Space ER 200 User manual

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

COMPOSIZIONE COMPOSITION ZUSAMMENSETZUNG COMPOSITION COMPOSICIÓN

42 pagine (copertine

comprese)

42 pages (including

cover pages)

42 Seiten (inkl.

Deckblätter)

42 pages (pages de la

couverture incluses)

42 páginas (incluidas

las portadas)

40 pagine numerate 40 numbered pages 40 numerierte Seiten 40 pages numérotées 40 páginas numeradas

• Per eventuali chiarimenti interpellare il più vicino rivenditore oppure rivolgersi direttamente a:

• For any further information please contact your local dealer or call:

• Im Zweifelsfall ober bei Rückfragen wenden Sie sich bitte an den nächsten Wiederverkäufer oder direkt an:

• Pour tout renseignement complémentaire s’adresser au revendeur le plus proche ou directement à:

• En caso de dudas, para eventuales aclaraciones, póngase en contacto con el distribuidor más próximo ó

diríjase directamente a:

SPACE ER 200 - ER 220

SPACE ER 150 - ER 160 - ER 165

MANUALE DI ISTRUZIONE

INSTRUCTION MANUAL

BETRIEBSANLEITUNG

MANUEL D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

SIMBOLOGIA UTILIZZATA NEL MANUALE

SYMBOLS USED IN THE MANUAL

IN DER BETRIEBSANLEITUNG VERWENDETE ZEICHEN

SYMBOLES UTILISES DANS LA NOTICE

SIMBOLOGÍA UTILIZADA EN EL MANUAL

SIMBOLI SYMBOLS ZEICHEN SYMBOLES SÍMBOLOS

VIETATO! FORBIDDEN! VERBOTEN INTERDIT! PROHIBIDO!

Obbligo!

Operazioni o

interventi da

eseguire

obbligatoriamente

Mandatory!

Operations or

jobs to be

performed

compulsorily

Vorschirift

Obligatorisch

auszuführende

Arbeitsvorgänge

oder Eingriffe

Obligation.

Opérations ou

interventions

obligatoires

Obigación.

Operaciones o

intervenciones que

hay que realizar

obligatoriamente

Pericolo!

Prestare

particolare

attenzione

Hazard!

Be especially

careful

Gefahr!

Äusserste

Vorsicht ist

geboten

Dager!

Faire trés

attention

Peligro!

Prestar especial

atención

Movimentazione

con carrello

elevatore o

transpallet

Handle using

fork-lift or pallet

transfer unit

Transport mit

Dabelstapler oder

Handgabelhub-

wagen

Déplacement

avec chariot

élévateur ou

traspalette

Desplazamiento

con carretilla

elevadora o

estibadora

Attenzione: carichi

sospesi

Caution: hanging

loads

Achtung:

hängende Lasten

Attention: charge

suspendue

Ateción: cargas

suspendidas

Attenzione: Non

sollevare mai la

macchina facendo

presa sull’albero

Caution: Never lift

the machine by

means of the

shaft

Achtung: Die

Maschine nie an

der Wuchtwelle

anheben.

Attention: ne

soulever pas

l‘équilibreuse en

ayant prise sur

l’arbre

Atención: no

levantar jamás la

máquina tomándola

por su eje

Pericolo: scariche

elettriche Shock hazard

Gefahr!

elektrische

Entladungen

Danger

d’électrocution

Peligro de

descargas

eléctricas

Indossare guanti

da lavoro Wear work gloves

Der Arbeit

angemessene

Handschuhe

tragen

Porter des gants

de travail

Colocarse guantes

de trabajo

Calzare scarpe da

lavoro Wear work shoes

Der Arbeit

angemessene

Schuhe tragen

Mettre des

chaussures de

travail

Usar zapatos de

trabajo

Indossare occhiali

di sicurezza

Wear safety

goggles

Schutzbrille

tragen

Porter des lunet-

tes de sécurité

Usar gafas de

seguridad

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 1/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

LIST OF CONTENTS

0 INSTRUCTIONS ........................................................................................................................2

0.1 PRELIMINARY SAFETY INFORMATION ....................................................................................................................2

1 INTENDED USE.........................................................................................................................3

2 OPERATOR TRAINING...........................................................................................................4

2.1 GENERAL PREVENTIVE MEASURES.........................................................................................................................4

2.2 INDICATION OF OUTSTANDING RISKS .....................................................................................................................4

3 COMPOSITION OF EQUIPMENT .........................................................................................5

3.1 MODELS ER200 - ER220 ......................................................................................................................................5

3.2 MODELS ER150 - ER160 - ER165 ........................................................................................................................6

3.3 SAFETY DEVICES....................................................................................................................................................7

3.4 TECHNICAL DETAILS ..............................................................................................................................................7

3.5 OVERALL DIMENSIONS...........................................................................................................................................8

3.5.1 Models ER200 - ER220 ................................................................................................................................8

3.5.2 Models ER150 - ER160 - ER165 ..................................................................................................................8

4 TRANSPORT AND INSTALLATION.....................................................................................9

4.1 TRANSPORT AND UNPACKING ................................................................................................................................9

4.2 INSTALLATION .......................................................................................................................................................9

4.2.1 Fitting the shaft on the flange.....................................................................................................................10

4.2.2 Fitting the protection guard (mod. ER165 only) ........................................................................................10

4.2.3 Brightness and contrast adjustment............................................................................................................11

4.2.4 Power connections......................................................................................................................................11

5 FITTING THE WHEEL ON THE SHAFT............................................................................12

6 SWITCHING THE MACHINE ON AND OFF.....................................................................13

7 WHEEL BALANCING ............................................................................................................14

7.1 DETERMINATION OF WHEEL DIMENSIONS ............................................................................................................14

7.1.1 Manual setting of wheel dimensions for dynamic balancing and ALU 1, 2, 3, 4 functions ........................14

7.1.2 Wheel dimension manual setting for ALU-S type correction......................................................................16

7.1.3 Manual setting of wheel dimensions for static correction ..........................................................................17

7.2 USER MANAGEMENT ............................................................................................................................................18

7.3 UNBALANCE MEASUREMENT ...............................................................................................................................19

7.3.1 Dynamic balancing.....................................................................................................................................19

7.3.2 Wheel positioning .......................................................................................................................................21

7.4 ALU AND/OR STATIC PROGRAMS......................................................................................................................22

7.4.1 Static balancing ..........................................................................................................................................23

7.4.2 ALU-S procedure........................................................................................................................................25

8 WHEEL BALANCING IN MOTORCYCLE MODE...........................................................27

9 WEIGHTS HIDDEN BEHIND SPOKES MODE..................................................................28

10 MATCHING PROCEDURE (RIM-TYRE OPTIMISATION)............................................31

11 SETUP OF UNITS OF WEIGHT MEASUREMENT AND RIM WIDTH/DIAMETER

AND SETTING CAR/MOTORCYCLE MODE....................................................................34

12 CALIBRATION ........................................................................................................................36

13 ERROR SIGNALS....................................................................................................................39

14 MAINTENANCE ......................................................................................................................39

15 STORAGE AND SCRAPPING ...............................................................................................39

16 MACHINE IDENTIFICATION DATA..................................................................................40

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 2/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

0 INSTRUCTIONS

Any damage caused by failure to follow the instructions in this manual or improper

machine use shall relieve SPACE s.r.l. of all liability.

0.1 Preliminary safety information

Before starting the machine:

•Read the instructions and the entire manual before using or working on the wheel

balancer. This manual represents an integral part of the product and is intended to

inform the user on how to use the wheel balancer model ER200, ER220, ER150,

ER160 and ER165. Look after the manual for the entire life of the machine. Keep it in

an easy to access place and refer to it every time the need arises. All machine

operators must be able to read the manual.

•Make sure the power supply is in conformity with the specifications shown on the

plate.

•Make sure the machine is properly positioned on the floor.

•Suitably position the machine power cables.

On starting the machine:

•Remove any foreign bodies from the tyre before spinning the wheel.

•Make sure the counterweights are fitted properly before spinning the wheel again.

In emergency conditions and before performing any maintenance:

•Isolate the machine from any power sources by means of the machine master switch.

Work environment and machine cleaning:

•The work environment must be kept clean and dry and must not be exposed to

atmospheric agents. It must also be well lit.

•Do not clean the machine using strong jets of water and compressed air.

•To clean plastic panels or tops, use alcohol (always avoid liquids containing solvents).

SPACE s.r.l. shall be entitled to make any changes to the models described in this manual a

t

any time for reasons of a technical and commercial nature

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 3/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

1 INTENDED USE

For models ER220, ER160 and ER165, after manually entering rim data (diameter,

distance and width) and having started wheel spin, the stop procedure becomes

automatic until the required weight is found.

Wheel spin with wheel balancer mod. ER200 and ER150 is on the other hand manual,

consequently stop is also manual by means of the pedal provided.

Numerous reasons exist for wheel unbalance, but this is usually caused by a non-

symmetric distribution of the rim fabrication materials, above all of the tyre with respect

to the rotation axis and equatorial plane of the wheel, to imperfect mutual rim-tyre

positioning and to incorrect wheel centring on the hub.

The purpose of this equipment is to cancel out, or at least reduce to within acceptable

limits, the vibrations of the wheel that cause driving problems and damage mechanical

parts. The equipment is suitable for all types of vehicle wheels and light commercial

vehicles.

This aim can be achieved by fitting counterweights of suitable size and in specific

positions to wheels that are not correctly balanced.

A wheel can be considered completely balanced only once it is dynamically balanced, as

this also ensures dynamic balancing.

The specifications are indicated in the "TECHNICAL DETAILS" paragraph (para. 3.4 on

page 7). As well as standard procedures, 4 options exist for light alloy wheels and the

ALU/Special function, which enables the two counterweights to be fitted in the most

appropriate positions.

Counterweight positioning is also reduced to a simple procedure. If, when balancing

spokes alloy wheels, the external weight becomes visible, a special procedure exists

(weights hidden behind spokes mode), which splits the weight in two and positions these

behind two spokes. Autotest, auto-calibration and guided calibration of the measuring

heads make it possible to always work with perfectly functional machines.

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 4/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

2 OPERATOR TRAINING

The machine must only be used by specifically trained and authorised personnel. To

ensure proper machine use and that measurements can be efficiently taken, operators

must be correctly trained and acquire the skills consistent with the instructions provided

by the manufacturer. In case of any doubts relating to machine use and maintenance,

refer to the instruction manual and then, if such doubts persist, contact an authorised

after-sales centre or SPACE s.r.l. technical assistance directly.

2.1 General preventive measures

•During operation and maintenance of this machine, always abide by the

safety and accident-prevention regulations in force.

•The machine must only be used by adequately trained and authorised

persons.

•UNDER NO CIRCUMSTANCES must the machine be used to spin anything

but vehicle wheels. Bad locking can cause rotating parts to come loose, with

potential damage to the machine and anything in the vicinity and injury to

the operator.

•This machine must only be used for the purpose for which it was expressly

intended.

SPACE s.r.l. declines all liability for injury or damage to persons animals and

things caused by improper machine use.

•Accessories and spare parts must be fitted by persons authorised by

SPACE s.r.l. and only original spare parts and accessories must be used.

•Operators should wear suitable protective clothing like gloves, safety

•The machine must only be operated in places where there is no danger of

explosions or fire.

•Removal or changes made to safety devices, or warning signals on the

machine can cause serious hazards and represents a violation of European

safety regulations.

•Before doing any maintenance jobs on the system, always disconnect the

power supply.

In case of doubt, do not interpret, but contact SPACE s.r.l. technical

assistance in order to obtain instructions suitable for performing operations

in total safety.

•Wheel balancer operators must not wear loose clothing, hanging ties, chains

or other accessories that could become trapped. Long hair should be properly

collected up and tied or protected.

•Do not allow unauthorised personnel to come near the wheel balancer during

the cycle.

2.2 Indication of outstanding risks

The machine was designed and manufactured in compliance with applicable regulations. The

risks connected to the use of the machine have been eliminated as far as possible. Other

outstanding risks are described in this manual; the machine also features self-adhesive

pictograms (chap. 3 on page 5) indicating hazard areas. In the event pictograms become

illegible, please order them from a dealer or directly from SPACE s.r.l. and replace them.

Please refer to Spare Parts manuals.

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 5/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

Caution: Never lift the machine by

means of the shaft

Shock hazard

Wear work gloves

Wear work shoes

Wear safety goggles

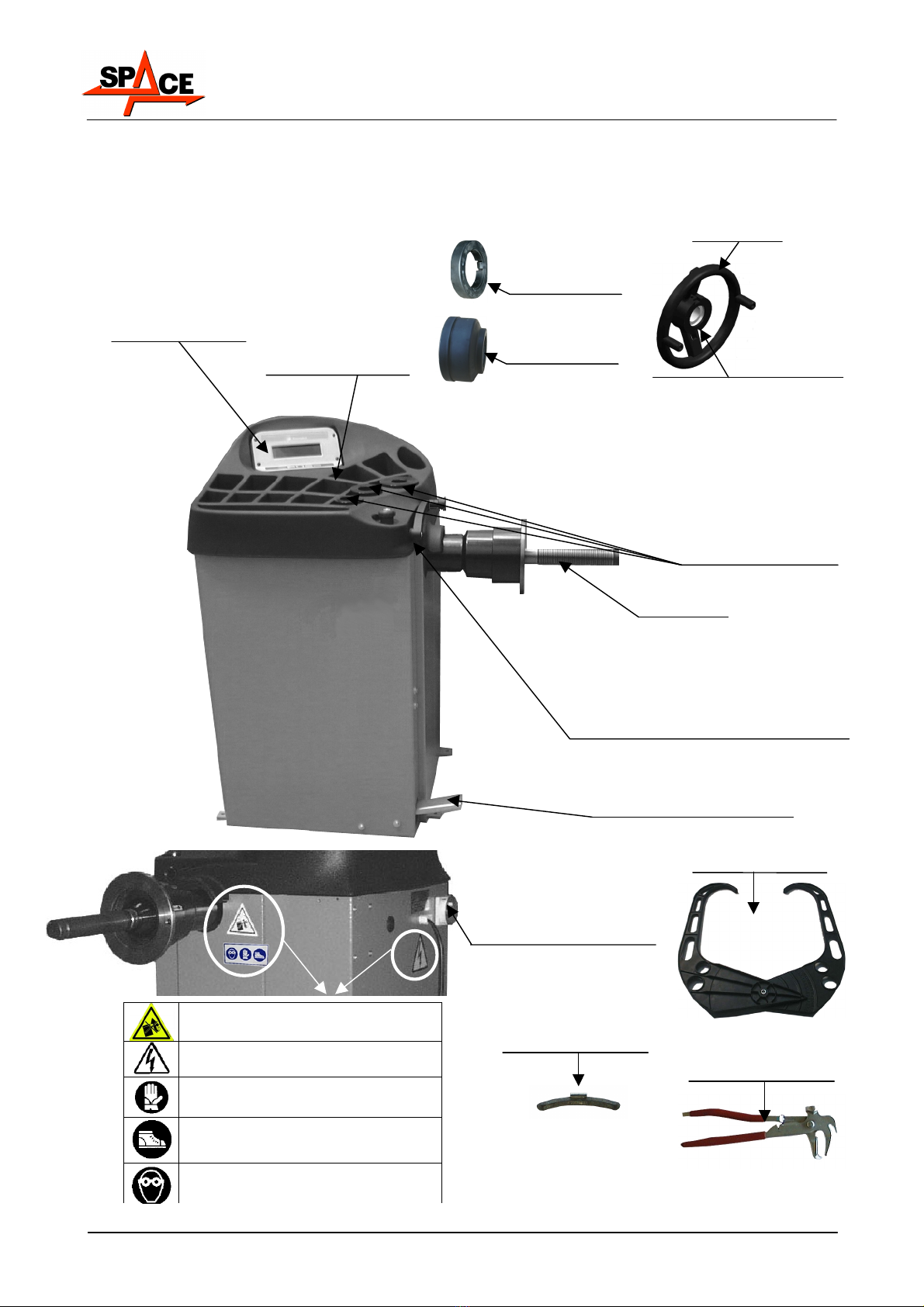

3 COMPOSITION OF EQUIPMENT

3.1 Models ER200 - ER220

PEDAL BRAKE

(MOD. ER200 ONLY)

DISPLAY SCREEN

INTEGRATED IN THE

WEIGHT HOLDER

SHAFT

ROD WITH RULE FOR MEASURING

THE DISTANCE OF THE INSIDE FLANK

OF THE RIM.

(IN INITIAL POSITION)

WEIGHT HOLDER

SMALL, MEDIUM

AND LARGE CONE

WEIGHT PLIERS

GAUGE FOR MEASURING

RIM WIDTH

CALIBRATION

WEIGHT (100g)

MASTER SWITCH (ON REAR

OF WHEEL BALANCER)

LOCKNUT

LEVER FOR QUICK

ENGAGEMENT/DISENGAGEMENT

MOD.ER220 ONLY

PRESSURE

RING

PROTECTION

CAP

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 6/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

3.2 Models ER150 - ER160 - ER165

PEDALE BRAKE

(MOD. ER150 ONLY)

DISPLAY SCREEN

INTEGRATED IN THE

WEIGHT HOLDER

SHAFT

ROD WITH RULE FOR MEASURING THE

DISTANCE OF THE INSIDE FLANK OF THE RIM

(IN INITIAL POSITION)

WEIGHT HOLDER

SMALL, MEDIUM

AND LARGE CONE

PROTECTION

GUARD (RAISED)

ON MOD. ER165 ONLY

WEIGHT PLIERS

LOCKNUT

LEVER FOR QUICK

ENGAGEMENT/DISENGAGEMENT

MOD.ER160/ ER165 ONLY

PRESSURE

RING

GAUGE FOR MEASURING RIM

WIDTH

CALIBRATION

WEIGHT (100g)

PROTECTION

CAP

MASTER SWITCH (ON REAR OF WHEEL

BALANCER)

Caution: Never lift the machine by means

of the shaft Wear work shoes

Shock hazard Wear work goggles

Wear work gloves

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 7/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

3.3 Safety devices

The wheel balancer features a number of safety devices. One of these is located on the

rear of the machine (master switch), see chap. 3, page 5. The master switch interrupts

power to the machine when turned clockwise.

In the case of model ER165 it is best to close the protection guard before spinning the wheel.

(key F1 on keyboard) can be pressed if required to manually stop the wheel in

case of an emergency.

3.4 Technical details

ER200

ER150

ER220

ER160 ER165

Max wheel weight 65kg 65kg 65kg

Max power absorption 40W 100W 100W

Power supply 230V 50/60Hz 1ph 230V 50/60Hz 1ph 230V 50/60Hz 1ph

Balancing precision ± 1g ± 1g ± 1g

Balancing speed 99 rpm 99 rpm 99 rpm

Min/max rim - machine distance 0÷400mm 0÷400mm 0÷400mm

Rim width setting 1.5” ÷ 22” 1.5” ÷ 22” 1.5” ÷ 22”

Diameter setting 10” ÷ 24” 10” ÷ 24” 10” ÷ 24”

Max wheel diameter inside protection --1016mm

Max wheel width inside protection --560mm

Sound emission level < 70 dB < 70 dB < 70 dB

Cycle time 7 sec 7 sec 7 sec

Weight 78kg (ER200)

68kg (ER150)

82kg (ER220)

72kg (ER160) 80kg (ER165)

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 8/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

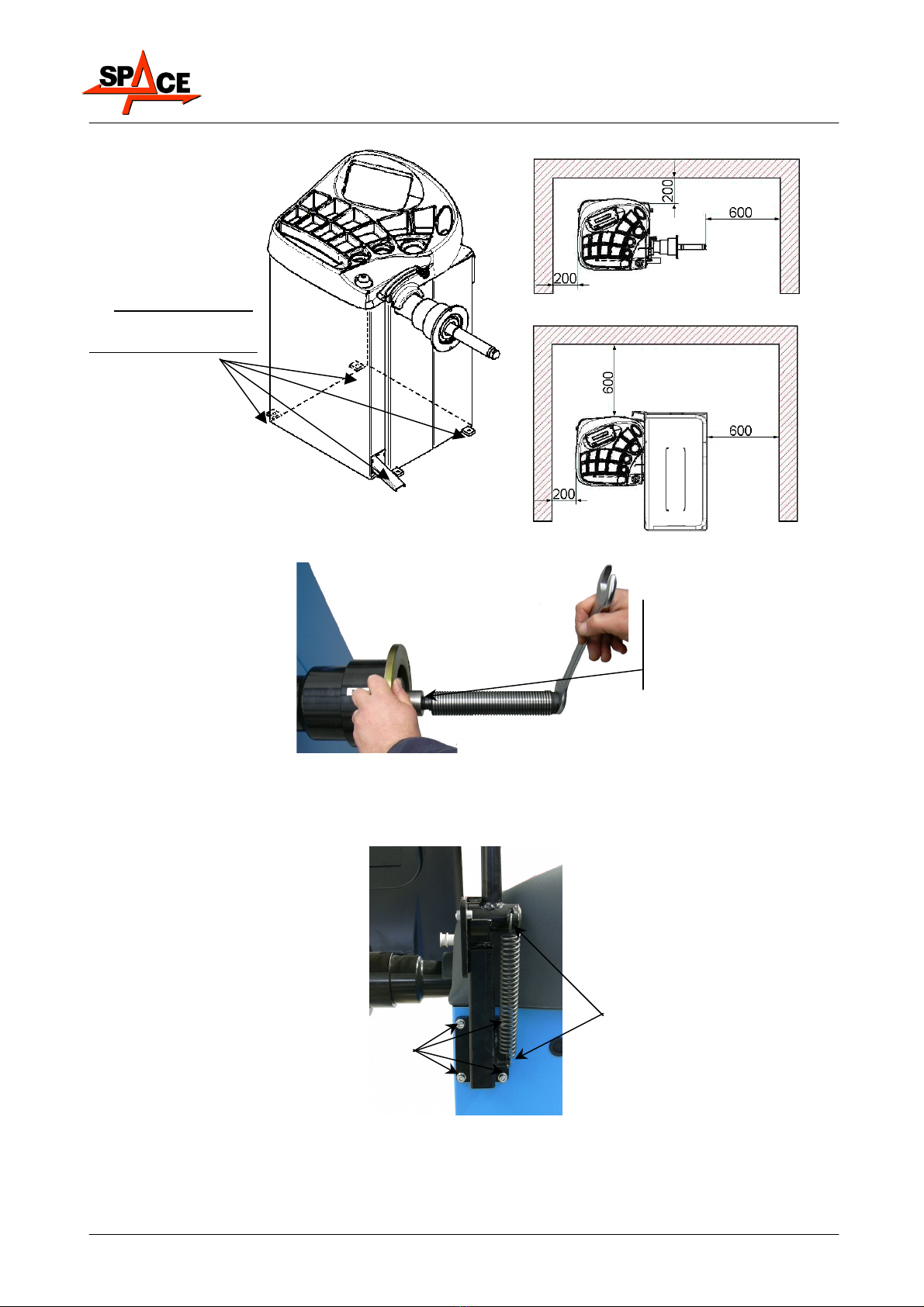

3.5 Overall dimensions

3.5.1 Models ER200 - ER220

3.5.2 Models ER150 - ER160 - ER165

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 9/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

4 TRANSPORT AND INSTALLATION

4.1 Transport and unpacking

The machine is supplied packed in a box fastened to a pallet to facilitate

transport. To transport the machine to the point where it is to be installed, use a

lifting and transport mechanism such as a fork-lift truck or lift with forks.

The lifting device must have a lifting capacity equal at least to the weight of the

packed machine. During transport, prevent the lifted machine from swinging.

The machine must be stored in its packaging, in a dry and ventilated

environment (with a temperature between -25° +55°C).

Never overturn or position the packaging horizontally. The pallet must always

rest on a flat and solid surface. Do not stack other packages on top of the

packaging. Always position so the instructions can be easily read.

DURING UNPACKING, ALWAYS WEAR GLOVES TO PREVENT ANY INJURY

CAUSED BY CONTACT WITH PACKAGING MATERIAL (NAILS, ETC.).

Make sure you have received all standard parts as previously listed.

The packaging material (plastic bags, polystyrene, nails, screws, wood, etc.) must

be collected up and disposed of through authorised channels, except for the

pallet, which could be used again for subsequent machine handling.

4.2 Installation

Position the wheel balancer where this is to be used. Never lift the machine by

means of the shaft.

Install the machine in a dry, covered and well-lit place, possibly closed or

protected against the elements. Before positioning the machine, make sure the

place chosen complies with applicable safety regulations and check the

minimum distances from walls or other obstacles (see Figure 1).

The position must be such as to allow the operator to see the area around the

machine. During operation in fact, the operator must make sure there is no one

or nothing in the vicinity of the machine that could represent a hazard.

The characteristics of the machine operating environment must be maintained

within the following limits:

- temperature: 0° + 45° C ; relative humidity: 30 ÷ 90 % (without dew);

The wheel balancer can operate on any solid and flat surface.

Make sure the 4 support points are resting properly on the floor and if necessary

shim.

The machine is best secured to the floor at the 4 above anchor points (Figure 1).

Anchoring is mandatory if wheels weighing more than 30 kg are used; use floor

anchors for M8 x 80 mm screws.

• drill 4 x 10 mm dia. holes opposite the holes in the page;

• fit the anchors and install the machine so this coincides with the holes made

and then tighten the screws (torque wrench setting: about 22 Nm).

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 10/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

Figure 1

4.2.1 Fitting the shaft on the flange

Figure 2

4.2.2 Fitting the protection guard (mod. ER165 only)

Figure 3

Fasten the shaft on the

flange using a setscrew

wrench

Check this is touching at the 4

support points provided.

Add shims as required;

Anchor if wheels are used

weighing > a 30kg

cTighten the 4 screws

sustaining the guard support

in the special inserts

positioned in the rear of the

unit using a socket wrench

dfit the spring between

the base of the support

and the anchor pin

MEASUREMENTS IN MILLIMETRES

ER200

ER220

ER150

ER160

ER165

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 11/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

4.2.3 Brightness and contrast adjustment

In the first page of the program press the below indicated keys to adjust brightness and

contrast. Such adjustment is identical for all display. See Figure 4. Try to find the best

settings, going across the all steps, because the settings can pass through clear, dark and

again clear.

NOTE: The settings done remains also after a shut-down.

Figure 4

4.2.4 Power connections

Before connecting up the machine, carefully check:

• power line specifications correspond to machine requirements as shown on the machine

plate;

• there is an earth lead and this is of suitable size (section greater or same as max section of

the power cables).

•that all the component parts of the power line are in good condition;

•that a wall switch exists solely for starting and stopping the machine. This must feature a

residual current and thermal magnetic circuit breaker, taking into account the electrical

power indicated on the wheel balancer.

Connect the machine up to the mains by means of the 3-pole plug provided (230 V single-

phase) through the wall socket.

If the plug provided is not suitable for the wall socket, fit a plug that complies with local and

applicable regulations. This operation must be performed by expert and professional

personnel.

Press repeatedly to

obtain more

brightness/contrast

Press repeatedly to

obtain less

brightness/contrast

Keep it pressed

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 12/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

5 FITTING THE WHEEL ON THE SHAFT

To achieve perfect balancing, the wheel must be carefully and properly fitted on the shaft.

Imperfect centring will inevitably cause unbalances.

Most important is that original cones and accessories are used. made specifically for

use on the wheel balancer.

Wheel fitting using the cones provided is illustrated below.

For alternative fittings, using optional accessories, refer to the special instructions provided

separately.

1. Remove any type of

foreign body from the

wheel: already-existing

weights, stones and

mud, and make sure

the shaft and the rim

centring area are clean

before fitting the wheel

on the shaft.

2. Carefully choose the cone

most suitable for the wheel to

be balanced. These

accessories must be

selected according to the

shape of the rim.

Carefully position the wheel

using the cone (otherwise

this could seize) until this

rests against the support

flange.

3. Fit the wheel

with the inner

side of the rim

towards the

wheel balancer

and against the

cone.

STANDARD WHEEL

4. Fit the protection

casing in the

locknut and

fasten against the

wheel.

Some aluminium wheels, with very high centring, must be fitted with the cone outside the

wheel.

1. Clean the shaft before

fitting the wheel.

2. Fit the wheel with the

outside of the rim

towards the wheel

balancer, until the wheel

is up against the support

flange.

3. Fit the cone with

the narrowest

part turned

towards the

wheel

4. Fit the grip-ring in the

locknut and secure

the cone.

ALUMINIUM WHEEL WHEEL FITTING

CONE PRESSURE

RING

LOCKNUT

SHAFT

SHAFT

WHEEL FITTING CONE

LOCKNUT

PROTECTION

CAP

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 13/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

6 SWITCHING THE MACHINE ON AND OFF

The ON/OFF master switch is located on the rear of the machine.

To start the machine and access the program, switch on the system by turning the master

switch to ON (I).

Wait a few seconds for the operating program to load and for the first program page to appear

on the display screen.

The monitor shows various types of information and presents the user with numerous

operation options.

Figure 5

ICON KEY DESCRIPTION

RED (F1) Displays the program configuration panel

YELLOW (F2) Displays the alu correction procedures.

/CENTRE Displays car or motorcycle mode

BLUE (F3) Displays the tests of the different services (4 different

services are managed) para. 7.2 on page 18

GREEN (F4) The dynamic balancing test starts

By means of the 5 keys located on the display mask (F1-F2-CENTRE-F3-F4) all the machine

functions can be used.

During program running, the various display pages show the different keys by means of

which the corresponding function can be immediately selected.

Many display pages contain several rows of keys. In this case, the next row of keys can be

displayed by means of the key corresponding to the icon .

To go back and display the previous row of keys, press the key corresponding to the icon

or in some cases .

Program

operation key

FIRST

PAGE

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 14/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

7 WHEEL BALANCING

7.1 Determination of wheel dimensions

7.1.1 Manual setting of wheel dimensions for dynamic balancing and ALU 1, 2, 3, 4

functions

SPACE wheel balancers feature a manual gauge and a graduated scale for determining wheel

dimensions (Figure 7 and Figure 8).

The rim distance dimension is always set with "mm" unit of measurement.

The width and diameter dimensions on the other hand can be set in "inches" or "mm". The

examples shown in this manual show measurements in "inches". To change the unit of

measurement from "inches" to "mm", see chap. 11 on page 34.

Figure 6

ICON KEY DESCRIPTION

RED (F1) Return to display previous page

YELLOW (F2) Decrease wheel dimension values

CENTRE Select and confirm the value to be set

BLUE (F3) Increase wheel dimension values

GREEN (F4) Perform spin

Press centre key ( ) to select the value to be set.

The display screen will show the selected value on black background and on the right the

same value in large characters (Figure 6).

Manually set the width. Generally speaking, the nominal width is indicated on the rim, but it

is always a good idea to position the graduated scale on the inner and outer side of the wheel

as shown in Figure 7 and determine the measurement to be set.

To enter the wheel width, the operator must select the “PLUS” or “MINUS” key

until the desired width is achieved.

Figure 7

Rim distance

value

Rim diameter

Selected dimension

displayed enlarged

User no. in use

Selected

program

Rim width (selected

d

im

e

n

s

i

o

n

)

MANUAL

GAUGE

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 15/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

Press the centre key ( ) to select the rim diameter dimension.

Enter the rim diameter by selecting the “PLUS” or “MINUS” key until the desired

value is achieved.

Press the centre key ( ) to select the rim distance dimension

Move the graduated scale from the initial position against the inner edge to measurement

position (see Figure 8). Read the value to be set on the rule.

Enter the rim distance by selecting the “PLUS” or “MINUS” key until the desired

value is achieved.

Figure 8

After setting all the wheel dimensions, press the centre key ( ) again to confirm. The

program will show the page in Figure 9.

Figure 9

ICON KEY DESCRIPTION

RED (F1) Return to display previous page

YELLOW (F2) User management (para. 7.2 on page 18)

CENTRE Select and confirm the value to be set

BLUE (F3) Display the next row of keys

GREEN (F4) Perform spin

MANUAL

GRADUATED

SCALE IN

MEASUREMENT

POSITION

Dimensions entered

and confirmed

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 16/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

7.1.2 Wheel dimension manual setting for ALU-S type correction

Select the ALU-S function as described in para. 7.4 on page 22 and press the “CENTRE key”

to confirm and enter the measurements.

The display screen will show the page in Figure 10.

Move the graduated scale to the position where the inner weight is to be fitted. Read the

value to be set on the scale. Enter the distance by selecting the “PLUS” or “MINUS”

key until the desired value is achieved.

Press the “CENTRE key” to confirm.

Figure 10

The "acquired dimension" indication is given by the first measurement point indication arrow,

which goes from white to black.

Figure 11

Move the graduated scale to the position where the outer weight is to be fitted (always hidden

inside the rim). Read the value to be set on the scale. Enter the distance by selecting the

“PLUS” or “MINUS” key until the desired value is achieved.

Press the “CENTRE key” to confirm.

Figure 12

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 17/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

The "acquired dimension" indication is given by the second measurement point indication

arrow, which goes from white to black.

Enter the wheel diameter (Figure 12) by selecting the “PLUS” or “MINUS” key

until the desired value is achieved. Press the "CENTRE key" to confirm.

The program will show the page in Figure 13.

Figure 13

To display all the measurements entered, press the "CENTRE key" several times.

Press the “F4 key” to start the spin.

7.1.3 Manual setting of wheel dimensions for static correction

Select the STATIC function as described in para. 7.4 on page 22 and press the "CENTRE key"

to confirm and enter the measurements.

The display screen shows Figure 14.

Move the graduated scale to the position where the weight is to be fitted. Read the value to be

set on the scale. Enter the distance by selecting the “PLUS” or “MINUS” key

until the desired value is achieved.

Press the “CENTRE key” to confirm.

Figure 14

The "dimension acquired" indication is shown by the measurement point indication arrow

which goes from white to black.

Figure 15

Dimensions

entered and

confirmed

INSTRUCTION MANUAL

SPACE s.r.l. ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

Page 18/ 40 SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

Enter the wheel width diameter (Figure 15), always selecting the “PLUS” or “MINUS”

key until the desired value is achieved.

Press the “CENTRE key” to confirm.

The display screen will show Figure 16.

Figure 16

To display all the entered measurements, press the "CENTRE key" several times.

Press the “F4 key” to start the spin.

7.2 User management

To select user management, select the following key on the presentation page (para. 6 on

page 13).

SPACE wheel balancers can be used by 4 different users at the same time, by selecting the

above indicated key several times, until the desired user is reached.

When the user key is pressed, the current user number appears on the display screen (U1,

U2, U3 and U4 in car mode or M1, M2, M3 and M4 in motorcycle mode).

The system stores the data relating to the last performed spin according to the different

operators. The desired user can be called every time the program displays the specific key.

The measurements stored for each user are lost when the machine is switched off.

User management is valid for any wheel balancer function.

IMPORTANT: To enable or disable the "User Control" function, see para. 11(Figure 44 on page

35). Once this function has been disengaged by pressing the "User key F3" on the

presentation page (para. 6 on page 13) on the top left of the monitor, the only used user

appears “U” in car mode or “M” in motorcycle mode.

Dimensions

entered and

confirmed

This manual suits for next models

4

Table of contents