Sovan's JF User manual

JF High-lifting Truck

INSTRUCTIONS

2013-01

1

1. Applications

JF manual hydraulic truck is a convertible apparatus for either carrying or stacking high-lifting

and palletized cargo. Also named High-lifting pallet truck, it features as stable lifting and

lowering, easy operation, safety and reliability, etc., and applies to the uses on hard flat ground.

2. Main parameters

Capacity (kg) 1000

Total lift height (mm) 800

Lowered fork height (mm) 85

Height of handless (mm) 432

Fork length (mm) 1150

Width over the forks (mm) 520,550,685

Steering wheel (mm) Ф180x50

Fork wheel (mm) Ф74x50

Truck weight (kg) 95~115

3. Assembling

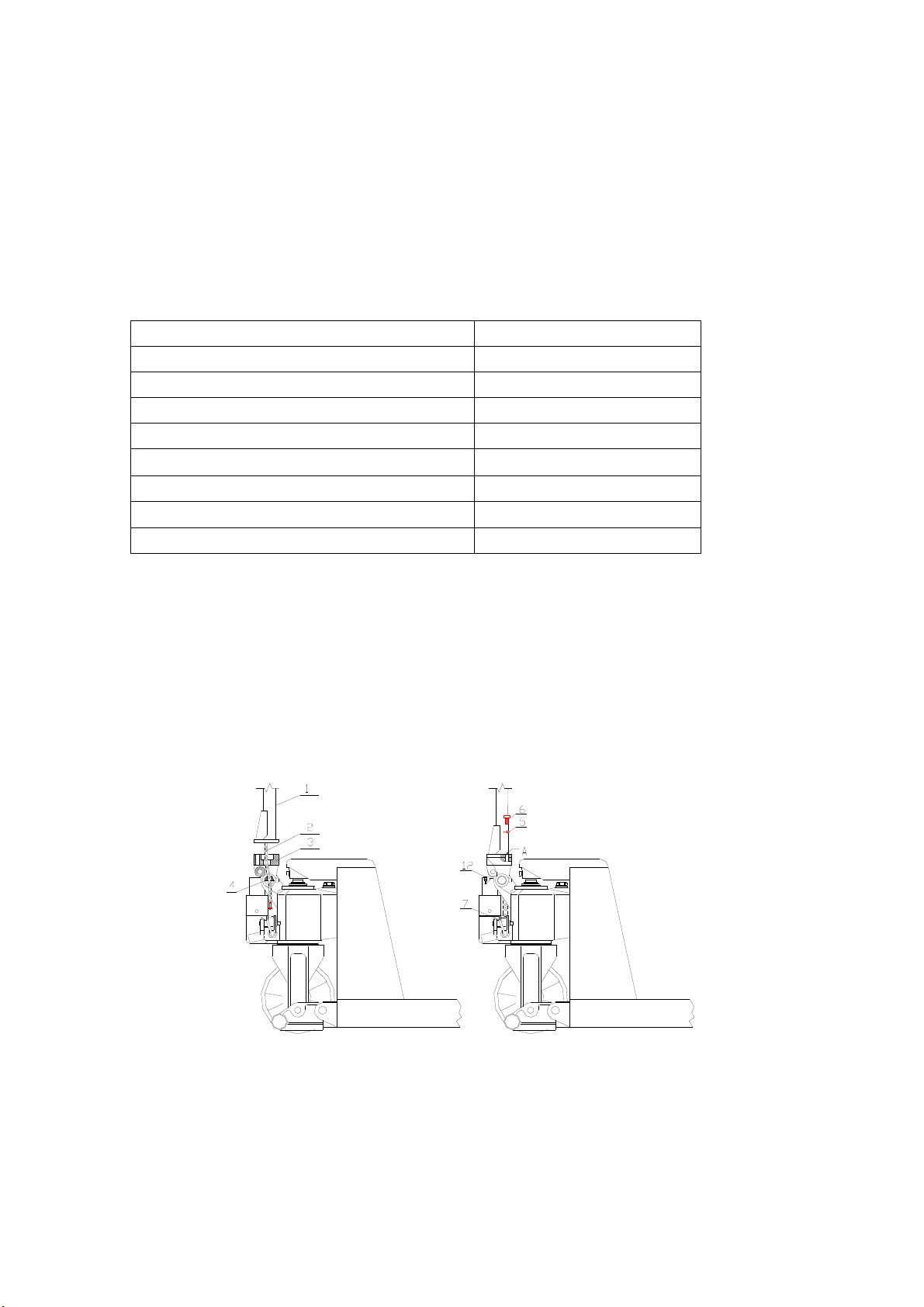

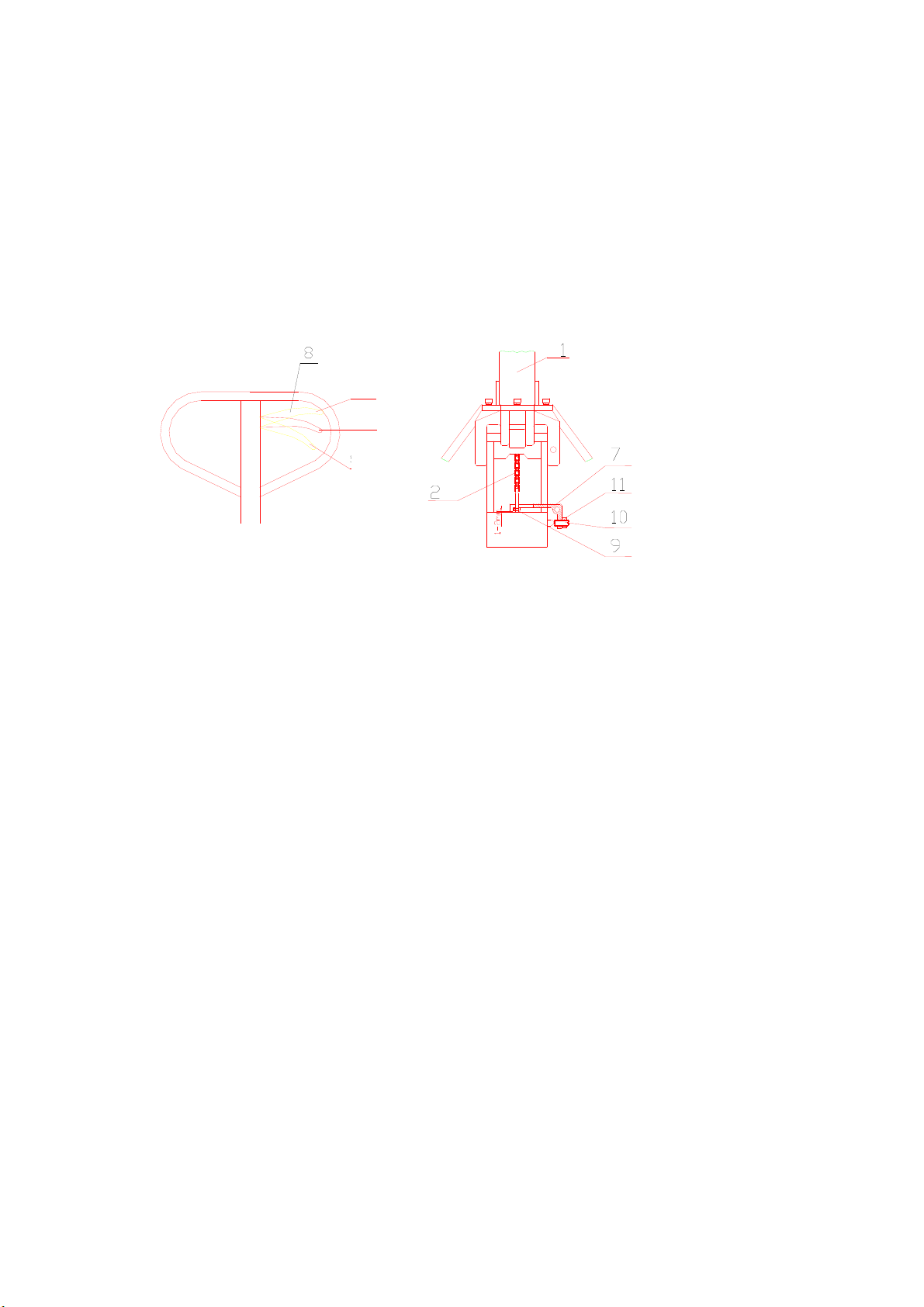

3.1 See Fig. 1. First, raise Handle (1), pass in order Roller Chain (2) through the holes of Rack

(3) and Axle Pin (4).

3.2 Put Spring Grommet (5) under Soket Head Cap Screw (6). Push Soket head Cap Screw (6)

into three A-shaped holes by a wrench and tighten it so that Handle (1) and Rack (3) are fixed.

See Fig. 2

Fig. 1 Fig. 2

2

3.3 Raise Lever Pad (7) by an iron stick and fit the screw and nut at the end of Roller Chain (2)

into the groove of Lever Pad (7). Then remove the iron stick to complete the assembling. See Fig.

2 and 4.

3.4 See Fig. 3. Position Trigger (8) at Fast Lifting, and adjust Nut (10) at the end of Roller Chain

(2) to raise Level Pad (7) at a gap of 1-2mm from the pedestal. This procedure is usually

unnecessary for a new truck. See Fig. 4.

3.5 Try shaking the handle and operate at the different gears of Trigger (8) to see whether the

truck works well at fast lifting, slow lifting and lowering. See Fig. 3.

3.6 Screw (10) in Fig. 4 is used for modification of the truck. In the event that the truck body

lowers shortly after rising or is unable to lift fast, turn Screw (10) a little in counterclockwise

before trying the truck again. In the event that the truck body is unable to lower, turn Screw (10)

a little in clockwise and then try the truck again until it restores normal lowering. Hexnut (11) at

Screw (10) functions as a lock, so it should be fastened before modification and locked after

modification.

4. Operation guidance

4.1 When Trigger (8) is at the bottom gear, the forks are ready for Fast Lifting. Shake the

Handle, and the fork will rise rapidly.

4.2 When Trigger (8) is at the middle gear, the truck is ready for Slow Lifting. Shake the Handle,

and the forks will rise slowly. The Trigger shall be so postitioned while the truck walks.

4.3 When Trigger (8) is at the top gear, the truck is ready for Lowering, and meanwhile the

truck shall lower automatically.

4.4 The cylinder of the truck is in a three-step lifting structure. That is, when the truck piston

at the second step starts up with heavy load, the truck must work at Slow Lifting, otherwise the

truct will get damaged.

4.5 When the cargo is to be removed from the forks, it must not be removed until lowered no

less than 200mm to the ground. The Trigger meanwhile shall be positioned at Slow Lifting.

Lowering

Slow lifting

Fast liftin

g

Fig 3 Fig 4

3

5. Examination before using

Air may be absorbed into hydraulic system when the truck is not used for a long time. The air can

be removed in the following ways:

1. See Fig.2. Relax Screw (12) in counterclockwise and slowly shake the Handle until the oil

overflows at this point. Stop the Handle and then tighten the Screw (12) in clockwise.

2. Put the Trigger at the load position. Fully shake the Handle for 4-6 times and then release

the Trigger. If needed, the above operation can be done for several times until normal

working.

6. The loading style and rated capacity

The ideal loading style demands that the gravity center of the cargo position in the center of the

forks. In the event of unbalanced loading, the rated capacity should be reduced. The rated

capacity is shown as the labels.

7. Maintenance

Everyday routine examination is necessary for solving the abnormal operations at sight. Do not

use the troubled truck for the sake of prelonging its work life. Every turning joint must be

lubricated by motor oil every three months, and see to that the wheels and axles are not

intangled by threads or other materials. All the wheels shall runs smoothly.

8. Possible failures and solutions

No

. Failure Causes Solution

1 Insufficient lifting. The gydraulic oil is not adequate. Add appropriate filtered

working oil.

2 Inadequate

restorage.

1. Too much hydraulic oil.

2. The turning part is caught up

due to deformation.

3. Seizing-up between piston and

guide screw.

1. Extract appropriate

amount of hydraulic oil.

2. Replace the part.

3. Replace the piston and

guide screw.

3 The forks do not

lower after rising.

1. Abnormal in unloading devices.

2. Deform and damage in parts.

1. Re-adjusting the

unloading device. See

3.6.

2. Replace the deformed

and damaged parts.

4 Leakage of

hydraulic oil.

1. Failure of oil seal.

2. Light break or errosion on the

surfaces of one or two parts.

3. Relax in joints.

1. Replace the seal.

2. Replace the damaged

parts.

3. Tighten the joints.

5 The forks does not

lift.

1. Viscosity of working oil is too

high or the working oil is not

added.

2. Impurity in oil.

1. Replace the working oil.

2. Remove the impurities in

the oil circuit and replace

the oil.

4

3. Abnormal of unloading device. 3. Re-adjust the nloading

device. See 3.6.

6

The forks drop

immediately after

lifting when

shaking the

handle, which

springs back

noticeable or the

forks lower

automatically after

lifting.

1. The valve is caught up by

impurities.

2. Air is in the hydraulic oil.

1. Disassemble the valve,

clean the parts and

reassemble it.

2. Refer to 5. Eexhaust the

air.

9. Warning

9.1 Read the instructions carefully and grasp the features of the truck before operation!

9.2 Lift the Trigger a litte up when lowering the truck by controlling the Trigger to make the

truck lower slowly. Never drag the Trigger rudely because rapid lowering will damage the truck

and cargo!

9.3 Do not shake the Handle hastily or frequently!

9.4 Rapid loading on the forks is not permitted!

9.5 Do not overload, or the truck can not work normally!

9.6 The gravity center of the cargo should be positioned in the middle of two forks.

Unbalanced loading will cause overturns of the turck after the cargo is lifted!

9.7 Relaxed or unstable cargoes are not permitted for loading!

9.8 Do not place the cargo on the truck body for long time!

9.9 Rudely dragging the truck is forbidden when the forks are over 300mm above the

ground!

9.10 Set the forks at the lowest position when the truck is not in working!

9.11 The truck is forbidden to carry man and the truck is also not permitted to move with

man standing on its forks. Any part of the operator’s body is not permitted to be placed under

the cargo. The truck in lifting is not permitted to be used as the platform for height-ascending

operation of man!

9.12 The truck is suitable for flat and hard ground. Do not use the truck on the slope!

9.13 Do not operate those not approved parts!

9.14 Do not try repairing the truck without training!

Table of contents

Other Sovan's Truck manuals