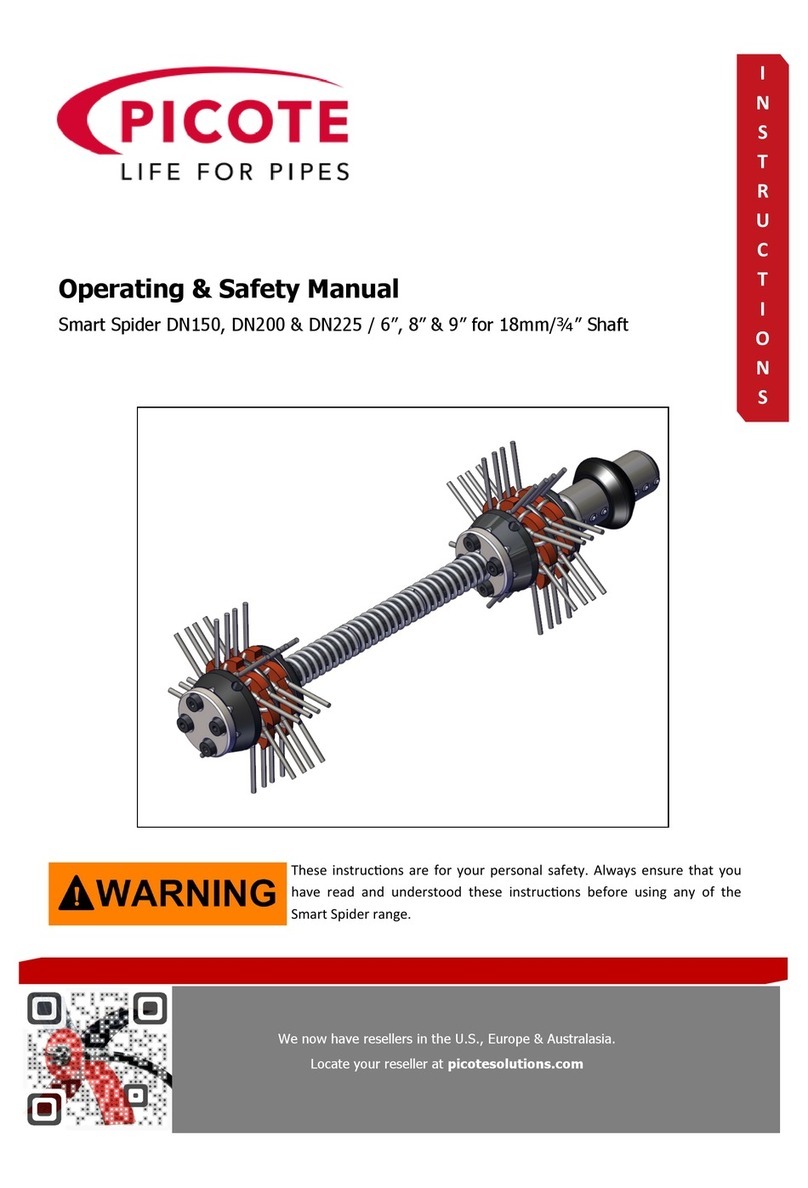

PICOTE Smart Spider DN150/6" Instruction Manual

Other PICOTE Pipe Cleaner manuals

PICOTE

PICOTE MINI SMART HEAT MILLER Use and care manual

PICOTE

PICOTE MIDI MILLER 12/12 Use and care manual

PICOTE

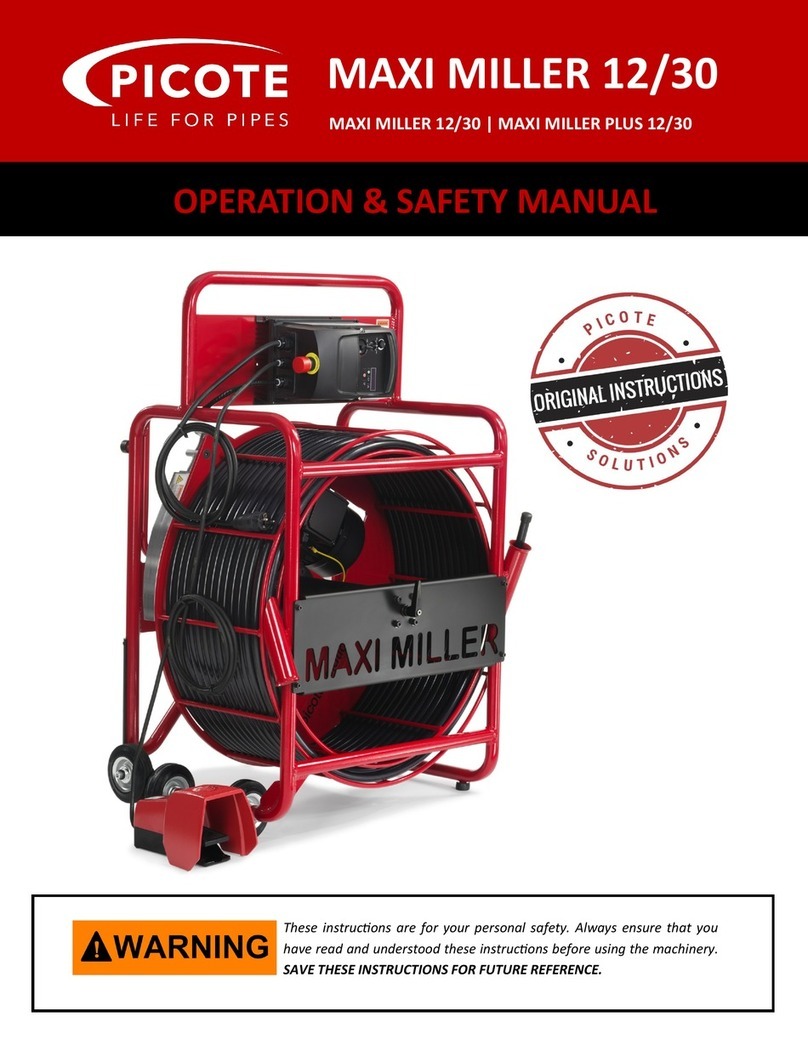

PICOTE MAXI MILLER 12/30 Use and care manual

PICOTE

PICOTE Smart Spider DN150/6" Instruction Manual

PICOTE

PICOTE SUPER MIDI 12/20 Use and care manual

PICOTE

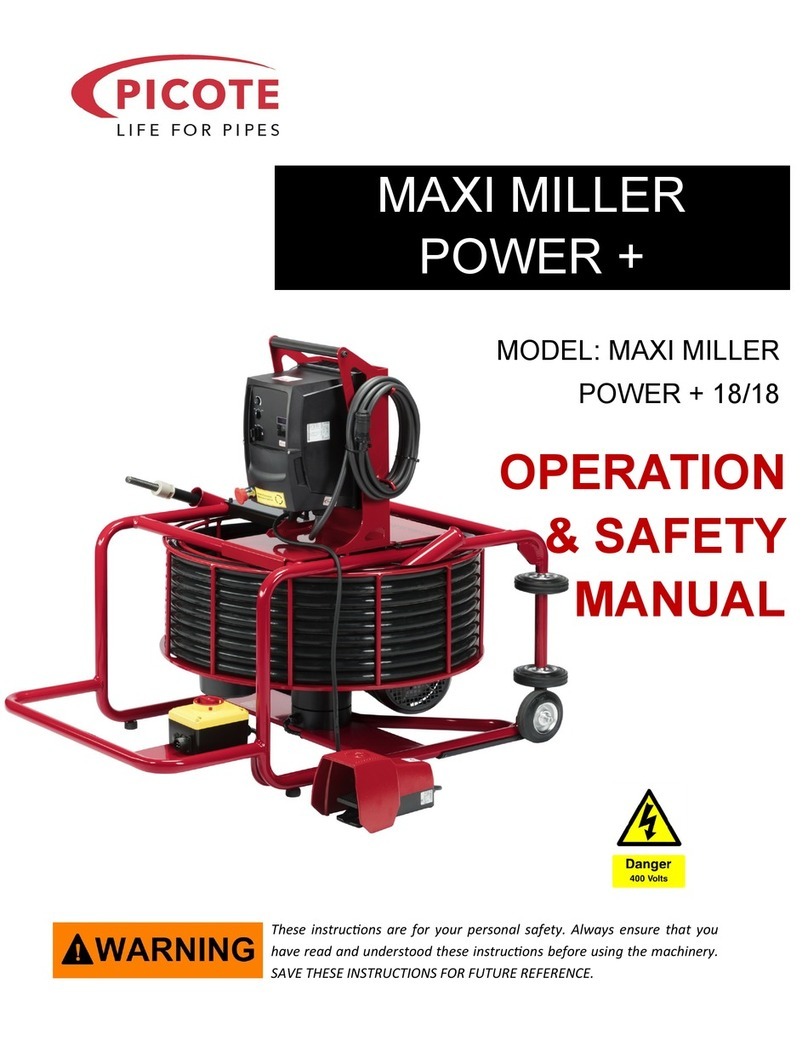

PICOTE MAXI MILLER POWER + 18/18 Use and care manual

Popular Pipe Cleaner manuals by other brands

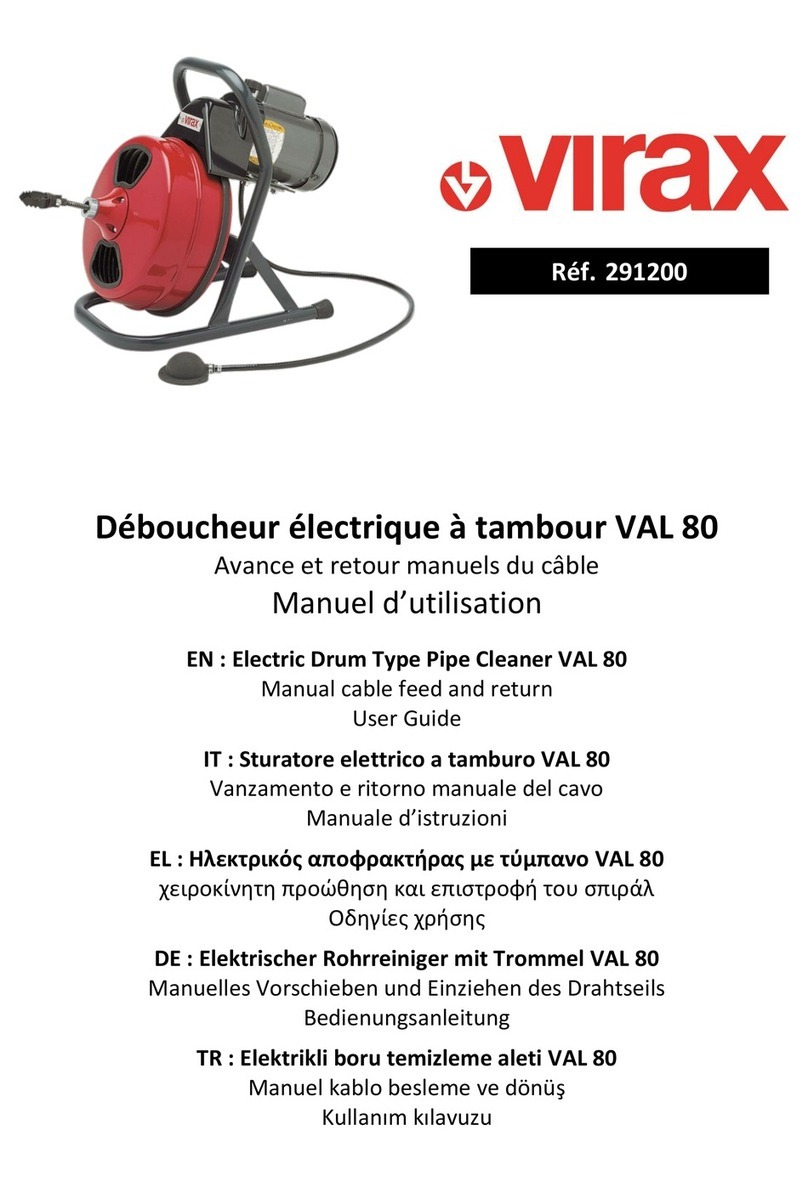

Virax

Virax VAL 80 manual

Ribimex

Ribimex Ribitech PRFDP User and maintenance manual

General Pipe Cleaners

General Pipe Cleaners Speedrooter 92 S92-450 operating instructions

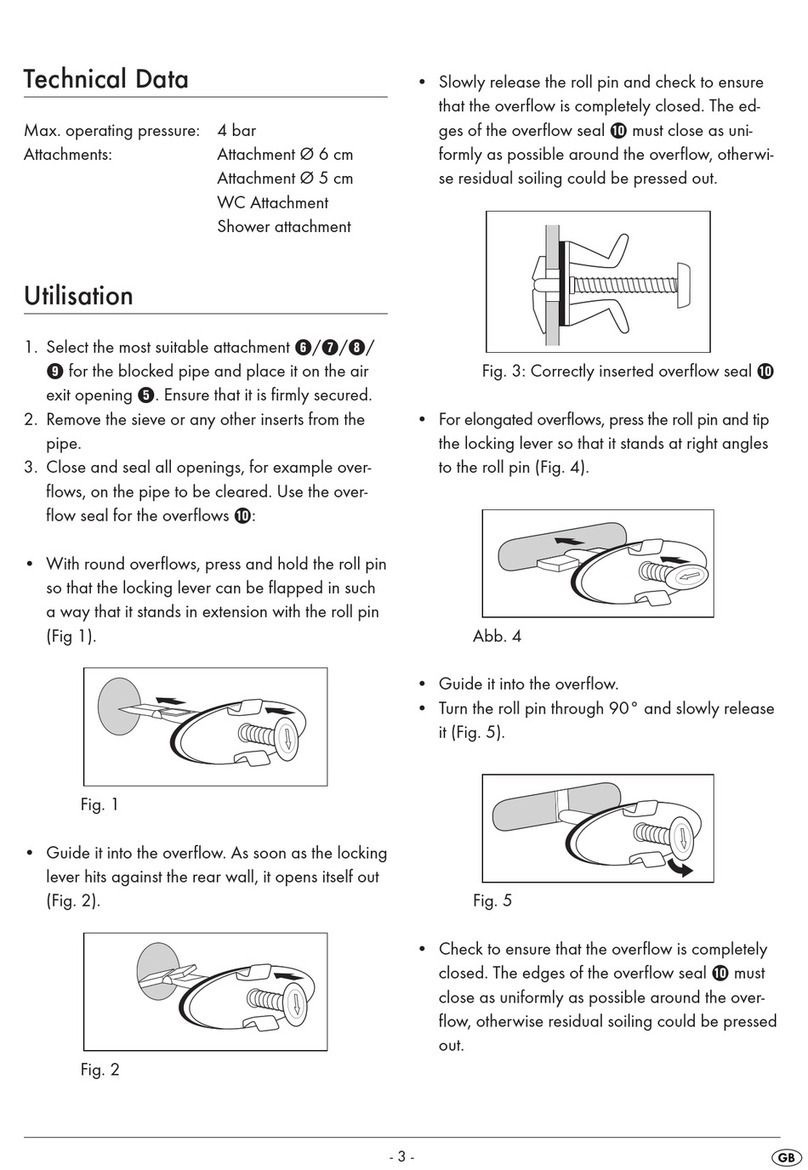

Parkside

Parkside 270382 Translation of the original instructions

General Pipe Cleaners

General Pipe Cleaners JM-1450 operating instructions

Dali

Dali GQ-75 instruction manual

General Pipe Cleaners

General Pipe Cleaners Gen-Eye SD operating instructions

Kompernass

Kompernass 64586 manual

Inder

Inder Power P-30 User instruction manual

Gap Power

Gap Power Speedrooter 92R operating instructions

Parkside

Parkside 102800 translation of original operation manual

General Pipe Cleaners

General Pipe Cleaners Speedrooter XL operating instructions

Wöhler

Wöhler DH 420 operating manual

Elliott

Elliott Roto-Jet II Series Operating and maintenance instructions

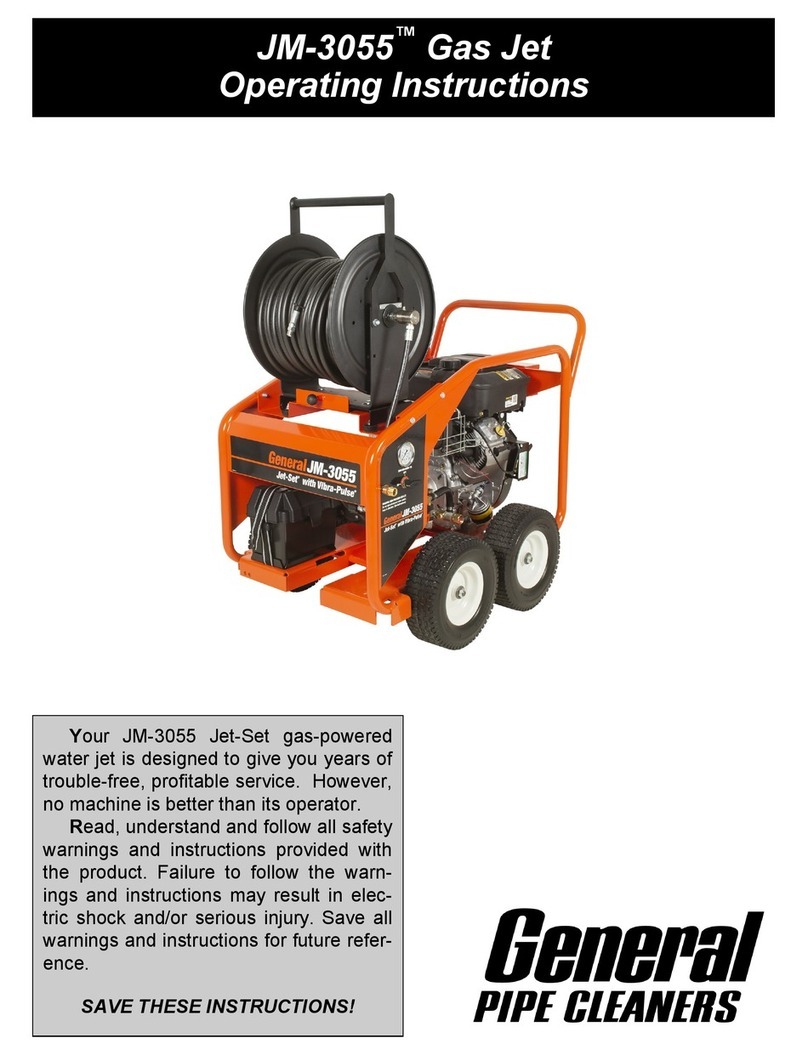

General Pipe Cleaners

General Pipe Cleaners JM-3055 operating instructions

General Pipe Cleaners

General Pipe Cleaners JM-2900 operating instructions

Westfalia

Westfalia 82 45 38 instruction manual

RIDGID

RIDGID KWIK-SPIN instruction sheet