SPE BEF 275 User manual

BEF275-1

Operating Manual

This manual is provided to persons purchasing an

SPE machine and may not be reproduced in part or full

without written permission of

SPE International Ltd.

This manual provides the basic information required

and is only to be used as a guideline.

The SPE machines are manufactured and covered by

SPE design registrations granted and pending.

SPE International Ltd reserves the right to alter the

equipment design and specification as required

without notice.

The SPE product range is subject to amendment and

improvement as a result of on going research

Honeyholes Lane, Dunholme, Lincoln LN2 3SU, England

Tel: +44 (0) 1673 860709 Fax: +44 (0) 1673 861119

Email: sales@spe-int.com

BEF275-1

Operating Manual

BEF275-1 OPERATING MANUAL

This manual covers to the best of our knowledge, the operation and maintenance of the BEF275

Multi-plane. Before operation of the equipment the manual must be read and understood by the

operator. The safety regulations must be followed at all times. Failure to follow these instructions

could result in damage to the machine and/or serious personal injury or death.

WARNING

Failure to follow this instruction may result in serious personal injury or death. SPE disclaims all

responsibility for damage to persons or objects arising as a consequence of incorrect handling of

the machine, failure to inspect the machine for damage or other faults that may influence the

operation prior to starting work, or failure to follow the safety regulations listed or applicable to the

job site.

BEF275-1

Operating Manual

INDEX

Page No

1 Starting Work

General Operation

2 Petrol Engine

Dust Control

3-4 Maintenance

5 Basic Maintenance Checklist

6 Safety

7-8 Accessories

9 -11 Cutter Drum Set Up

12 Spare Parts Breakdown

13 Body Components

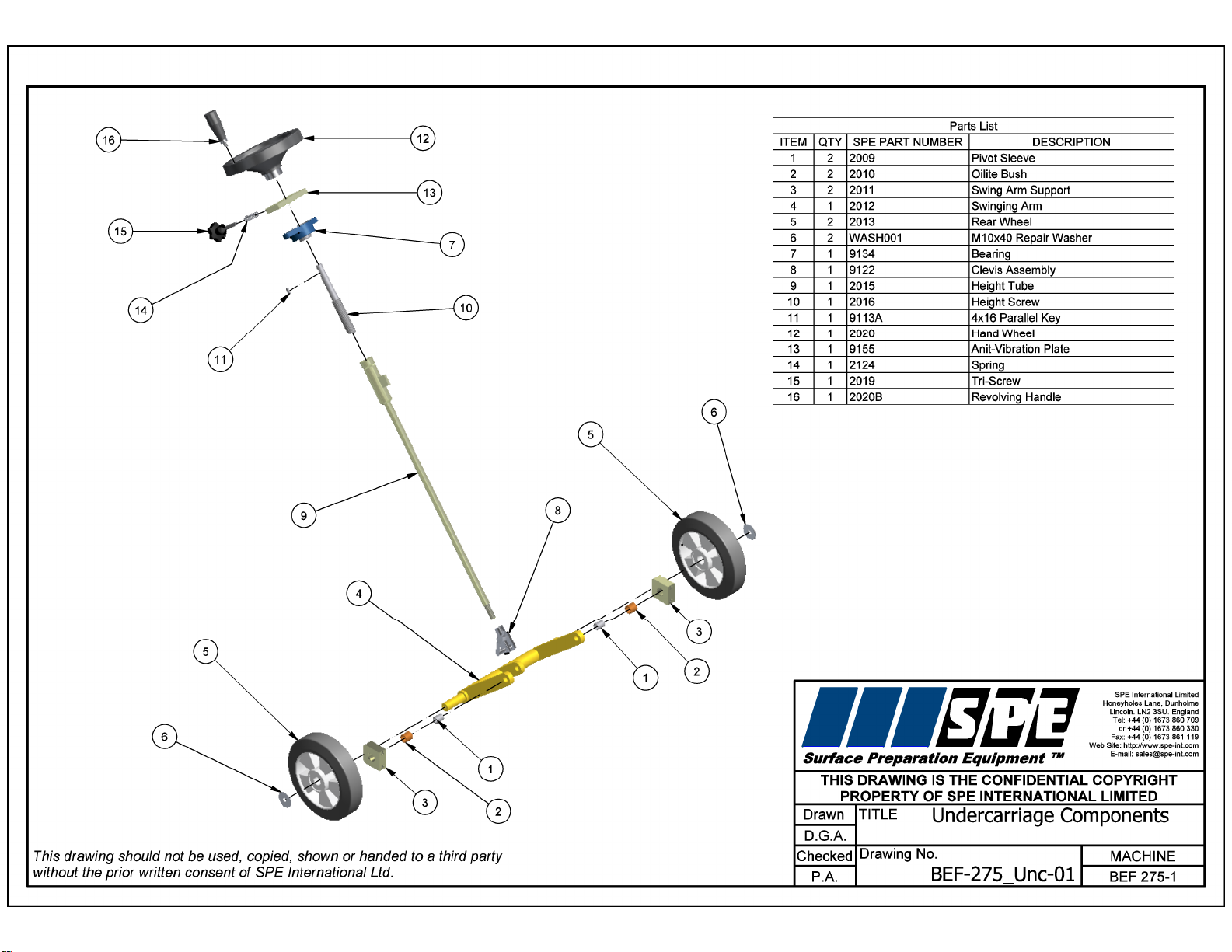

14 Undercarriage Components

15 Drive Components

16 Specifications

17 Noise and Vibration Assessment

18 Warranty

19 Declaration of Conformity

20 Conditions of Sale

BEF275-1

Operating Manual

STARTING WORK

Check the following prior to starting the equipment

- Check the condition of the cutter drum assembly

- Check all nuts and bolts for tightness

- Check the drive belt condition and tension

- Check the drive pulleys are clean and undamaged

- Check the engine oil level

- Check the air filter is clean

1. Before starting the machine, ensure the cutter drum assembly is clear of the ground.

2. Adjust the handlebars to a comfortable height and position.

3. Connect the dust control hose if a vacuum is being used

4. Start the engine. See manufacturers manual for further guidance

Slowly rotate the hand wheel until the cutters make contact with the surface to be prepared. It is

essential that the cutters are not lowered too far and too hard onto the surface as seriousdamage

could be caused to the machine and the cutter drum assembly.

5. Lock the hand wheel using the locking screw when the correct cutting depth is set.

GENERAL OPERATION

The cutters must be allowed to "float" on the cutter shafts without downward pressure. This

floating action allows the cutters to perform as the designer intended i.e. as flails rather than as

grinders or picks.

The machine should operate smoothly with a minimum of vibration. When the depth of cut

is correctly set, very little effort should be required to operate the machine backwards and

forwards - the recommended method of operation.

Excessive downward pressure on the cutters may marginally improve the work rate/finish but the

definite increase in wear rates on the cutter drum assembly and machine components is the

negative result. Remember two light passes are quicker and more cost effective than one slow

heavy pass. Tests have proven conclusively that a heavy downward pressure reduces the cutter

and drum life by over 50%.

The BEF275 is normally operated in a forward direction, the operator variesthe speed of travel to

determine the final finish having already pre-set the depth control. It is recommended to operate

the machine with a backwards and forwards action, while maintaining overall forward motion.

Each pass should be overlapped to produce a uniform finish.

1

BEF275-1

Operating Manual

PETROL ENGINE

This manual should be read in conjunction with the Owners Manual of the petrol engine. The

engine is designed to give safe and dependable service if operated according to the instructions.

Read and understand the Owners Manual before operating the engine. Failure to do so could

result in personal injury or equipment damage.

Note: Avoid tipping the BEF275 backwards, when fitted with the Honda

GX340 engine, for longer than a minute. The engine oil can run into the cylinder head

causing the piston to hydraulically seize. In the event of a hydraulic seizure never try to

force the engine to turn over. Remove the spark plug and slowly turn the engine over by

hand. Ensure the ignition and fuel are turned "off". If this method is unsuccessfulthenthe

engine should be returned to the manufacturer.

DUST CONTROL

To remove dust, connect an industrial dust collector or vacuum to the 50mm port at the rearof the

machine. We recommend the SPE VAC316 for almost 100% dust control. In the absence of a

dust control unit it is acceptable to spray water onto the surface or to feed water down thevacuum

port. Cutter drum assembly life is increased by around 10% when operating the machine in this

way.

2

BEF275-1

Operating Manual

MAINTENANCE

Prior to any maintenance or adjustment, stop the engine.

After use: Clean the machine to remove all build up of dust and surface residues. If usingahose

pipe or pressure washer take care that water is not directed onto the engine and switches.

Note: Engine and switches are not waterproof

Drum removal:

Remove the bolts on the side plate and then screw two of the bolts back into the twotappedholes

in the side plate. Continue winding these bolts in and this will push the side plate off the dowel

pins. Remove the side plate. Pull out the cutting drum - the drive shaft may come out with the

drum assembly as this is only a push fit into the drive bush.

Fitting a new cutter drum is simply a reversal of the above procedure, a little care must be takento

align the drive shaft, cutter drum and support end drive bush.

EXCESSIVE FORCE IS NOT NEEDED TO REFIT THE CUTTER DRUM.

Cutter Drum Maintenance:

When changing the cutter drum always check that the flail shafts are not worn with pronounced

grooves and also that the centres of cutters and spacers are not elongated and beginning to

"mushroom". The drum assembly is hitting concrete with great force at over 1,600 times every

minute! Expenditure on consumables must be expected and built into all job costing.

While changing the drum, the condition of the drive shaft and side plate bearings should be

checked. If any roughness, side play or leakage of grease is detected, then new bearings should

be fitted. Lightly oiling the drive shaft will prevent a build up of rust which could cause difficulty

when changing the drum. At the same time check the belt tension and condition, also checking

the pulley grooves are clean and undamaged.

The drive shaft is manufactured from high quality steel and then heat treated to produce the

special properties required. The shaft is extremely strong and virtuallyunbreakablewhenusedas

intended. If, however, sideways pressure is exerted on the shaft while not supportedatbothends

then it can be damaged.

With the drum removed, check that the vacuum port is free from blockages and that the dust skirt

is in good condition.

Remove all build up and deposits of material from the under side of the drum housing. On certain

applications, e.g. the removal of damp self levelling compounds, it may be necessary to clean

away deposits hourly! Failure to do so could result in overload of the drum assembly, engine and

the drive belts.

Cont’d ………

3

BEF275-1

Operating Manual

Height Adjustment Maintenance

Ensure the height screw thread is cleaned and then lightly oiled. Periodicallyitshouldbe removed

and the female, threaded section cleaned out and oiled. At thesametimetheself aligningbearing

should be greased

The clevis pin should be oiled regularly to maintain a light, smooth height adjustment.

General Maintenance

Great care should be taken to ensure the belts have the correct tension and also the correct

alignment. Serious damage could be caused to the drive shaft, drive shaft bearings and engine if

the belts are excessively tight.

Note: Never operate the BEF275 without a belt guard

All components should be checked daily for tightness and the drive belts for correct tension.

Check the individual manufacturers service recommendations for full details on the engine.

4

BEF275-1

Operating Manual

BASIC MAINTENANCE/CHECKLIST

DAILY: (or every 8hrs to 10hrs)

Check the cutters

Check the flail shafts

Check all nuts and bolts for tightness

Check the belt tension and condition

Check engine oil daily

Change the engine air filter if not using vacuum unit

See engine manufacturers maintenance details before starting engine.

WEEKLY:

All the above with following:-

Grease all moving parts on the height adjustment mechanism

Remove the side plate

Check the drum

Check the bearings

Check the drive bushes

Check the drive shaft

Check the support wheels and grease.

MONTHLY:

All the above with following:-

Strip down fully the winding mechanism

Clean all the threads and re-grease

5

BEF275-1

Operating Manual

SAFETY

Only trained operatives should be allowed to work the BEF275.

All operatives should wear ear defenders, goggles and an effective dust mask.

Note; It is possible that the noise level produced by the BEF275 could exceed 90dbA. Personal

noise protection must be worn.

To control dust, it is recommended that an SPE dust control unit is used in conjunction with the

machine.

Never leave the BEF275 unattended while in use. Always stop the engine and set the height

adjustment fully up before leaving the machine.

Always ensure that the engine switch is in the off position and disconnect the spark plug cap

before attempting to service the machine. Never remove the side plate or belt guard until the

cutter drum has come to a complete standstill. Never tip the machine backwardsuntil the cutters

have come to rest.

Never operate a petrol engine BEF275 inside or in a poorlyventilatedarea. Carbonmonoxidegas

is emitted.

Never refill the petrol tank whilst inside a building.

Always stop the engine before refuelling.

Never refill the petrol tank when the engine is hot.

Never release the machine from operators control during use. The cutting action of the

drum will propel the machine forward at high speed. If the operator has anyproblem whilst

operating the machine, turn the red stop button on the engine or tip backwards.

Noise and vibration will occur at various levels dependant on the attachments and work being

completed. SPE have assessments conducted under test conditions detailed in the operating

manual. (See page 17). However it is recommended that additional tests are taken on site to

provide the operator with accurate information on using the equipment within the guidelines

laid down by the health and safety executive.

6

BEF275-1

Operating Manual

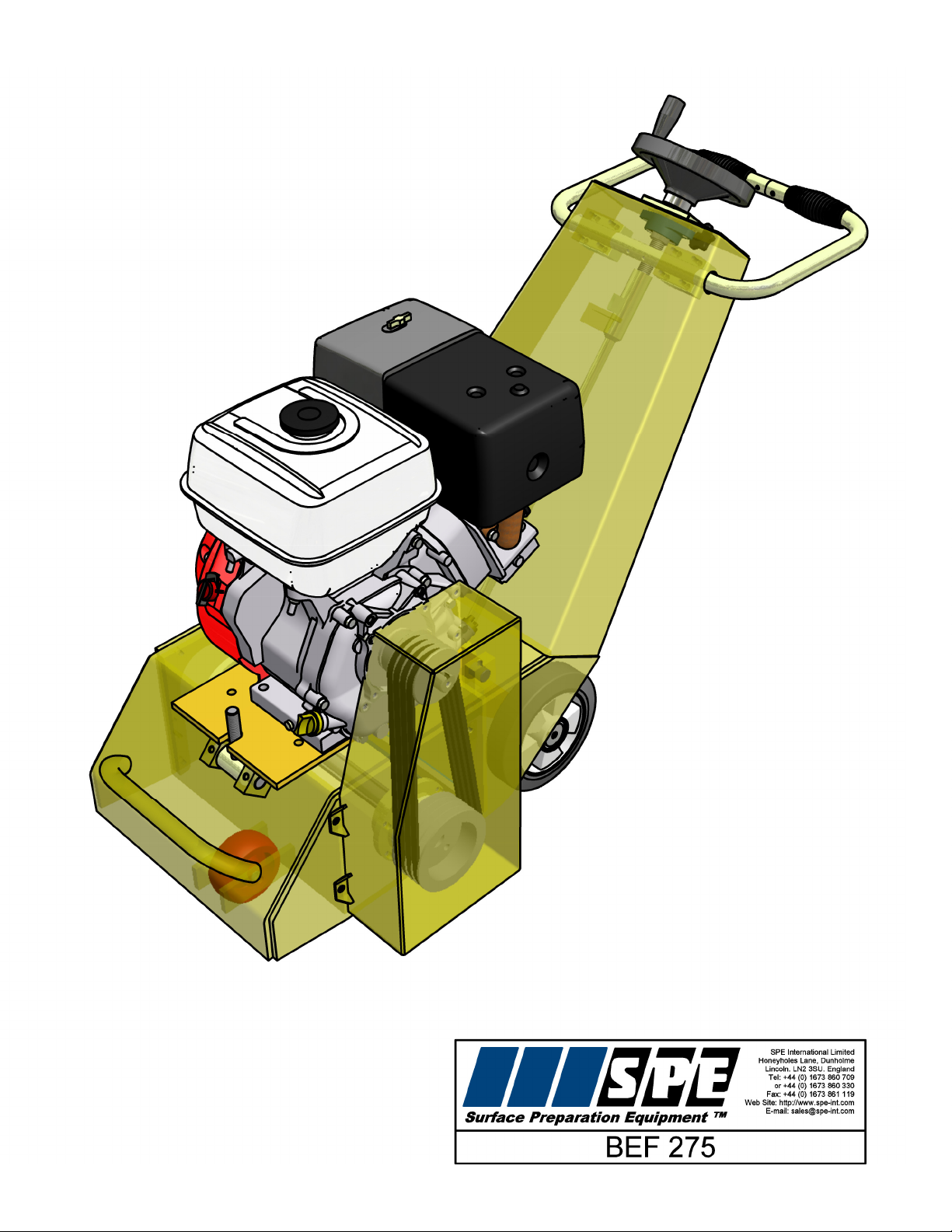

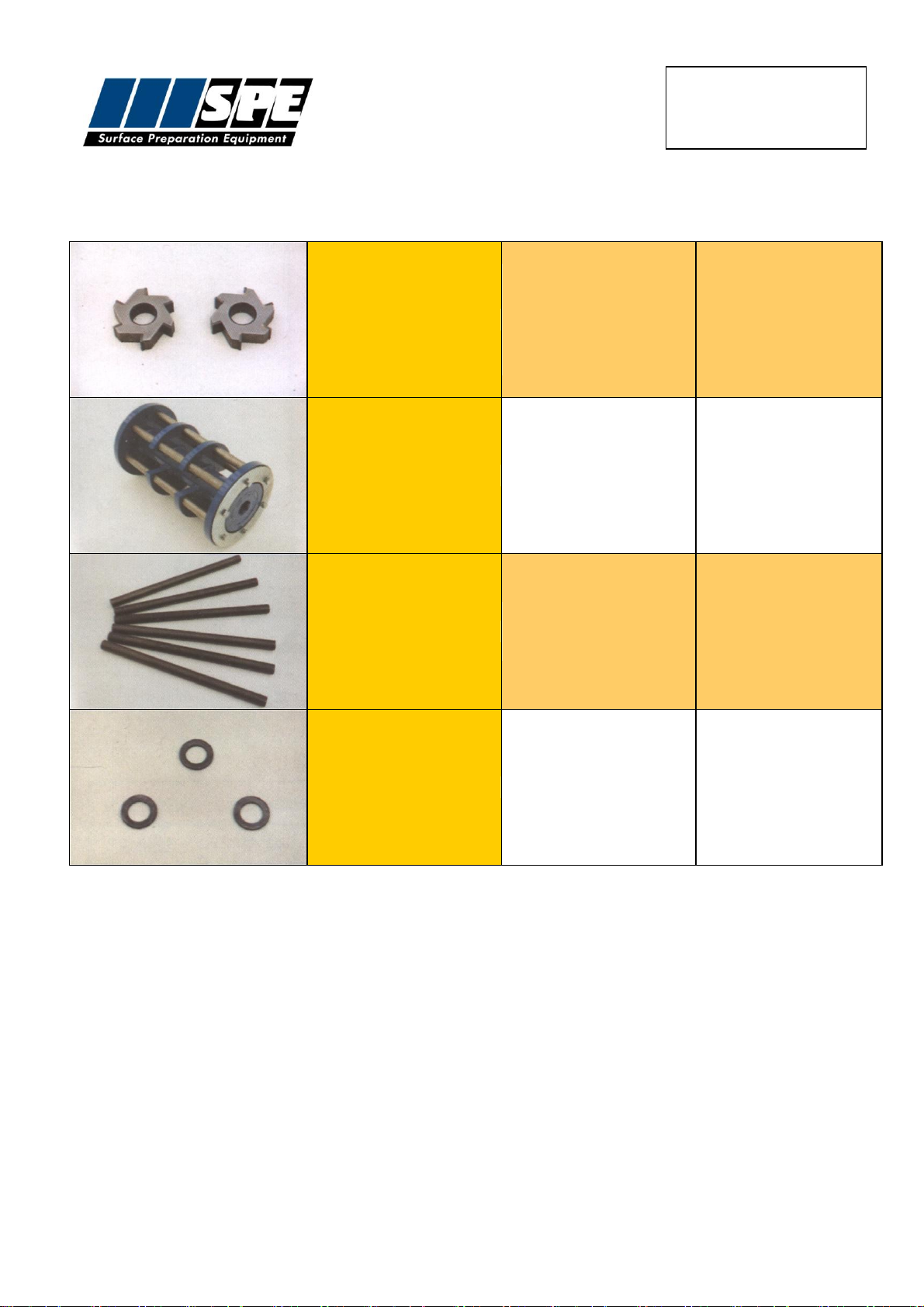

Part No

Description

Application

27501

Heavy duty drum complete with

T.C.T cutters and spacers.

For all concrete texturing,

scabbling planing and grooving

applications. Removal of bridge

deck and car park membranes,

heavy industrial contamination,

epoxy coatings and road

markings, reducing concrete. Use

on heavy applications for longer

life with higher output.

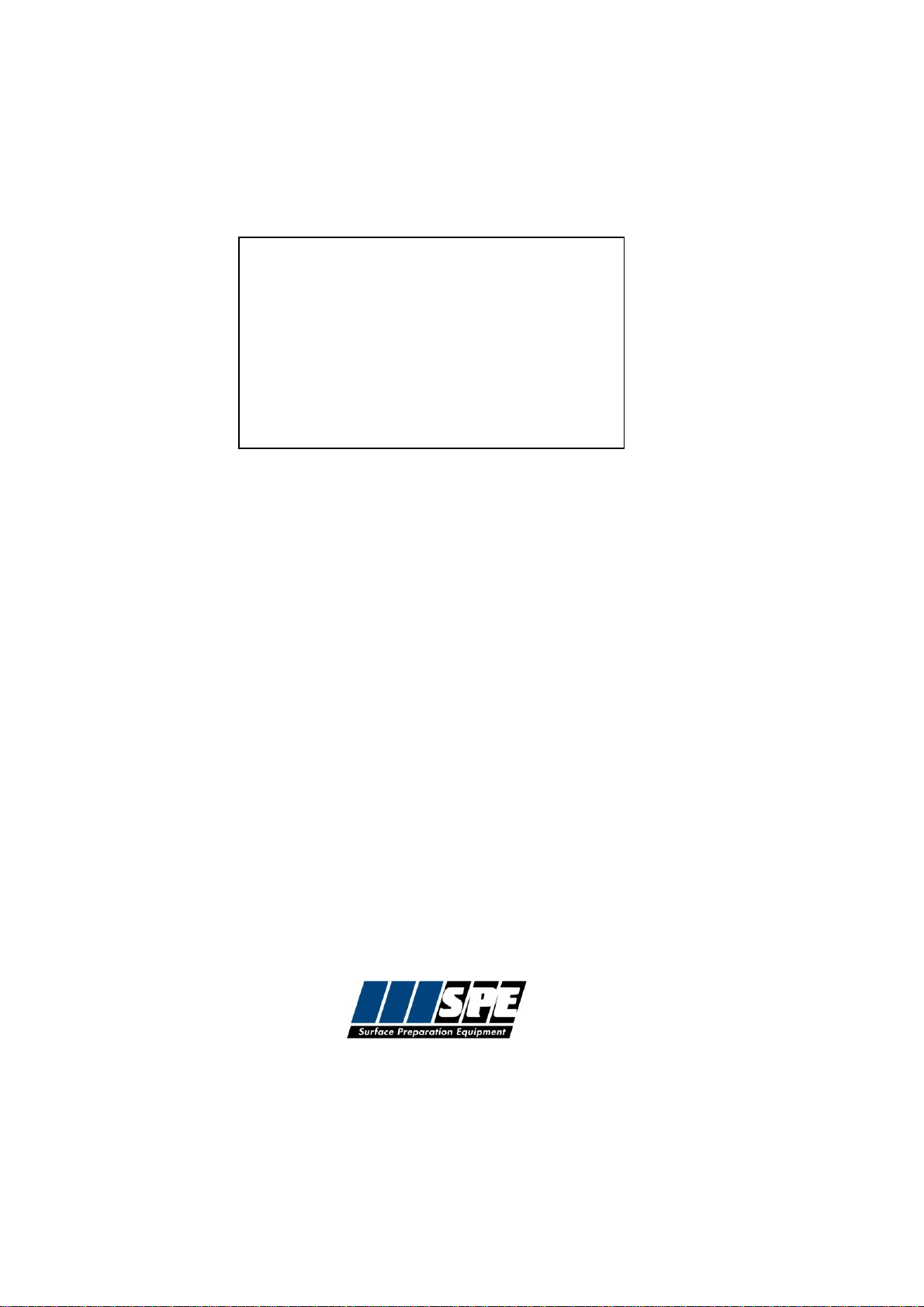

27502

Heavy duty drum complete with

beam flails.

For the removal of paint, laitence

and coatings from floors. De-

rusting and de-scaling ship decks.

Also used for removing build up of

grease, dirt and ice deposits.

Keying of concrete when a fine

textured surface is required

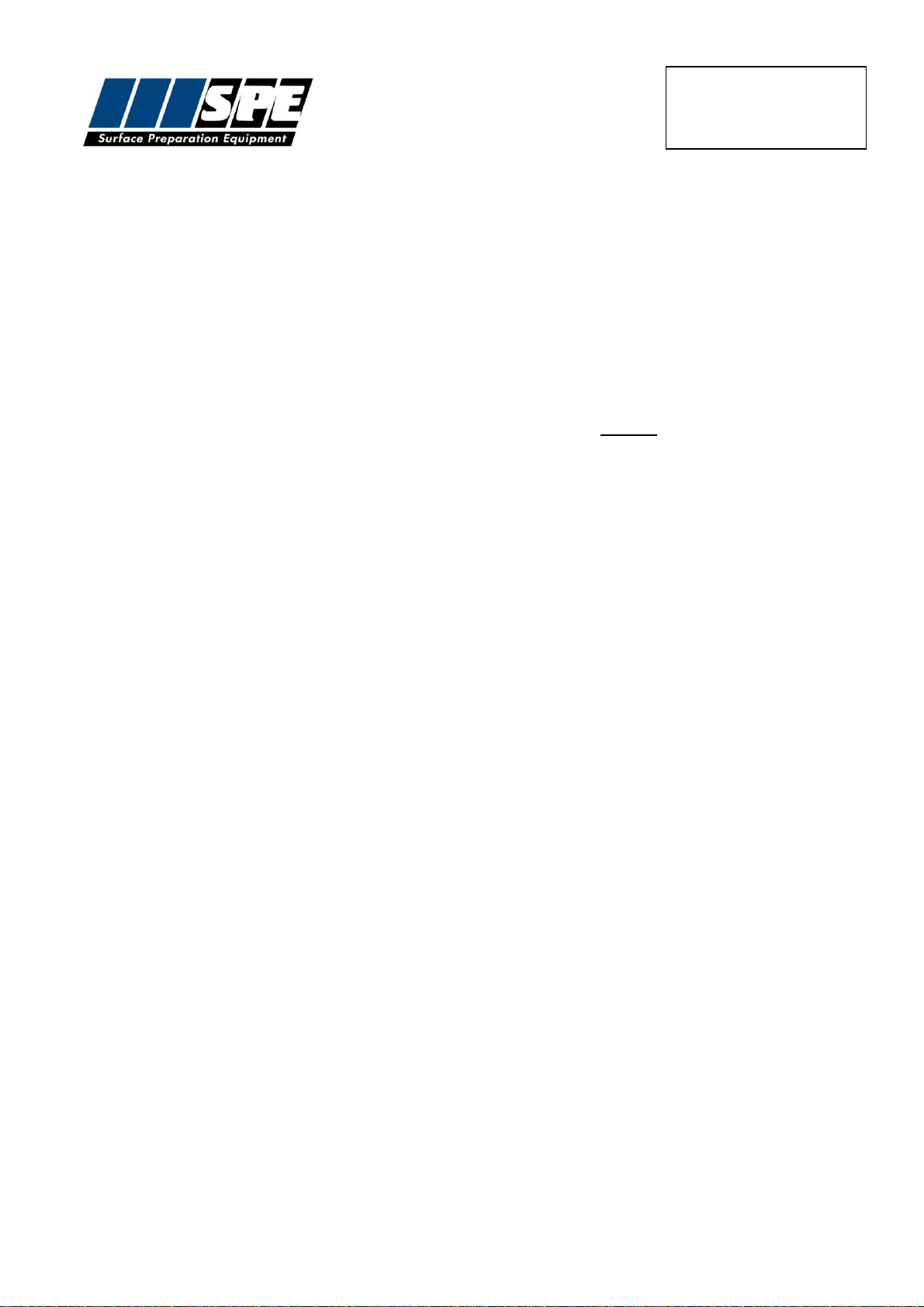

27504

Heavy duty drum complete with

milling cutters and spacers

For removal of thermoplastic

road/runway markings. Very

efficient and cost effective with

none of the problems associated

with burning off thermoplastics.

Also for the removal of bituminous

and rubber deposits.

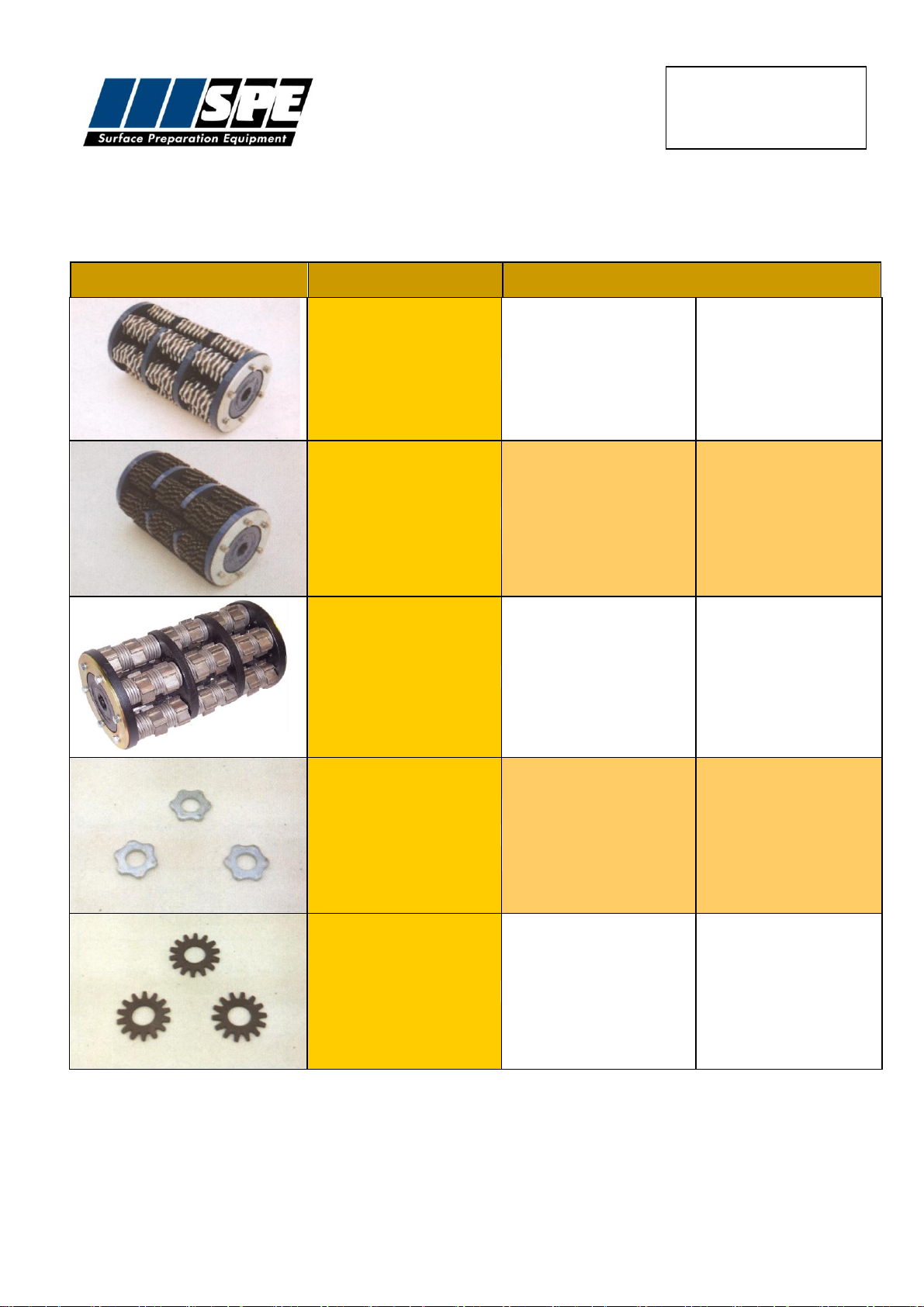

60600

T.C.T Cutter: 6 point hardened steel

cutter with tungsten carbide inserts

For all concrete texturing,

scabbling planing and grooving

applications. Removal of bridge

deck and car park membranes,

heavy industrial contamination,

epoxy coatings and road

markings, reducing concrete. Use

on heavy applications for longer

life with higher output.

60120

Beam cutter: Heat treated steel

cutter

For the removal of paint, laitence

and coatings from floors. De-

rusting and de-scaling ship decks.

Also used for removing build up of

grease, dirt and ice deposits.

Keying of concrete when a fine

textured surface is required.

ACCESSORIES

7

BEF275-1

Operating Manual

BEF275-1 ACCESSORIES

60620

Milling Cutter: Tipped with Tungsten

carbide.

For the removal of thermoplastic

road/runway markings, rubber

based deposits and cold plastic

coatings from asphalt and

concrete.

27500

Heavy duty drum complete with flail

shafts.

For use with various cutter

configurations.

27518

Heavy duty flail shaft.

Hardened cutter shaft.

40240

Spacing washer.

Hardened spacing washer.

8

BEF275-1

Operating Manual

12

BEF275-1

Operating Manual

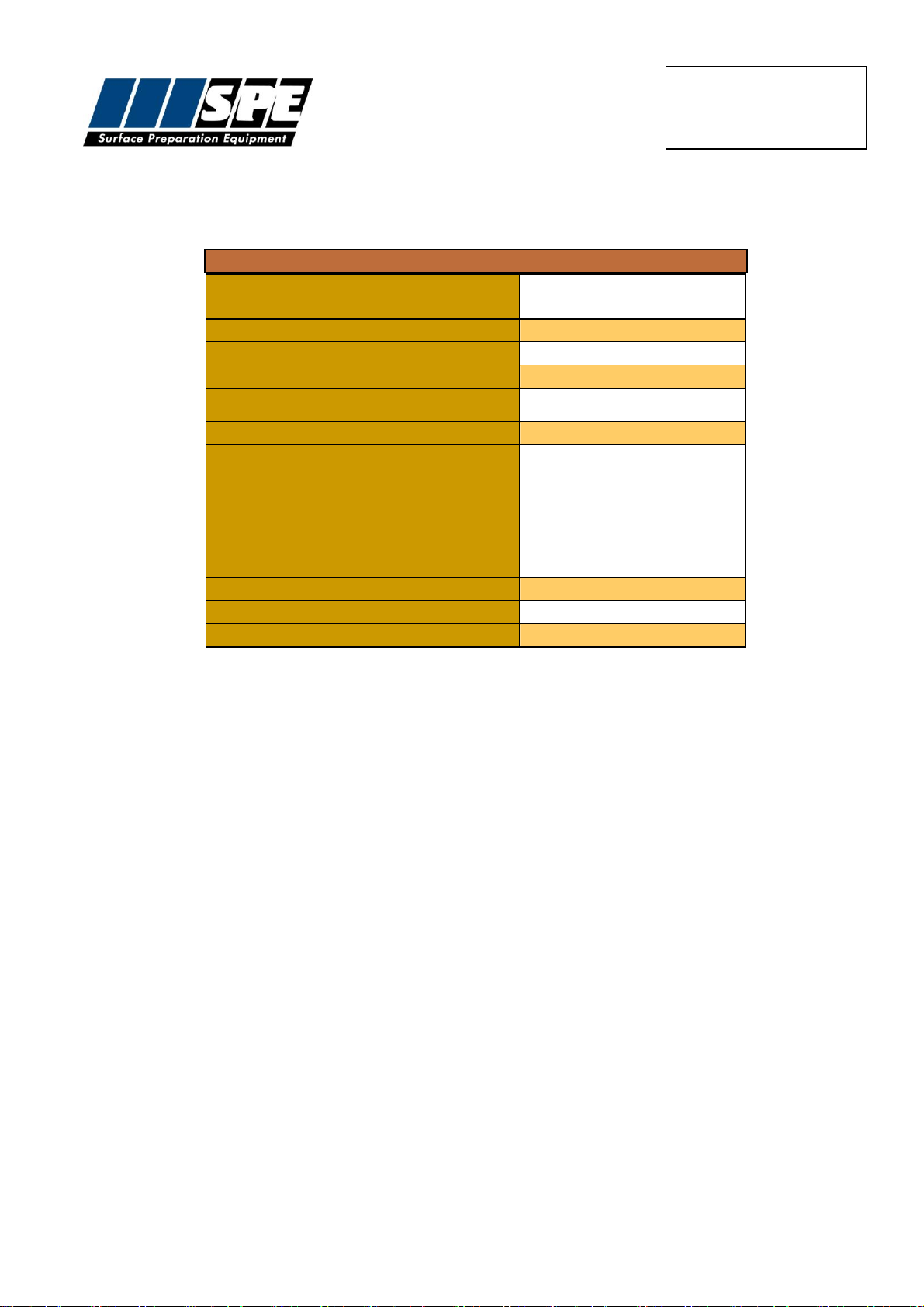

SPECIFICATION SHEET

Specifications

Type

BEF275

Petrol

Part Number

BEF275-1

Power Output

11hp

Voltage

-

Cycles

Cutter Head Speed (rpm)

1530/1640

Machine Dimensions:

(mm)

Length

Width

Height

Weight (kg)

1220

511

900

145

Working width of cutters (mm)

275

Working distance from walls (mm)

65

Engine/Motor speed (rpm)

3000

16

BEF275-1

Operating Manual

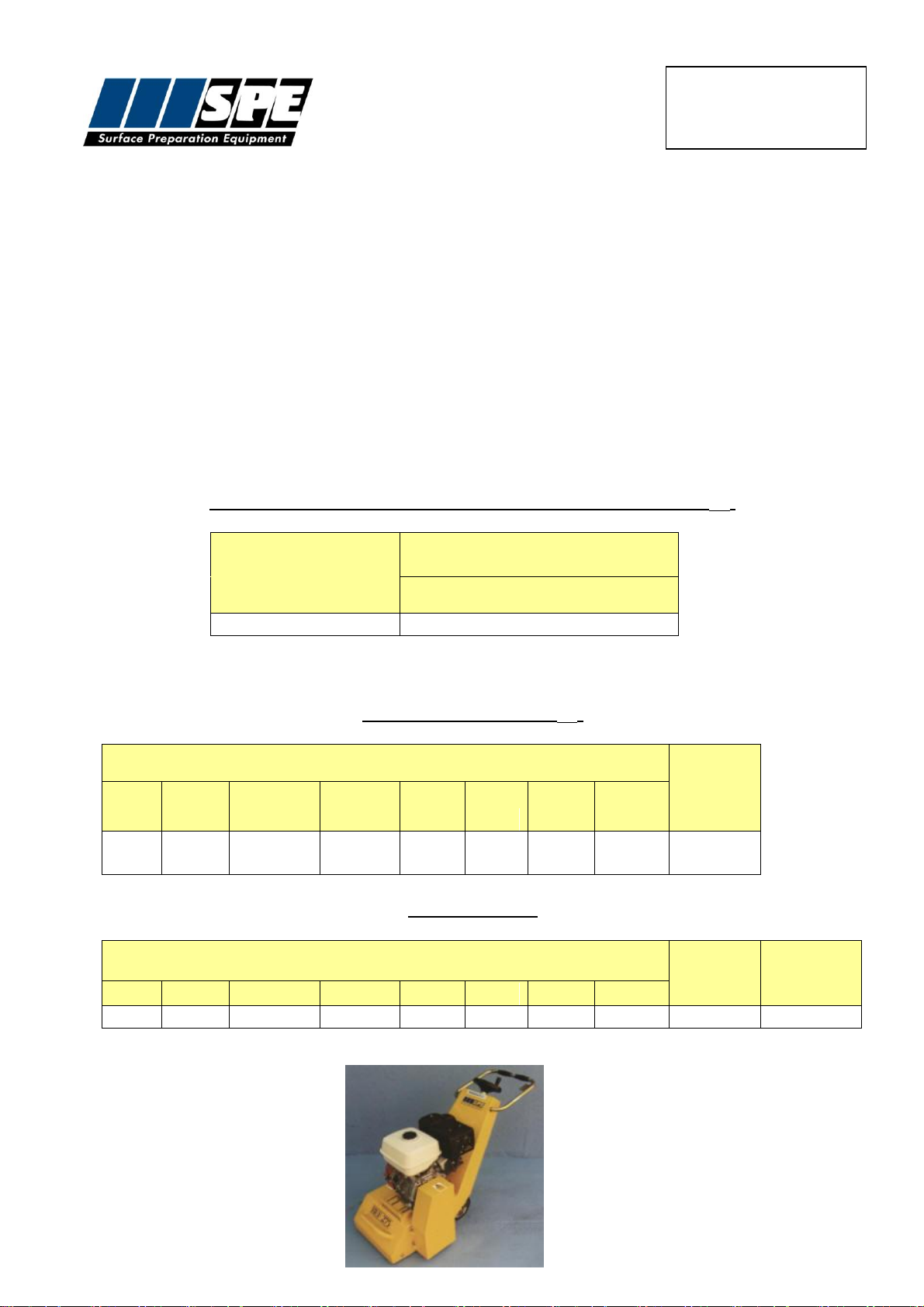

RECORD OF NOISE AND VIBRATION ASSESSMENT

Manufacturer:

SPE

Type:

Scarifier

Model No.

BEF275-1 Petrol

Motor:

Honda GX340 11HP

Operation :

Concrete floor surface

Inserted Tool:

TCT cutters

Running Conditions:

2910 rpm

HAV Note:

Operc

HAND-ARM VIBRATION

Frequency Weighted Energy Equivalent Accelerations (ah,w)

Measurement

Position

Acceleration (m/s2)

Vector Sum

Handle

5.3

NOISE LEVELS

Sound Power Level (LWA)

LWA at Octave Band Centre Frequency (Hz)

Sound

Power

Level

LWA

63

125

250

500

1000

2000

4000

8000

69.2

87.6

93.1

97.1

102.2

100.

3

96.9

89.9

106.0

Operator's Ear

LAeq,T at Octave Band Centre Frequency (Hz)

Overall

Level

(LAeq,T)

LPeak

dB(C)

63

125

250

500

1000

2000

4000

8000

54

71.2

76.3

85.3

89.7

87.7

83.1

75.9

92.3

107.3

17

BEF275-1

Operating Manual

WARRANTY

The standard warranty period of this equipment is 12 months from the date below in accordance

with the company Conditions of Sale (copy attached).

Warranty start date:

As despatch date

Model:

BEF275-1

Serial no:

Customer name:

Customer Address:

Manufacturer:

SPE International Ltd

Honeyholes Lane

Dunholme

Lincoln

LN2 3SU

England

Telephone:

+44 (0) 1673 860709

Fax:

+44 (0) 1673 861119

Email:

sales@spe-int.com

Web site:

www.spe-int.com

18

BEF275-1

Operating Manual

DECLARATION OF CONFORMITY

WE

SPE INTERNATIONAL LTD

OF

Honeyholes Lane

Dunholme

Lincoln

LN2 3SU

DECLARE that under our sole responsibility for the supply/manufacture of the product

(Description/name) BEF275 Multiplane

(Model/type) BEF275-1

to which this declaration relates is in conformity with the following standards and other normative

documents following the provisions of Directive 2006/42/EC.

....................................................

Brian Jacklin –Technical Manager

SPE INTERNATIONAL LTD

19

BEF275-1

Operating Manual

The quotation overleaf and any order placed following such quotation are subject to the following conditions of sale in which SPE

International Limited is referred to as the “Company”.

1. Validity of quotation

No order received from a customer by the Company shall constitute a contract until accepted in writing by the Company.

2. Prices

Prices quoted by the Company are firm for 30 days only or until previously withdrawn. Unless otherwise stated all prices are exclusive

of any applicable Value Added Tax for which the customer shall be additionally liable to the Company.

3. Delivery

Delivery periods and dates are given in good faith but are not the subject of any warranty or condition and time shall not be of the

essence of the contract in these respects. No liability will attach to the Company if delivery periods or dates are not met for any

reason whatsoever.

4. Payment

Save as may otherwise be agreed in writing the customer shall pay the price in full on or before the estimated delivery date

whereupon the Company shall raise a receipted invoice. Each invoice includes an Overdue Account Levy of 5% of the total invoice

value inclusive of VAT. Subject to payment in full being made on or before the due date a sum equal to the Overdue Account Levy

shall be credited to the customers account with the Company. Until such time as payment in full has been made the Company shall

be under no obligation to allow or effect of any goods to the customer.

5. Warranty

The Company warrants that all goods supplied by it will correspond to their specifications and will be free from defects in materials or

workmanship for a period of 12 months from the date of delivery. The Company’s obligation in the event of a breach of this warranty

is limited to the repair or replacement of any defective goods which shall be returned at the cost and expense of the customer to the

Company. This warranty is given in lieu of all the other warranty or conditions expressed or implied (whether by statute or otherwise)

and is subject to the following conditions:-

5.1 Claims must be notified in writing to the Company within seven days from the date of delivery or (where the defect is not

apparent on reasonable inspection) as soon as practicable after discovery of the defect.

5.2 The Company shall be under no liability in respect of any defect in the goods arising from any drawing, design or specification

supplied by the customer.

5.3 The Company shall be under no liability if the defect or failure in the reasonable opinion of the Company arises from wilful

damage or misuse, negligence by the customer or any third party. Failure to follow the Company instructions, usage of non-

recommended parts and materials, alteration or repair of the goods without the prior approval of the Company or non-recommended

maintenance.

5.4 The Company shall be under no liability if the price for the goods has not been paid by the due date for payment.

5.5 The above warranty does not extend to:-

5.5.1 Parts, materials or equipment not manufactured by the company in respect of which the customer shall be entitled only to the

benefit of any such warranty or guarantee as is given by the manufacturer to the Company.

5.5.2 Any component part of the goods or associated parts coming into contact with abrasive elements or dust within surface

Preparation equipment.

5.5.3 Fair wear and tear of moving parts within the goods.

5.6 Except in the case of death or personal injury caused by the Company negligence, the Company shall not be liable for any

consequential loss or damage (whether for loss of profit or otherwise) or other claims for consequential compensation.

6. Carriage

Packing, carriage and insurance charges in respect of delivery of the goods to the customer will be charged to the customer at cost to

the company.

7. Damage in Transit

The company does not accept any liability for loss or damage to the goods while in transit to the customer.

8. Risk

The risk in the goods shall pass to the customer on delivery to the customer or (if earlier) when possession of the goods is taken by a

carrier for delivery to the customer.

9. Force Majeure

The Company shall not be liable to the customer or be deemed to be in breach of any contract with the customer by reason of any

delay in performing or any failure to perform any obligation of the Company obligation in relation to the goods if the delay or failure

was due to force majeure or to any other cause beyond the Company’s reasonable control.

10. Reservation of Title

The goods sold under these conditions shall remain the absolute property of the Company and legal title in the goods shall remain

vested in the Company until payment in full of all amounts invoiced or due to the Company in respect of the goods. If the customer

shall enter into liquidation have a winding up order made against it or have a Liquidator, receiver, administrator or administrator

receiver shall be appointed over its assets, income or any part there of before the property in the goods has passed in accordance

with this condition the Company shall be entitled immediately after giving notice of its intention to repossess any goods to enter upon

the premises of the customer with such transport as may be necessary and to repossess any goods to which it has title under this

condition. No liquidator, receiver, administrator or administrative receiver of the customer shall have authority to sell goods to which

the Company has title without the prior written consent of the Company.

11 Insolvency of Customer

If the customer being a body corporate, shall pass a resolution or suffer an order of the Court to be made for winding –up, or if a

Receiver, Administrator or Administrative Receiver shall be appointed or, being an individual or partnership, shall suspend payment ,

propose or enter into any composition or arrangement with his or their creditors, or have a bankruptcy order made against him or

them, then the Company shall have the right, without prejudice to any other contract with the customer, not to proceed further with the

contract and shall be entitled to charge for work already carried out ( whether completed or not) and for goods and materials already

purchased for the customer such charge to be an immediate debt due from the customer.

12. Patent Rights, etc

The acceptance of a quotation includes the recognition by the customer of the Company under any patents, trademarks, registered

designs or other intellectual property rights relating to the goods and the customer undertakes that patent numbers, trademarks or

other trade markings on goods supplied shall not be obliterated, altered or defaced.

13. Applicable Law

These conditions shall be governed by and construed in accordance with English law and parties acknowledge and accept the

exclusive jurisdiction of the English Courts.

20

CONDITIONS OF SALE

This manual suits for next models

1

Table of contents

Other SPE Lawn And Garden Equipment manuals