Southworth PalletPal Stack-n-Go FPS2500-90 NAS User manual

OWNER’S MANUAL

Model # ______________________________________

Serial # ______________________________________

Date placed in Service __________________________

SOUTHWORTH PRODUCTS CORP

P.O. Box 1380 • Portland, ME 04104-1380

Telephone: (207) 878-0700 or (800) 743-1000

Fax: (207) 797-4734

www.SouthworthProducts.com

Email: [email protected]

PalletPal Stack-n-Go

Model FPS2500-90 NAS

For models that do not have GC or ST stamped into the mast

September 2019

2 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

Please note:

This manual was current at the time of printing.

To obtain the latest, most updated version, please contact

Southworth’s Customer Service Department or go to our website:

www.SouthworthProducts.com, under Parts & Service

you will nd a complete list of current

owner’s manuals to print.

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 3

SOUTHWORTH

TABLE OF CONTENTS

INTRODUCTION............................................................................................................. 5

RESPONSIBILITY OF OWNERS AND USERS .............................................................. 6

Safety Alert Symbols and Signal Words ........................................................................... 7

SAFETY PRECAUTIONS ................................................................................................ 8

INSTALLATION INSTRUCTIONS .................................................................................. 10

Inspection .......................................................................................................... 10

Removal from Pallet .......................................................................................... 10

Preparation for Use ............................................................................................ 10

Battery ................................................................................................................ 10

Set Up Procedure for PalletPal Stack-n-Go Straddle Legs ............................... 11

OPERATOR INSTRUCTIONS ....................................................................................... 12

Suggested Daily Operator Checklist................................................................... 14

BATTERY MAINTENANCE & CHARGING .................................................................... 15

MAINTENANCE ............................................................................................................ 16

TROUBLESHOOTING ................................................................................................... 17

STACKER BODY COMPONENTS................................................................................. 18

CABINET ASSEMBLY .................................................................................................... 19

CARRIAGE ASSEMBLY................................................................................................. 20

OUTRIGGER LEG ASSEMBLY...................................................................................... 21

INNER MAST ASSEMBLY.............................................................................................. 22

OUTER MAST ASSEMBLY ............................................................................................ 23

STEERING ASSEMBLY ................................................................................................. 24

CONTROL POD ............................................................................................................. 25

DRIVE WHEEL ASSEMBLY........................................................................................... 26

POWER UNIT ASSEMBLY............................................................................................. 27

CYLINDER ASSEMBLY ................................................................................................. 28

ELECTRICAL DIAGRAM................................................................................................ 29

BATTERY CONNECTION DIAGRAM ............................................................................ 30

LABEL LOCATION DRAWING ....................................................................................... 31

ORDERING REPLACEMENT PARTS ........................................................................... 32

WARRANTY STATEMENT ............................................................................................ 33

4 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 5

SOUTHWORTH

INTRODUCTION

This manual attempts to provide all of the information necessary for the safe and

proper installation, operation and maintenance of the Southworth Products battery

operated, PalletPal Stack-n-Go. It is important that all personnel involved with the

installation, maintenance or operator of the stacker read this manual. Additional

manuals are available upon request or at www.SouthworthProducts.com.

Each Southworth stacker is equipped with nameplate, serial number and model

identications. Please refer to these numbers when ordering parts or requesting

further information.

This Southworth stacker is designed for lifting, lowering and positioning a wide

variety of loads. WHERE UNIQUE SITUATIONS ARISE, WHICH ARE NOT COV-

ERED IN THIS MANUAL, CALL SOUTHWORTH PRODUCTS FOR FURTHER

INSTRUCTIONS.

The battery operated stackers are designed for dry in-plant/non-hazardous locations

only. They can be used in a 8' or larger aisle. These units are not for personnel

lifting.

6 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accordance with

Southworth’s owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive leakage, miss-

ing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed electric or

hydraulic lines, damaged or malfunctioning controls or safety devices, etc. shall be removed

from service until it is repaired to the original manufacturer’s standards.

Repairs

All repairs shall be made by qualied personnel in conformance with Southworth’s instructions.

Before Operation

Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating instructions

and safety rules.

• Inspected the device for proper operation and condition. Any suspect item shall be care-

fully examined and a determination made by a qualied person as to whether it con-

stitutes a hazard. All items not in conformance with Southworth’s specication shall be

corrected before further use of the equipment.

During Operation

The device shall only be used in accordance with this owner’s manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Southworth industrial positioning equipment shall be made

only with written permission from Southworth.

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 7

SOUTHWORTH

CERTIFIED OPERATOR TRAINING

You must be trained and certied to operate this powered stacker. Federal law states that only properly

trained operators are permitted to operate a powered industrial stacker and that your employer must train

you and certify that you are qualied. (OSHA 1910.178 29QFR-7-1-06 Edition)

Southworth does not offer operator training. Operator training programs may be offered by your local

Southworth dealer or obtained online. Enter, "powered industrial truck operator training" into a search

engine.

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of paramount

concern. This is a powerful machine with moving parts, and is capable of causing personal injury if proper precautions

are not taken. Therefore, throughout this manual, certain hazards have been identied which may occur in the use

of the machine, and there are appropriate instructions or precautions which should be taken to avoid these hazards.

In some cases, there are consequences which may occur if instructions or precautions are not followed. Below are

the symbols and signal words along with their denitions referenced from ANSI Z535.4 - Product Safety Signs

and Labels.

Safety Alert Symbols

These are the safety alert symbols.. They are used to alert you to potential physical injury haz-

ards. Obey all safety messages that follow this symbol to avoid possible injury or death.

For use with DANGER signal word

(Red Background)

For use with WARNING signal word

(Orange Background)

For use with CAUTION signal word

(Yellow Background)

Signal Words

The meaning of different signal words as dened by ANSI Standard Z535.4 indicates the relative

seriousness of the hazardous situation.

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a haz-

ardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE is used to address practices not related to personal

injury.

(Red Background)

(Orange Background)

(Yellow Background)

(Blue Background)

SAFETY

INSTRUCTIONS

SAFETY INSTRUCTIONS (or equivalent) signs indicate safety-

related instructions or procedures.

(Green Background)

8 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

The battery operated stackers are very powerful lifts

capable of doing large amounts of work.

DO NOT OPERATE THESE LIFTS WITHOUT

CAREFULLY READING THIS MANUAL. In order

to provide for the safe operation of these stackers,

Southworth has identied certain hazards that may oc-

cur during the maintenance and use of these lifts. For

safety reasons these units are designed to be serviced

or repaired in the fully lowered position. If performed

properly, this will greatly reduce the possibility of

injury.

WARNING!

When servicing the unit:

1. Key should be in "OFF" position.

2. E-stop should be depressed.

3. Disconnect the batteries at the terminals.

• Do not perform any repair work on lifts if

there is a load on the forks or platform.

• Do not perform any repair work if the forks

or platform is in the raised position.

• All personnel must stand clear of the lift

while in motion.

• Do not put hands or feet under the forks or

platform.

• Do not stand underneath the forks or plat-

form.

• Do not stand in front of the stacker while in

motion.

• Do not stand, sit or climb on the lift.

• Do not use the lift on soft, uneven or unstable

surfaces.

• Do not exceed the load center or capacity.

WARNING!

You or others around you can be seriously injured

or even killed if you don't use this stacker correctly.

Read and obey all warnings and instructions in this

manual and on the stacker. It is your responsibil-

ity before starting work to make sure it is in good

working order.

Always be alert to the area around you and watch where

you are walking. Be careful that you don't get pinned

or crushed between the stacker and a xed object such

as a wall or post.

• Watch your hands and feet. A foot or hand

caught between the stacker and a xed object will

be crushed or even cut off.

• If traveling forks rst, keep both hands on

the control handle and be careful when changing

direction of travel. Keep your feet clear of the

stacker.

• Keep the stacker under control at all times.

Operate at a speed that allows you to stop safely.

Be even more careful on slippery or uneven sur-

faces. Do not run over objects on the oor.

• Perform all stacker movements smoothly and

at a speed that will give you time to react if an

emergency occurs.

Tipovers and falls are very serious accidents; you can

be crushed or even killed. To prevent injury, know

where you are at all times and follow the rules of safe

stacker operation.

• Be careful when working around docks,

dockboards and trailers. Stay away from the

edge of docks and ramps. Check to make sure the

wheels of truck or trailers are chocked.

• Travel with the load or forks close to the

ground. Watch for overhead obstructions. Per-

form all stacker movements smoothly and at a

speed that will give you time to react in an emer-

gency.

• Keep your hands and feet away from all mov-

ing parts such as masts, chains, forks or wheels.

• Never stand on or under the forks, or allow

anyone else to stand on or under them. Never ride

on the stacker or allow anyone else to ride. There

is no safe place to sit or stand.

• Before you leave your stacker, be sure to

lower the forks to the oor. Shut the stacker off

with the key.

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 9

SOUTHWORTH

WARNINGS

DO NOT use this stacker until you have been trained

and authorized to do so.

DO NOT operate until you have read all warnings and

instructions.

DO NOT exceed load center or load weight capacities

(check capacity plate).

DO NOT operate until you have checked the conditions

of the stacker: lift systems, forks, chains, and cables.

DO NOT use if any part is damaged, worn or not work-

ing properly.

DO NOT use on ramps or inclines. Only smooth level

surfaces.

DO NOT use for lifting or carrying people.

DO NOT handle unbalanced, unstable or loosely

stacked loads.

DO NOT travel with forks or platform in an elevated

position.

DO NOT handle tall, unsecured or unstable loads that

could fall.

DO NOT allow people to stand or pass under forks or

platform with or without load.

DO NOT operate when parts of anyone’s body may be

close to mast structure or any moving parts.

DO NOT drop loads on platform or forks.

DO NOT alter or modify this stacker in any way.

10 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

INSTALLATION

A. INSPECTION:

Upon receipt of the stacker, inspect the equipment com-

pletely to determine if there is any shipping damage, and

that the lift is complete. Southworth tests and inspects

every piece of equipment prior to shipment. If damage

is apparent, a freight claim must be led with the freight

company. Do not use the stacker if there appears to be

any damage. With the stacker in a lowered position,

check the following:

• Check for signs of damage especially to the

back cabinet that houses the battery, electrical/

hydraulic power pack.

• Check all electrical and hydraulic connec-

tions for tightness.

• Remove back panel.

1. Turn key switch to "OFF" position.

2. Push in E-stop and unscrew the red knob,

3. Lift off back panel. There is enough wire

to the key switch to allow the panel to be set

aside.

• Inspect for any bent or damaged parts.

B. REMOVING FROM PALLET

Each of the Southworth stackers is shipped out on a

pallet or skid. Prior to removing the unit from the pal-

let or skid, remove all tie down straps and packaging.

Visually inspect the unit as closely as possible.

With an overhead hoist or forklift, carefully pick up the

unit taking into consideration the center of gravity of the

unit. If you choose to pick the unit with an overhead

hoist, use a nylon sling and hoist with a minimum of

2,000-lb. capacity. The nylon sling will not do any dam-

age to the steel construction of stacker. Pick the unit

up. On conventional masts use the top crossmember of

the lift. On narrow masts the cover must be removed

to access lifting equipment. Be careful of the stacker

swinging once fully lifted off the pallet or skid. Have

all personnel completely cleared from the area.

Pick the unit up approximately six inches above the

pallet or skid. Once raised, remove the pallet or skid

from below the lift. Do not move the lift around in the

air. Lower the stacker on the ground.

C. PREPARATION FOR USE

This stacker left our factory in new condition. It has been

inspected and weight tested to assure all performance

standards have been met.

Visually inspect the stacker for damage. Check for at-

tachments and accessories that may have been ordered.

If there is any damage or missing parts, report it to your

carrier and your Southworth dealer immediately.

Remove all metal/plastic bands, cardboard and other

material used for shipping purposes.

Check to see if chains are in place, and that the lift sys-

tem is in working order. Inspect for oil leaks.

Connect battery cable. Check cables and wires on bat-

tery charger as well as battery.

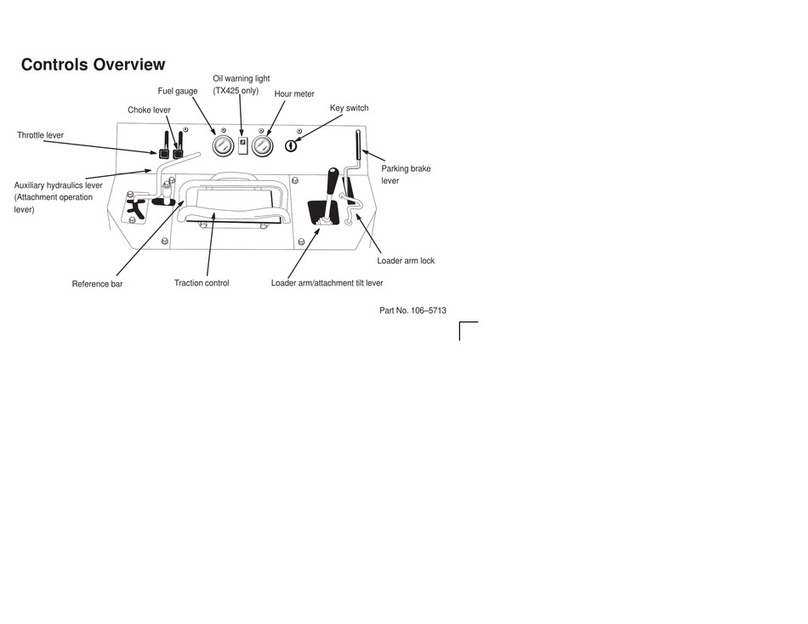

Figure 1: Operational buttons BELLY BUTTON SWITCH

LIFT UP

LIFT DOWN

HORN

SPEED CONTROL

DIRECTION CONTROL

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 11

SOUTHWORTH

Back off all bolts and follow steps.

First - tighten Bolt 1 to 85 foot pounds.

Second - tighten Bolt(s) 2 to 85 foot pounds.

Third - tighten Bolt 3 to 25 foot pounds - NOT 85.

Last - securely tighten all lock nuts.

Set up procedure for Stack N Go Straddle legs with 3 or 4 Bolts:

Proper Drive Wheel traction is obtained for the Stack N Go Straddle unit using this Procedure

All Stack N Go Models are designed and intended to operate on an unnished concrete oor surface. If any

Stack N Go is operated on smooth or polished concrete, sealed concrete, epoxy sealed oor, linoleum or

other smooth surfaces Drive Wheel traction performance may be affected; If traction issues are encountered

Rubber Drive Wheels are available through special order. Please contact Customer Service.

When any Stack N Go is operated on a wet, oily, powdery, sandy or non-uniform liquid or granular surface

Drive Wheel traction performance will be affected and loss of traction will occur.

SET-UP PROCEDURE FOR STACK N GO STRADDLE LEGS

NOTE: STRADDLE LEGS MUST BE ADJUSTED IN ACCORDANCE WITH THIS PROCEDURE

1. Stack N Go unit located on at, clean uniform surface, unloaded, forks raised a minimum of 1” off the oor

2. Determine the desired/required straddle width dimension (2 inches greater than pallet width, 1” on each side of

the pallet or load, up to a maximum of 50 inches inside width)

3. Be sure to fully loosen all bolts before moving stabilizing legs. Adjust one stabilizer leg at a time – using a pry

bar, pinch bar, rubber mallet etc. move the straddle leg out from the base tube to the desired position. Do not

move too far, see picture below, if the ¼” wide painted White Line is visible the leg is pulled out too far; Maxi-

mum movement 5 ½” for each leg for 2200 pound units, 4 ½” for each leg for 3000 pound units.

4. Adjust second Straddle Leg – using a pry bar, pinch bar, rubber mallet etc. move the straddle leg out from inside

the base tube to the desired straddle width position.

5. Straddle Legs must be symmetrically adjusted, both legs adjusted to the same extended dimension!

CRITICAL – STRADDLE BOLT TIGHTENING SEQUENCE & PROCEDURE

CRITICAL PROCEDURE FOR PROPER WHEEL TRACTION

Bolts

Bolt

Bolt

5½"

NOTE:

When adjusted correctly, white

line cannot be seen.

12 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

OPERATION

A. OPERATING INSTRUCTIONS:

AUTHORIZED OPERATORS SHOULD READ

AND UNDERSTAND ALL INSTRUCTIONS,

PRECAUTIONS AND WARNINGS.

IMPROPER USE OF THIS LIFT TRUCK

COULD RESULT IN INJURY AND/OR

DAMAGE TO LOAD AND EQUIPMENT.

To Raise and Lower:

There are two buttons located on both sides of the

handle. The inside one is for raising the forks. The

outside one is for lowering the forks. When operating,

always make sure the load being lifted is within the

loading capacity of your stacker and the load has been

stacked safely on the pallet. Also, make sure that the

length of the forks corresponds to the length of the pal-

let. In this way, the load rollers will place themselves

in the opening at the end of the pallet, so that when you

raise the forks, you will not break the bottom boards

of the pallet. Always make sure that when entering the

pallet that the forks are in the fully lowered position.

Be careful when lifting pallets that are too short or too

long for the stacker. It might destroy your pallet by

breaking the bottom boards, and if the forks project

through the end of the pallet, the tips of fork may go

into the next pallet that is behind the pallet that you are

lifting, which may bend the tips of forks and overload

the capacity of the stacker.

Travel Function:

To travel, rotate the buttery controls throttle on the

upper part of the handle. When rotating the buttery

control CW towards the forks, the stacker runs forwards

in the forks rst direction. When rotating the buttery

CCW towards you, the stacker runs backwards in the

handle rst direction. Always make sure the stacker

clears any obstruction when traveling, and that your path

of travel is clear of people. Never carry loads above the

loading capacity of the stacker. It is suggested that when

traveling without a load, the forks be in the lowered

position. The speed of the stacker is increased by the

degree of the rotation in either direction; it functions

like a throttle. When you release your hand from the but-

tery control, it automatically will resume to the neutral

position and the speed of the stacker will slow down.

Electric Brake:

Your stacker is equipped with an electric magnetic

brake. The brake is applied when the handle is in its

vertical position between 10 – 15 degrees and lowered

position between 80 – 90 degrees. The brake could be

released when you pull down the handle at any point

between 15 – 80 degrees. Always make sure the brake is

released before operating the stacker. When the stacker

is running, you could brake the stacker by raising the

handle to its vertical position or lowering the handle to

its lowest position. Or, to turn the buttery controls in

the opposite direction, the change in direction of the

motor will slow down, stop, and reverse the direction

of stacker. When parked, always put the handle in the

full vertical position with the brake applied and the

forks in lowered position.

Reversing Safety:

At the end of the handle there is a large, red reversing

bar (belly button switch) that is designed to protect

the operator from injury. When the operator runs the

stacker backwards, and the end of the handle comes

in contact with the operator’s body, the stacker will

automatically reverse direction and travel away from

the operator. When the reversing safety bar comes in

contact with your body during operation, immediately

release your hands from the buttery control and put the

handle up to its vertical position or down to its lowest

position and the brake is on. The reversing safety bar

will automatically resume to its original position after

being activated.

Horn:

As standard equipment, a horn that is located on the

top of the handle.

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 13

SOUTHWORTH

• Inspect the lift for damaged or worn parts.

Do not use if not in safe operating condition.

• Use lift on hard level surfaces only.

• Make sure load is evenly distributed, not

loose or unstable, and is as far back on platform

or forks as possible. Do not pick up loads on tips

or forks or edge of platform.

• For fork models, adjust forks to the maxi-

mum practical width. Pick up loads on both

forks.

• Do not overload. Check load center and load

weight capacities on the nameplate.

• Make sure travel and work area is clear of

obstructions.

• Check overhead clearance before lifting loads

or transporting.

B. DAILY OPERATIONS

MAINTENANCE CHECKS:

1. Battery

A. Check for corroded and loose terminals.

A white powder substance will be present if

there is any existing corrosion.

B. Visually inspect for any cracks or damage

to the casing.

C. Check for loose battery tie-downs.

2. Charger

A. Inspect wire connections.

B. Check power cord for nicks/damage.

C. Check power charger for proper mounting.

3. Hydraulic System

D. Inspect pump and cylinder for oil leaks.

E. Check hydraulic oil level.

F. Check hydraulic ttings and hoses.

G. Check ram for nicks/damage.

4. Frame Assembly

A. Check chain roller assembly connections.

B. Check for any worn or damaged parts.

14 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

DAILY OPERATOR CHECK LIST

CHARGE CONDITION/BATTERY CHECK LIST

1. Check Battery Discharge Indicator (Fuel Gage and Hour Meter) – Be sure unit is

showing proper Charge Level before operating unit

2. Check to be sure Charging Cord is Unplugged and properly stowed before operat-

ing unit

3. Inspect Battery Wire Connections – All connections should be tight with No Corro-

sion (white powder) showing at the Battery Terminals

4. Inspect Battery Case – There should be no cracks or visible damage to the Battery

Case

WALK AROUND INSPECTION

1. Check general condition of Stacker (loose or broken parts, oil, dangling wires, dents,

cracked covers etc.)

2. Check metal frame, mast, carriage and font load supports for cracked welds, worn or

at rollers, loose or disconnected chains, loose pins, missing snap rings, and loose or

missing hardware – bolts, nuts washers etc.

3. Check for evidence of hydraulic leaks

4. Make sure all precautionary labeling is in place and legible

FUNCTIONAL INSPECTION

1. Check Drive – Forward and Reverse Function

2. Check Lift – Up and Down Function

3. Check Function for Belly Button Reverse

4. Check Horn Function

5. Check Brake Function

OPERATOR ID DATE

DO NOT USE OR OPERATE STACKER IF ANY FUNCTION IS NOT

OPERATING PROPERLY OR IF STACKER APPEARS UNSAFE IN ANYWAY

REPORT CONCERNS TO SUPERVISOR IMMEDIATELY!

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 15

SOUTHWORTH

BATTERY MAINTENANCE

A. PREPARING TO CHARGE A BATTERY

1. Always turn off E-stop and key switch before work-

ing with the batteries.

2. Be sure the area around the stacker and the battery

is well ventilated while battery is being charged.

3. The battery terminals, connections and wiring

connections should be clean and free of corrosion.

When cleaning any of these components wear a face

shield or other suitable protective eyewear.

B. BATTERY CHARGING

Charging must be performed with the charger that is

provided with or prewired into the machine. During

charging, the temperature in the battery must not exceed

120 F. Charging simultaneously with truck operation

is not recommended. Plug the charger into a 115 volt

outlet. Charge until the battery gauge indicator lights

show fully charged (approximately 6-8 hours).

C. WARNINGS AND BATTERY INFORMATION

Avoid use of open ame near batteries. At temperatures

around freezing point, battery capacity is reduced by

30%. The battery terminals, connections and wiring

should be clean and free of corrosion. When cleaning

any of these components, wear a face shield or other

suitable protective eyewear. Read, understand, and fol-

low all battery and battery manufacturer's specic pre-

cautions while working with and/or charging batteries.

D. BATTERY MAINTENANCE

To measure the voltage, use a digital voltmeter (DC) on

the battery poles. The truck must not have been in use

for the previous 30 minutes.

DANGER

Never alter the AC cord or plug provided. If it will

not t outlet, have proper outlet installed by a quali-

ed electrician. Improper connection can result in a

risk of an electric shock.

1. Disconnect the charger from the 115 volt wall out-

let once the indicators read fully charged.

Note: The batteries are designed for intermittent

use. Continual usage will wear the battery out and

charging will be required.

E. CHARGER OPERATION

Power Lamp

1. Green: Connection correct. Charger will operate

normally.

2. Red: Bad connection or bad battery.

Fault

1. Red light blinks 3 times in 5 seconds: The output

between charger is faulty, loose, or bad connection

2. Red light blinks 5 times in 5 seconds: The tempera-

ture is too hot for the charger to operate.

3. Building power is not compatible; too low or too

high. +- 10% is the general rule.

Charge Lamp

1. Red: Charger can charge normally. The battery is

less than 70%

2. Orange: Battery is between 70% and 100% charged.

3. Green: Battery is at 100%. Fully charged.

4. No light: The charger can not charge the battery.

Voltage of the battery may be too low to cause the char-

ger to start. It must be at 10.5 volts to initiate charge.

VOLTAGE

Approx. 12.7 V Fully charged

Approx. 12.2 V 1/2 charged

Approx. 12.0 V 1/4 charged

Approx. 11.6 V Discharged

16 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

MAINTENANCE

Operation of Southworth Stack N Go is very simple

— as is their construction. They require very little

maintenance. Reasonable care will result in excellent

trouble-free performance. The Stack N Go is designed

for one-man operation and ease of performance.

• Grease oor wheels and casters at least once

a month

• Use only Hydraulic Oil AW32 or Dextron III

in the hydraulic system.

• Do not overload your lift.

• Check brakes, steering mechanisms and con-

trols before each use.

A. WEEKLY OPERATIONS

MAINTENANCE CHECKS:

DAMAGE: Check for bent, dented, worn or broken

parts.

LIFT SYSTEM: Check to assure that there is no bind-

ing or excessive play in the forks. Check for quiet and

smooth operation of the lift cylinder. Check all moving

parts and linkage.

LEAKS: Check hydraulic system for leaks and hydru-

alic oil level.

WHEELS AND CASTERS: Check for wear and that

they are turning smoothly.

LIFT CHAINS: Check to see that they are in place

and not loose.

FORKS: Check that they are not bent or cracked.

BRAKES: Ensure brakes work properly.

CABLES; WIRES: Check that there are no loose

cables or wires.

LABELS: Ensure all precautionary labels and guards

are in place.

B. MONTHLY OPERATIONS

MAINTENANCE CHECKS:

1. Battery (maintenance free)

A. Clean terminals.

B. Clean battery compartment area if there are

signs of corrosion.

2. Hydraulic System

A. Clean and inspect hydraulic cylinder.

B. Lubricate chain with a rust inhibitive lubri-

cant (light machine oil).

C. Check chain tension. It should be even

on both chains. The chain should be tight

enough so that it does not come off of the

roller assembly.

3. Frame Assembly

A. Clean and lubricate all roller bearings, cam

followers and all moving parts.

B. Clean and inspect all welds.

C. Check wheels for wear and damage.

D. Inspect nameplate for legibility. Place the

serial and model number shown on the name-

plate on the cover of the manual for future

reference.

4. Electrical

A. Check batteries, motors, controllers, limit

switches, electrical conductors and connec-

tions.

CAUTION:

DO NOT USE LIFT IF IT IS NOT

OPERATING PROPERLY,

OR APPEARS UNSAFE IN ANY WAY!

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 17

SOUTHWORTH

TROUBLESHOOTING

Before starting the troubleshooting, you have to:

A. Put the truck on an even and solid surface.

B. Turn off key switch or disconnect the battery ter-

minals.

1. Unit will not lift (motor does not

run)

• Faulty wiring from fuse to lift switch in handle

• Faulty lift switch

• Faulty wiring from battery positive terminal to

pump contactor to pump motor

• Burned out brushes in pump motor

• Low hydraulic pressure caused by:

¨ Pressure relief valve needs adjustment

¨ Pump check valve stuck open

¨ Faulty solenoid valve

• Faulty wiring from lift switch to solenoid

• Faulty lift contactor

• Defective control circuit fuse

• Chain or roller bound

• Check oil level

2. Forks will not lower

• Look for binding in chains or rollers

3. No electrical power

Dead Batteries:

¨ Keyswitch on "OFF" position

¨ E-stop button depressed

¨ Loose or dirty battery connections

¨ Blown fuse(s)

• Faulty wiring from fuse to travel control switch

• Faulty control switch

• Faulty wiring from travel control switch direction

contactor

• Faulty contactor

4. No Traction

• Idler wheel needs adjustment

IDLER WHEEL ADJUSTMENT

The following is a procedure for adjusting the idler

wheel on the Southworth Stack N Go. Under normal

conditions this should not be necessary becaus the idler

wheel has been adjusted at the factory.

Tools Needed:

Phillips head screw driver

Medium crescent wrench

1 block of wood (2 x 4)

1. Place unit on a at surface.

2. Turn key to the OFF position and push emergency

stop button down.

3. Remove the 2 screws from the main orange cover

that covers the unit.

4. Remove the emergency stop button by unscrewing.

5. Slide the main cover up and place the block of wood

under the right hand side to hold open exposing the

idler wheel and adjusting the screw.

6. With the adjustable wrench loosen the jam nut on

the idler wheel adjusting screw.

7. Loosen the adjusting screw until you have no ten-

sion between the adjusting screw and idler wheel.

You will have some play between the idler wheel

and the left front wheel.

8. Now tighten the screw until you just make contact

with the idler wheel. Continue adjusting until the

idler wheel just touches the oor.

9. Tighten jam nut. You may have a slight rocking

back and forth, from the left front to right rear idler

wheel, but this is not uncommon.

10. Now remove the wooden block and lower the cover

back into place inserting the 2 screws and tighten.

Screw the E-stop button back on.

11. Your adjustment is complete

If the wheel is worn, replace wheel.

18 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

STACKERBODYCOMPONENTS

Item Description Qty

1 LegAssy 1

2 OuterMastAssy 1

3 InnerMastAssy 1

4 LiftFrameAssy 1

5 RearBoxAssy 1

6 SteeringAssy 1

Southworth PalletPal Stack-n-Go / FPS2500-90 NAS 19

SOUTHWORTH

CABINETASSEMBLY

Item Description Qty Item Description Qty Item Description Qty

1 PowerUnit 1 12 BatteryBoxCover 1 23 Bolt 4

2 DriveCover 1 13 Battery2 24 Washer 4

3 BatteryCharger 1 14 BatteryMeter 1 25 Nut 4

4 SteeringCover 1 15 KeySwitch 1 26 CasterWheel 1

5 BodyWeldment 1 16 E‐StopSwitch 1

6 RearBoxCover 1 17 Bolt 2

7 CoverHolder 1 18 Washer 2

8 ElectricalCompon

e

1 19 BatteryHolder 2

9 Screw 6 20 Bolt 2

10 Washer 2 21 Washer 4

11 Bolt 2 22 Nut 4

20 Southworth PalletPal Stack-n-Go / FPS2500-90 NAS

PalletPal Stack-N-Go

CARRIAGEASSEMBLY

Item Description Qty Item Description Qty

1 Fork 2 6 SnapRing 4

2 SnapRing 2 7 LiftFrame 1

3 ForkShaft 1 8 SnapRing 4

4 RollerWheel 4 9 CarriageRollerWheel 4

5 RollerWheelShaft 4

Table of contents

Other Southworth Compact Loader manuals