Quick Start Guide

UPC20+

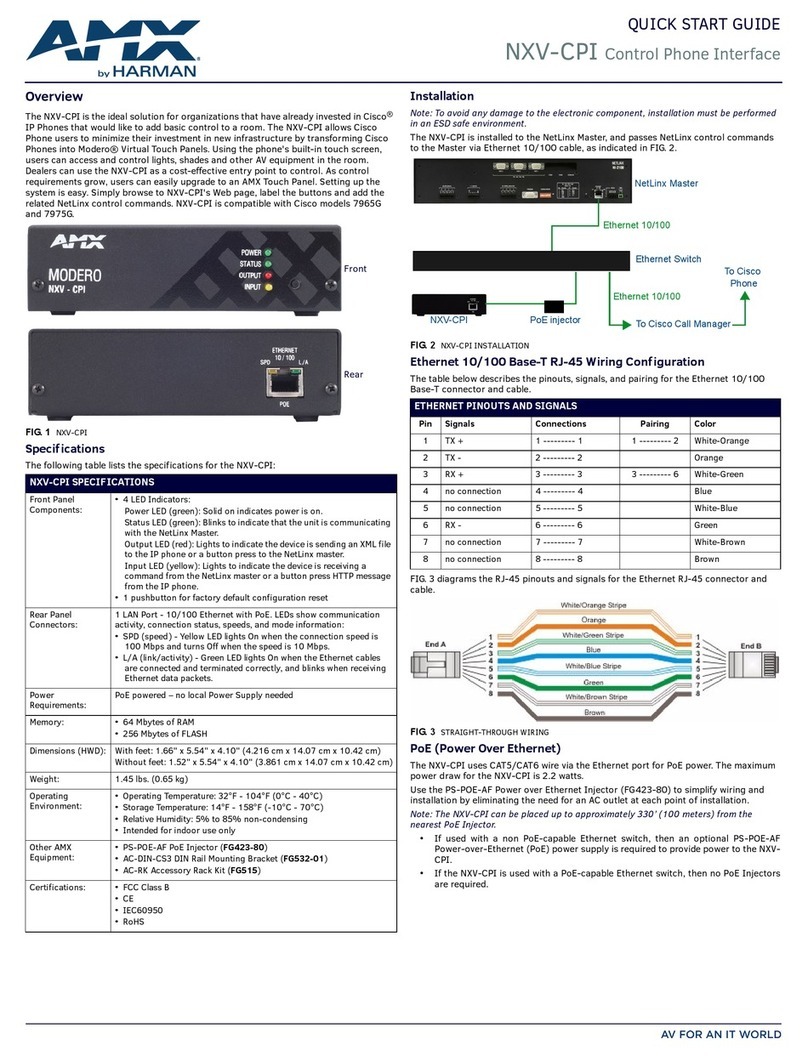

ATTENTION: READ THIS FIRST!

For more detailed installation, configuration, programming, and operating instructions,

refer to the UPC20+ Universal Power Controller Instruction Manual available on-line at

www.amx.com.

IMPORTANT SAFETY INSTRUCTIONS

When using your UPC20+ (FG672), basic safety precautions should always be

followed, including the following:

1. Read and understand all instructions before using. Close supervision is

necessary when any appliance is used by or near children. Do not leave appli-

ance unattended while in use.

2. Care must be taken as burns can occur from touching hot parts.

3. The appliance switch is provided with the symbols 0 indicating off and 1

indicating on. The symbols O and | may be used for this purpose.

4. Do not operate appliance with a damaged cord or if the appliance has been

dropped or damaged - until it has been examined by a qualified serviceman.

5. Position the cord so that it will not be tripped over, pulled, or contact hot surfaces.

6. If an extension cord is necessary, a cord with a current rating at least equal to

that of the appliance should be used. Cords rated for less amperage that the

appliance may overheat.

7. Always unplug appliance from electrical outlet before cleaning and servicing and

when not in use. Never yank cored to pull plug from outlet. Grasp plug and pull to

disconnect.

8. Let appliance cool completely before putting away. Loop cord loosely around

appliance when storing.

9. To reduce the risk of electric shock, do not immerse this appliance in water or

other liquids.

10. To reduce the risk of electric shock, do not disassemble this appliance, but take it

to a qualified serviceman when service or repair work is required. Incorrect

reassembly can cause electric shock when the appliance is used subsequently.

11. The use of an accessory attachment not recommended by the manufacturer

may cause a risk of fire, electric shock, or injury to persons.

12. Connect this appliance to a grounded outlet.

13. Disconnect this unit from its source of supply before replacing any part.

14. This appliance has a polarized plug (one blade is wider than the other). To

reduce the risk of electric shock, this plug is intended to plug into a polarized

outlet only one way. If the plug does not fit fully into the outlet, reverse the plug. If

it still does not fit, contact a qualified electrician. Do not modify the plug in any

way.

SAVE THESE INSTRUCTIONS

UPC20+ Wiring Requirements

In the United States, the UPC20+ must be wired by an authorized electrician in

accordance with the National Electrical Code, ANSI/NFPA 70-1987, as well as all local

codes.

In the European community, the UPC20+ unit must be wired by an authorized

electrician in accordance with all applicable European codes.

A readily accessible disconnect device shall be incorporated into the fixed wiring.

An insulated earthing conductor that is identical in size, insulation material and

thickness to be earthed and unearthed branch circuit supply conductors, except that it

is green with or without one or more yellow stripes, is to be installed as part of the

branch circuit which supplies the unit or system. The earthing conductor described is

to be connected to earth at the service equipment, or supplied by a separately derived

system, at the supply transformer or motor generator set.

Product Information

Using Motor Control mode, the UPC20+ output alternates between two relays,

providing a brief pause in-between relay contacts, to protect the motor. A timing

adjustment potentiometer is user adjustable for automatic release of the relays. (The

range is 0 to 90 seconds). 1-, 2-, and 3- button control modes are selectable.

In Power Control mode, the UPC20+ provides power control for two independent

circuits with a combined total load of 20 Amps. Single-button momentary/latching and

2-button latching modes are selectable.

•Momentary Power Relay contacts are closed only as long as a closure from

input to common is maintained.

•Latching Power Relay contacts are toggled (from open to closed and closed to

open) each time a closure from input to common is momentarily pulsed.

Note: The UPC20+ cover contains information on high voltage wiring, low voltage

wiring, and DIP switch settings.

The UPC20+ will work the NXC-I/O10 input/output control card.

Specifications

Control Options Modes

Note: If UPC20+ is powered up when changes are made to Dip Switch

settings, then power must be cycled before changes can take effect.

•Single Button Mode operates with one pushbutton in a sequence: Up, Stop,

Down, Stop and so on for each successive button press.

•Two/Three Button Mode operates with two pushbuttons, one for Up and one for

Down.

•Momentary On/Off operates only when the button is pressed.

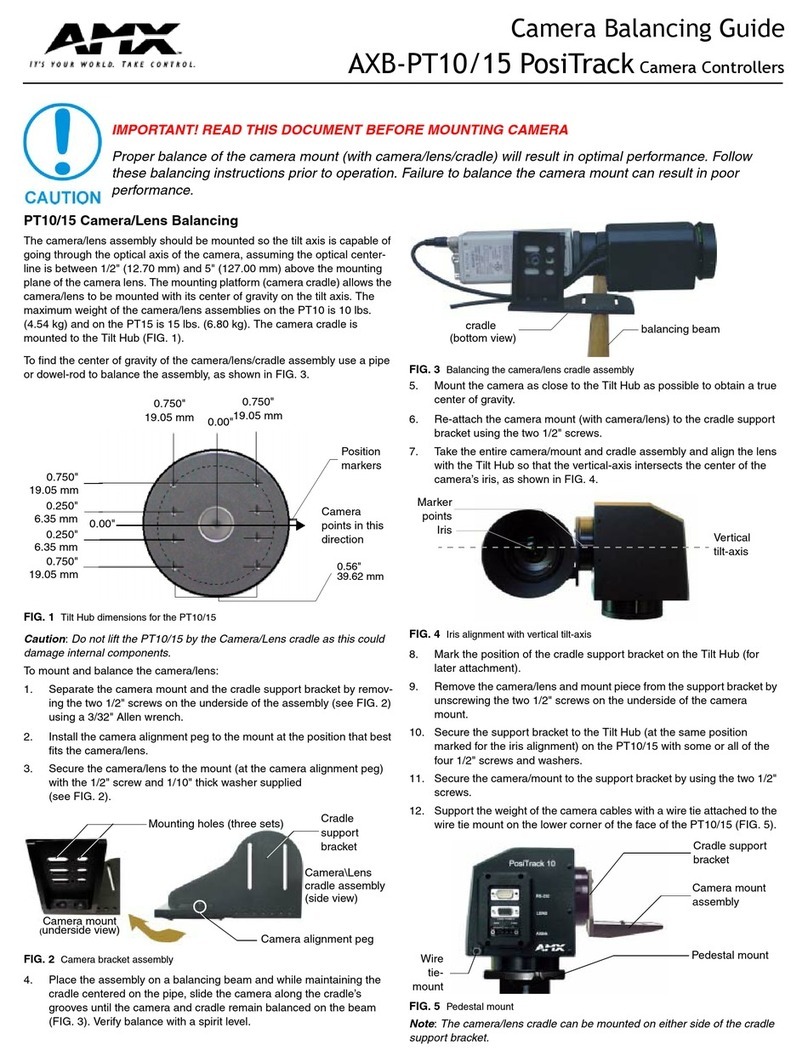

FIG. 1 UPC20+ inoperative mode warning label

ATTENTION INSTALLER

FACTORY SET TO INOPERATIVE MODE

(UNIT WILL NOT WORK UNTIL DIP SWITCHES ARE SET)

SEE CHART ON LID TO SET

DIP SWITCHES FOR ACTIVE MODE

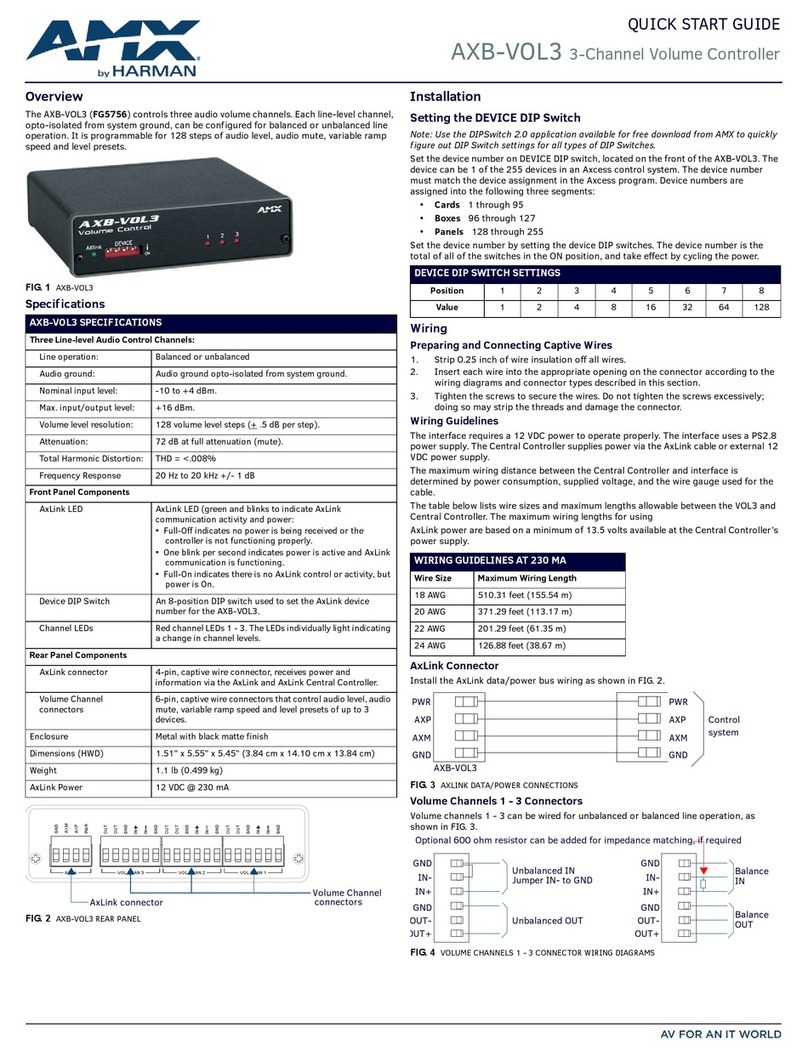

UPC20+ Specifications

Power Self-powered when used with 110/220 VAC

Power input (for control

board) 120/240V ~, 50-60 Hz, 0.05/0.025A

-or-

12 VDC, 0.2A max

Power output per relay • 20A @ 120/240V ~, 50-60 Hz (RESISTIVE LOAD)

• 6A @ 277V ~, 50-60 Hz (FLUORESCENT BALLAST)

• 1 HP @ 120V ~, 50-60 Hz (INDUCTIVE LOAD)

• 2 HP @ 240V ~, 50-60 Hz (INDUCTIVE LOAD)

Total Current through both relays CAN NOT exceed 20 amp.

Maximum operating ambi-

ent temperature

55°C

Approvals UL / C-UL / CE

Includes • 1-, 2-, and 3-button logic modes

• Local test switches with status LEDs

• 120, 240, and 277 VAC control capability

Inputs • 4 closure inputs, operation defined by mode.

• One IR remote sensor input.

• Motor Control mode alternates between the timed operation of

the two power relays.

• Power Control mode allows independent control of both power

relays.

Control Ports Two 2400 W power relays. Total combined current through both

relays is 20 Amps.

Input Power Switch (S1) • Set this switch according to the high voltage wiring that will be

connected to terminals 5 and 6 on P1.

• Set switch S1 to the line input voltage value used before

applying power to the UPC20+.

High Voltage Terminal Block

(P1)

High voltage input and output wiring for motor or power control.

Low voltage and Control

Terminal Block (P2)

Contact closure, open-collector or CMOS logic level remote

control wiring. Inputs 5 - 8 are referenced to the common

connection at pin 4.

Jumper JP1 Sets control mode of the unit to contact closure or remote sensor

serial data.

Test Switches (PB1 and

PB2)

Provides local operation of relays K1 and K2 for testing power

circuits or motors connected to the relay terminals. An LED

indicates relay power applied.

Motor Time Delay Potenti-

ometer (R8)

Only used in motor control modes. User adjusted for setting relay

release time between 0 and 90 seconds.

DIP Switch (S2) Provides selection of control mode options. See the Motor Control

Mode DIP Switch S2 Positions table on page 1 and the Control

Input Wiring to Connector P2 Terminals table on page 2 for control

mode settings.

Enclosure Metal with black matte finish, knockouts for conduit.

Dimension (HWD) • 8.5" (10.5" including flange) x 4.5" x 2.2"

• (220 mm (270 including flange) x 110 mm x 60 mm)

Weight 3.0 lbs. (1.4 kg) with flange

Options 12 VDC power supply (for 277 VAC applications)

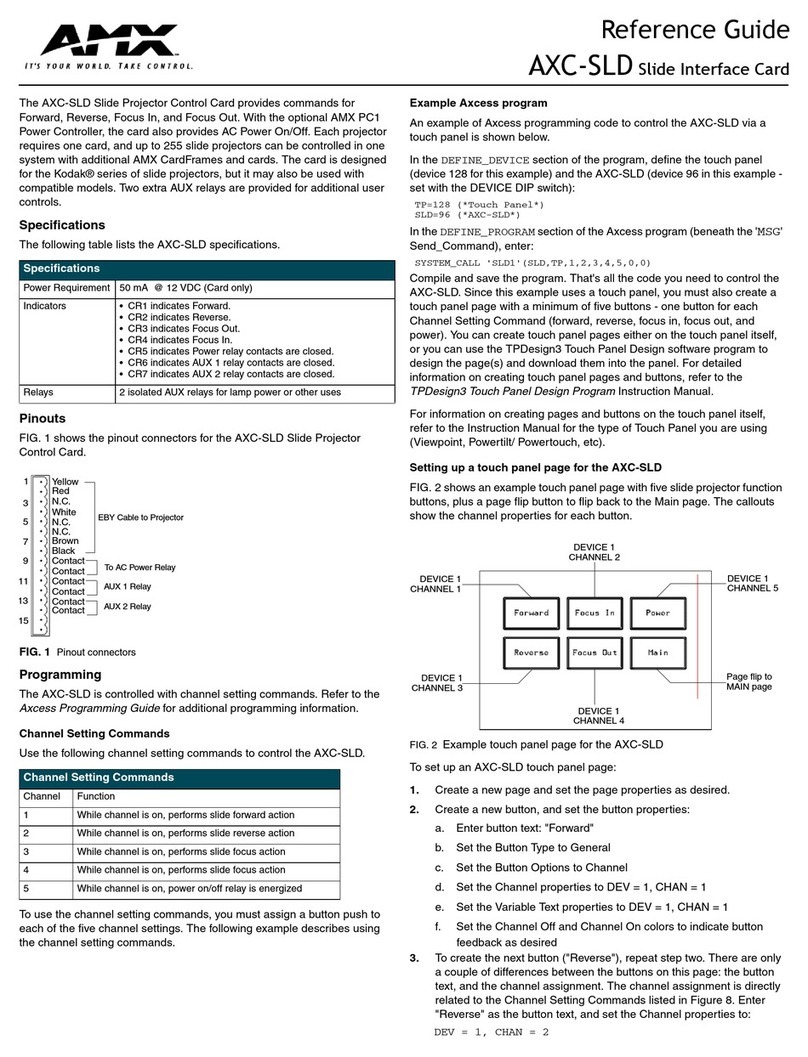

Motor Control Mode DIP Switch S2 Positions

1 2 3 4 Control Mode

On On Off On Single button

Off Off Off On 2-button

Off On Off On Momentary On/Off

!

!