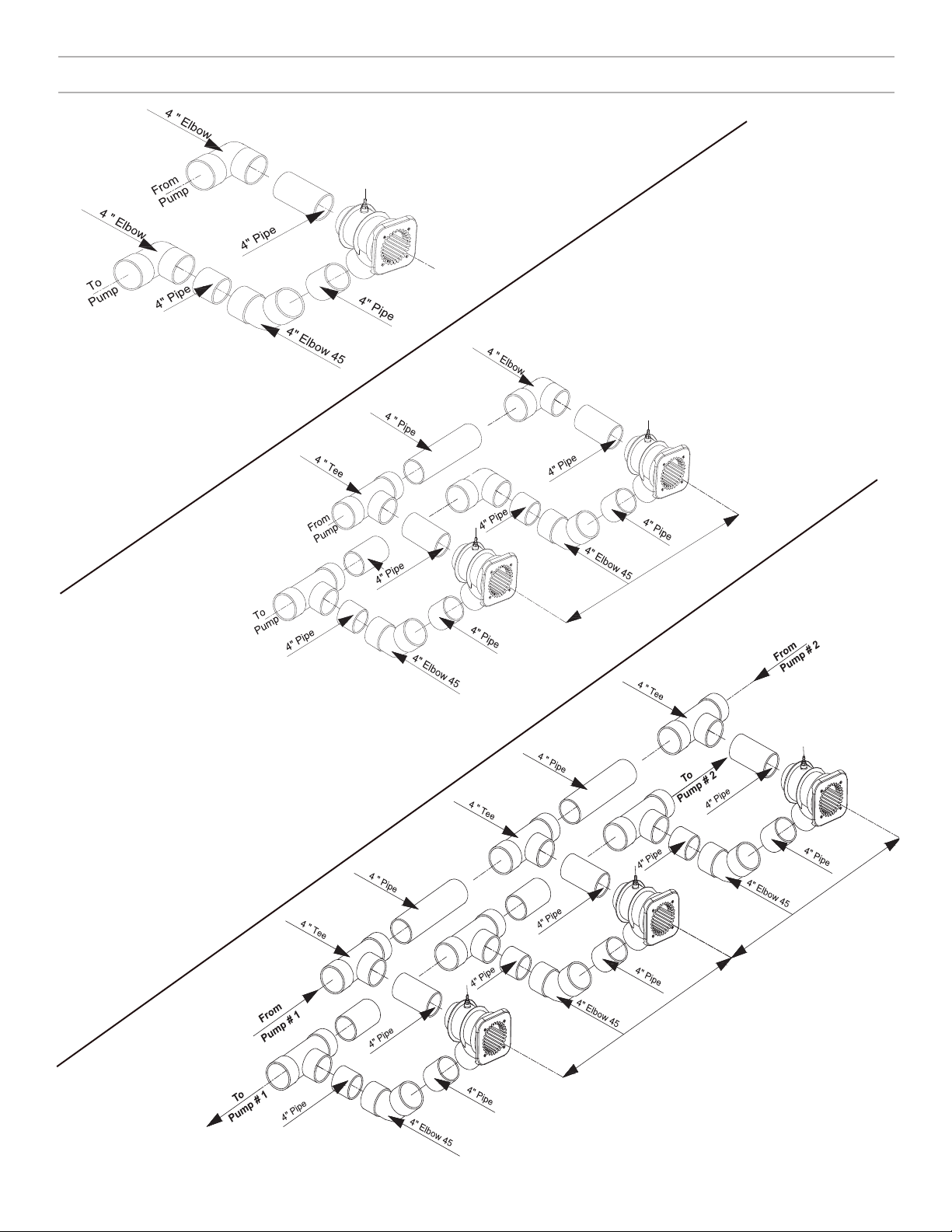

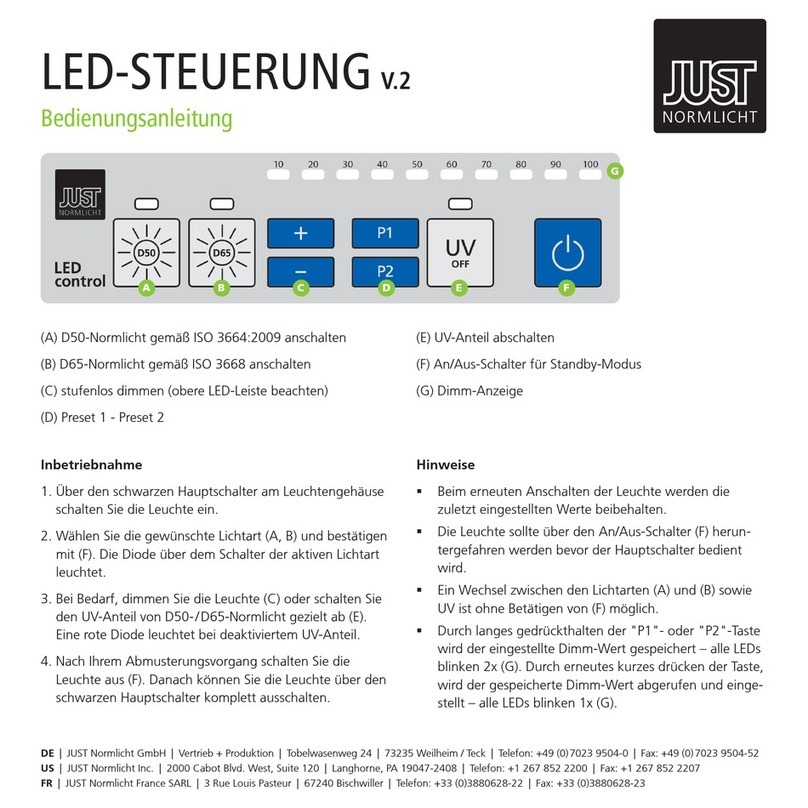

1. Using the clamping ring (part #3) as a template, drill holes

in the pool wall for installation. The center line of the clamping

ring should be 12” BELOW the water level (See Figures 14 &

15). Two additional holes will need to be drilled at the 3 and

9 o’clock positions for installation of the jet housing (part #7).

The four brass inserts in the clamping ring should be at the 2,

4, 8 and 10 o’clock positions (See Figure 14).

2. Mount the housing (part #7) and one clamping ring gasket

(part #12) on BEHIND the pool wall using two (2) #14 x 1”

counter sunk screws (part #27). Install the screws from the

inside of the pool wall through the holes drilled at 3 and 9

o’clock positions. (See Figure 14)

3. Install the clamping ring (part #3) and a second clamping

ring gasket (part #12) in FRONT of the pool wall using eight

(8) M6 screws (part # 9/2, 9/3, or 9/4). Screw lengths vary

depending on the installation. NOTE: A good RTV silicone may

be used with the gasket when mounting the jet housing, but in

most cases is not necessary. Installer should decided whether

or not the silicone is necessary.

NOTE: When installed properly, the center of the housing (part

#7) will be 12” BELOW the surface of the water and the air

regulator hose nipple (part #14) will be at the top center of

the jet housing.

CAUTION: When installing the BaduStream Cover (part #8).

Use a Phillips head screw driver and tighten to 1.5 Nm or hand

tight. DO NOT use electrical or air drills. (NOTE: The square

cover, part #8, will have an uneven appearance if the housing

is not installed properly.)

4. For the air regulator assembly, one 1/2” hole must be

provided, preferably along the vertical axis, approximately

3-4” ABOVE the water line. (See Figures 14 & 15). Using the

60 x 11 x 2mm air regulator gasket (part #21), mark and drill

two 1/4” mounting holes (See Figure 14). Use the two (2) 1/4 -

20 air holder screws (part #18) and two 1/4-20 air holder nuts

(part #19) to mount the air regulator holder.

NOTE: Part #18 & Part #21 go in FRONT of the pool wall; Part

#19 & Part #17 go BEHIND the pool wall.

5. Keep all parts not being used now in original box. Store in a

safe place until needed.

6. Once the pool is complete, install the square cover (part #8)

using the four (4) square cover screws (part #9/1).

For Liner Pools Only: Install the jet housing and air regulator

prior to installation or replacement of the pool liner.

For Steel Walled Pools: An optional butterfly gasket (part

#12.1) maybe purchased to replace the two (2)clamping ring

gaskets (part #12). Increase the jet housing hole in Figure 14

from 5.59” to 5.75” for installation.

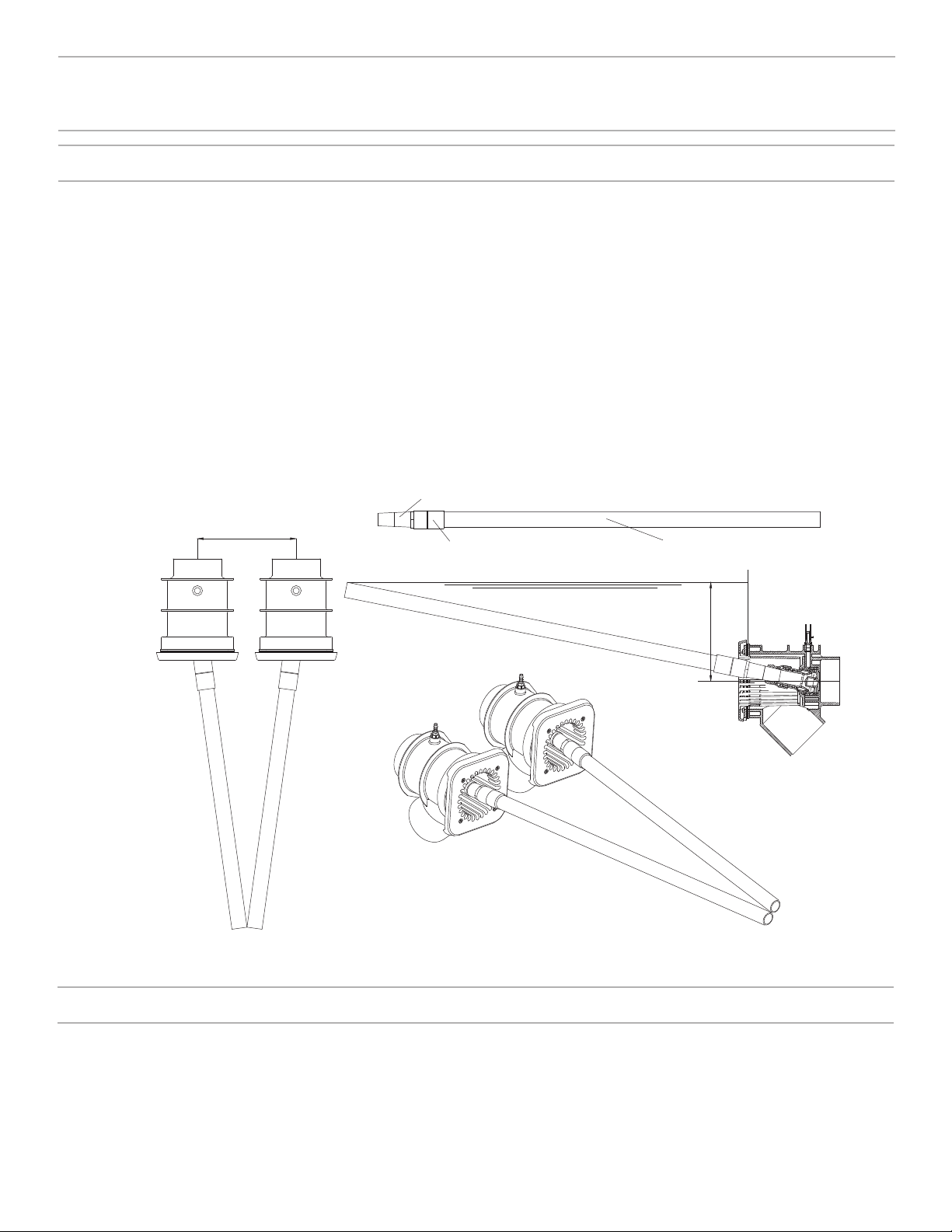

12”

Housing

Discharge

Deck

Air Regulator

Air Line

3”

Minimum Water Level

Suction

Liner &

Wall

Fitting 4”

Pipe

Fitting 4”

45oElbow

Water Level

0.5” 1.70”

0.25”

12”

3”

Minimum

0.3”

25o

6.54” dia

5.59” dia

For Liner & Fiberglass Pools Only

(Jet House Mounting Holes)

14

Liner and/or Fiberglass Pool Installation

Figure 14

Figure 15

Cutout Pool Wall for BaduStream housing.

BaduStream in Liner or Fiberglass Pool.