• When pump hot or poison liquid, there should be a guard or a sign to prevent people from touching pump surface

by accident.

• The pump should be sited in a well ventiled and ambient temperature should be bigger than 0C (frost free position).

• The arrow on the flange indicates the flowing direction. The direction of motor rotation is clockwise from motor end which

can be seen from the sign on motor fan cover.

• If motor power is not more than 2.2Kw, pump can be installed horizontally or vertically on pipes.

• If motor power is bigger than 2.2kW, pump must be installed vertically on pipes.

Notice:

• The motor for pump must site higher than pipes.

• When installation, there should be enough space on top of pump for cleaning and dismantling in order to move

motor and clean up parts.

The enough space as follows:

• It should be 300mm if motor is less than 4.0kW.

• It should be 100mm if motor is 5.5kW or bigger than 5.5kW.

• In the pump room, on very top of the motor, it should be well ventilated by air or by mechanism device.

If the pump is used to pump thick and easy to froze liquid at 0C which will lead to block the pump, heat device can be used.

When the pump stops, if it is so cold that will lead to frozen the folowing liquid, water-out hole must face down and it must be

opend.

1. If the pump or pipes will be cleaned or maintained usually, it is required to install valves on the two sides

of the pipes to prevent from draining the system.

2. If the pipes on the two sides can support pump and matched motor power is less or equal to 2.2kW,

pump can be hung on the pipes.

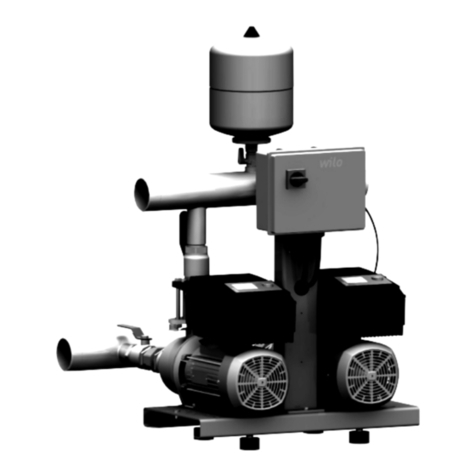

3. If the matched motor power is bigger than 2.2kW, place some concrete base or vibaration resistant device

as fig. shows below. The base or vibaration resistance device is also workable with motor less than 3kW.

4. When installing pipes, pump must be supported hardly. in order to prevent pipes from being pressed greatly.

5. The inlet size of pump must be fulfilled with the designed flow and designed pressure for suction.

6. When installing pipes, it must be avoided that grain or deposit to go down to the bottom of the pump.

7. When installing pipes; it must be avoided that there was air in the pipes, especially in suction pipe.

Noteice: Pump is not allowed to be started if the valves are closed completely, which will lead to temperature rising or vapor.

It will damage flow part or seal of pump. Before starting pump, open inlet valves fully, open outlet valve a little or open little

flow bypass, the flow should be 10% of the nominal flow which is indicated in the pump nameplate.

Installation and Operation

• Requirement for pipes