Metal Work FLUX 0 User manual

FLUX 0

DIGITAL FLOWMETER AND PRESSURE SENSOR

USER MANUAL

2

3

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-1-

KFP01 Series Instruction Manual

Product Safety Instructions

■

This section indicate the levels of risks with the labels of Danger, Warning and Caution.

Danger indicates high level of risk, will lead to fatal or serious injuries if not

avoided.

Warning indicates medium level of risk, it might cause death or serious injuries.

Caution indicates low level of risk, it might result in minor injuries, such as scald,

electric shock, etc. and the product, equipment and machines might be damaged.

Danger

Warning

Warning

Caution

■

Precautions for use

Operated within the specified voltage.

Malfunction or damaged product, electric shock or fire may

be resulted by exceeding the specified voltage range.

Do not exceed the maximum load current.

It may damage the product.

Do not use any load that generates surges.

Surge protection is present but applying surge voltage

repeatedly will ultimately damage the product.

When using with inductive load (such as relay or solenoid),

please install a flyback diode across the load (polarity must

be observed).

Observed the internal voltage drop.

When used at a specified voltage, if the sensor is functional

but the load does not work, please check if the operating

voltage of the load meets the following formula.

Power Supply – Internal voltage > Minimum operating

voltage drop of sensor voltage of load

Do not operate the product outside the specifications.

The sensor will be damaged by exceeding the flow rate and

working pressure.

Do not use flammable fluids and/or permeable fluids.

They may cause fire, explosion or corrosion.

➀

➁

➂

➃

➄

➅

■Working fluid and working environment

Do not use in an explosive gas atmosphere.

The sensor does not have explosion-proof structure, fire,

explosion or corrosion can result.

Do not use near a surge voltage generated area.

Solenoid lifters, high frequency induction furnaces and

motors, etc. can generate high surge voltages, if using near

the sensor will cause the internal circuit components to

deteriorate and cause damages.

Sensors can not withstand lightning strikes.

The product is CE compliant, but can not resist surge

voltage of lightning strikes, take measures to avoid

lightening strikes in the system.

Do not use in an environment where sensors could

be splashed by water or oil.

Enclosure rating is IP40, please avoid water or oil splashed

environment to prevent adversely effects.

Do not use in an environment subject to large

temperature cycling.

Internal components of the sensor will be affected adversely

by large heating/cooling cycles other than ordinary changes

in temperature.

Do not mount the product in locations where it is

exposed to radiant heat.

This could result in damage and/or malfunction.

➀

➁

➂

➃

➄

➅

4

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-2-

KFP01 Series Instruction Manual

■Installation Precautions

Ensure the flow direction of the fluid.

Please follow the flow direction indicator for installation and

piping.

Flush out all dirt and dust by air blow before connect

the piping to the sensor.

Do not drop or hit.

When installation, do not drop, hit or apply excessive shock

(100m/s2). Internal damage can cause malfunction even if

the housing appears to be undamaged.

Do not install multiple products in close proximity.

The heat generated from each product could cause the

temperature to rise and change the characteristics of

product or deterioration of the plastic parts. Please set the

products 10mm apart from each other.

Hold the sensor body when installing.

The tensile strength of the cable is 24.5 N and apply

excessive pulling force can cause damage to the sensor.

➀

➁

➂

➃

➄

■Other Precautions

After power is supplied, the output will remain off until

the display is turned on. Please operate the sensor

after the value is shown.

Stop the control systems before perform setting

changes.

During the initial flow and pressure setting, the product will

switch the output according to the existing settings until the

changes are complete.

➀

➁

■Installation Precautions

Please follow the specified tightening torque.

Over tighten will damage the product.

Do not mount the sensor in a place that will be used

as a foothold.

The product may damage if sit or step on it accidentally.

When mounting without a bracket, please use P type

self-tapping screw- M3 x L 6mm.

Do not remove the fixed pin for the One-Touch Fitting.

To avoid losing the internal parts and cause malfunction.

➀

➁

➂

➃

■Maintenance Precautions

The accuracy could change by 2 to 3% when the

piping is removed or replaced.

Do not insert a stick or wire into the piping ports.

Do not touch the terminals or connectors when power

is on.

➀

➁

➂

■Wiring Precautions

Check wire color and terminal number when wiring.

Incorrect wiring can cause permanent damages to the

sensor, check wire color and terminal number against the

manual before wiring.

Avoid repeatedly bending or stretching the lead wire.

It can cause damage to the sheath, or breakage of the

wire.

Confirm wiring insulation

Please avoid poor insulations (and interference from

another circuit, poor insulation between terminals, etc.) it

can lead to over current being applied to the product,

causing damage.

Do not route wires and cables together with power or

high voltage cables.

The product may malfunction due to interference or noise

and surge voltage from power and high voltage cables.

Do not short-circuit the load.

When the load is short-circuited, an error will be displayed.

But excess current may cause damage to the sensor.

Do not connect wire when the power is on.

It may cause damages to the sensors/equipment/machines.

➀

➁

➂

➃

➄

➅

Warning

Caution

5

KFP01 Series Instruction Manual

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-3-

■

Fluid

Disclaimer

Check the regulator and flow adjustment valve before

introducing the fluid.

If the pressure or flow rate exceeded the specified range,

the sensing element may be damaged.

Recommended Equipments and Installation

Recommended Equipments and Installation Example

Our warranty applies solely to our product, not to any other damages and injuries which occur by earthquakes,

fires, the acts by third party, other matters, acts intentionally, acts accidentally, misuse, or other abnormal conditions

that are not the responsible of KITA.

Our warranty applies solely to our product, not to any other additional damages (the loses of business profits,

business interruption, etc.) incurred due to using or misusing the product.

Our warranty excludes any injuries and damages happened by using the product beyond the specified range of

catalog or/and not following the instruction manual.

➀

The sensing element cannot measure properly if

foreign matter adheres to it.

On the inlet side, be sure to install an air filter below

the filtration level of 10um.

➁

➂

➃

➀

➂

➁

➄

KFP01 Series

Pressure Sensor

Flow Sensor

Or

Flow Sensor

KFP01 Series

Pressure Sensor

Or

Air Source

Filter

Regulator

Micro Mist Separator

(Oil Mist Filiter)

Air Dryer

KFP01 Series

Flow Sensor

Pressure Sensor

※NOTE:

When measuring the pressure of the inlet side, install a throttle valve or solenoid valve on the outlet side.

When measuring the pressure of the outlet side, install a throttle valve or solenoid valve on the inlet side.

Inlet

Outlet

Air Source

Filter

Regulator

Micro Mist Separator

(Oil Mist Filiter)

Air Dryer

Inlet

Outlet

Throttle Valve

※NOTE:When measuring the pressure of the inlet side, install a throttle valve or solenoid valve on the outlet side.

※NOTE:When measuring the pressure of the outlet side, install a throttle valve or solenoid valve on the inlet side.

Air Source

Filter

Regulator

Micro Mist Separator

(Oil Mist Filiter)

Air Dryer

Throttle

Valve

Inlet

Outlet

Warning

6

7

INDEX

1. INSTALLATION PAGE 8

1.1 PIPING PAGE 8

1.2 MOUNTING BRACKET / OPTIONAL PARTS PAGE 9

1.3 WIRING DIAGRAMS PAGE 10

1.3.1 PNP Output, analog output and external input PAGE 10

2. HOW TO USE PAGE 11

2.1 NAMES AND FUNCTIONSOF INDIVIDUAL PARTS PAGE 11

2.2 FUNCTION INSTRUCTION PAGE 12

2.3 OPERATION INSTRUCTIONS PAGE 13

2.3.1 [F-01] OUT1 Setting selection PAGE 14

2.3.2 [F-02] OUT2 Setting selection PAGE 19

2.3.3 [F-03] LCD Display color selection PAGE 20

2.3.4 [F-04] Response time selection PAGE 21

2.3.5 [F-05] Display refresh time selection PAGE 23

2.3.6 [F-06] Unit selection PAGE 25

2.3.7 [F-07] Flow reference standard selection PAGE 26

2.3.8 [F-08] Analog output selection PAGE 27

2.3.9 [F-09] Accumulated value hold selection PAGE 28

2.3.10 [F-10] Flow sensor display mode selection PAGE 29

2.3.11 [F-91] Power-save mode selection PAGE 30

2.3.12 [F-92] External input selection PAGE 31

2.3.13 [F-94] Fine adjustment setting PAGE 32

2.3.14 [F-95] Forced output function PAGE 34

2.3.15 [F-99] Reset to the default setting PAGE 35

2.3.16 Pressure zero adjustment function PAGE 36

2.3.17 Instantaneous flow zero adjustment function PAGE 37

2.3.18 Reset accumulated flow function PAGE 38

2.3.19 Peak value display PAGE 39

2.3.20 Bottom value display PAGE 40

2.3.21 Key lock / unlock mode PAGE 41

3. ERROR CODE INSTRUCTION PAGE 42

4. TECHNICAL DATA PAGE 43

5. THERMAL MASS FLOW SENSOR PRINCIPLES PAGE 44

6. DIMENSIONS PAGE 45

7. CONSTRUCTION PAGE 45

8

1. INSTALLATION

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-5-

Installation

KFP01 Series Instruction Manual

1Installation

1.1 Piping

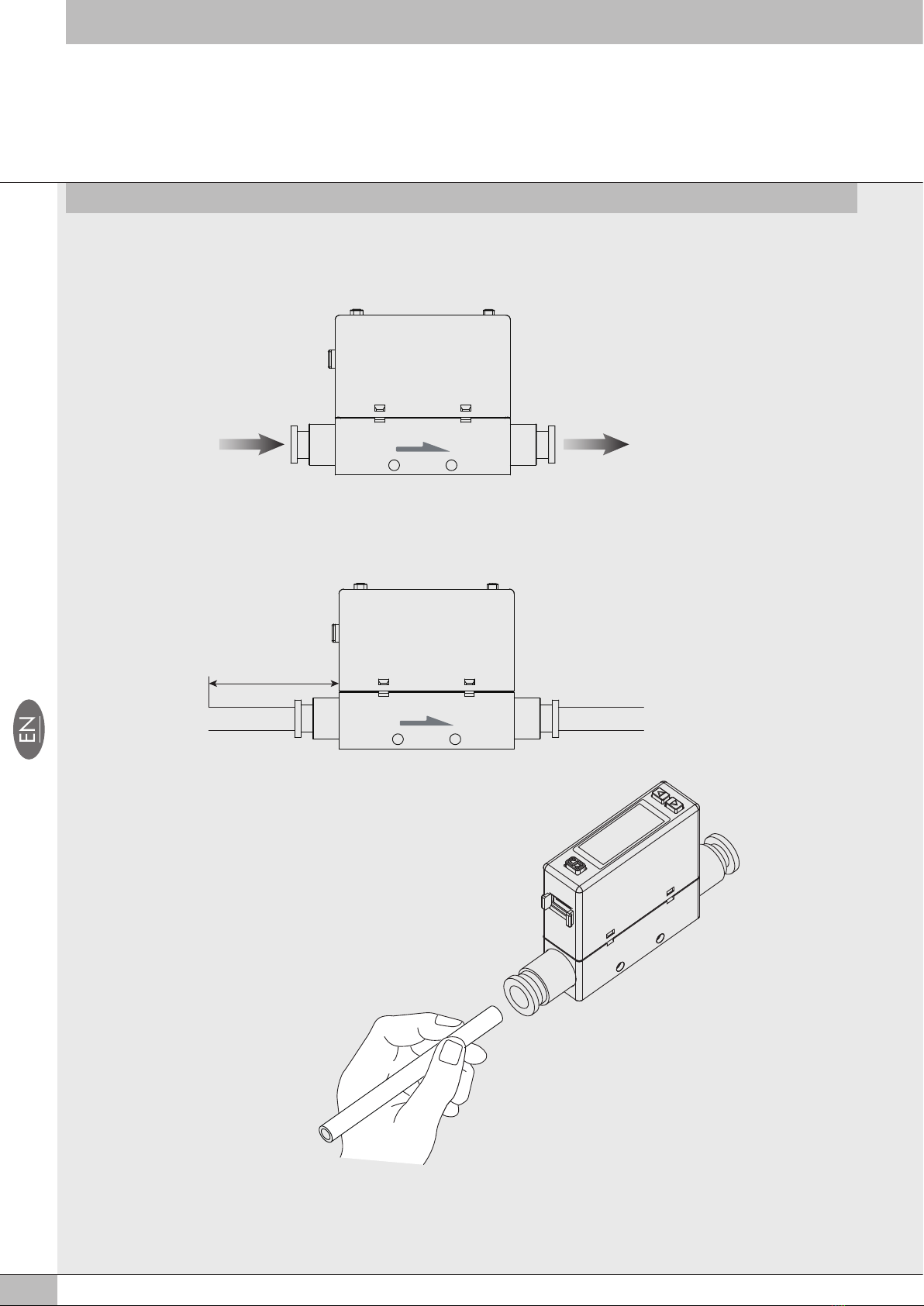

Install the pipe by following the arrow indication that shows the air flow

direction on the product.

Blow the air to flush out the foreign matters,

dust and etc. before installing the pipe.

Uncleaned air may cause malfunction or

damage to the product.

Piping for the One-Touch Fitting, insert the

tube firmly into the fitting and make sure it

cannot be pulled out.

Also using the proper tube cutter is

recommended to ensure square

edge tube.

Flow direction

Use straight piping 8cm or longer to connect the Piping Port (Inlet side).

If straight piping is not installed, the accuracy may vary by ± 2% F.S..

※Straight Piping: The pipe is without bending and the cross sectional areas of the

pipe keeps the same.

Piping Port

(Inlet side)

straight piping 8cm

or longer

Piping Port

(Outlet side)

9

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-6-

KFP01 Series Instruction Manual

Installation

Mounting

screw

Mounting screw Mounting screw

P Type

Size : 3.0

Length : 6mm

※The tightening torque for bracket mounting screws

should be under 0.5 ± 0.1 N.m.

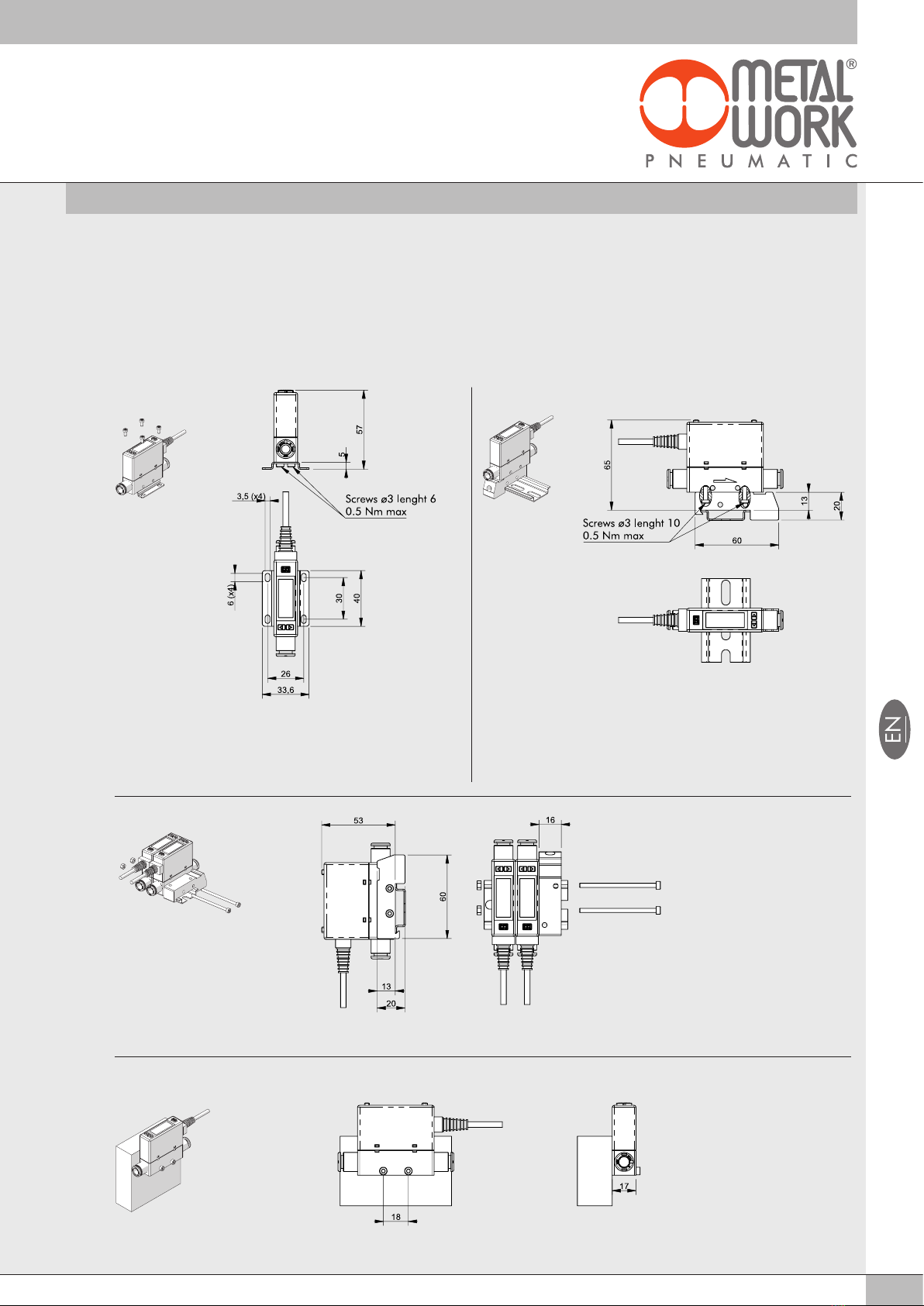

1.2 Mounting Bracket / Optional Parts

The LCD display may be difficult to see at certain angles.

The sensor can be installed horizontally or vertically, but the flow rates

may change because of the installation way of the product or piping.

The tightening torque for screws should be under 0.5 ±0.1 N.m.

1.Horizontal mounting

(by Through-Hole)

2.Bracket mounting

AB

D

C

Fixing with bracket code 90009A001 using the included Ø3

self-tapping screws and M3 screws Single fixing on DIN bar with code bracket 90009A002 using the

included Ø3 self-tapping screws

Multiple fixing on DIN bar with code bracket 90009A002 using the lateral holes Ø3.4 with M3 screws and nuts

Side fixing using M3 screws, minimum length 23 mm

10

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-8-

Installation Instructions

KFP01 Series Instruction Manual

●PNP Output / Analog Voltage Output / External Input

●PNP Output / Analog Current Output / External Input

1

2

3

4

5

6

Brown (Power supply +)

Brown (Power supply +)

Blue (Power supply –)

Blue (Power supply –)

Black (Output 1)

White (Output 2)

Black (Output 1)

White (Output 2)

Yellow (External input)

Yellow

(External input)

Orange

(Analog output)

Orange

(Analog output)

1

2

3

4

5

6

1kΩ

1.3 Wiring Diagrams

1.3.

1PNP Output, Analog Output and External Input

Brown

Orange

Yellow

Black

White

Blue

Pin No. Line color Content

1 Brown Power supply (DC 12 to 24V DC)

4 Black Output 1 (Max. load current:125mA)

5 White Output 2 (Max. load current:125mA)

3 Yellow External input

2 Orange Analog voltage output:1 -5V

Analog current output:4 -20mA

6 Blue 0V (GND)

1

2

3

4

5

6

Main CircuitMain Circuit

Load

Load

Load

Load

Load

11

2.1 Names and Functions of Individual Parts

Setting Button

Use for selection each mode

and set value confirmation.

▼Button

▲Button

Use for mode selection,

ON/OFF switching and

set value adjustment.

Use for mode selection,

ON/OFF switching and

set value adjustment.

Lead Wire

Connector

Piping Port (Inlet side)

Output 1 Indicator

3 Color LCD Display Flow Symbol

Flow Display

Button

Button

Analog Signal Indicator

Output 2 Indicator

Output 1 Indicator

Output 2 Indicator

Analog Signal Indicator

Pressure Symbol

Pressure Display

Setting Button

Pressure Unit

Display Section

Flow Unit

Display Section

Piping Port (Outlet side)

LCD Display

Through-Hole

Use to mount the product

on a plate directly.

Body

Connector

Ag OUT1OUT2 Ag OUT1OUT2

kgf/cm2bar psi kPa Pulse ft3/min mL3/min

2. HOW TO USE

12

2.2 Function Instruction

●Function Setting Mode

●Measurement Mode

Item Explanation

[F-01]

[F-02]

[F-03]

[F-04]

[F-05]

[F-06]

[F-08]

[F-09]

[F-10]

[F-91]

[F-92]

[F-94]

[F-95]

[F-99]

[oUt1 ] OUT 1 setting

[oUt2 ] OUT 2 setting

[CLor ] LCD Display color selection

[rESP] Response time selection

[UPdA ]

Display refresh time selection

[Unit ] Unit selection

[rEFE] Flow reference standard

selection

[ AnG ] Analog output selection

[EEPr] Accumulated value hold

selection

[ diS ] Flow sensor display mode

selection

[ ECo ]

Power-Save mode selection

[ inP ] External input selection

[FinE ] Fine adjustment Setting

[FoUt ] Forced output function

[rESt ] Reset to the default setting

Select Output 1 corresponding to flow sensor or

pressure sensor. Set the flow rate or pressure

value to switch ON/OFF.

Select Output 2 corresponding to flow sensor or

pressure sensor. Set the flow rate or pressure

value to switch ON/OFF.

Select back light color and display mode.

Select the response time for analog output.

Pressure sensor: 2.5ms ~ 1500ms.

Flow sensor: 50ms ~ 1500ms.

Display refresh cycle can be set in 200ms, 500ms

or 1000ms.

Select the UNIT of pressure / flow sensor.

Select the flow value is shown under standard (ANR)

or normal condition (NOR).

Select the analog corresponding to pressure or flow

sensor.

To save the last accumulated flow value every 2 or

5 minutes.

Select to display Instantaneous Flow or Accumulated

Flow Mode.

Select if turn on power-save mode to reduce power

consumption

Select for Accumulated flow rate zero clear,

Auto-Shift or Auto-Shift zero.

The displayed value can be adjusted slightly.

To turn the analog ON/OFF forcibly.

Return to the factory default setting.

[F-07]

Function

Code

Item Explanation

Pressure display

Flow display

Accumulated flow rate display

Pressure zero setting

Instantaneous Flow rate zero setting

Accumulated flow rate zero clear

Peak value display

Bottom value display

Key lock/unlock mode

Display pressure value.

Display instantaneous flow rate.

Display accumulated flow rate.

The displayed pressure value can be adjusted to "0".

The displayed instantaneous flow rate value can be adjusted to "0".

The accumulated flow rate can be set to "0".

The maximum pressure or instantaneous flow can be detected when

the power is supplied for a period.

The minimum pressure or instantaneous flow can be detected when

the power is supplied for a period.

To prevent errors occurring due to unintentional changes of the set values.

13

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-12-

KFP01 Series Instruction Manual

How to Use

At Measurement Mode, press button for more than 3 sec. to display

[F-01]. Press or button to select other setting functions.

Press for 3 sec. at Function Setting Mode to return to Measurement

Mode.

2.3 Operation Instructions

Function Selection Mode

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Measurement Mode

Function Selection Mode

Press button for

more than 3 sec.

Enter in each function setting

Ag

kPa L /min

Press button

14

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-13-

KFP01 Series Instruction Manual

How to Use

2.3.1 [F-01] OUT1 Setting Selection

Setting corresponding sensor and operating mode of OUT1.

●1. Flow sensor setting

Press or button at Function Setting Mode to display

[F-01] [oUt1].

Ag

kPa L /min

Sensor Selection

Press or button to select

flow sensor of OUT1.

Flow sensor

Ag

kPa L /min

Selected

Output

Sensor

Pressure sensor

Press button

(to be continued)

Ag

kPa L /min

Output Mode Setting

Select output mode:

Press or button to select output

mode of OUT1.

4 output modes included.

Hysteresis Mode

※NOTE:The Accumulated Pulse Output Mode can only be set in OUT1, and OUT2 does not have this setting.

Ag

kPa L /min

Selected

Mode

Selected

Sensor

Window Comparator Mode Accumulated Output Mode

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Accumulated Pulse

Output Mode

Ag

kPa Pulse L /min

Press button

Press button

15

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-14-

KFP01 Series Instruction Manual

How to Use

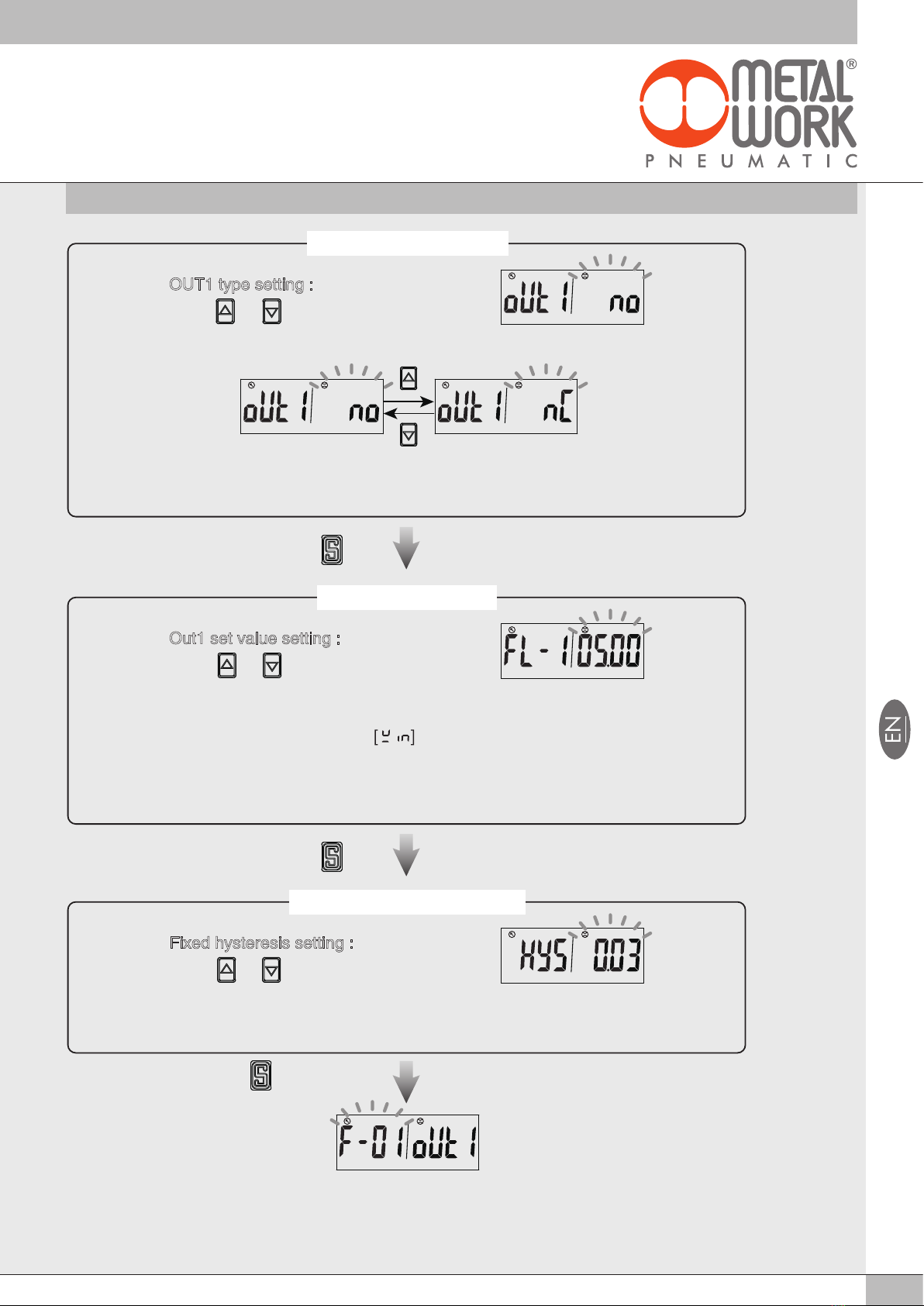

Fixed Hysteresis

Mode

NO mode NC mode

Ag

kPa L /min

Selected

Output

Selected

Mode

Output Type Setting

OUT1 type setting :

Press or button to select OUT1

type.

Ag

kPa L /min

Ag

kPa L /min

※NOTE:Type setting will not display when Accumulated Pulse Output Mode is set.

Ag

kPa L /min

Set ValueSelected

Mode

Set Value Setting

Out1 set value setting :

Press or button to adjust the set

value.

Hysteresis Mode [HYS]:[FL-1],[FH-1]

Window Comparator Mode :[FL-1],[FH-1]

Accumlated Output Mode [ADD]:[AddL],[AddH]

※NOTE:Set value setting will not display when Accumulated Pulse Output is set.

Ag

kPa L /min

Set Value

Fixed Hysteresis Setting

Fixed hysteresis setting :

Press or button to adjust fixed

hysteresis value.

※NOTE:Fixed hysteresis setting will not display when Hysteresis Mode, Accumulated Output Mode and

Accumulated Pulse Output Mode is set.

Ag

kPa L /min

Press button

Press button

Press button to return to

Function Selection Mode

16

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-15-

KFP01 Series Instruction Manual

How to Use

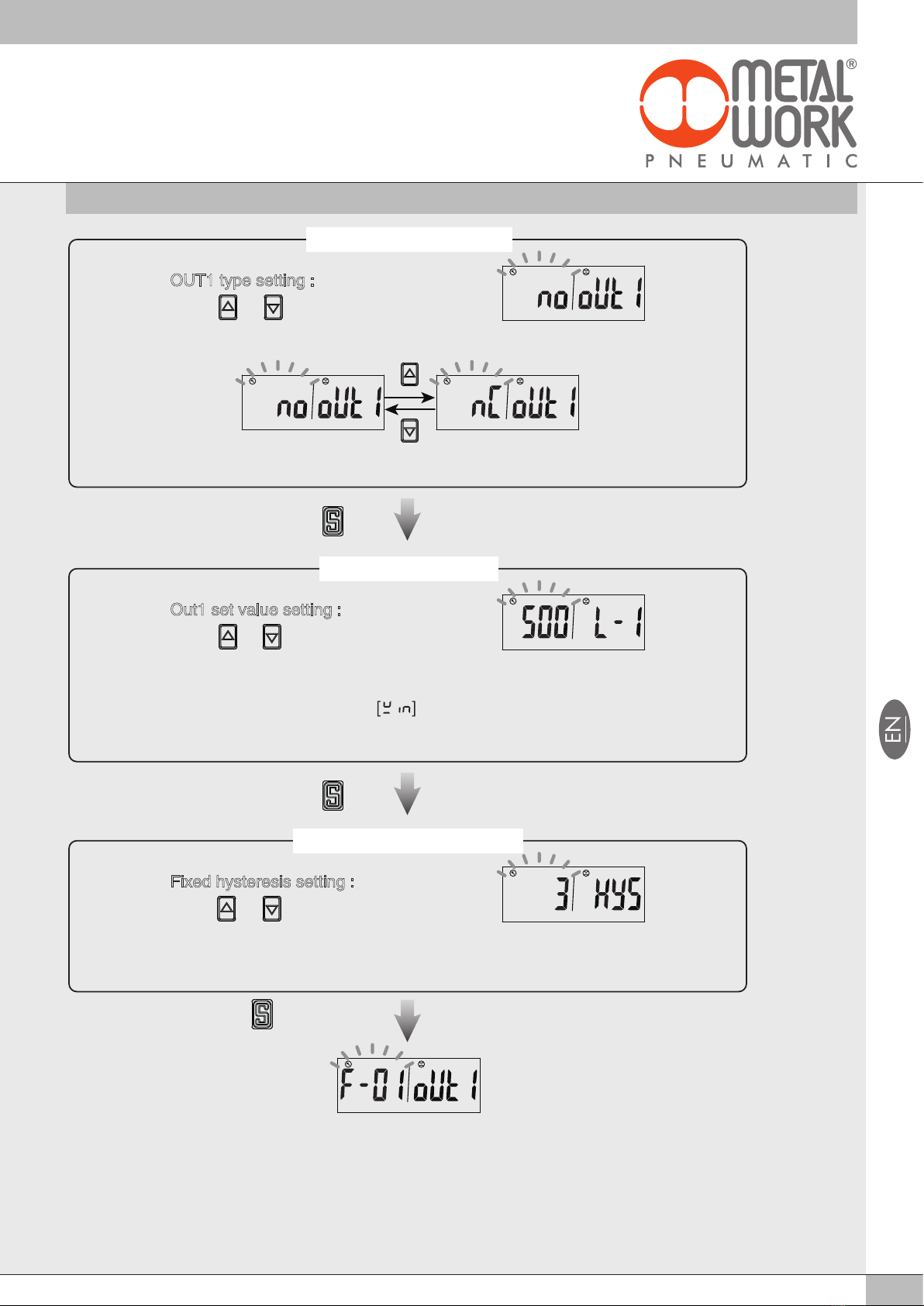

●2. Pressure sensor setting

Press or button at Function Selection Mode to display

[F-01] [oUt1].

Output Mode Setting

Select output mode:

Press or button to select output

mode of OUT1.

Hysteresis Mode

Ag

kPa L /min

Window Comparator Mode

One Point Set Mode

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Press button

Ag

kPa L /min

Sensor Selection

Press or button to select

pressure sensor of OUT1.

Flow sensor

Ag

kPa L /min

Pressure sensor

Ag

kPa L /min

Press button

(to be continued)

Press button

Selected

Output

Sensor

Selected

Mode

Sensor

17

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-16-

KFP01 Series Instruction Manual

How to Use

NO Mode NC Mode

Ag

kPa L /min

Output Type Setting

OUT1 type setting :

Press or button to select OUT1

type.

Ag

kPa L /min

Set Value Setting

Out1 set value setting :

Press or button to adjust the set

value.

Hysteresis Mode [HYS]:[L-1],[H-1]

Window Comparator Mode :[L-1],[H-1]

One Point Set Mode [oPS]:[P-1]

Ag

kPa L /min

Fixed Hysteresis Setting

Fixed hysteresis setting :

Press or button to adjust fixed

hysteresis value.

NOTE:Fixed hysteresis setting will not display when Hysteresis Mode is set.

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Press button

Press button

Fixed Hysteresis

Mode

Set Value

Selected

Mode

Output

Selected

Set Value

Mode

Press button to return to

Function Selection Mode

18

OFF

ON

OFF

ON

Flow / Pressure

Hysteresis Mode

Hysteresis Mode

FL-1(FL-2)

L-1(L-2)

FH-1(FH-2)

H-1(H-2)

OFF

ON

OFF

ON

FL-1(FL-2)

L-1(L-2)

FH-1(FH-2)

H-1(H-2)

OFF

ON

0 L

OFF

ON

0 L

Time

AdH1 AdL1

AdH2 AdL2

OFF

ON

Time

50ms

Flow Range 500mL

5mL

1000mL 5L 10L 50L 100L 200L

10mL 0.05L 0.1L 1L 2L0.5L

Pulse Output Rate

Normal Open Mode

Normal Close Mode

FL-1(FL-2)

L-1(L-2)

FH-1(FH-2)

H-1(H-2)

OFF

ON

OFF

ON

P-1(P-2)

FL-1(FL-2)

L-1(L-2)

FH-1(FH-2)

H-1(H-2)

P-1(P-2)

Time

AdH1 AdL1

AdH2 AdL2

Pressure

Flow

【NOTE:】

*1. In case hysteresis is set at less than or equal to 2 digits, switch output may chatter if input pressure fluctuates near the set point.

*2. When using window comparator mode, the difference between two set points must be greater than the fixed hysteresis, otherwise

will cause the switch output to malfunction.

Window Comparator Mode

One Point Set Mode

Accumulated Output Mode

Accumulated Pulse Output Mode

Flow / Pressure

Accumulated Output Mode

Flow

One Point Set Mode

Pressure

Window Comparator Mode

Flow / Pressure

Flow / Pressure

19

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-18-

KFP01 Series Instruction Manual

How to Use

2.3.2 [F-02] OUT2 Setting Selection

Setting corresponding sensor and operating mode of OUT2.

1. Press or button at function setting mode to start "OUT 2

Setting" [F-02] [oUt2].

2. Check the [F-01]for the same follow setting.

NOTE:The OUT2 Setting dose not have Accumulated Pulse Output Mode.

20

@2019 KITA Sensor Tech. Co., LTD. URL hiip://www.kita.com.tw

-19-

KFP01 Series Instruction Manual

How to Use

2.3.3 [

F-03

] LCD Display Color Selection

4 LCD Display Color Modes of output value selection.

< Operation >

Press or button at Function Selection Mode to display

[F-03] [CLor].

Output Selection

Press the or button to select color

display for OUT1 or OUT2.

Display color of OUT1

Ag

kPa L /min

Display color of OUT2

Display Color Mode Selection

Press the or button to select

Display Color Mode.

ON : Green

OFF : Red

ON : Red

OFF : Green

ON : Green

OFF : Green

ON : Red

OFF : Red

Ag

kPa L /min

Display Color

Mode

Selected

Mode

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Ag

kPa L /min

Press button

Press button

Selected

Output

Color

Display

Press button to return to

Function Selection Mode

Table of contents

Other Metal Work Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Seetru

Seetru G23 Installation, operating, & maintenance instructions

Bedfont

Bedfont G210 operating manual

Precaster

Precaster TIO30 Operation manuals

SIGLENT

SIGLENT SHA800A quick guide

Alcohol Monitoring Systems

Alcohol Monitoring Systems SCRAM Agent reference guide

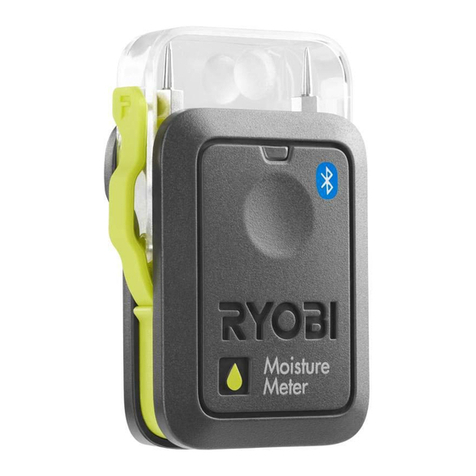

Ryobi

Ryobi Phone Works ES3001 Important safety instructions