Page 3

Table of Contents

Warning ............................................................ 2

Table of Contents............................................. 3

OPERATING SECTION

Model 758 Water Jet Specifications.................. 4

Model 758 Water Jet Features ......................... 5

Jet Applications Areas ...................................... 6

Uncrating and Prep ....................................... 7-8

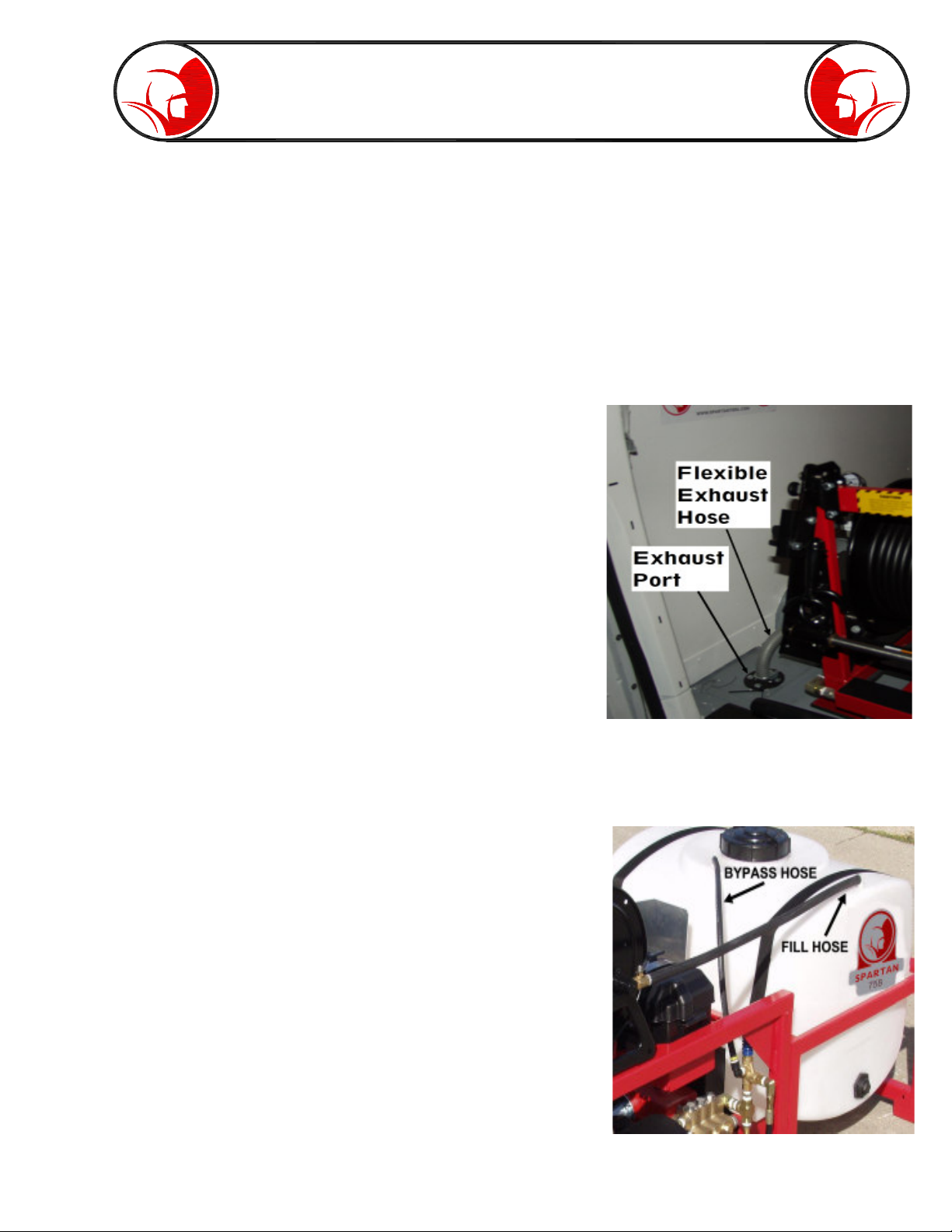

Pump and Pressure System ............................ 8

High Pressure Water Jetting ............................ 9

Water Tank Filling ........................................... 10

Operator Controls ..................................... 10-11

Engine Operating Procedure .......................... 12

Setting up for Operation ................................. 13

Power Rewind Operating Instructions ............ 14

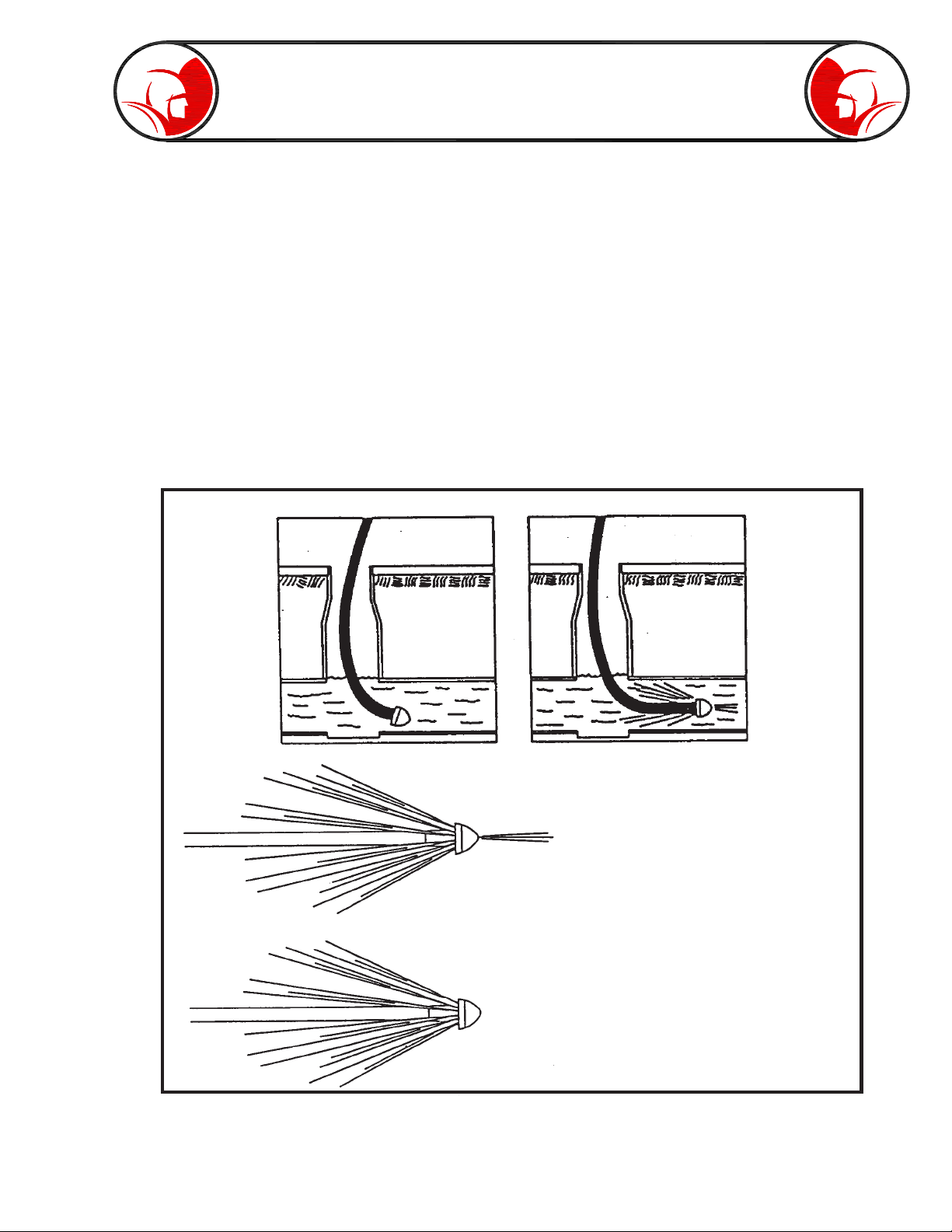

Pulsation ........................................................ 15

Lubrication & Maintenance ........................ 16-18

Fuel, Oil & Coolant Recommendations .......... 19

Operating Instructions ............................... 20-21

Pipe Jetting Procedure ................................... 21

When Obstruction Are Encountered .............. 22

1/4” Drain Hose .............................................. 22

Wash Down Kit - 73817300 ........................... 23

Mobile Hose Reel - 73816800 (Optional) ........ 23

Venturi Pump - 77763700 (Optional) ............. 24

Cold Weather Protection ................................ 24

758 Pump System Malfunction Chart ............. 25

Troubleshooting .............................................. 26

PARTS & ACCESSORIES SECTION

How To Use Parts & Accessories Section ..... 27

Special Note ................................................... 27

Wiring Diagram .............................................. 28

758 Skid Mount Assembly - 75824300 ...... 29-34

758 Pump Assembly - 75802700 .............. 35-37

758 Fill Reel Assembly - 73815700 ................ 38

758 H.P. Reel Assembly - 75824900 ......... 39-40

758 Power Pak - 75820200 ....................... 41-42

758 Engine Control Box - 75818400 ............... 43

758 Control Panel - 75808300 ........................ 44

758 Water Tank Assembly - 73829500 ........... 45

758 Pump Parts List ...................................... 46

758 Pump Torque Specifications .................... 46

758 Pump - Exploded View ............................ 47

758 Pump Repair Kits .................................... 48

Unloader - 75802800 ...................................... 48

Air Foot Switch ............................................... 49

758 Decal Package - 75814400 ..................... 49

758 Accessories............................................. 50