0 Safety ....................................................................................................... 1

1.1 Safety Publications ...............................................................................................................1

1.2 Danger, Warning, Caution, Note Labels & Notices As Used In This Manual...............................1

1.3 Tool Room OP and Production OP .........................................................................................7

1.4 Safety Precautions................................................................................................................8

2.0 Installation of TRAK VMC2 Series Machining Centers........................... 10

2.1 Installation Requirements ...................................................................................................10

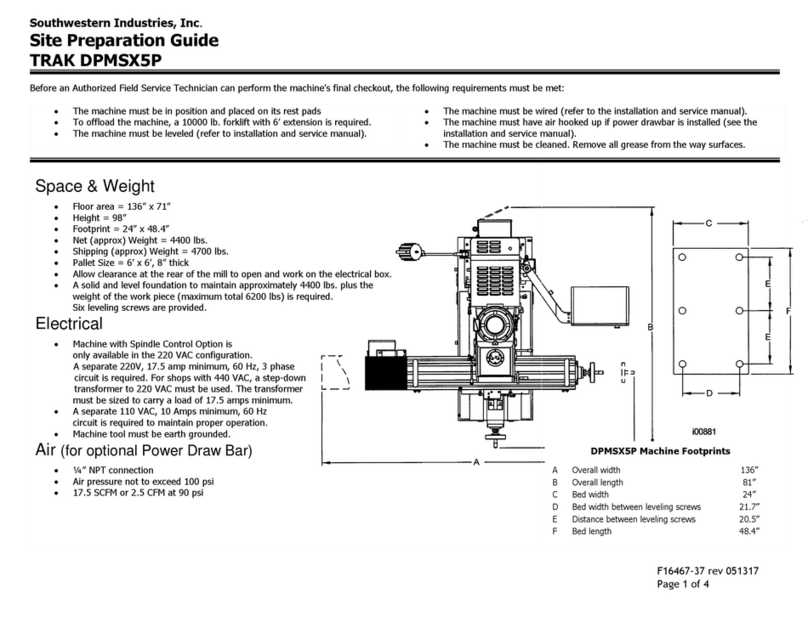

2.2 Overall Dimensions VMC2 (inches) ......................................................................................10

2.3 Cleaning the VMC2 .............................................................................................................14

2.4 Lifting and/or Placing the VMC2 ..........................................................................................15

2.5 Uncrating the VMC2............................................................................................................17

2.6 Leveling Procedure .............................................................................................................18

2.7 Shortages: Inventory Checklist............................................................................................18

2.8 Electrical Connection ..........................................................................................................19

2.8.1 Transformer Option ........................................................................................................19

2.8.2 Single Phase Power Option..............................................................................................21

2.9 Connection ........................................................................................................................21

2.9.1 Air Regulator/Air Pressure Switch/Solenoid Assembly Mounting .........................................21

2.9.2 Air Connection................................................................................................................23

2.9.3 Air Regulators and Solenoids ...........................................................................................23

2.10 Installation Checklist...........................................................................................................24

2.11 Coolant and Coolant Wash System ......................................................................................25

2.12 Air Blast System .................................................................................................................26

2.13 Lubrication.........................................................................................................................26

2.13.1 Way Lubrication ..........................................................................................................26

2.13.2 Other VMC2 Lubrication Points.....................................................................................28

2.14 TRAK VMC2 Machine Specifications .....................................................................................29

2.15 Maximum Spindle Torque & HP ...........................................................................................30

2.16 ProtoTRAK RMX Euclid Block Procedure ...............................................................................31

3.0 Troubleshooting by Symptom................................................................ 33

3.1 Problems Relating to Machining Results ...............................................................................33

3.1.1 Poor Finish .....................................................................................................................33

3.1.2 Circles Out of Round .......................................................................................................33

3.1.3 Parts Have Incorrect Dimensions .....................................................................................34

ii

TRAK Machine Tools

Southwestern Industries, Inc.

TRAK VMC2 with ProtoTRAK RMX CNC Safety, Installation, Maintenance, Service & Parts List

3.2 Motion Related Problems ....................................................................................................35

3.2.1 Run Away Axis................................................................................................................35

3.2.2 Axis Will Not Jog with Electronic Handwheel .....................................................................35

3.2.3 Searching Axis................................................................................................................36

3.2.4 Homing Error –Axis, Tool Changer ..................................................................................36

3.3 Computer Related Issues ....................................................................................................37

3.3.1 USB Not Working on Pendant Enclosure ...........................................................................37

3.3.2 Programming Panel Does Not Power On...........................................................................38

3.3.3 Blank Display..................................................................................................................39

3.3.4 White Display .................................................................................................................40

3.3.5 System Will Not Boot ......................................................................................................40

3.3.6 E-Stop Error ...................................................................................................................41

3.3.7 Overlay Keys Not Responding..........................................................................................42

4.0 Tool Changer Problems.......................................................................... 44

4.1 Automatic Tool Changer (ATC) Will Not Move ......................................................................44

4.2 Spindle Will Not Orientate Properly......................................................................................45

4.3 Tool Will Not Clamp or Unclamp in the Spindle .....................................................................45

4.4 Service Codes ....................................................................................................................46

4.4.1 Section A - Software Code Details....................................................................................48

4.4.2 Section B - Machine Set-Up Code Details..........................................................................49

4.4.3 Section C - Diagnostic Code Details..................................................................................51

4.4.4 Section D - Operator Defaults/Options Codes Details ........................................................52

4.5 Critical Service Codes that Must Be Performed .....................................................................53

5.0 Diagnostics............................................................................................. 54

5.1 The Machine Tool & Set-Up ................................................................................................54

5.1.1 The Milling Machine Checklist ..........................................................................................54

5.1.2 A Special Word About Linear Guides ................................................................................54

5.1.3 Lubrication .....................................................................................................................55

5.1.4 Machining Set-Up ...........................................................................................................55

5.2 The Mechanical Drive Train .................................................................................................56

5.2.1 Ballscrew Alignment........................................................................................................56

5.2.2 Protecting the Axis from a Crash......................................................................................56

5.2.3 Z Axis Mechanical Brake ..................................................................................................56

5.2.4 Linear Guides .................................................................................................................57

5.2.5 Lubrication .....................................................................................................................57

iii

TRAK Machine Tools

Southwestern Industries, Inc.

TRAK VMC2 with ProtoTRAK RMX CNC Safety, Installation, Maintenance, Service & Parts List

5.2.6 Way Covers....................................................................................................................57

6.0 Procedure for Replacements & Maintenance ........................................ 58

6.1 Replacements ....................................................................................................................58

6.1.1 X Axis Motor Replacement...............................................................................................58

6.1.2 Y Axis Motor Replacement...............................................................................................61

6.1.3 Z Axis Motor Replacement...............................................................................................62

6.1.4 AC Spindle Drive Replacement.........................................................................................65

Safety, Installation, Maintenance, Service and Parts List ..........................................................i

1.0 Safety ....................................................................................................... 1

1.1 Safety Publications ...............................................................................................................1

1.2 Danger, Warning, Caution, Note Labels & Notices As Used In This Manual...............................1

1.3 Tool Room OP and Production OP .........................................................................................7

1.4 Safety Precautions................................................................................................................8

2.0 Installation of TRAK VMC2 Series Machining Centers........................... 10

2.1 Installation Requirements ...................................................................................................10

2.2 Overall Dimensions VMC2 (inches) ......................................................................................10

2.3 Cleaning the VMC2 .............................................................................................................14

2.4 Lifting and/or Placing the VMC2 ..........................................................................................15

2.5 Uncrating the VMC2............................................................................................................17

2.6 Leveling Procedure .............................................................................................................18

2.7 Shortages: Inventory Checklist............................................................................................18

2.8 Electrical Connection ..........................................................................................................19

2.8.1 Transformer Option ........................................................................................................19

2.8.2 Single Phase Power Option..............................................................................................21

2.9 Connection ........................................................................................................................21

2.9.1 Air Regulator/Air Pressure Switch/Solenoid Assembly Mounting .........................................21

2.9.1.1 Pressure Switch Connection ...........................................................................................22

2.9.2 Air Connection................................................................................................................23

2.9.3 Air Regulators and Solenoids ...........................................................................................23

2.10 Installation Checklist...........................................................................................................24

2.11 Coolant and Coolant Wash System ......................................................................................25

2.12 Air Blast System .................................................................................................................26

2.13 Lubrication.........................................................................................................................26

2.13.1 Way Lubrication ..........................................................................................................26

2.13.2 Other VMC2 Lubrication Points.....................................................................................28

This manual suits for next models

1

Table of contents

Other Southwestern Industries Power Tools manuals