Spa-Quip Intuitive Series User manual

SPA-QUIP LTD

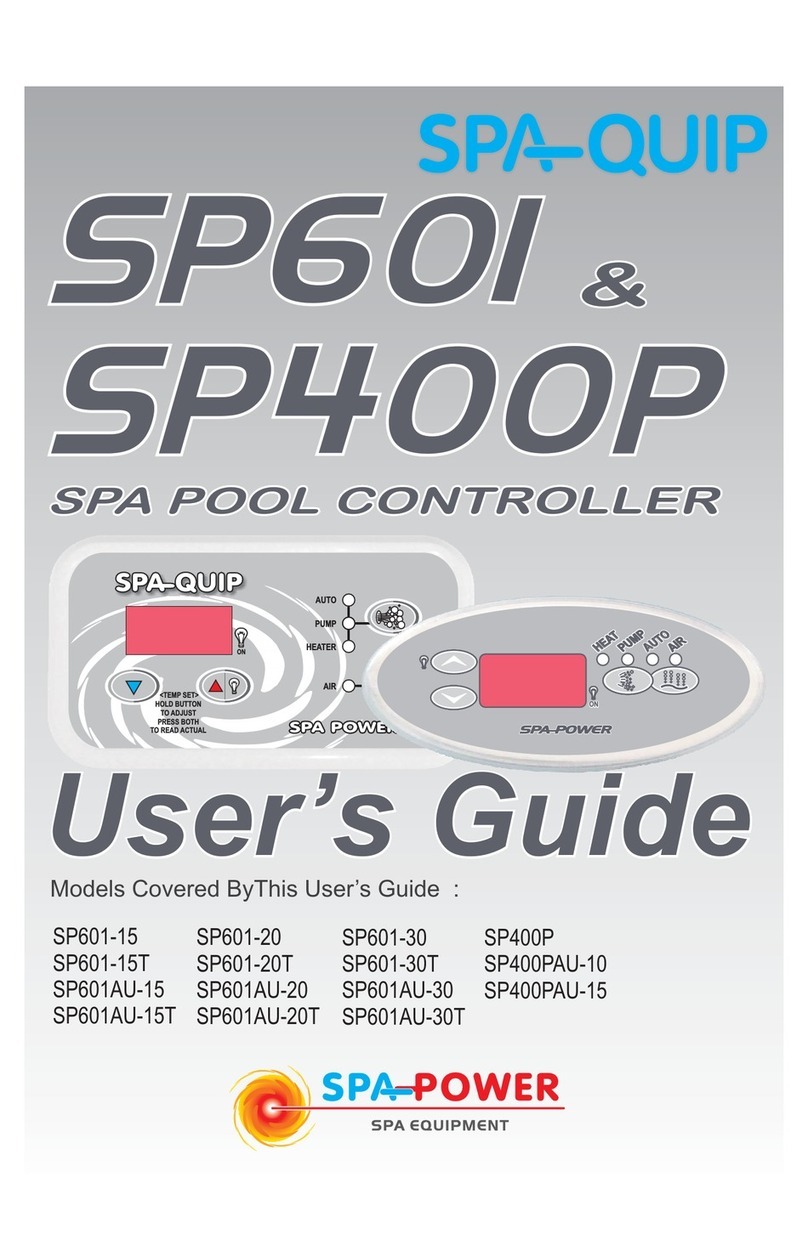

3 BUTTON ELECTRONIC

STANDARD SPA POOL

CONTROLLER

DATE INSTALLED

SERIAL NUMBER

SOLD BY

INSTALLED BY

STARTUP TESTING

DEALER STAMP:

Intui3butbk.99-PSE/NRC

Contents

1.....OPERATING INSTRUCTIONS:

2.....SPA POOL START UP

2.....PRIMING FUNCTION

3.....PUMP FUNCTION SWITCH

4.....AIR SWITCH

Single speed version:

Multi speed version:

4.....LIGHT/AUXILIARY SWITCH

4.....THERMOSTAT CONTROL

5.....THE TIME CLOCK FUNCTION

5.....INSTALLATION GENERAL

7.....CONTROL BOX & HEATER INSTALLATION

7.....INSTALLATION OF HEATER ELEMENT

8.....SWITCH INSTALLATION

8.....SPECIAL NOTES

9.....TROUBLE SHOOTING GUIDE

10...WATER CHEMISTRY

11...WARRANTY POLICY

Manufactured by:

SPA-QUIP LTD

PO Box 302-114, N.H.P.C.

Auckland. New Zealand

Ph (649) 415 8622, Fax (649) 415 8621

Email: [email protected].

Australian Distrubution and Service:

SPA-QUIP (Australia) PTY LTD

Unit 2A, 4 Hudson Ave

Castle Hill, NSW 2154

Ph (612) 9634 5600, Fax (612) 9634 5900

Email: [email protected]

MY SPA IS TOO

HOT IN SUMMER!!

Many people would like to reduce the normal

running temperature of their spa, which is usually

38º or 39º in winter to 26º or less in summer.

All spas are supplied with an efficient heater, made more

efficient with the insulation around spa. This is what spas

are all about - HOT WATER and the therapeutic effects

of hot water and massage jets.

Manufacturers make no attempt too supply a system that cools water.

Please consider this......

a) In the winter your spa gets cold because the air temperature is cold. To combat

this we heat the water and keep the spa covered when not in use. If the spa is

turned off and the ambient temperature is 15º, eventually the spa will lose heat until

it too is 15º.

b) In the summer the same applies – you can turn the heater down, even turn the

pump off, but if the daytime temperature is 38º - 42º then the spa will also remain at

that temperature.

Here are a few suggestions......

The quickest way is to change the water. However, eventually even this new water

will also heat up to the air temperature and need changing to cooler water.

Turn the heater down, but you also have to reduce the pump running times as well,

as the pump alone adds heat to the spa. Pump running time is controlled by both

heating and filtration requirements. Some control can be obtained by adjusting the

sleep times to longer periods and the on times for night running where the ambient

temperatures are cooler.

If the nighttime temperature is low, leave the cover off the spa to let heat escape,

but put it back on during the day to keep heat out. Make sure the spa is shaded from

direct sunlight.

You are lucky to live in a semitropical climate, but when it is hot EVERYTHING

IS HOT, unless air conditioned.

Before operating the spa pool ensure the following conditions are checked:

1/ That the spa pool support equipment is properly plugged in. Check that

each item is plugged into the correct socket as marked on the controller's

label.

2/ Ensure that the power supply is correctly rated, ie. a 15 amp system is

plugged into a 15 amp rated outlet. Rating is printed on front decal of

control box.

3/ The control

must not be installed on an extension cord

.If the location of

a suitable supply is further from the spa than required ensure a

qualified

electrician

fits a suitable power supply lead or power point.

4/ Fill the spa pool to the correct operating level as specified by the

manufacturer.

5/ The spa pool equipment must be adequately ventilated. Ensure the

manufacturer has provided proper ventilation in spa pool cabinet.

Page 1

OPERATING INSTRUCTIONS:

The Intuitive Series heat pump and control system has been designed so that

the pool can be automatically operated maintaining predetermined heat and

filtering operations. An in built clock puts the system into a sleep mode when

absolute quiet is needed.

Fig 1: Control box

with analogue

time clock

Fig 2: Lamp flashes red/

green for no water

Page 2

PRIMING FUNCTION

The system will automatically run for 10 seconds to prime itself. While

unprimed the lamp associated with the pump switch will flash (Fig 2). The

pump switch can be further operated manually as an aid to priming. Once

water is achieved the control will operate in the automatic mode (see fault

finding section for possible causes of water absence - page 9).

6/ Ensure that you the Spa pool owner understand how to operate the

equipment. Check with your supplier if you are having difficulty.

Note:

In some installations, severe electrical interference can cause the control

to lock into a fault condition. If this continues, check with an electrician or with

the supplier's service representative to ensure that your power supply is

adequate. The manufacturer does not guarantee that all power supplies are

suitable.

SPA POOL START UP

1/ The spa pool must be properly filled. Ensure there is no obstruction to the

skimmer (if fitted) and the water level is well above the minimum level.

2/ Check that all valves are in correct operating position.

3/ Ensure cartridge filter is properly cleaned.

NOW-

1/ Turn the power supply switch on where lead is plugged into supply.

2/ Turn the mains switch on, at face of control box if fitted.

Note

: Some models

feature an Earth Leakage Circuit Breaker on the cord set and the reset

switch should be in the on position. When the switch is initially turned on

the pump and blower should momentarily switch on. This is simply the

microprocessor resetting itself.

3/ Turn the thermostat control knob around clockwise to high to allow system

to operate (Fig 6).

4/ The control automatically starts in demand heat mode. The switch mode

light should be yellow/orange (Fig 3).

5/ The time clock should be adjusted to allow system to operate (pg 5). The

spa pool should now be heating.

Note

: Initial heat up time will vary and is

dependent on ambient temperature, type of cover, size of pool, quality of

insulation etc. If the pump is not operating refer to trouble shooting section

(page 9).

Ampac Int. Systems Ltd

P.O.Box 1000-33 N.S.M.C.

Auckland, New Zealand

Model____________S/No_____________Date purchased_______________

Spa-Quip Ltd

PO Box 302-114

North Harbour Post Centre

Auckland, New Zealand

WARRANTY POLICY

1. We undertake to repair, or at our option, replace without

cost to the purchaser either of materials or labour, any part

which within 12 months from the date of purchase is found to

be defective, provided that the product has been used in

accordance with the Instruction Book, under normal domestic

use and has not been subject to misuse, neglect or accident or

dismantled, repaired or serviced by any other than an

authorised Spa-Quip Ltd or Spa-Quip (Australia) Pty Ltd

service agent.

2. All claims for warranty must be done through the retailer or

supplier from whom the product was purchased. Proof of

purchase or the warranty card stamped by the supplier must be

supplied.

3. This warranty is a “return to base” warranty which means

the item must be returned to the manufacturer for repair. An

exchange unit may be provided in this case. If replacement or

service under this Warranty Policy is required and distance

prevents you calling personally, forward your product FREIGHT

PREPAID to the nearest authorised Spa-Quip Ltd or Spa-Quip

(Australia) Pty Ltd service agent.

4. Any costs incurred to repair a unit that is not covered by

warranty will be passed on to the consumer including cost

incurred to remove the faulty unit and replace with an

exchange unit. Spa-Quip Ltd or Spa-Quip (Australia) Pty Ltd

are not responsible for any on site costs for goods not covered

by warranty.

Page 11

PSE 0985 NRC

The pump can be operated manually at any time by pushing the switch until

the lamp indicates red. During manual operation the pump will run up to 3

hours with the heater turning on and off under thermostat control. Repressing

the switch restarts the 3 hour timer. At the completion of the manual running

time the controller will revert to automatic mode.

Standby mode switches the pump functions off if absolute quiet is required.

This function is also on a timer reverting to automatic mode after 3 hours.

PUMP FUNCTION SWITCH

When the pump switch is depressed it toggles between auto, manual and

standby modes. The default start up mode is automatic so that in event of a

power failure, the pool always starts in the heating mode.

When in the automatic mode, the indicator shows yellow/orange (Fig 3). The

time clock will automatically turn the system on and off at preset times (see

time clock setting instructions - page 6).

During the on periods as set by the clock and while in automatic mode the

pump and heater are controlled by the thermostat setting, commonly referred

to as a demand heat system. The controller will switch the pump and heating

on and off as well as the intelligent filtration cycling when required.

Fig 3: Automatic mode

Page 3

AB 0695

SPA WATER TREATMENT

RECOMMENDED CHEMICAL VALUES

CHLORINE........... 1.5 - 3.0 PPM ( PARTS PER MILLION )

pH................. 7.4 - 7.6

TOTAL ALKALINITY... 100 - 120 PPM

FAILURE TO MAINTAIN YOUR SPA WATER CHEMISTRY TO

THE ABOVE VALUES CAN BE UNHEALTHY BOTH TO YOU

AS BATHERS, AND TO YOUR SPA POOL EQUIPMENT.

pH

This is a measure of how acid or alkaline the spa water is (below

7.0 is acid, above 7.0 is alkaline). Low pH will cause corrosion of

any metalwork in the water (element, thermostat pockets). High

pH will cause scale formation and cloudy water.

TOTAL ALKALINITY

This is a measure of how resistant your spa water is to change of

pH. A low TA (0 - 80 ppm) will allow the pH to fluctuate rapidly,

normally to the acid end, and will make it very hard to correct the

pH back to the ideal range.

CHLORINE

Levels of sanitiser are important to prevent the build up of

bacteria and algae in the pool water. Chlorine is not the only

sanitiser available to do this. Other sanitisers are Bromine,

Ozone.

DAMAGE TO THE ELEMENT, THERMOSTAT POCKETS AND

ASSOCIATED METALWORK DUE TO THE POOR

MAINTENANCE OF WATER CHEMISTRY IS NOT COVERED

BY WARRANTY.

Page 10

Indicator

yellow/orange = auto mode

red = manual

green = standby

red - green flash = no water

Heating indicator

AIR SWITCH

Fig 4: Air control switch and indicator

Single speed version:

The air blower injects air into the spa pool water usually from the seat well or

floor of the spa depending on design. Often the air will feel colder than the

water and can be used as an aid to reducing water temperature as desired by

the bather. When operated the lamp will show red. While the blower is operat-

ing the pool heating is automatically turned off (load shedding). When blower

turned off lamp extinguishes and heating resumes if required, dependent on

operating mode.

Multi speed version:

The multi speed switches the blower through three different speeds. When

switch pressed the blower starts at full speed with the lamp indicator showing

red. Each subsequent step reduces speed with the lamp changing to yellow/

orange for mid speed and green for low (Fig 4). The multi speed version is

available with or without air heating. As above the pool heating is switched off

when the blower is operating, however the pump will remain running.

NOTE: The blower function has an in-built 30 minute timer.

THE LIGHT/AUXILIARY SWITCH

This is a single on/off function normally used to run the pool light. When on, a

red lamp (Fig 5) is illuminated.

NOTE: The light function has an in-built 30 minute timer.

Fig 5: Auxiliary switch function

Page 4

TROUBLE SHOOTING GUIDE

FAULT CAUSE REMEDY

No power (LEDs not on) Supply fault. Check fuse or circuit breaker at

switch board. Check switch

plugged into control box. Check

RCD on cord set.

Power available but will not

run. Air lock in plumbing. Re-plumb system to eliminate

air-locks.

No water (LED lamp flashes

on pump switch) Valves shut. Air lock.

Insufficient water. Probe

requires cleaning.

Open valves. Correct plumbing.

Make sure water above

skimmer minimum level. Call

serviceman to clean water

probe.

Pump will not switch on. Pump switch in time clock

mode. Switch to manual mode. Check

time clock also override switch

on clock face. Make sure pump

is plugged in securely. Check

overload switch on motor if

fitted.

Pump operates but no

pressure. Jets turned off (if fitted).

Water level low. Suction

blocked. Air leak on suction

line. Filter dirty.

Turn jets on. Top up pool to

correct level. Unblock suction.

Repair air leaks. Clean filter.

Blower/Aux will not go. Accessory not plugged in. Make sure accessory plugged

into socket on control box.

No Light. Light not plugged in. Lamp

blown. Check plug is secure in correct

socket on control box. Replace

blown lamp.

Spa will not reach heat or

has trouble maintaining heat. Temperature control set to

low. Blower operating.

Excessive heat loss. Spa not

operated long enough. Clean

filter - check for obstructions.

Adjust temperature control

clockwise to increase heat.

Turn blower off (heating is

disabled while operating). Fit

pool cover. Check time clock

settings (sleep mode).

Dependent on pool insulation &

site location, heating perfor-

mance may be effected.

LEDs flashing High temperature cut out.

Electronic failure. Turn power off at mains switch

for 5 seconds. Refer Fig 9:

page 8 for reset information.

Page 9

IF ANY OF THE ABOVE MEASURES FAILS TO RECTIFY THE LISTED FAULTS CONTACT

YOUR DEALER OR THE NEAREST SERVICE CENTRE LISTED ON INSIDE FRONT COVER.

LED indicator

Single speed = red

Multi speed high = red

medium = yellow/orange

low or ramping = green

LED indicator = red when on

Fig 6: Temperature control knob

Page 5

THE TIME CLOCK FUNCTION

The time clock is used to regulate the operating times of the pool equipment.

This function is used to turn all operations of the pool to standby or sleep

mode. The clock is only effective in the auto mode (Fig 3). Any functions left

on like the pool light or blower will be terminated when the controller goes to

sleep. When the clock allows the controller to run again, pump and heating will

resume. However the light and blower will remain off until their switches are

pressed again.

To set the time (Fig 7) remove clear cover from clock. The clear lens [1] over

SWITCH INSTALLATION

The Intuitive control pad must be installed in compliance with local electrical

body regulations. Particular attention should be paid to the certain zones that

are part of the regulations, ie. in certain areas the switch must be installed on

the top side or outer side of the lip of the pool.

A rectangular hole of 93mm x 40mm x 35mm deep is required to mount the

Intuitive control pad. Cable access is required at base of hole. Switch is

mounted on a bead of silicon with label right reading from the bathers point of

view. (Please note that the yellow/orange colour generated for the mode

function can only be viewed from this perspective). The switch lead should be

positioned clear of other support equipment and their power leads where

possible. It is advisable to allow a drip loop in cable to avoid water/

condensation seeping into the controller's socket. The switch cable plug

should be orientated and pushed firmly into its mating socket where the

locking tabs will close about it. In case of removal use locking tabs which act

as ejectors in reverse. Do not try to remove switch plug by its lead.

SPECIAL NOTE

All equipment attached must not exceed the total rating as specified on the

cover of the control box. NB. 10 and

15 amp versions available. It is

essential that 15 amp rated controllers

are plugged into the correct mains

socket. (The plug will not fit standard

outlet sockets). When connecting to

the power supply ensure that the lead

is installed in conjunction with all local

electrical regulations. Do not install

power lead where damage may be

caused by people walking over it or

similar.

DO NOT OPERATE

CONTROL ON AN EXTENSION

LEAD

. Ensure that plugs are in there

correct position and fully inserted. If

the controller flashes in fault condition

check and operate the small

RED Over Temperature Reset Button

(Fig 9) on

the heating element cover. If the controller fails to reset allow time for the

Reset Device to cool down (20 - 30 mins) before trying again. If it still fails then

Technical Service is required.

Fig 9: Reset button

Page 8

THE THERMOSTAT CONTROL

The thermostat adjustment knob (located on the top of control box - Fig 6)

may need to be adjusted slightly for the first few days of operation to obtain

the desired temperature of 36°C or that which is comfortable to the bather as

indicated by a pool thermometer. Turning the thermostat to maximum will not

make the pool heat any quicker. (Control range approx. 25° - 40° degrees

Celsius).

NOTE: The initial heating of the water will take a number of hours dependent

on various factors:-

1/ The quality of the insulation around the pool.

2/ The quality and fit of the pool cover. (While heating or when not in use it is

recommended that a good fitting cover be installed).

3/ The ambient temperature surrounding the pool and whether it is an indoor

or outdoor situation.

4/ Proper water flow through the filter pump and heater.

5/ That all air bleeds where possible are turned off and the air blower is not

operating.

6/ The quality of the power supply.

the clock face should be rotated clockwise only to set the time. The

segments each representing 10 minutes are pulled out as shown [2] to activate

sleep mode. A minimum of 2 adjacent segments are needed between sleep

and auto modes. Figure 10 shows the sleep mode set to switch off at midnight

through to 7am the following morning. The clock is set to 7.45am as indicated

by the hands and the white arrow [3] on the outer segments. The clock may be

overridden at any time by entering the manual function (Fig 3) or operating the

override switch [4]. The indicator [5] is shown in the normal operating position

"0". When settings are complete be sure to refit clock cover.

Fig 7: Time clock (If time clock is different to one shown refer to insert)

INSTALLATION GENERAL

The control system has been designed so that it is easily removed for service,

or so that any ancillary spa equipment can be removed without the need of an

electrician. It is recommended that the control and equipment are positioned

so they are accessible. The heat pump system allows for the filter to be

installed on either the suction or return lines of the heater. All other equipment

including chlorinators must be installed after the heater. The control box

mounting points are located below the plastic cover screws (Fig 8A) at each

corner of the lid. These are designed to take a type 6PK 25mm screw or a

similar type on a mounting matrix of 190 x 140mm (Fig 8).

Page 6

Fig 8: Mounting method for

control box.

Page 7

Fig 8A

[1] Clock lens

[2] Segments

[3] Time indicator

[4] Override

switch

[5] Indicator

CONTROL BOX & HEATER INSTALLATION

The control box must be installed in a position considering the following

matters.

A/ The control box must be mounted in a vertical plane so that the front label

is right reading. The ventilation holes in the controller lid must have

unrestricted air flow.

B/ It must be mounted so that water can not be splashed on it or its

connections, ie. mounted above the filter opening, hair and lint pot or

drainage valves. The controller must be protected from rain & splashing.

C/ It must be mounted so the end user can easily operate the time clock.

D/ It must be mounted so the leads of the support equipment can be easily

plug into the control box sockets.

E/ It must be positioned so the heating element can reach the heating "T" on

pump.

F/ It must be mounted so that all spa support equipment is accessible and

can be easily removed for service.

G/ The control box must be installed on a stable platform so that it is not

subjected to vibration.

H/ The control box is designed so that the pump/s, blower and light where

fitted can be plugged into the box. The sockets are clearly marked.

INSTALLATION OF HEATER ELMENT

The element must be installed so that the lead is not stretched and the

element/control box can be easily removed for service. Pay attention to

instructions on element cover ensuring the element is positioned correctly.

The ‘O’ ring provided must sit properly on the shoulder of the element when

tightening the lock nut. Tighten the lock nut by hand only, tools are not

required.

Other Spa-Quip Controllers manuals