Spandau pumpen PXK Series User manual

Product name

Centrifugal pumps

Product line: PXA… / PXK…

Original installation instruction with included

operating manual

in accordance with EC-Machinery

Directive 2006/42/EC

Version 02

Imprint page 2

EN

mprint

This original installation instr ction with incl ded

operation man al complies with EC-Machinery

Directive 2006/42/EC and is an integral part of the

described prod ct. It m st be kept for f t re se.

This original installation instr ction with incl ded

operation man al was created in accordance with

the valid standards and reg lations on doc menta-

tion, VDI 4500 and EN 292.

© SKF Lubrication Systems Germany AG

This doc mentation is protected by copyright. The

photomechanical reprod ction, copying, and distri-

b tion of this doc mentation or parts thereof by

means of processes s ch as data processing, data

carriers, and data networks is strictly prohibited

witho t the express permission of SKF L brication

Systems Germany AG.

We reserve the right to make content and technical

changes.

Service

If yo have technical q eries, please contact one of

the following plants:

SKF L brication Systems Germany AG

Prod ct range Spanda P mpen

Motzener Straße 35/37

12277 Berlin

Germany

Tel. +49 (0)30 72002-0

Fax +49 (0)30 72002-261

Kontakt@Spanda p mpen.de

www.spanda p mpen.com

Table of contents page 3

EN

Table of contents

Original installation instruction in accordance

with EC-Machinery Directive 2006/42/EC

mprint 2

Service 2

Table of contents 3

nformation concerning the EC Declaration of

Conformity and the EC Declaration of

ncorporation 4

General information 5

Meaning of symbols and corresponding

information 5

1. Safety information 7

1.1 Intended se 7

1.2 A thorized personnel 8

1.3 Danger relating to electric c rrent 8

1.4 Danger relating to hydra lic press re 8

2. Fluids delivered 9

3. Assemblies and type designation 10

4. Composition and function 11

5. nstallation instruction 12

5.1 Positioning and mo nting 12

5.2 Connecting dimensions 14

5.3 Installation of Pipes 14

5.4 Connection of Pipes 14

5.5 Fastening to the Container 14

5.6 Electrical connection 15

5.7 Sense of Rotation 15

Operating manual 16

6. Transport, delivery and storage 17

6.1 P mps 17

6.2 Electronic and electrical devices 17

6.3 General information 17

7. Start-up and operation 18

8. Shutdown 19

8.1 Temporary sh tdown 19

8.2 Definitive sh tdown 19

9. Maintenance 20

9.1 General notes 20

9.2 Disassembly and Assembly PXA 21

9.2.1 Disassembly of the P mp 21

9.2.2Assembly of the P mp 22

10. Faults 25

11. Technical data 28

11.1 Design feat res 28

11.2 Mechanical design 28

11.3 Electrical design 28

11.4 Meas rements 29

12. Notes 33

Information concerning the EC Declaration of Conformity and the EC Declaration of Incorporation page 4

EN

nformation concerning the EC Declaration of Conformity and the EC Declaration of

ncorporation

For the prod ct(s) designated below:

Centrifugal pump

Prod ct line:

PXA… / PXK…

SKF herewith certifies that it conforms to the perti-

nent safety req irements set forth in the following

Co ncil Directive(s) for the harmonisation of the

laws of the Member States...

•Machinery Directive 2006/42/EC

•Low-voltage Directive 2006/95/EC

•Electromagnetic compatibility 2004/108/EC

Notes:

(a) This declaration certifies conformity with the

aforementioned directive(s), b t does not

contain any ass rance of properties.

(b) The safety instr ctions in the doc mentation

incl ded with the prod ct m st be observed.

(c) The certified prod ct m st not be started p

ntil it is ass red that the machine, vehicle or

the like in which the prod ct was installed

meets the provisions and req irements of the

national directives to be applied. This is in par-

tic lar important for the implementation of the

Use of Work Directive.

(d) Operation of the prod cts on non-standard

mains voltage as well as nonobservance of in-

stallation instr ctions can affect the EMC

properties and electrical safety.

SKF f rther declare that the above mentioned

prod ct:

•is meant for integration into a machine / for

connection to other machinery according to

the EC-Machinery Directive 2006/42/EC,

Appendix Part B. Starting p the prod ct

is not admissible ntil it is ass red that the

machine, vehicle or the like in which the

prod ct was installed meets the provisions

and req irements of the reg lations set forth

in the EC Directive 2006/42/EC.

•with reference to the EC Directive 97/23/EC

concerning apparatus subjected to

pressure this prod ct m st only be sed as

intended and according to the notes in the

doc mentation. Especially observe the

following:

Prod cts of SKF L brication Systems Germany AG

m st not be sed in con¬j nction with fl ids, gro p

I (hazardo s fl ¬ids), according to the definition of

article 2 paragraph 2 of the Directive 67/548/EC

dtd. 27th J ne, 1967; and are not approved for

application with s ch.

None of the prod cts man fact red by SKF L -

brication Systems Germany AG are approved for

application in con¬nection with gases, liq efied

gases, gases dissolved nder press re, steams or

fl ids that will reach a steam press re of more

than 0.5 bar above the normal atmospheric

pres¬s re (1013 mbar) in the admissible ap-

plica¬tion temperat re range.

When sed as intended, the prod cts s p¬plied by

SKF L brication Systems Germany AG do not

reach the limit val es listed in the Article 3 par. 1,

sections 1.1 to 1.3 and par. 2 of the Press re

Eq ipment Directive 97/23/EC. Therefore they do

not come nder the req irements set forth in

annex I of that Directive. They are not labelled with

the CE mark with reference to the Directive

97/23/EC. They are classified by s to come nder

Article 3 par. 3 of the Direc¬tive.

The EC Declaration of Conformity and EC-Declara-

tion of Incorporation is part of the prod ct doc -

mentation. These doc ments are delivered with

the prod ct.

General information page 5

EN

General information

Meaning of symbols and corresponding

information

In this installation instr ction, these symbols are

sed to highlight safety information that comm -

nicates a partic lar risk to persons, material assets,

or the environment.

Pay attention to this information and be especially

caref l in sit ations where a risk is indicated. Pass

on all safety instr ctions to other people as appro-

priate.

Hazard symbols

Information that is attached directly to the prod ct

- s ch as the examples below - m st be observed.

S ch signs m st be kept in a legible state.

•Rotational direction arrow

•Fl id connection label

Keywords in safety information and their

meanings

The responsibility is yours!

Read this installation instr ction thoro ghly and

pay attention to the safety information.

nformation symbols

D N 4844-2

W000

General

risk

D N 4844-2

W008 Voltage

D N 4844-2

W026

Hot

surface

D N 4844-2

W028

Slip

hazard

Keyword Use

Danger! Indicates a danger of inj ry to

persons

Caution! Indicates a danger of damage

to property or the environment

Note! Indicates additional

information

Note

⇒ Prompts yo to take action

• Used for b lleted lists

> Indicates other iss es, ca ses or

circ mstances

∗ Provides additional information

Product name

Centrifugal Pump

Product line: PXA… / PXK…

Original installation instruction

in accordance with

EC-Machinery Directive 2006/42/EC

1. Safety information page 7

EN

1. Safety information

Please observe the following safety instr ctions to

ens re tro ble-free f nctioning of the nit and

prevent damage.

The operator of the described prod ct

m st ens re that this installation in-

str ction is read and nderstood by all

persons who are involved with the as-

sembly, operation, maintenance, and

repair of the prod ct. This installation

instr ction m st be kept close at hand.

Note that this installation instr ction is

an integral part of the prod ct. It m st

be handed over to the new operator of

the prod ct if the prod ct is sold.

The described prod ct was man fact red in accor-

dance with all generally acknowledged reg lations

pertaining to technology, occ pational safety, and

accident prevention. However, dangers that can

ca se physical inj ry to persons or damage to

other material assets might still occ r d ring the

se of the prod ct. This prod ct sho ld therefore

only be sed if it is in a technically perfect state and

with f ll observance of the information provided in

this installation instr ction. In partic lar, malf nc-

tions that might affect the safety of the prod ct

m st be rectified immediately.

Especially errors that co ld affect safety m st be

resolved witho t delay.

Safety meas res corresponding to the parameters

of the l bricant s pplied m st be stip lated.

The safety mechanisms m st not be damaged,

dismantled, or in any way made inoperable, nor

m st they be replaced by parts which have not

been expressly approved of by VOGEL.

In addition to the information provided

in the installation instr ction, all gener-

ally valid reg lations on accident pre-

vention and the environment m st be

observed.

1.1 Intended se

All SKF L brication Systems Germany

AG prod cts may only be sed for their

intended p rpose and in accordance

with the specifications of the installation

instr ction for the prod ct in q estion.

Spanda P mpen Immersion p mps, type PXA or

PXK, are m lti-stage centrif gal p mps for

p mping of mineral oil based oils and em lsions as

well as synthetic cooling and l brication agents

witho t abrasive and long fibro s components.

They are designed for vertical installation.

Any other se of this prod ct constit tes improper

se.

Only a thorized l bricants for the p mp

type may be s pplied. Uns itable

l bricants co ld lead to the p mp failing

and possibly severe property damage

and personal inj ry.

Una thorized modifications to the

p mps and the se of na thorized

spare parts and aids are prohibited and

void the warranty.

Worn-o t nits m st be made inoperable and

disposed of properly.

1. Safety information page 8

EN

Prod cts of SKF L brication Systems Germany AG

m st not be sed in con¬j nction with fl ids, gro p

I (hazardo s fl ¬ids), according to the definition of

article 2 paragraph 2 of the Directive 67/548/EC

dtd. 27th J ne, 1967; and are not approved for

application with s ch.

None of the prod cts man fact red by SKF L -

brication Systems Germany AG are approved for

application in con¬nection with gases, liq efied

gases, gases dissolved nder press re, steams or

fl ids that will reach a steam press re of more

than 0.5 bar above the normal atmospheric

pres¬s re (1013 mbar) in the admissible ap-

plica¬tion temperat re range.

If it is not shown separately prod cts of SKF

L brication Systems Germany AG m st not be

sed in areas exposed to explosion hazards as

discribed in the ATEX Directive 94/9/EC.

1.2 A thorized personnel

The prod cts described in the installation instr c-

tion may only be installed, operated, maintained,

and repaired by q alified experts. Q alified experts

are persons who have been trained, instr cted, and

familiarized with the end prod ct into which the

described prod ct is installed. These persons are

considered capable of s ch tasks d e to their

ed cation, training, and experience with valid

standards, conditions, accident prevention reg la-

tions, and assembly meas res.

They are entitled to carry o t the req ired tasks

and to recognize - and th s avoid - any dangers

that might otherwise occ r.

A definition of what constit tes a q alified person

and information on the prohibition on allowing

work to be carried o t by nq alified personnel are

stip lated in DIN VDE 0105 and IEC 364.

1.3 Danger relating to electric c rrent

The electrical connection for the described prod ct

may only be established by q alified, instr cted

persons who have been a thorized to carry o t the

task at hand by the operator. All local electrical

operating conditions and reg lations s ch as DIN

and VDE m st be observed. Improperly connected

prod cts can res lt in considerably damage to

property and inj ry to persons.

Working on prod cts that have not been

disconnected from the power s pply can

ca se inj ry to persons.

Assembly, maintenance, and repair

work may only be carried o t by q ali-

fied experts on prod cts that have been

disconnected from the power s pply.

The s pply voltage m st be t rned off

before any prod ct components are

opened.

1.4 Danger relating to hydra lic

press re

The described prod ct is nder press re

when it is being operated. The prod ct

m st therefore be depress rized before

starting assembly, maintenance, or re-

pair work and before making any

changes to the system.

2. Fl ids delivered page 9

EN

2. Fluids delivered

•Clean, t rbid and air-free fl ids witho t long-

fibered or abrasive constit ents

•Low viscosity cooling and c tting oils, mineral

and synthetic types

•Aq eo s em lsions

•Water

•Cleaning liq ids

•Acids and bases

The following limit values m st be complied with

when contaminated or highly visco s fl ids are

involved:

Max. gain size:

Ø

2mm with PXA/PXK 02/04

Ø

3mm with PXA 10/18

Max.

contamination:

50 g/m

3

bei PXA/PXK 02/04

100 g/m

3

bei PXA 10/18

Max. kinematic viscosity 20 mm

2

/s

Check the motor power when the density or

viscosity deviates from that of water.

Temperat re range: -10°C bis +90°C

3. Assemblies and type designation page 10

EN

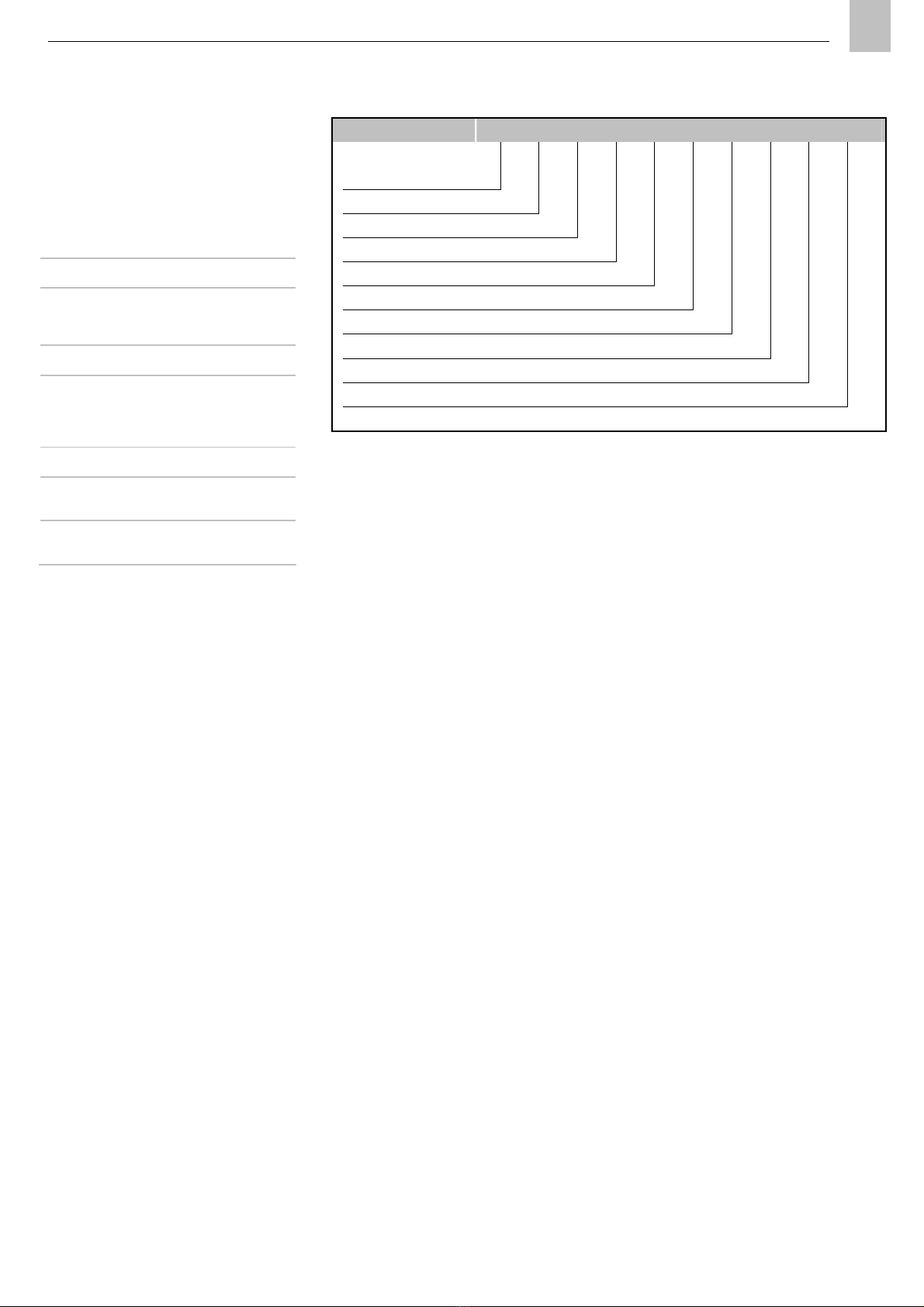

3. Assemblies and type designation

Spanda P mpen Immersion p mps, type PXA or

PXK, are offered in different sizes which mainly

differ in dimension and p mping o tp t. The

f nctional principle of all sizes is identical.

The respective size or designation of yo r p mp as

well as f rther important identification data is

given on the nameplate.

Series PXA

PXK

p to 25bar

p to 7bar

Size 02

04

10

18

2 m³/h

4 m³/h

10 m³/h

18 m³/h

N mber of stages 02 - 25 N mber of

active stages

Materials G

E

Cast iron

(standard)

stainless steel

(only PXA/PXK

02/04)

Seal types B

G

Split b sh

Glide ring seal

P mp version S

V

Basic version

prepared for

extension pipe

Immersion depth 185 bis 626 Immersion

depth of p mp

in mm

Table 1. Type key

Designation PXA 04 02 G B S 185 D 01 AA

Series

Size

N mber of stages

Materials

Seal type

P mp version

Immersion depth

Motor size index1)

Electric s pply1)

Motor version1)

1) The motor data can be extracted from the motor’s nameplate.

4. Composition and f nction page 11

EN

4. Composition and

function

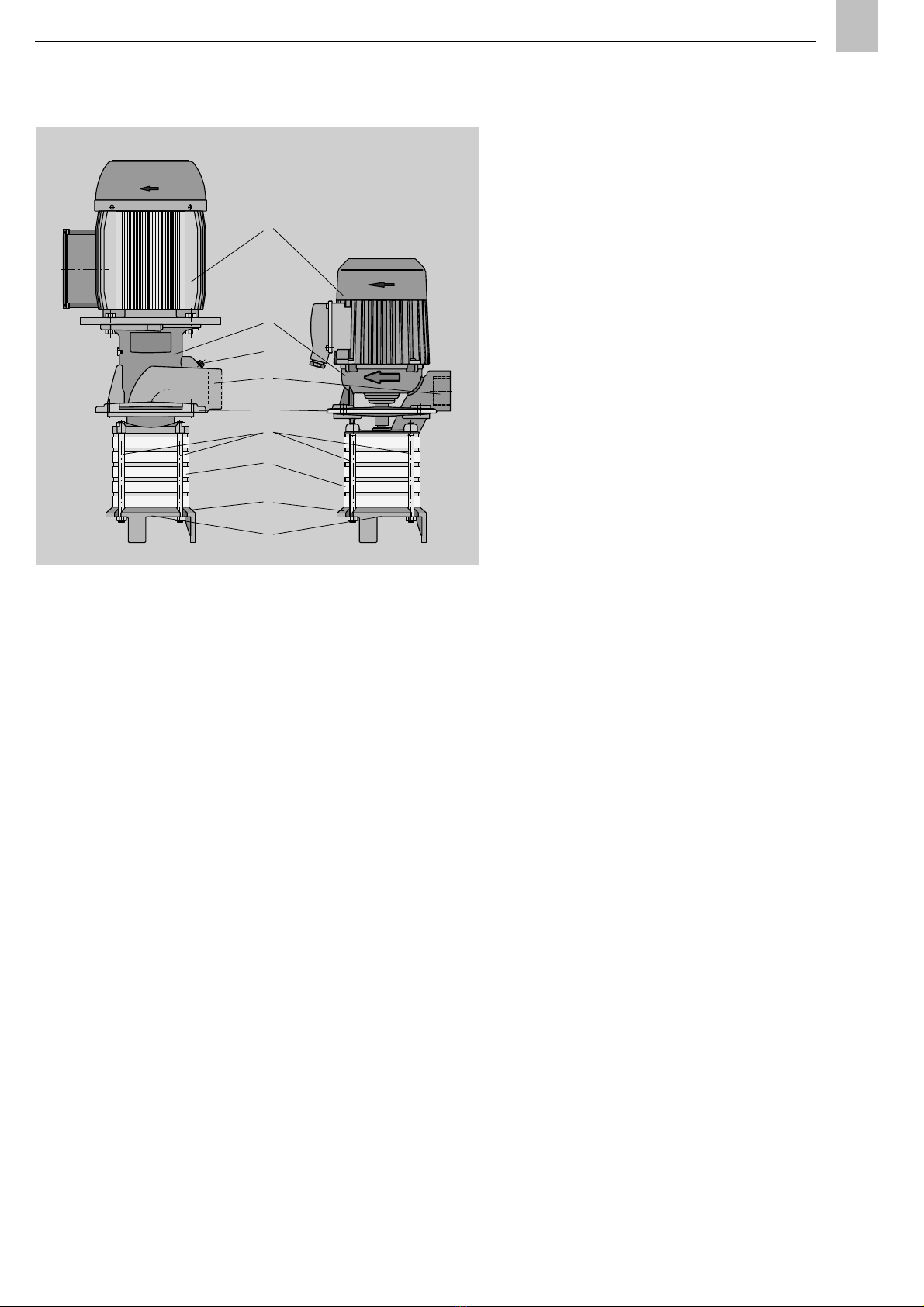

Fig.1 shows the principle design of the p mps PXA

or PXK.

The p mps are sed in s ction operation. They are

designed for vertical installation.

The electric drive (1) is installed on the p mp

connector (2), to which the individ al p mp stages

(7) are fastened by means of tie rods (6).

The connector ho ses the p mp shaft bearing and

the sealing. The press re connection (4) and the

assembly flange (3) for installation on the medi m

container are likewise part of the connector. The

p mp PXA also feat res a venting screw (5) near

the press re connection.

A variable n mber of p mp stages s pplies the

medi mn that is drawn in at the p mp bottom (8)

thro gh the intake opening (9).

Fig.: 1. Design of the

pumps PXA and PXK

1 Drive

2 Pump connector

3 Assembly flange

4 Pressure connection

5 Venting screw (PXA

only)

6 Tie rod

7 Pump stage

8 Pump bottom

9 ntake opening

1

6

5

4

3

2

7

8

9

PXA

PXK

5. Installation instr ction page 12

EN

5. nstallation instruction

The prod ct described in the installation instr ction

may only be installed, operated, maintained, and

repaired by q alified experts. Q alified experts are

persons who have been trained, instr cted, and

familiarized with the end prod ct into which the

described prod ct is installed. These persons are

considered capable of s ch tasks d e to their

ed cation, training, and experience with valid

standards, conditions, accident prevention reg la-

tions, and operating meas res. They are entitled to

carry o t the req ired tasks and to recognize - and

th s avoid - any dangers that might otherwise

occ r.

A definition of what constit tes a q alified person

and information on the prohibition on allowing

work to be carried o t by nq alified personnel are

stip lated in DIN VDE 0105 and IEC 364.

Before assembling/positioning the prod ct, remove

the packaging material and any transportation

safety devices s ch as sealing pl gs. Keep the

packaging material ntil yo are s re that there

are no delivery discrepancies that need to be

clarified.

The prod ct m st not be tipped p or

dropped.

Regional accident prevention reg lations and the

operating and maintenance instr ctions of the

operator m st be observed when carrying o t all

assembly work on machines.

5.1 Positioning and mo nting

Immersion p mps, type PXA and PXK, are

designed for vertical installation inside the medi m

container. If yo need a p mp that can be installed

in a different position, please contact yo r p mp

s pplier.

Before installing the p mp, remove packing

materials and transport safety devices (e.g. blind

pl gs in the intake and press re connections).

The p mp m st be transported only by means of

the transport eyes.

If an intake pipe has been ordered, it is s pplied

separately and m st be screwed seal tight into the

conical thread in the intake ho sing before the

p mp is installed. Select the sealing material in

harmony with the operating conditions and

temperat res.

When installing the intake pipe, ens re that the

sealing material does not enter the interior of the

p mp or the pipe.

To allow installation of the p mp on the container

ho sing, the p mp has a 4-hole installation flange

with standard dimensions (see specifications).

When selecting the installation site, ens re

s fficient space for installation, cabling, inspection

and ventilation. The distance between the air

intake of the motor and walls, components etc.

m st be at least ¼ of the diameter of the air intake

opening. The air flow direction is from the air

intake opening to the p mp.

5. Installation instr ction page 13

EN

Versions:

with empty intermediate chambers

with extension t be

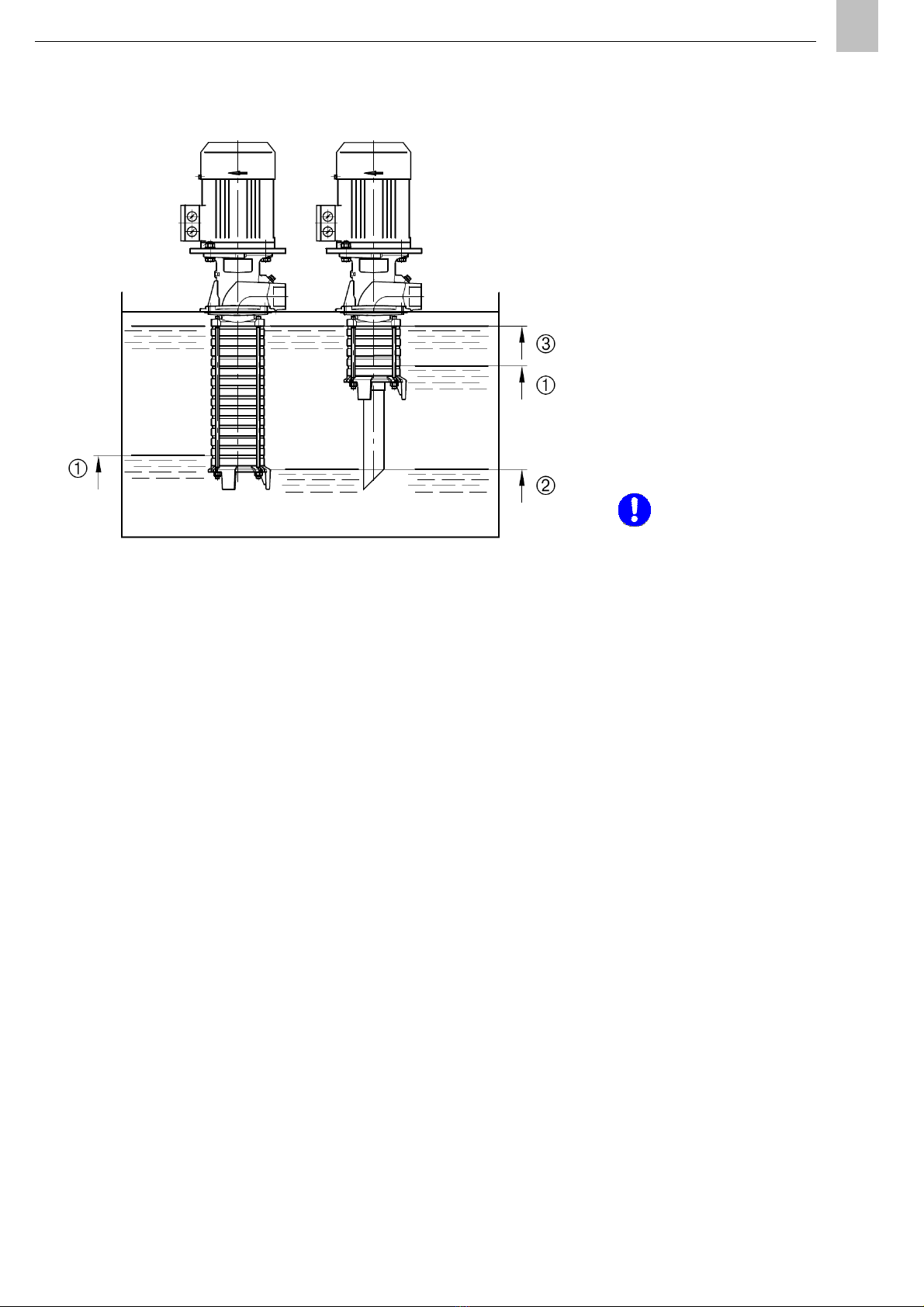

When installing the p mp, take the maxim m and

minim m fl id levels into consideration (Fig.2).

When the p mp is switched on the minim m level

of fl id has to be above the bottommost p mp

chamber

.

The p mp then delivers all the way to the intake in

the chamber or t be

. The maxim m permissible

level of fl id amo nts to 30mm below the

reservoir’s cover

.

The prod ct sho ld be mo nted in a way that

protects it from h midity and vibrations. It sho ld

also be easily accessible so that all other installa-

tion work can be carried o t witho t problems.

Make s re that there is a s fficient amo nt of

circ lating air to prevent the excessive heating of

the prod ct. For information on the maxim m

permitted ambient temperat re, see the technical

data.

The prod ct m st be installed vertically in accor-

dance with the specifications of the c stomer

doc mentation.

If no c stomer doc mentation is

available, c stomer doc mentation can

be req ested directly from SKF

L brication Systems Germany AG.

Fig. 2: different delivery characteristics at the same immersion depth

5. Installation instr ction page 14

EN

5.2 Connecting dimensions

Flange and port dimensions to DIN EN 12157

5.3 Installation of Pipes

When installing pipes, observe the following notes

to ens re tro ble-free f nction of the p mping

circ it:

•All elements of the p mping circ it, s ch as

pipes, sh t-off armat res, valves etc., which

come in contact with the medi m m st be

cleaned caref lly. Inside the lines, seals m st

not protr de toward the interior, to prevent

contaminants from reaching the interior of the

p mp and ca sing damage or destroying the

p mp.

•Use only pipes or hoses which are s itable for

the operating press re of the respective p mp,

the prevailing temperat res and the media to

be p mped.

•The lines m st be connected so that no force

is transmitted to the p mp ( nconstrained

connection). Therefore it is recommended to

install the press re lines to the p mp before it

is fastened to the container cover.

•The flow of the medi m in the lines sho ld not

be obstr cted by sharp bents, edge valves and

ret rn flaps. Unavoidable red ctions of the

line's cross-section m st be softened by

sloping transitions. S dden changes of the

flow direction m st be avoided in any case.

•The lines m st be seal tight and installed in

s ch a way that air may not be sh t in at any

point.

•The pipes sho ld always be laid o t rising. It

sho ld be possible to vent press re lines at the

highest spot.

•The cross-section of the press re line sho ld

at least reach the cross-section of the

press re connection.

5.4 Connection of Pipes

The pipes are connected to the press re ho sing of

the p mp at the connection provided. Ens re that

no force is transmitted to the p mp.

Connect the pipe with a flat face end seal and a

cylindrical thread. If tapered threads are sed, a

s itable sealing material m st be sed.

The screw-in torq e sho ld not exceed 70 Nm,

since the p mp connector may otherwise b rst or

break off.

5.5 Fastening to the Container

Once the press re line has been installed, the

p mp can be fastened to the container at a

maxim m tightening torq e of 15 Nm.

5. Installation instr ction page 15

EN

5.6 Electrical connection

The p mp may be connected only by

properly q alified and instr cted

personnel. Comply with the notes in this

operating man al.

Connect the p mp motor according to the

information on its nameplate considering the

s pply voltage available on site.

For installation, observe the applicable standards,

s ch as VDE 0100, VDE 0101, and VDE 0165, as

well as the req irements of the local energy

s pplier.

Cables and lines m st be fastened to the terminal

box with a cable fitting incl ding strain relief.

Connect the motor according to the electric

diagram in the terminal box of the motor.

If the p mp has been stored for a longer period in

a h mid room, the isolation resistance between

motor winding and p mp ho sing sho ld be

meas red.

At a winding temperat re of abo t 20 °C the

minim m resistance for low voltage motors is 1 kΩ

per Volt rated voltage. If the resistance is lower,

the motor m st be dried in a warm room or with

heating devices, ntil the req ired isolation

resistance is reached.

5.7 Sense of Rotation

The sense of rotation of the motor m st agree with

the arrow on the p mp. To check the sense of

rotation, open the valves in the press re and intake

lines and switch the motor on for a short time

(approx. 1 s).

Wrong sense of rotation will damage the

p mp.

Product name

Centrifugal pump

Product line: PXA… / PXK…

Operating manual

6. Transport, delivery and storage page 17

EN

6. Transport, delivery

and storage

SKF L brication Systems Germany AG prod cts

are packaged as is s al in the trade in

accordance with the reg lations of the recipient

co ntry and in accordance with DIN ISO 9001.

O r prod cts m st be transported with care.

Prod cts m st be protected against mechanical

infl ences s ch as impacts. Transport

packaging m st be labelled with the

information 'Do not drop!'.

The prod ct m st not be tipped p

or dropped.

There are no restrictions relating to land, air, or

sea transportation.

Following receipt of the shipment, the prod ct

or prod cts m st be checked for damage and

the shipping doc ments sho ld be sed to

make s re that the delivery is complete. Keep

the packaging material ntil yo are s re that

there are no delivery discrepancies that need to

be clarified.

The following conditions apply to the storage of

SKF L brication Systems Germany AG

prod cts:

6.1 P mps

•The p mp m st be transported only by

means of the transport eyes (if provided).

•For storage ens re dry, d st-free and low-

vibration (veff 0.2 mm/s) environment.

We recommend to store the nit in vertical

position.

•If stored for longer periods, the sability

period of the grease in the bearings is

red ced.

•If the nit is stored for more than 12

months, the condition of the grease m st

be checked before the nit is taken into

operation. Also, the isolation resistance

between motor winding and ho sing m st

be meas red. If the resistance is 1 k per

Volt rated voltage, the motor winding m st

be dried.

6.2 Electronic and electrical devices

•Ambient conditions: Dry, d st-free

environment; storage in well-ventilated,

dry area

•Storage time: 24 months max.

•Permitted air h midity: < 65%

•Wareho se temperat re: 10 - 40°C

•Light: Direct s nlight/UV radiation m st be

avoided; nearby so rces of heat m st be

screened

6.3 General information

•Ens re that no d st gets into stored

prod cts by wrapping them in plastic film

•Store prod cts on racks or pallets to

protect them from rising damp

•Before placing prod cts into storage,

protect ncoated metal s rfaces - and

drive parts and mo nt s rfaces in

partic lar - from corrosion sing long-

term corrosion protection

•At 6-monthly intervals: Check prod cts for

corrosion. If signs of corrosion are fo nd,

improve the corrosion protection

meas res.

•Drives m st be protected against

mechanical damage

7. Start- p and operation page 18

EN

7. Start-up and

operation

Before taking it into service, all connections at

the p mp m st be checked. Be s re, the intake

and press re connections of the p mp are

nstopped.

The p mp m st r n smoothly and evenly. To

perform checks, yo can remove the fan hood

and spin the p mp shaft several times by

t rning the fan impeller man ally. Be s re to

reinstall the fan hood afterward.

Check the sense of rotation of the p mp pon

start- p. It m st agree with the direction

indicated by the arrow on the press re ho sing.

The container m st be filled with fl id to the

level indicated in section “Set p”.

The p mp m st not r n dry. Wrong

sense of rotation and/or dry r n may

damage the p mp.

Also ens re that no inadmissible dirt is inside

the container or piping system and that the

intake filter works properly.

PXA

Take the p mp PXA into operation as follows:

•Close the sh t-off valve on the press re

side.

•Open the venting screw.

Take care of the direction of the

venting opening points in order to

prevent being hit by escaping fl id.

•Switch on the p mp and check the sense of

rotation. It m st agree with the direction

indicated by the arrow on the p mp

ho sing.

•Open the sh t-off valve on the press re

side a little, allowing the medi m to flow

thro gh.

•Close the venting screw as soon as fl id

drools from the valve.

•Now yo can open the sh t-off valve on

the press re side.

PXK

Take the p mp PXK into operation as follows:

•F lly open the sh t-off valve on the

press re side - if installed - and ens re the

press re connection is nstopped.

•Switch on the p mp and check the sense of

rotation. It m st agree with the direction

indicated by the arrow on the p mp

ho sing.

•Let the p mp r n ntil a stable s pply

condition is reached or no more air b bbles

are visible in the medi m.

•Now yo can adj st the req ired s pply

vol me sing the sh t-off valve on the

press re side.

The p mps sho ld be operated on a contin o s

basis whenever possible. If, for example, that is

not possible for technical reasons, constant

p mp delivery can be reg lated by an control

valve or the like.

If the p mp is to be operated intermittently at

short intervals, please contact the s pplier for

cons ltation.

8. Sh tdown page 19

EN

The p mp m st be operated only within the

defined o tp t range. The respective

identification data is given on the nameplate of

the p mp.

When the p mp operation is interr pted, the

minim m fl id level may drop to the intake

opening. However, ens re that the fl id level

will not drop f rther d ring operation, since the

p mp will otherwise r n dry.

When the p mp stands still, the filling level

m st not drop below the val e indicated in

chapter “Assembly” in section “Set p”.

Otherwise the p mp might r n dry when the

p mp starts and the filling level drops.

The p mp m st not r n dry, since it

may otherwise be damaged.

8. Shutdown

8.1 Temporary sh tdown

Yo temporarily sh t down the described

prod ct by disconnecting the electrical,

pne matic, and/or hydra lic s pply

connections. For more information, see the

section 'General information' in this installation

instr ction.

If yo wish to sh t down the prod ct for a

longer period of time, refer also to the

instr ctions in the section 'Transport, delivery,

and storage' of this installation instr ction.

When placing the prod ct back into operation,

pay attention to the information in the sections

'Assembly' and 'Start- p of this installation

instr ction.

8.2 Definitive sh tdown

All regional legal g idelines and legislation on

the disposal of contaminated eq ipment m st

be observed when sh tting down the prod ct

for the final time.

L bricants can contaminate the

gro nd and waterco rses.

L bricants m st be sed and

disposed of properly. Regional

reg lations and laws on the se and

disposal of l bricants m st be

observed.

In exchange for the inc rred costs, SKF

L brication Systems Germany AG can take back

the prod ct and arrange for its disposal.

9. Maintenance page 20

EN

9. Maintenance

9.1 General notes

Working on prod cts that have not

been disconnected from the power

s pply can ca se inj ry to persons.

Assembly, maintenance, and repair

work may only be carried o t by

q alified experts on a prod ct that is

not connected to a power s pply.

The s pply voltage m st be

disconnected before any prod ct

components are opened.

The described prod ct is nder

press re when it is being operated.

The prod ct m st therefore be

depress rized before starting

assembly, maintenance, or repair

work and before making any

changes to the system.

Immersion p mps, type PXA or PXK, are largely

maintenance-free. To ens re perfect f nction,

yo sho ld check the p mp reg larly for

exterior damage or leakage.

The medi m p mped as well as intake filters

and screens sho ld be checked reg larly for

contamination and sho ld be cleaned or

replaced as needed.

Also, ens re that the ho sing of the p mp

motor remains free from d st, foreign objects

etc., to ens re good heat exchange between

motor and ambient air for nhindered s rface

heat dissipation.

All electrical connections and lines m st be

checked reg larly for damage and to ens re

that they are firmly in place.

Any fa lts fo nd m st be properly rectified

before the p mp is activated again.

Yo m st not dismantle the prod ct

or parts therefore d ring the

stat tory g arantee period. Doing so

invalidates all g arantee claims.

Only original SKF L brication

Systems Germany AG spare parts

may be sed. Yo m st not carry o t

alterations to the prod ct or se

non-original spare parts or

reso rces. Doing so invalidates the

stat tory g arantee.

SKF L brication Systems Germany AG is not

liable for damage ca sed by improper

assembly, maintenance, or repair work.

This manual suits for next models

5

Table of contents

Other Spandau pumpen Water Pump manuals

Popular Water Pump manuals by other brands

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MM..D Series Addendum to owner's manual

Zoeller

Zoeller 503 Installation guides

Coleman

Coleman 120V QuickPump How to use and enjoy

BRINKMANN PUMPS

BRINKMANN PUMPS SBA1600 operating instructions

Ismatec

Ismatec MCP-CPF Process operating manual

KSB

KSB RPH Series operating instructions

Ceco

Ceco Sethco 2500 Series Operation manual

SPX

SPX Johnson Pump F2P10-19 1/2 slang 12 V instruction manual

Graco

Graco Check-Mate 450 Instructions-parts list

Graco

Graco 231169 Instructions-parts list

Gardena

Gardena 1490 operating instructions

Wilo

Wilo VeroLine-IPH-O Installation and operating instructions