SPE BEF200N User manual

BEF200N

OWNER’S MANUAL AND PARTS BOOK

www.BARTELLGLOBAL.com

Doc. #OIPB-S18001

Orig. Rel. –08/2020

Curr Rev. -00

BEF200N

PARTS BOOK OIPB-S18001

2

www.BARTELLGLOBAL.com

Bartell Morrison Inc.

170 Traders Blvd E

Mississauga, Ontario, Canada

L4Z 1W7

Tel: (647) 953-4100

Fax: (647) 953-4101

Bartell Morrison USA LLC

200 Commerce Drive, Unit A

Freehold, NJ, USA

07728

Tel: (848) 225-8100

Fax: (848) 225-8101

SPE International Ltd

Honeyholes Lane

Dunholme, Lincoln, England

LN2 3SU

Tel: 01673 860709

Fax: 01673 861119

Innovatech

4701 Allmond Ave

Louisville, Kentucky, USA

40209

Tel: (425) 405-9100

Fax: (425) 405-9101

© 2020 Bartell Morrison Inc.

This manual is provided to persons purchasing an SPE machine and may not be

reproduced in part or full without written permission of SPE International Ltd.

This manual provides the basic information required and is only to be used as a guideline.

The SPE machines are manufactured and covered by SPE design registrations granted and

pending. SPE International Ltd reserves the right to alter the equipment design and

specification as required without notice.

Address inquiries or reference permissions care of:

Bartell Morrison Inc., 170 Traders Blvd E., Mississauga, Ontario, Canada, L4Z 1W7

REV.

DATE

DESCRIPTION

APPROVED BY:

00

09/20

Initial Release

AN

BEF200N

PARTS BOOK OIPB-S18001

3

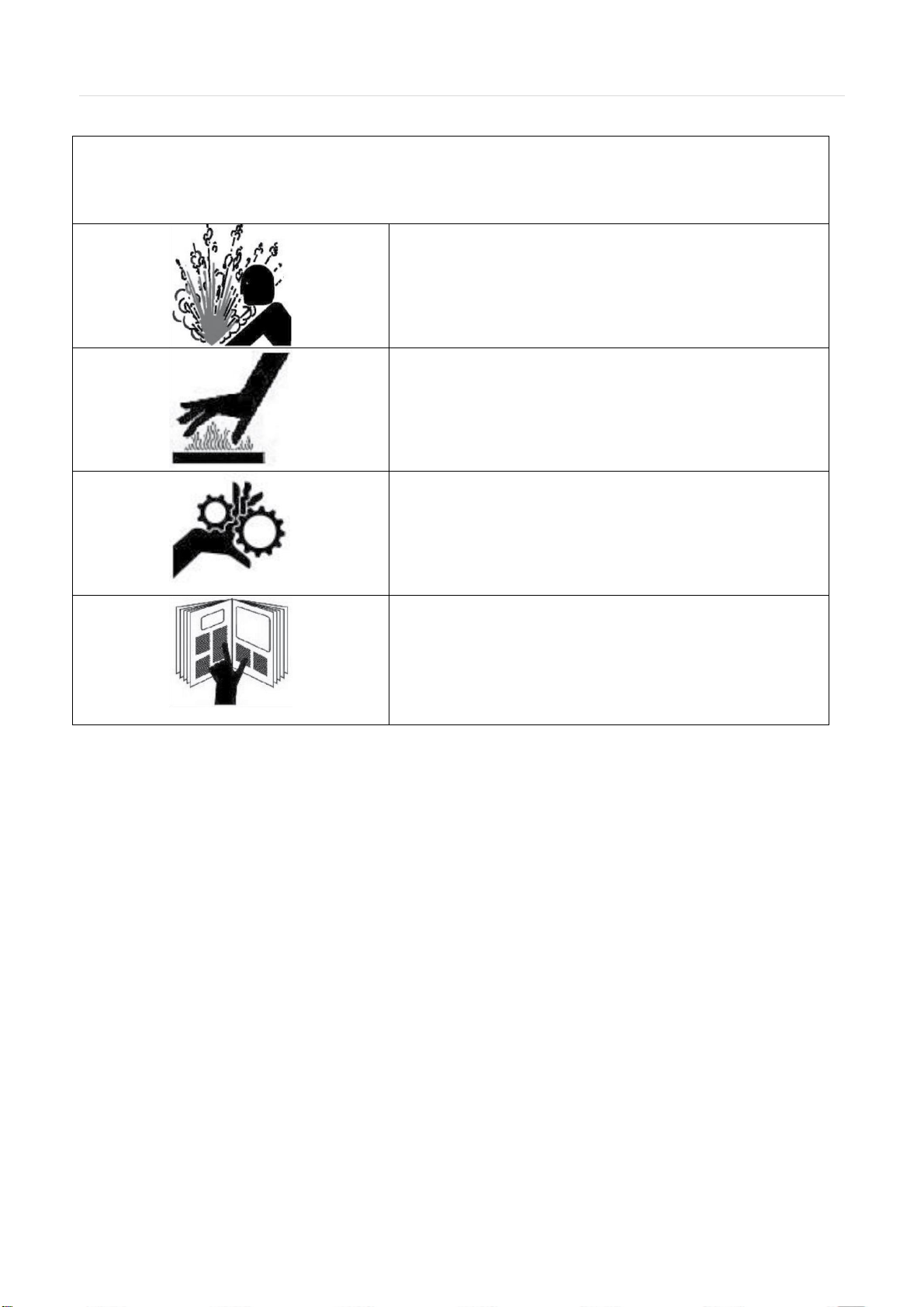

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or where

ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or muffler

when engine is operating or shortly after it is turned

off. Serious burns may occur.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all guards

and safety devices are in place and functioning

properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before using

this machine. Failure to follow operating

instructions could result in serious injury or death.

BEF200N

PARTS BOOK OIPB-S18001

4

TABLE OF CONTENTS

ABOUT THIS MANUAL................................................................................................................... 5

SAFETY INSTRUCTIONS ................................................................................................................. 5

START-UP OPERATION .................................................................................................................. 6

GENERAL OPERATION................................................................................................................... 7

ELECTRICAL REQUIREMENTS ......................................................................................................... 8

CUTTER DRUM REMOVAL ............................................................................................................. 9

CUTTER DRUM MAINTENANCE ..................................................................................................... 9

GENERAL MAINTENANCE............................................................................................................ 10

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN...................................................... 11

MAINTENANCE CHECKLIST .......................................................................................................... 13

PARTS LIST 1 - SCARIFIER............................................................................................................. 14

GENERAL ASSEMBLY DIAGRAM: BEF200N..................................................................................................................14

GENERAL ASSEMBLY DIAGRAM: BEF200N –PARTS LIST 1..........................................................................................15

PARTS LIST 2 - SCARIFIER............................................................................................................. 16

FASTENERS: BEF200N..................................................................................................................................................16

FASTENERS: BEF200N –PARTS LIST 2 .........................................................................................................................17

ELECTICAL DIAGRAM .................................................................................................................. 18

BEF200N-1...................................................................................................................................................................18

BEF200N-2...................................................................................................................................................................19

BEF200N-2A ................................................................................................................................................................19

Electrical Components ................................................................................................................ 22

BEF200N-1...................................................................................................................................................................22

BEF200N-2...................................................................................................................................................................22

BEF200N-2A ................................................................................................................................................................22

BEF200N-3...................................................................................................................................................................23

Specification Sheet ..................................................................................................................... 24

Noise & Vibration Assessments................................................................................................... 25

BEF200N Electric –TCT Cutters...................................................................................................................................25

BEF200N Electric –Beam Cutters ...............................................................................................................................26

BEF200N Petrol –TCT Cutters.....................................................................................................................................27

BEF200N Petrol –Beam Cutters .................................................................................................................................28

Warranty.................................................................................................................................... 29

Declaration of Conformity........................................................................................................... 30

Conditions of Sale....................................................................................................................... 31

BEF200N

PARTS BOOK OIPB-S18001

5

ABOUT THIS MANUAL

To the best of our knowledge, this manual covers the operation and maintenance of the

BEF200N Scarifier. Before operation of the equipment this manual should be read and

understood by the operator. The safety regulations must be followed at all times, and service

of electrical components should be carried out by authorised personnel.

SAFETY INSTRUCTIONS

Failure to follow these instructions may result in serious personal injury or death. SPE

disclaims all responsibility for damage to persons or objects arising as a consequence of

incorrect handling of the machine and failure to inspect the machine for damage or other

faults that may influence the operation prior to starting work.

•Only trained operatives should be allowed to work the BEF200N.

•All operatives should wear all PPE including ear protection, goggles, an effective dust

mask and boots.

•Never leave the BEF200N unattended while in use.

•An SPE dust vacuum unit is recommended to control dust.

•Never leave the engine/motor running when machine is not in use.

•Always ensure that all power leads are disconnected before attempting to service the

machine. The service of electrical components should be carried out by authorised

personnel.

•Never remove the side plate or belt guard until the cutter drum has come to a complete

standstill.

•Never tip the machine backwards until the cutters have come to rest.

•Never operate the machine outdoors in wet conditions as the electrical components are

not waterproof.

Noise and vibration will occur at various levels dependent on the attachments and work

being completed. SPE have assessments conducted under test conditions detailed in the

operating manual. (See Noise and Vibration Assessments). However, it is recommended

that additional tests are taken on site to provide the operator with accurate information on

using the equipment within the guidelines laid down by the Health & Safety Executive.

Table of contents

Other SPE Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions