Sparktacular FX Machines SparkOne User manual

OWNERS MANUAL

877-792-1101 • SparktacularFXmachines.com

COLD SPARK TECHNOLOGY

Warnings and Cautions

Designed to alert you to potential hazards and important information to assist with carrying out activities

on this machine safely and efficiently. Examples and descriptions of safety statements have been provid-

ed as follows:

Warning: A warning alerting to harmful or potentially dangerous activities. A suggestion is given to

prevent accidents. DO NOT ignore this advice.

Please note that the SparkOne Machines must be operated using time intervals. The maximum opera-

tional running time is 90 seconds per single discharge cue. If the maximum operational running time of 90

seconds is used, a 1-3 minute interval in between cues is recommended.

Eye Protection

While the SparkOne Machine is in operation it is advised that those in proximity to the fallout area wear

safety glasses. If the material enters the eye, flush thoroughly with water.

Voltages

Warning: High voltages are present in the machine and controller when electrical power is present. There

is a danger of injury from electrical shock. Under no circumstances are you permitted to, or should you

attempt to dismantle the machine and/or controller or attempt to remove or adjust any components fitted

within/to the machine and/or controller. ONLY FULLY TRAINED SPARKTACULAR SERVICE ENGI-

NEERS ARE QUALIFIED TO DIAGNOSE AND MAINTAIN THE MACHINE AND CONTROLLER.

Customers who open their machines will have their warranty VOIDED.

Caution Against Liquids

Warning: The machine should never be exposed to wet conditions. Keep the machine and controller dry

and do not use on rainy or snowy days unless covered. Do not leave the machine exposed to excessive

humidity.

Warning Fountain Nozzle

Please make sure no debris drops into the fountain nozzle of the SparkOne unit. If debris enters the

nozzle, clean out all debris before resuming normal operation. Uncleared debris can cause the machine

to malfunction and present an increased risk of fire or overheating. DO NOT cover the fountain nozzle or

ventilation.

Warning on Granules - Extinguishing Methods

If the granules ignite, the suggested method of extinguishing is by a Class D extinguisher or sand. If

granules are activated DO NOT try to empty the SparkOne unit as the rush of air will initiate the granules

into a spark. DO NOT use water-based or ABC extinguishers to put out granules. If granules are poured

into the fountain nozzle, DO NOT SHOOT THE MACHINE! Contact Sparktacular FX Machines immedi-

ately for further assistance

SAFETY

.

Safe Distance

The minimum recommended safe distance for performers is 6-10 feet. For audiences a minimum safe

distance of 12-15 feet is required. Flammable materials need to be kept at a distance of 15 feet. Keep the

SparkOne machine out of reach of the public and children. Ensure the machine is protected from flamma-

ble materials.

Warning Temperature

NOTE: DO NOT CHANGE THE TEMPERATURE ON THE BACK OF THE MACHINE WITHOUT CON-

SULTING WITHA SPARKTACULAR FX SAFETY TECHNICIAN. Granules are affected by the tempera-

ture and under on circumstance shoule altered. Pleae refer to the temperature chart for granule size and

machine model.

Warning Firing Effect

Do not touch the sparks when the machine is operating. The sparks created from the machine should

never be touched. Use the appropriate safety distance mentioned in Safe Distance section.

In Case of Emergency

If an emergency arises in which the SparkOne machine(s) needs to be shut off immediately, hit the “Stop

All” button on the touch screen controller to stop operating and turn the key to the "safe" position. Turn off

all high voltage inside the SparkOne unit. The machine will still be connected to the console and turned

on but only the low draw DMX brain has power.

Noise Emission

The noise that emits from the SparkOne Machine does not exceed 80db. This means that the machine is

not harmful to hearing. Hearing protection is not required while operating, using, or standing near the

SparkOne machine.

Cleaning

Before operating the SparkOne machine some checks must be done to keep the machine running at

optimal performance. Before each use inspect the fountain nozzle. Make sure that there are no burnt

granules building up in the fountain nozzle. To clean the unit, if there is debris in the tub, invert and shake.

If the buildup does not break loose, a cleaning brush is recommended to remove the buildup. Before and

after every use you must go through the clear material process to ensure granules do not build up inside

the machine, which will prolong the life of the machine.

Power Supply Requirement

Please be sure to use the correct connector according to the operating power of the SparkOne unit. All

USA models are 110V. European and other international models are 220V. If necessary, connect directly

to a power distribution box with separate cables. Please note: one power cord can support a maximum of

2 SparkOne units (One 20-amp circuit can handle the 2 units). Each unit can be powered individually, or

daisy chained together with the powercon series cables provided.

SAFETY

TABLE OF CONTENTS

SparkOne Model (SH-03B) 1

Safety and Warnings Read Prior to Use 2 - 3

Introduction of SparkOne System 4 - 5

Operations Panel 6

Interface 7 - 8

Operations 9 - 11

2 - Instructions

The SparkOne system has two main components, the SparkOne SH-03B and the Pyro Sim Controller. The

SparkOne SH-03B has all safety features built into the smart feedback protocol, which is viewable on both the

SparkOne unit itself and the Pyro Sim Controller.

NOTE: IF THE SPARK ONE UNIT IS CONNECTED DIRECTLY THROUGH DMX AD DOES NOT RUN

THROUGH THE HOST CONTROLLER, THE FEEDBACK CANNOT BE ACCESSED OR VIEWABLE ON THE

DMX CONTROLLER.

3 - Brief Introduction of the Functions

a - The SparkOne is controlled through the DMX 512 standard. The SparkOne machine is designed to work on 2

DMX channels or 4 DMX channels. (selectable on unit and controller)

b - The effect is adjustable by height, density, and duration.

c - Adjustable effect height- SparkOne currently has 4 height increments. Heights are dependent on granule size

being used. Please speak to a Sparktacular FX Machines representative about granule sizes.

NOTE: HEIGHT INCREMENT LEVEL 1 IS INACTIVE. THE LOWEST HEIGHT INCREMENT BEGINS ON

HEIGHT INCREMENT 2 AND GOES THROUGH HEIGHT INCREMENT 5

d - The machine has continuous feedback when connected to the host controller for overheating protection and

redundant safeties when connected to the Pyro Sim Controller.

e - The Pyro Sim Controller can display feedback from the SparkOne unit and diagnose its working status with

error codes.

1 - Description of Products

SparkOne is a revolutionary and innovative pyrotechnics simulation machine. It uses a newly designed

delivery control system for a fountain style special effect that uses DMX communication and is compatible

with other DMX controlled equipment.

SparkOne Unit

Dimension: 8.12” × 8.59” × 9.68”

Weight: 17.0lbs

Input: AC 100-120V/60Hz/5.5A

AC 200-240V/50Hz/2.7A

Power: 600W

Work Temp.: 968 F- 1040 F

Casing: Galvanized Metal

Fountain Height: 6.5’ – 17’

Hopper Capacity: 150g

Lifetime: >3 years

Interface type:double DMX input

interfaces, double AC power interfaces

4 - DMX512 Signal Link

When using DMX512 mode, the signals among those units are in parallel. The Shielded-Twisted-Pair cable must

be applied when connecting multiple units. Each unit is connected through the DMX signal receptacles (XLR

connector) Input and Output, and the three pin XLR plug terminals connecting the unit must be corresponding to

each other. While connecting communication cables, it is suggested to use DMX signal terminal to avoid signal

weakening caused by the signal reflection. DMX signal terminal is a three pin XLR plug with 120ohm/1m resis-

tance. The terminator should be plugged into the DMX out port of the last unit being used.

The configuration of the three Pin XLR Plug: 1 Signal Ground line; 2 Signal-; 3 Signal+

NOTE:

ATTENTION!!! SparkOne unit automatically heats once powered on. Press “HEAT” two times until

“STOP HEAT” is read across the digital screen.

After turning on the SparkOne unit, press the “Heat” button on the Pyro Sim Controller. SparkOne will

then begin to warm up to working temperatures. Please allow 3-4 minutes for the units to heat up. When

the READY sign on the back of the SparkOne unit turns solid green, it indicates that the SparkOne is

ready. Additionally, the temperature displayed on the digital screen of the Pyro Sim Controller will turn

solid green indicating the SparkOne is ready.

The key must then be turned to the ARM position to activate shooting. Turning the key from the “ARM”

position to the “SAFE” position will stop the effect immediately.

To prevent anything from effecting cool down or impeding operation, do not cover the fountain nozzle,

top or sides of the SparkOne unit. Please allow room around the machine for air to flow and air vents to

breathe.

Please add granules if you observe the machine producing inconsistency in effect appearance. DO NOT

pour granules in chamber while machine is active.

SparkOne Unit

Operations Panel

ON

OFF

DMX IN DMX OUT POWER IN (12.OA)

FUSE

6.3A 250V

POWER OUT (6.5A)

POWER

READY

MENU DOWN UP ENTER

DMX FAULT HEAT

SPARK

PACK

Manufacturer Importer:

Sparktacular FX Machines

17698 Bee Line Hwy

Jupiter FL 33478 USA

Model: SW05

877.792.1101

sparktacularFXmachines.com

100 - 120V 60 Hz 600W - 5.5 A

Dim: 208 x 218x 246mm

Weight: 7.5Kg

Minimum 10ft distance from audience. Subject to local authority requirements.

Au moins 3 mètres de distance du public La reglementation de la

distance finale est réservé aux pompiers locaux

WARNING: Hazardous voltage inside, please do

not remove cover except by trained personnel.

Avertissement: Tension dangeriuse á l´int é rieur,

ne pas enleverle couvercl, sauf par un personnel form é

MADE IN CHINA

Maximum allowable cascade: 3 Pieces

Cascade maximale autoris é e; 3 pièces

Caution: Machine produces sparks • Attention: La machine produit des étincelles

TM

TM

SCAN CARD HERE

READY

The indicator will change from

flashing to solid status after heating

is completed. The machine will enter

ready-to-operate status.

LCD

Displays user

DMX

Solid LED means DMX

communication is successful. If

LED is not flashing it means

communication is unsuccessful.

FAULT

When this LED is lit, there is a fault

code. Look at LCD screen to see what

error code is displayed.

HEAT

: LED is lit when the system is

fully heated

UP

Increase parameter

MENU

Select to enter into menu

Radio Frequency Identification

Each packet of Spark Pack granules comes with an RFID card that has 12 minutes of shot time on it. This card gets

scanned (touched) to this area. When scanned successfully, the machine display will darken, then light up and display the

new time remaining after the ready light flashes once. This process is used to initialize the machines on first use and is

performed every time the machine is low on time. (E4) The time is put onto the machine, and the clock will run when the

machine is shooting. The card is single use only. The maximum amount of time allowed to be scanned onto the machine is

30 minutes of shot time. If the RFID card has already been used or is faulty, the ready light will flash rapidly, and the display

will not flash or display remaining time.

ON OFF SWITCH

FAN

DOWN

Decrease parameter

ENTER

Confirm and save

parametersdisplayed.

POWER IN

SH-03B is 110Vac

blue/gray Powercon

connector

DMX IN

SH-03B 110Vac

DMX Communication Cable

DMX OUT

SH-03B 110Vac

DMX Communication Cable

POWER OUT

SH-03B is 110Vac blue/gray

Powercon connector

CONTROL BUTTON AREA

CARD SWIPE AREA

LED

INTERFACE PLUGGING AREA

Main Interface

• Displays DMX Address.

• Displays the present temperature of the inner core.

• Displays the error information if any.

Interface

E0 System IC Systematic error. Power cycle machines

E1 Motor Protect Over current protection of the motor. Power cycle machine

E2 Temp. Sensor Temperature sensor is not connected or damaged

E3 P Temp. Over The equipment stops due to the over-heat of the chassis

E4 Time Remain The SparkOne is low on shot time remaining

E5 K Temp. Over The equipment stops due to overheating of the heating assembly

E6 Heating Failure Heating system may have issues. Please power cycle when this error

happens. If the error still persists, try E-stopping the system.

If problem still persists, call Sparktacular

E7 Tip Over The equipment stops due to tip over.

ERROR CODE DESCRIPTION

The Interface Setting

Press “MENU” button to enter the interface to set either temperature or DMX address. Each time the MENU button

is pressed, the interface will show different setting options before returning to main interface

Set Temperature 550 C Set Temperature (should be on 550 C for Spark One)

Set DMX Address 1-512 Set DMX address

Set DMX channel mode 2 or 4 Set DMX Channel

Channel

OPTION ILLUSTRATIONSCOPE

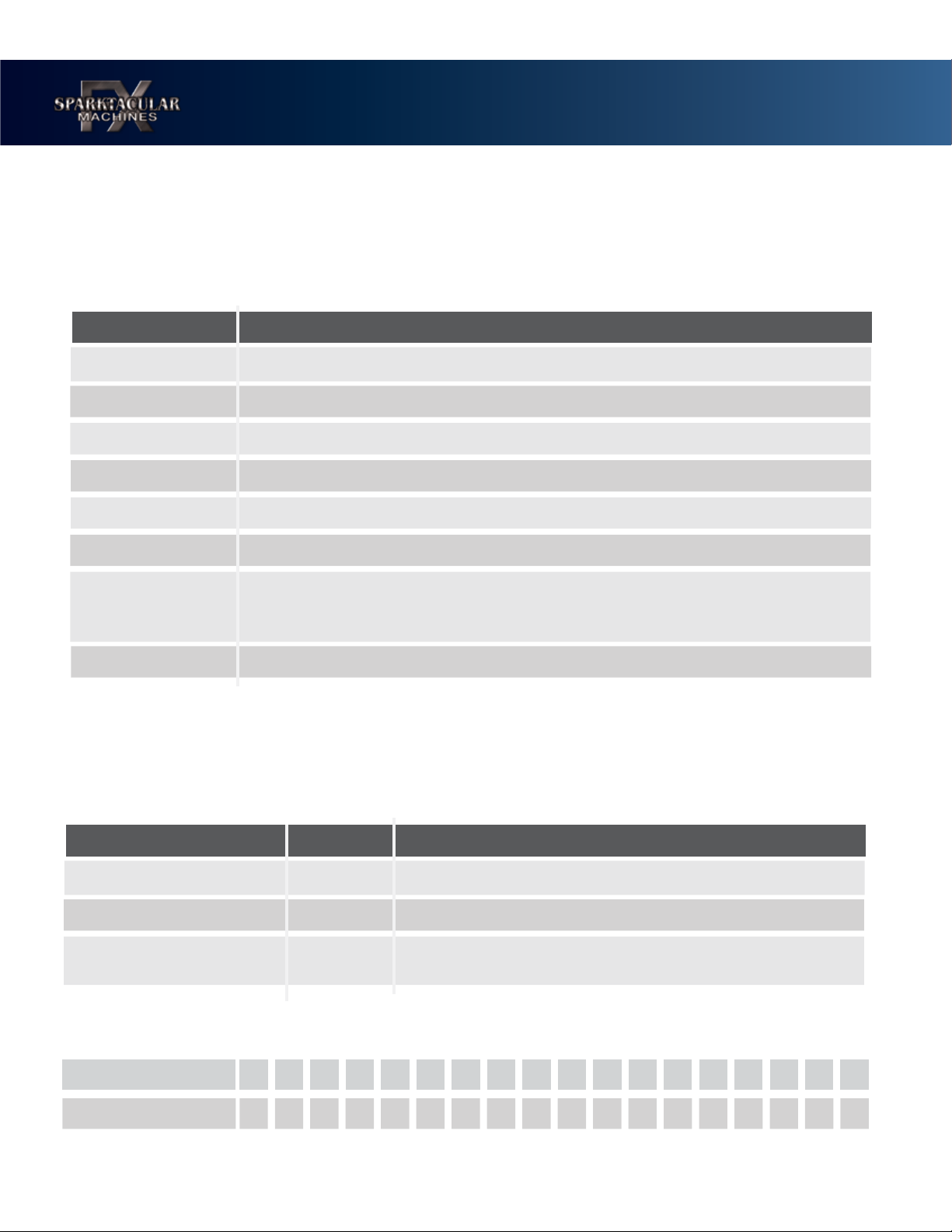

The following chart is for the 2 channel settings:

SparkOne No.

DMX Address

1234567891011 12 13 14 15 16 17 18

1357911 13 15 17 19 21 23 25 27 29 31 33 35

Interface

DMX Channel Mode:

2 DMX Channel, when the system occupies two channels.

Stop

Fountain Height 1

Fountain Height 2

Fountain Height 3

Fountain Height 4

0-39

40-90

91-140

141-190

191-255

FUNCTION

FIRST

CHANNEL

Pre-heat Off

Emergency Stop

Pre-heat Off

Clear Material

Pre-heat On

0-10

20-40

60-200

240-255

FUNCTION

SECOND

CHANNEL

Clear Material Off

Clear Material On

Stop

Fountain Height 1

Fountain Height 2

Fountain Height 3

Fountain Height 4

0-39

40-90

91-140

141-190

191-255

FUNCTION

FIRST

CHANNEL

Pre-heat Off

Pre-heat On

0-20

21-25

0-20

21-255

Emergency Stop Off

Emergency Stop On

0-20

21-255

FUNCTION

SECOND

CHANNEL

FUNCTION

THIRD

CHANNEL

FUNCTION

FOURTH

CHANNEL

DMX Channel Mode: 4 DMX Channel, when the system occupies four channels

Advanced Interface

Set Temperature 520-560 Default setting 550

Density@ Height 1 Adjusts the Value of the Granular feed or density #1*

Density@ Height 2 Adjusts the Value of the Granular feed or density #2*

Density@ Height 3 Adjusts the Value of the Granular feed or density #3*

Density@ Height 4 Adjusts the Value of the Granular feed or density #4*

OPTION ILLUSTRATIONSCOPE

***Density of granules at each height can be adjusted at 50%,75%,100%***

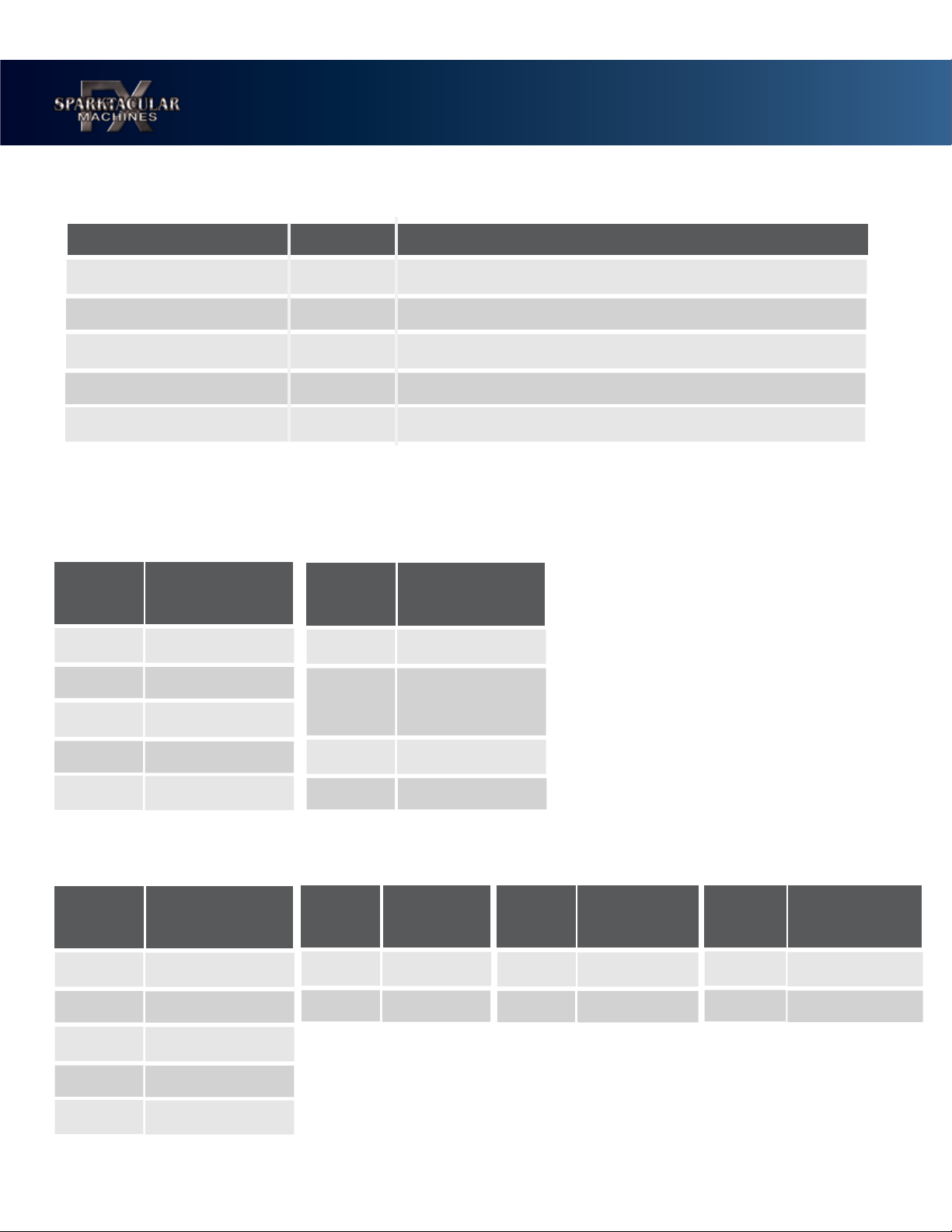

System Preparation and Start

Fill the SparkOne units with granules

Fill granules into the hopper on the top of SparkOne unit. The hopper has a maximum storage capacity of 150

grams of granules.

Please Note that there are 2 sizes of the granules 1) Medium and 2) Large. They are of different meshes, and the

effect height varies from 6.5ft to 17 feet depending on what granule size is used.

Operating

GRANULES

Remove chamber top plug and pour

granules into granule chamber.

Insert chamber

plug back into

the chamber

after pouring

the granules.

TOP VIEW

WARNIG!!! DO NOT POUR GRANULES INTO PORT

SPARK

PACK

1 Fill the unit with granules

To activate the SparkOne unit, the

RFID card needs to be scanned at

the closest possible distance. Once

activation succeeds, the remaining

usage time of the machine will be

displayed on the screen.

Operating

ATTENTION!!!

READ PYRO SIM MANUAL

PRIOR TO USE

ON

OFF

DMX IN DMX OUT POWER IN (12.OA)

FUSE

6.3A 250V

POWER OUT (6.5A)

POWER

READY

MENU DOWN UP ENTER

DMX FAULT HEAT

SPARK

PACK

Manufacturer Importer:

Sparktacular FX Machines

17698 Bee Line Hwy

Jupiter FL 33478 USA

Model: SW05

877.792.1101

sparktacularFXmachines.com

100 - 120V 60 Hz

600W - 5.5 A

Dim: 208 x 218x 246mm

Weight: 7.5Kg

Minimum 10ft distance from audience. Subject to local authority requirements.

Au moins 3 mètres de distance du public La reglementation de la

distance finale est réservé aux pompiers locaux

WARNING: Hazardous voltage inside, please do

not remove cover except by trained personnel.

Avertissement: Tension dangeriuse á l´int é rieur,

ne pas enleverle couvercl, sauf par un personnel form é

MADE IN CHINA

Maximum allowable cascade: 3 Pieces

Cascade maximale autoris é e; 3 pièces

Caution: Machine produces sparks • Attention: La machine produit des étincelles

TM

TM

SCAN CARD HERE

2 Power On Controller

4 Activate Machie

3 Power On SparkOne

POWER

IN OUT

5 Start system

After setting parameters, please turn key from “safe’ to “arm”. Press the “Fire” button to start SparkOne. Files can be selected

manually or can be selected in any of firing Modes. There are 8 file modes per effect file that can be programmed and selected.

Once units are firing, the only buttons that will work are “stop all” on the digital screen and the “fire” button. Turning the key from

“arm” to “safe” during the firing of the effect will immediately stop the firing of the effect.

5 Shut off system

After completing the clear material procedure, allow 30-40 minutes for SparkOne units to cool down. Allowing

the SparkOne units to cool down is a MUST to prevent damage to the inside of the machine. Once SparkOne

units have returned to idle temperatures, they may be placed back in their road cases or housing. Invalidating

the HEAT button and keeping the unit on will speed up the cooling process. Never place your fingers or any

objects in the fountain nozzle

6 Clear Material

CLEAR MATERIAL MUST BE PERFORMED AFTER EVERY USE TO AVOID DAMAGE!!!

• Switch power off on SparkOne unit. Remove chamber cap on top of the machine and have containment material in place for the

granules (can be a piece of paper, bag, jar, etc).

• Turn the SparkOne upside down and empty remaining granules in chamber. Once chamber is clear of remaining granules, place

SparkOne upright and reattach the chamber cap.

• Switch power on and make sure HEAT is turned on (HEAT must be activated to run clear material procedure.)

.

• Press the FIRE button to shoot one last “LIVE” shot. Allow the last “LIVE” shot to run until granules are no longer exiting the

fountain nozzle (this can take up to 30 seconds depending on granules lodged in the tract of the SparkOne).

• After firing the last “LIVE” shot, press CLEAR MATERIAL button on Pyro Sim Controller. Allow for CLEAR MATERIAL to run for

30-40 seconds or until granules are no longer exiting fountain nozzle. --Once granules are no longer exiting the fountain nozzle,

please turn HEAT off to begin cool down period.

Warning: Please follow this process to clear materials and extend the life of your machine.

Please store the unused granular materials in a container (such as a glass jar) or sealed bag and store in a cool, dry area. The

SparkOne Granules should not be exposed to humid environments for long durations of time. If necessary, dispose of the granular

materials by burning. Make sure granules are clear of foreign matter and refilled back into hopper when using the machine to

dispose of excess granules.

Operating

Table of contents