Speck pumps Badu Stream II User manual

2999999189 - Rev. 0920 - SW FA.300.JP

Technical Support:

Address: Speck Pumps

8125 Bayberry Road

Jacksonville, FL. 32256

USA

Hours: (Monday - Friday) 8:00 am to 5:00 pm EST

Toll Free: 800-223-8538

Phone: 904-739-2626

Fax: 904-737-5261

Website: www.usa.speck-pumps.com

Manufactured by Speck Pumps, Jacksonville Florida USA, ©2021 All Rights Reserved.

This document is subject to change without notice.

Date of Installation:

Installed by:

Serial Number:

For Service Call:

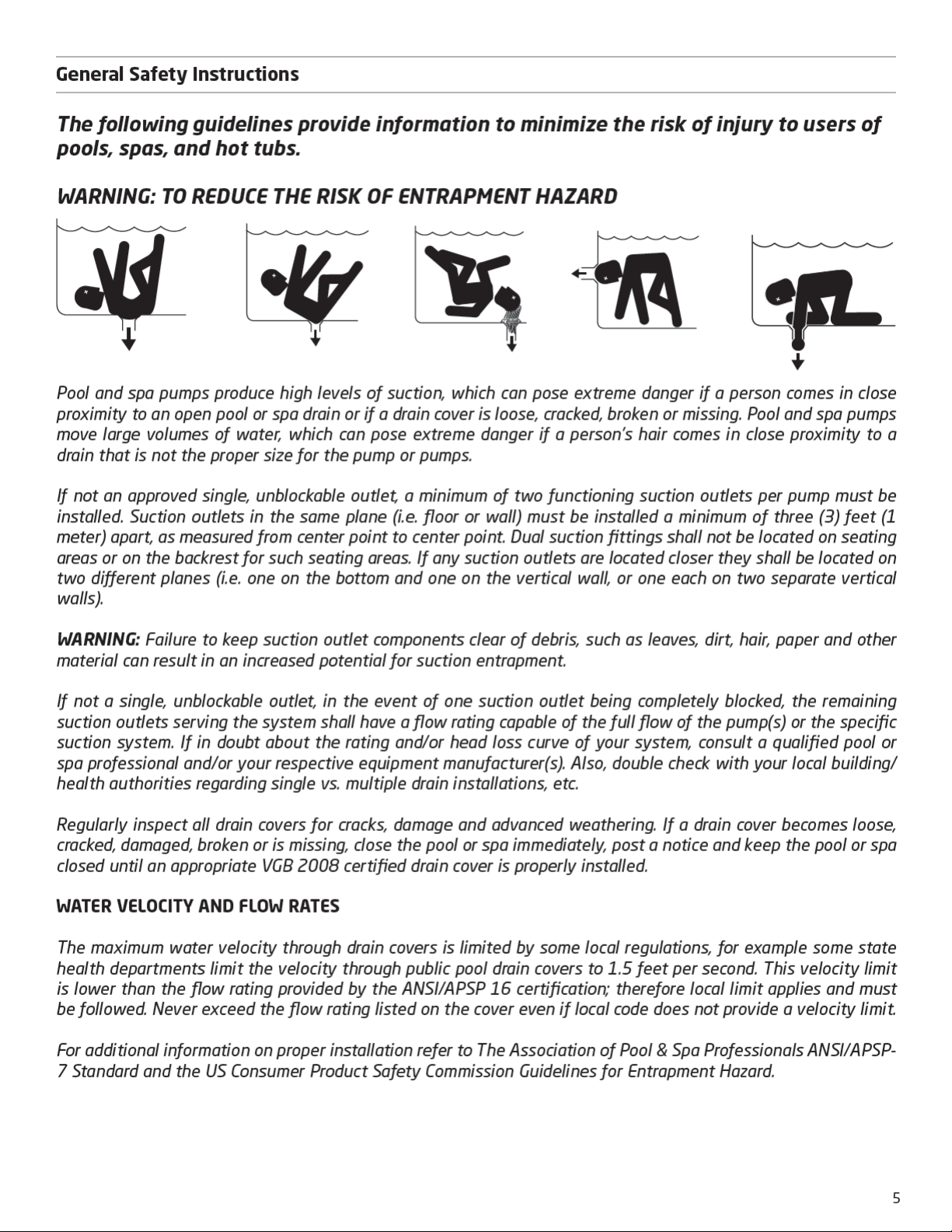

Swim Jet Combination Fitting - Manufacturers Warnings

4

WARNING: Before Installing this product, read and follow all warning notices and instructions which are included.

Failure to follow safety warnings and instructions can result in severe injury, death, or property damage. Call

(800) 223-8538 or visit www.usa.speck-pumps.com for additional copies of these instructions.

1 Important Safety Instructions

MUST BE INSTALLED by an experienced and qualified pool industry professional ONLY.

Attention Installer: This manual contains important information about installation, operation, and safe use of

this product. This information should be given to the owner and/or operator of this equipment. Most states and

local codes regulate the construction, installation and operation of pools and spas. It is important to comply with

these codes, many which regulate the installation and use of this product.

1. DO NOT locate this fitting in seating areas or on the back rests for such seating areas.

2. This fitting should be mounted in the vertical pool wall only per manufacturer’s instructions.

3. All fittings and fasteners should be examined for damage or tampering before each use.

4. Any missing, broken, or cracked fittings must be replaced before using this product. Only genuine Speck

replacement parts may be used.

5. Acceptable fittings/pipe sizes are listed on page 8 of this manual. No other sizes are permitted.

6. Never exceed the maximum flow rate stated on this product.

7. The anti-entrapment cover must be in place when using this product. DO NOT use this product if the cover is

missing, broken, or loose.

8. The anti-entrapment cover (part# 8) should be replaced within 10 years from installation date.

9. Installation requires a Phillips screw driver. Hand tighten only. DO NOT use electrical or air drills.

10. Consult your physician before exercising with the Badu®Stream II or using the massage hose.

11. DO NOT permit children to use this product unless they are closely supervised at all times.

12. DO NOT remove any safety alert labels such as DANGER, WARNING, or CAUTION. Keep safety alert labels

in good condition and replace missing or damaged labels.

13. Stay alert, watch what you are doing and use common sense. DO NOT use unit if you are tired and/or ex-

hausted. DO NOT use unit while under the influence of drugs, alcohol, or any medications.

CAUTION: DO NOT increase pump size; this will increase the flow rate through the system and exceed the

maximum flow rate stated on this product.

IMPROPER INSTALLATION OR USE OF THIS PRODUCT MAY PRESENT A RISK OF HAIR OR BODY ENTRAPMENT

AND DROWNING. Install this equipment in accordance with the instructions provided.

As the manufacturer, Speck Pumps-Pool Products, Inc., hereby certifies that their Swim Jet Combination Fitting

meets or exceeds the requirements of the Virginia Graeme Baker Pool & Spa Safety Act, VGB 2008 and ANSI/

APSP 16-2011 standards and safety regulations as set forth by the Consumer Products Safety Commission.

“Read, and then keep these instructions for future reference”

7

2 General Description

Receiving Information

The Badu SwimJet Systems from Speck Pumps are designed to be installed during the construction of your pool to create a

water treadmill for anyone wanting a therapeutic and eective exercise.

The Badu SwimJet Systems can be installed in any type of pool, large or small, from gunite to vinyl liner. It has no protruding

parts ensuring pool user’s safety, is very compact and installs at minimal cost. The self-contained, flush-mounted unit is a

jet-propulsion system that pumps water into the pool creating a current in excess of 5,700 gallons per minute from a single

recessed jet housing.

Topping o the experience is the pulsating massage hose which can be attached to the jet nozzles for easy and convenient

massage treatments for joints and muscles. (NOTE: The massage hose is sold separately.)

Badu®Stream II

3 Installation Information

1. Upon receipt of the swimjet system, check the cartons for damage. Open each carton and check the pump(s), jet housing(s),

and control box for concealed damage, such as cracks, dents, or a bent base. If damage is found, contact the shipper or

distributor where the swimjet was purchased.

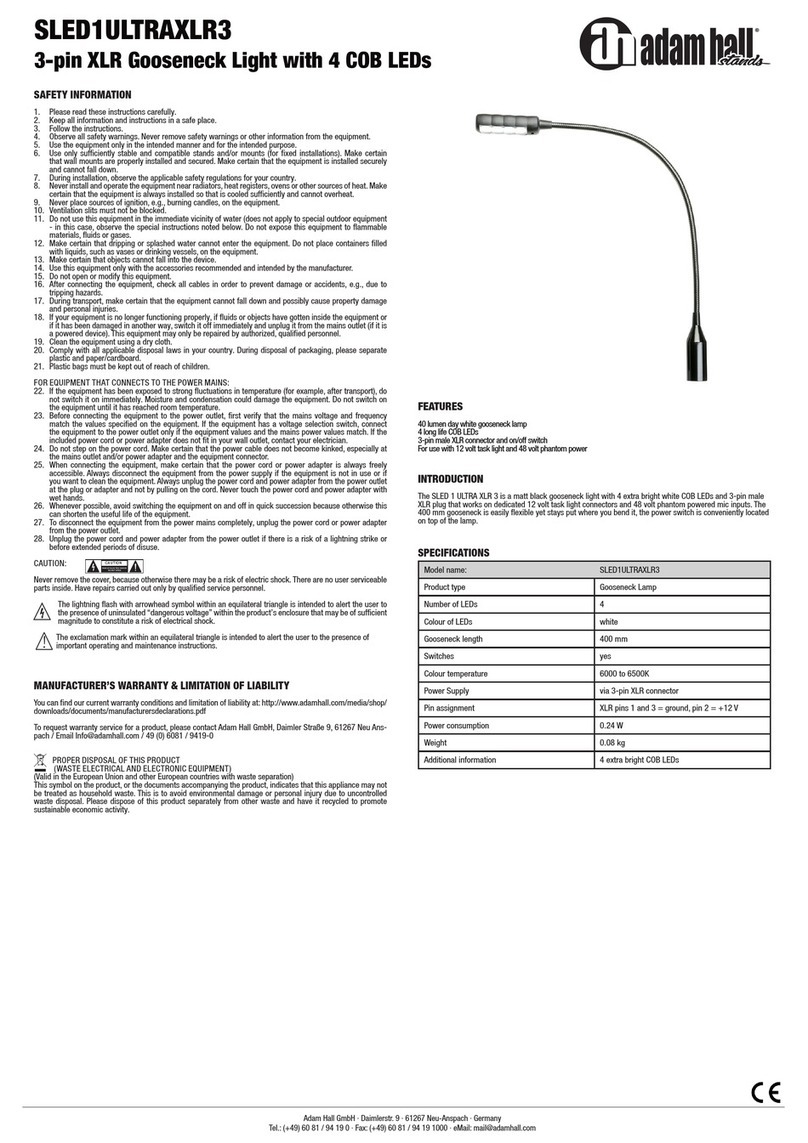

2. Inspect the contents of each carton and verify that all parts are included. (See Image 1)

A

DF

B

E

C

G

Image 1

BaduStream II System (1 jet & 4 HP pump)

Flush-mount jet housing

Square, anti-entrapment cover (81/4” x 81/4”)

undetectable pump suction. (Optional Round

Cover available)

Adjustable water flow jet nozzle

Air regulator adjusts amount of air bubbles in

water flow.

Control box complete with GFCI and WiFi

control module.

SPECK Model 21-80/33GS 4.0 HP (or a SPECK

Model 72-VI 3.5 HP) self-priming, single

phase plastic pump with built-in thermal

overload (no motor starter required). Optional

three phase pump and control box available.

(NOTE: Flooded suction pump available for

installation below water level.)

System (ON/OFF) LED Touch Button - Complete with 1.5” threaded housing fits into any 1.5” return fitting. The

Touch button turns the swimjet system ON/OFF. Waterproof button may be installed below water level.

A.

B.

C.

D.

E.

F.

G.

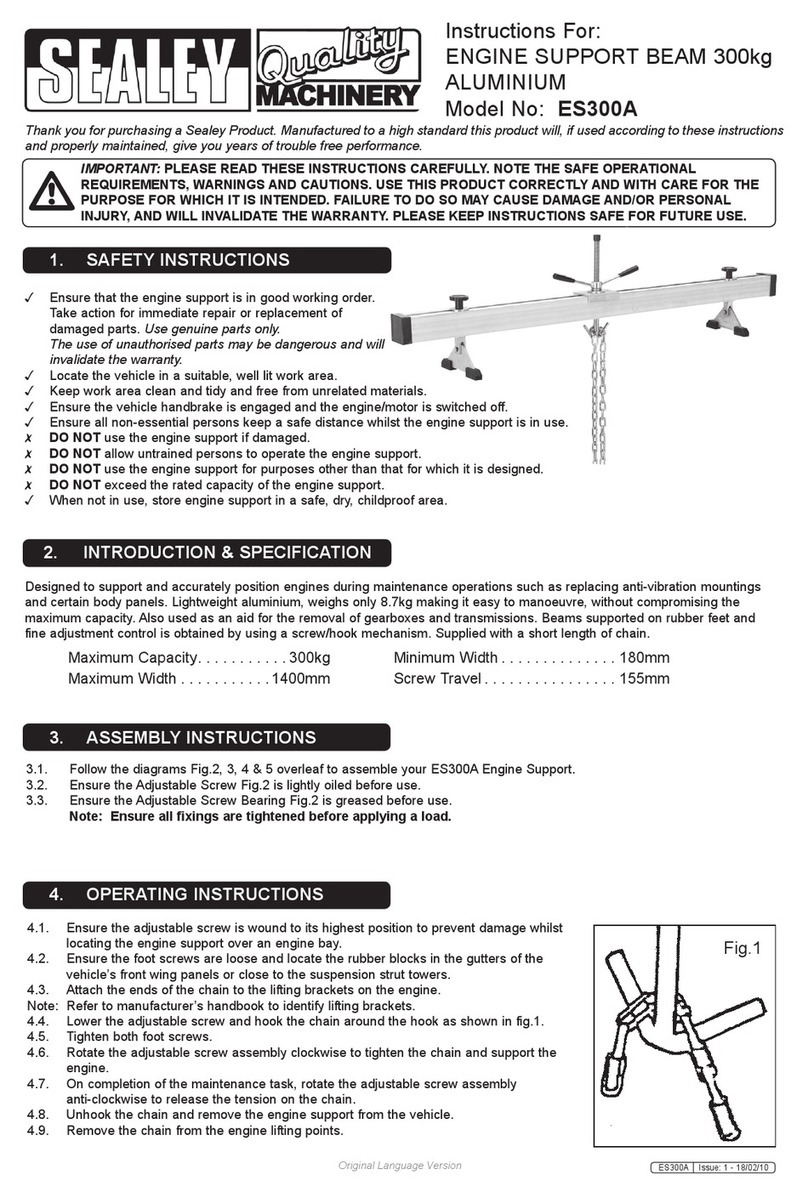

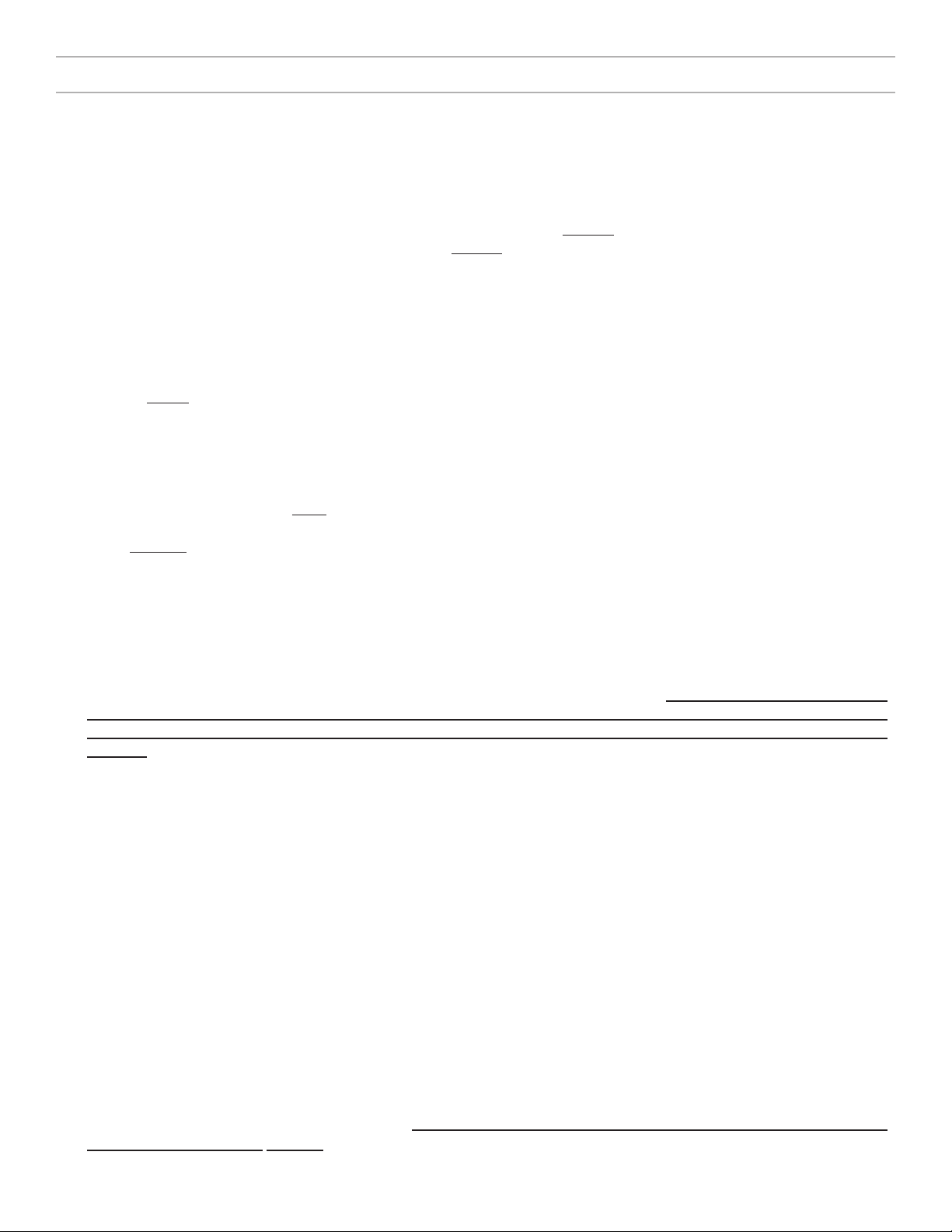

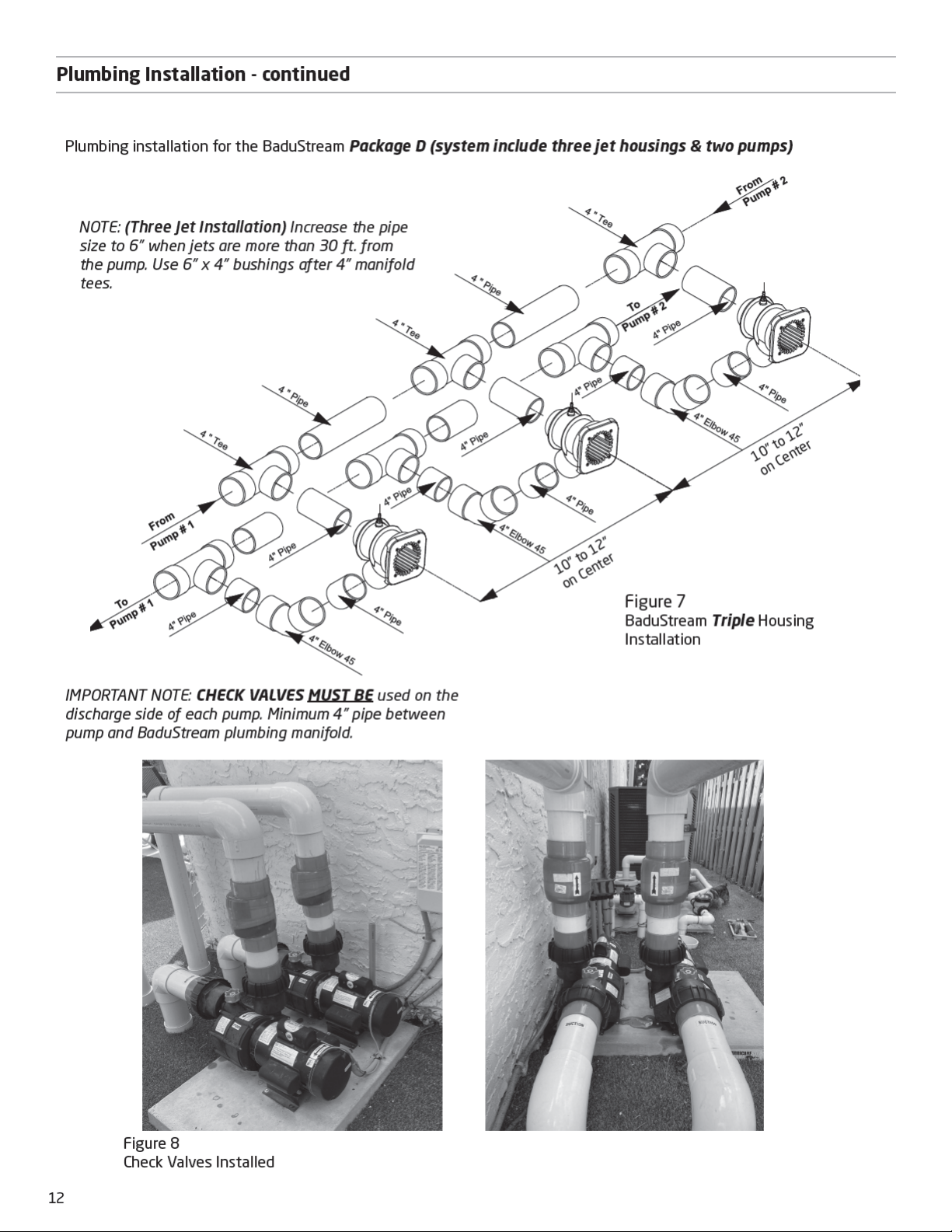

Plumbing Installation

8

For optimal performance, use 4” plumbing when the total distance between the pump and jet housing is 30 ft or less.

The plumbing should be as direct and free from turns or bends as possible because elbows and other fittings can

create large friction losses and reduce the performance of the system. The shortest length of pipe with the

minimum number of fittings possible should be used to avoid any significant friction loss due to the pipe and

fittings. NOTE: Refer to Figure 2 for the BaduStream head loss curve.

A maximum of seven (7) 90oelbows may be used with 30 ft of horizontal 4” pipe for the suction line and 30 ft of

horizontal pipe for the discharge line without negatively aecting the performance of the system.

NOTE: This applies to each individual pump used on the system. Refer to Figure 4 for the maximum TDH allowed to

achieve recommended flow rates.

If more elbows are required for the installation, 4” sweeps must be used in place of the elbows. When using sweeps

instead of elbows, a maximum of nine (9) 4” sweeps may be used with 30 ft of horizontal 4” pipe for the suction line

and 30 ft of horizontal 4” pipe for the discharge line without negatively aecting the performance of the system. NOTE:

This applies to each individual pump used on the system. Refer to Figure 4 for the maximum TDH allowed to achieve

recommended flow rates.

If the pump(s) cannot be located within 30 ft of the jet housing(s) using the maximum number of 4” elbows or sweeps

stated above, then 6” plumbing must be used. For the suction line, use 6” plumbing and fittings from the connection

at the jet housing (or at the manifolds for two and three jet systems) to a point directly beneath the pump. From that

point, install a 6” elbow. Then run 4” pipe vertically up to the suction connection of the pump and finish with a 4” elbow.

For the discharge line, 6” plumbing should be installed from the discharge connection of the pump all the way to the

pressure connection of the jet housing (or manifolds for two and three jet systems).

For two and three jet systems, the jet housings must be installed as close to 10” center to center as possible for

maximum performance. DO NOT install the jet housing more than 12” apart on center. (See Figure 1 & 1A)

n

n

n

n

n

CAUTION: The discharge connection is at the center of the back of the jet housing. The suction connection is at the bottom

of the jet housing.

CAUTION: The suction line should remain below water level from the suction connection at the jet housing to a point directly

beneath the pump.

CAUTION: The center of the BaduStream jet nozzle(s) must be located 12” BELOW the water line for maximum performance

and eciency. The air regulator(s) should be located 3-4” ABOVE the water line.

CAUTION: In areas with soft soil conditions or with frequent earth movement, a flexible section of 4” hose should be

installed at the back of the jet housing to prevent plumbing or jet housing damage.

CAUTION: For trouble-free pump priming (up to 4 feet above the water line), first install a 6” long riser in the discharge

connection on top of the pump(s). Then install an elbow and lead the discharge line(s) downward to the discharge connection(s)

at the BaduStream jet housing(s) (Not required with 3.5 HP pump Model 72). On systems with 3 jet housings and 2 pumps,

check valves MUST be installed at the discharge connections at each pump.

CAUTION: Allow at least 12 hours curing and bonding time. Insucient curing and bonding times can result in leaks and

flooding.

CAUTION: Throughout the entire installation, make sure the plumbing connected to the BaduStream jet housing is well

supported. Unsupported plumbing WILL crack the jet housing.

CAUTION: DO NOT use the pump as a fixed point (support) for the plumbing.

CAUTION: When using 6” pipe, install 6” x 4” reducer bushings as close to the jet housing(s) as possible. For systems with 2

or 3 jet housings, install the 6” x 4” reducer bushings as close to the 4” manifold tees as possible. The 6” suction line should

be run from the jet housing(s) and remain under the water line to a point directly beneath the pump. Install a 6” elbow at

that point. Then run 4” pipe vertically up to the suction connection of the pump and finish with a 4” elbow.

0

U.S. Gallons per Minute

60

20

40

10

30

50

Total Head in Feet

180 200 220 240 260 280 300

~

70

9.25”

3.25”

0.79”

1.97”

1.97”

4.49”

4.92”

8.27”

7.32”

6.54”

5.59”

4.72”

4.49”

4.92”

Plumbing Installation - continued

9

Higher resistance which results in less ecient priming and a higher

risk of cavitation.

Longer priming time (up to 12 min).

Keep the suction and pressure lines as short and straight as possible.

If the pump is positioned further away, then the pipe dimensioning

has to be adapted so that almost loss-free flowing is ensured.

BaduStream II Head Loss Curve (Single Jet Housing)

Figure 2 Figure 3

BaduStream dimensional drawing

NOTE: Suction lines which are too long have significant disadvantages:

n

10” - 12” from center to center

10” - 12” from center to center 10” - 12” from center to center

Two Jet (10” - 12” from center to center)

Figure 1

Three Jet (10” - 12” from center to center)

Figure 1A

n

n

n

Air Regulator

Discharge Line

Vertical

Check Valve

Vertical Suction Line

6 " Riser

Control Box

Valves (Optional)

Discharge Line

Horizontal Suction Line

4"

4"

4"

4"

4"

3"

Minimum

Horizontal

12"

Maximun 4 Feet

Allow 12" to prevent

cavitation of the pump

Disconnect

Service

Water Level

Pump

Pressure Line

max. 30 feet with 4 " pipe

(Check Valve(s) are required if the pump is

more than 4 ft. ABOVE the Water Level)

Plumbing Installation - continued

10

* 6” pipe will allow distances of well over 50 ft. There is

50ft of cable included with the touch button. If a longer

distance to the control box is required, a junction box

can be installed above the water line to splice additional

cable as required.

Figure 4 NOTE: Valves are recommended when pump is installed below water level

(flooded suction applications).

NOTE: To avoid stress on the jet housing, the jet housing and 2 to 3 inches of

plumbing stub out may be encased in gunite or concrete.

NOTE: The BaduSteam assembly package contains all necessary parts for the installation of the unit into concrete, gunite,

liner or fiberglass pools.

CAUTION: All necessary screws and bolts included with the BaduStream are stainless steel. ALL screw threads and

threaded inserts are METRIC! ONLY METRIC bolts and nuts may be used! The two exceptions are the suction and discharge

connections on the BaduStream and pump housing (4” slip connections) and the mounting hardware for the air regulator

assembly (1/4 -20 threads). All screws should be HAND TIGHT. DO NOT use drills or pneumatic tools. DO NOT over tighten!

Plumbing Requirements

BaduStream II Pump Distance Pipe Size Approx. Flow TDH

Three Jets (2) 4 HP 10 to 30 ft.

up to 50 ft.*

4”

6”

651 GPM

651 GPM

42 ft

42 ft

Two Jets 4 HP 10 to 30 ft.

up to 50 ft.*

4”

6”

380 GPM

400 GPM

34 ft

32 ft

One Jet 4 HP 10 to 30 ft.

up to 50 ft.*

4”

6”

217 GPM

217 GPM

53 ft

53 ft

One Jet 3 HP 10 to 30 ft.

up to 50 ft.*

4”

6”

200 GPM

200 GPM

12 ft

12 ft

13

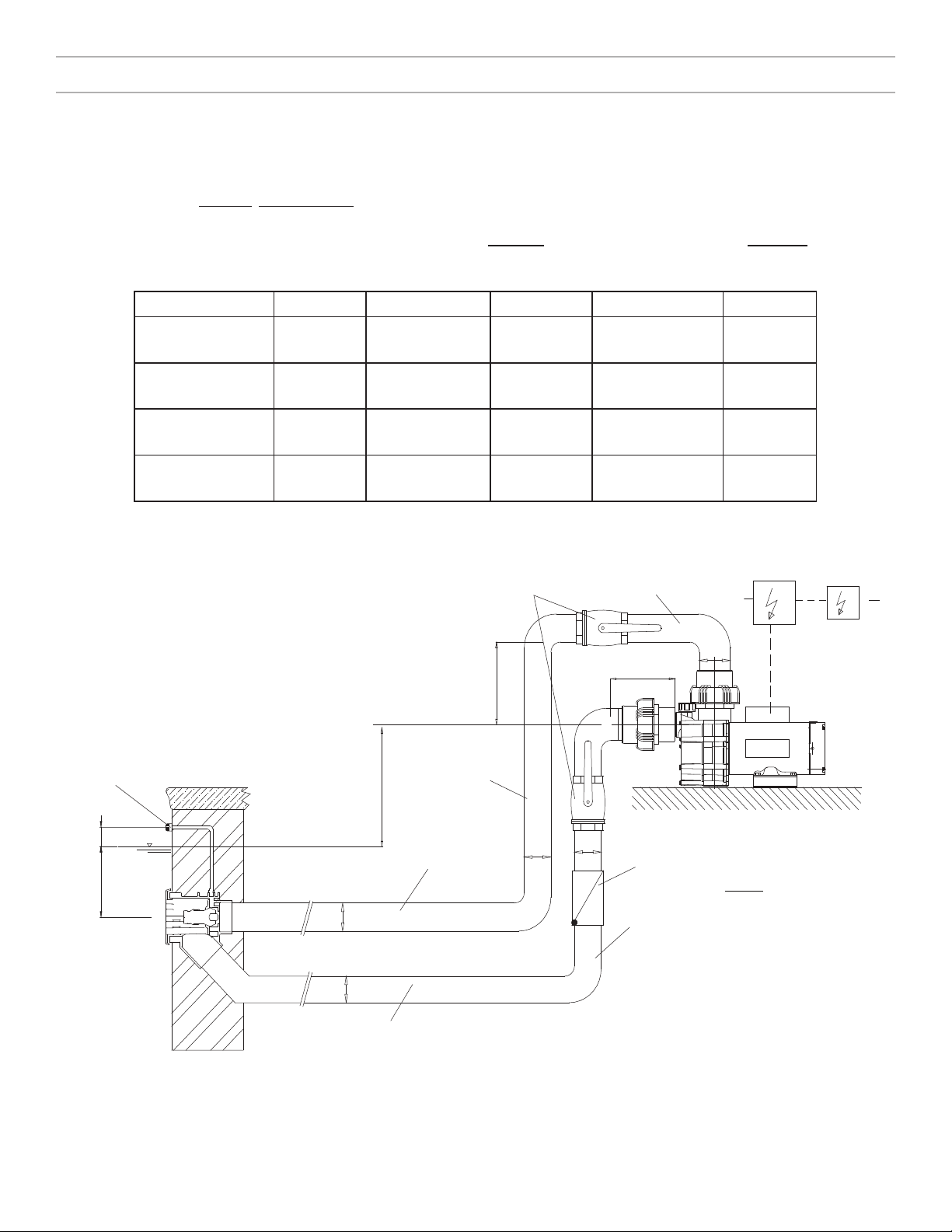

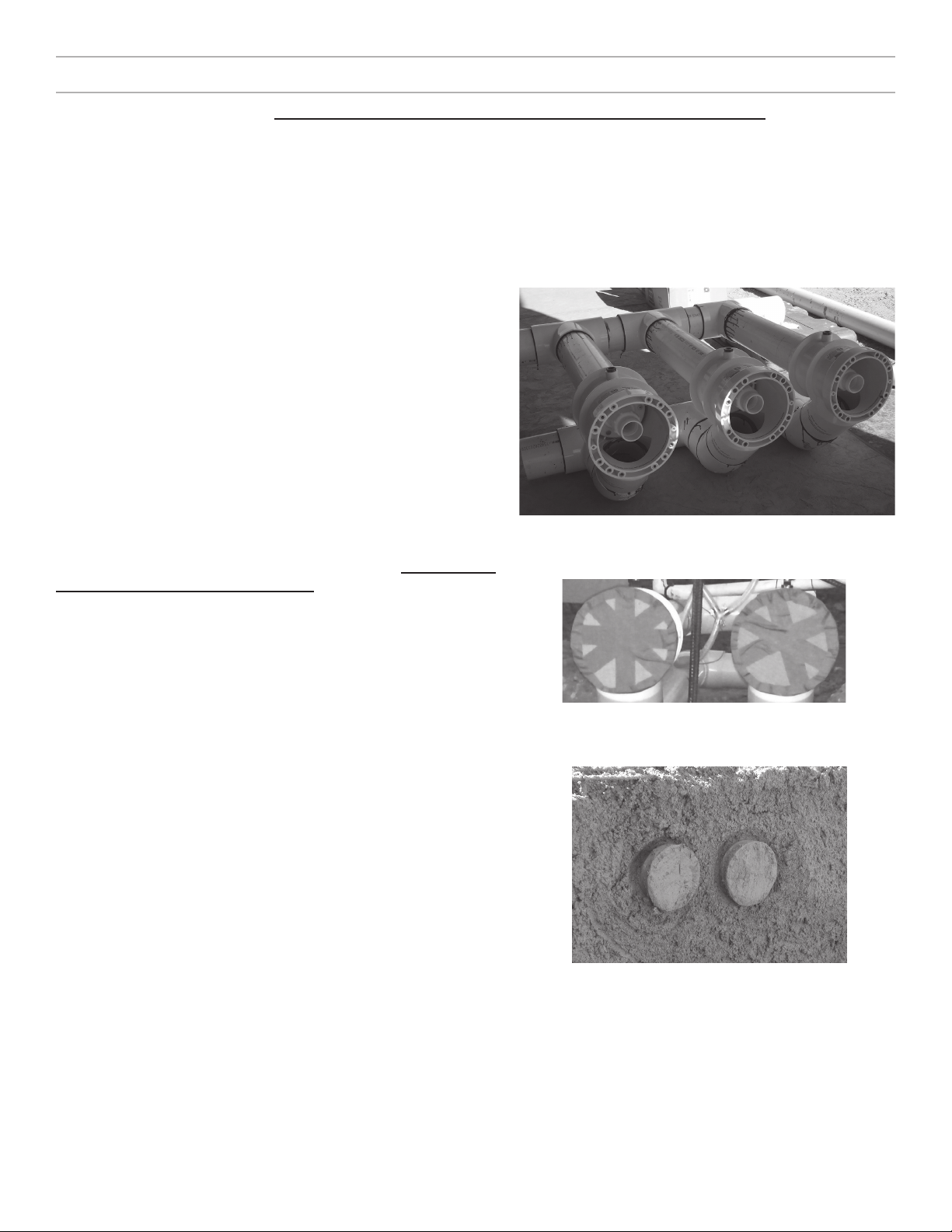

1. Pre-plumb BaduStream jet housing(s):

4. Install the air regulator. NOTE: Air regulator location should be 3”- 4” ABOVE the water level.

Figure 11

V-Shaped Groove in Gunite

Install plumbing manifold (for two and three jet systems) or

approximately 12” of 4” SCH 40 pipe (for single jet systems)

to both suction and discharge fittings on the jet housing(s).

See Figure 9

Thread one (1) air regulator hose nipple into the top of each

jet housing. Secure plastic air regulator hose (part #15) to

the air regulator hose nipple(s) (part #14) using the hose

clamp(s) (part #16).

A.

B.

2. Tape the jet housing(s) to keep concrete out of threaded inserts

and out of the inside of the housing(s). See Figure 10.

3. Place the jet housing(s) between the steel rebar. Note: The jet

housing location is very important.

A.

B.

C.

D.

E.

Figure 9

Pre-Plumbed Jet Housings

Figure 10

Taped Jet Housings

NOTE: The following parts ARE NOT USED IN A GUNITE or CONCRETE INSTALLATION:

Clamping Ring Gasket (Part #12)

1/4-20 x 1-1/2” Bolt (Part #18)

1/4-20 Nut (Part # 19)

1/4” Washer (Part #20)

Air Regulator Gasket 60 x 11 x 2 mm (Part #21)

#14 x 1” Screw (Part #27)

n

n

n

n

n

n

Make sure that the air regulator hose nipple (part #14) is

at the top and center of each jet housing. Failure to do

so will result in the square cover (part #8) appearing

uneven.

The center of each jet housing (the nozzle) must be located

12” BELOW the water line for maximum performance and

eciency.

Recheck the location of the jet housing while applying

gunite or pouring concrete. Make sure the jet housing

remains properly aligned and level.

Front edge of each jet housing should finish even with

inside pool wall. Scrape out a V-shaped groove around the

jet housing, approximately 1.5” deep to allow marcite to

seal against the jet housing. See Figure 11.

To avoid stress on the housing, the jet housing and 2 to 3

inches of plumbing stub out may be encased in gunite or

concrete. Caution: Too much stress on the plumbing may

crack the BaduStream II housing.

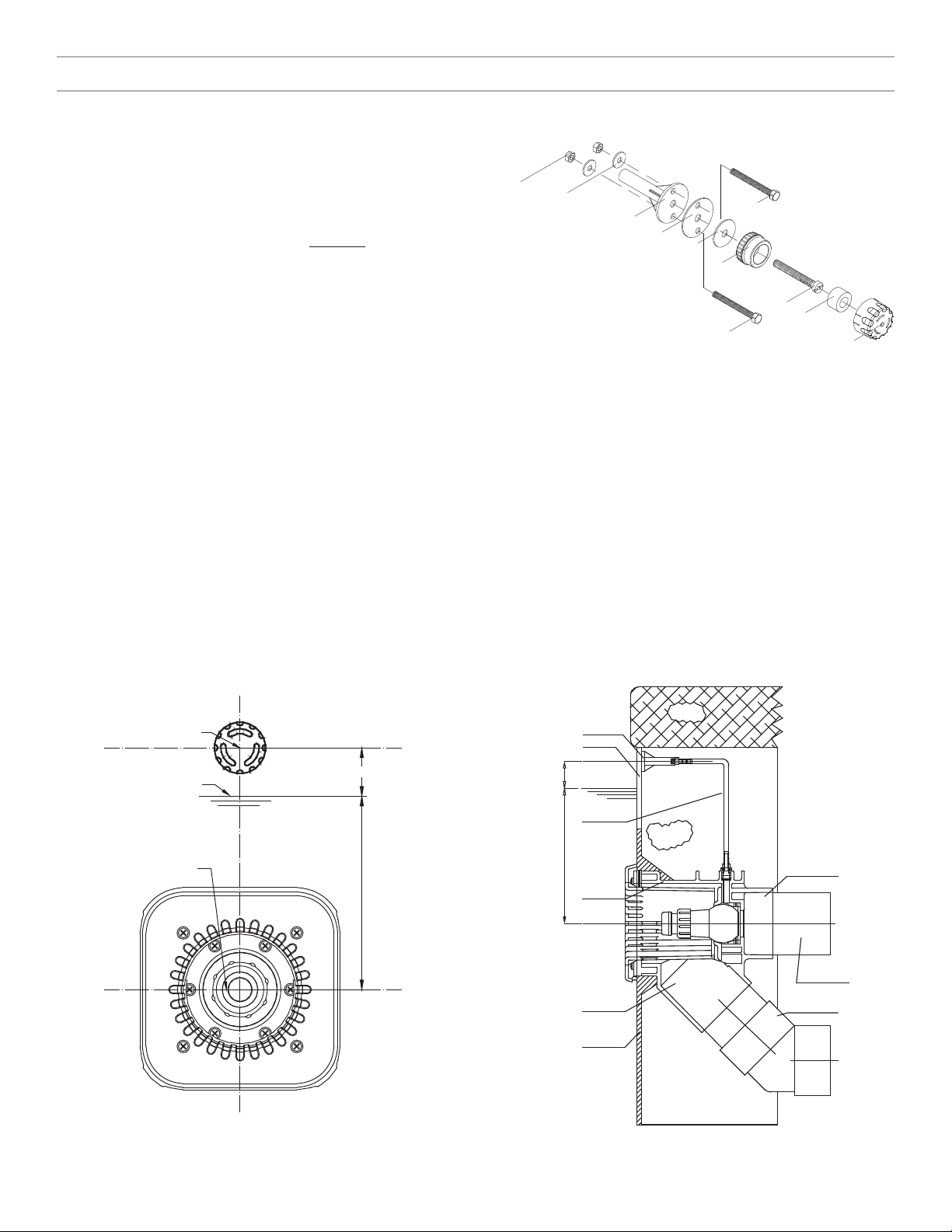

A. Thread one (1) air regulator hose nipple (part #14) into the back of the air regulator holder (part #17). Connect the

free end of the plastic air regulator hose to the nipple on the back of the air regulator holder. Secure with a hose clamp

(part #16).

Concrete or Gunite Installation

19

18

20

17

21 26

23

18 22

24 25

12”

3” Minimum

Nozzle

Water Level

Air Regulator

Housing

Discharge

Tile

Deck

12”

Concrete

Wall

Air Regulator

Air Line

3”

Minimum Water Level

Suction

Plaster

Fitting 4”

Pipe

Fitting 4”

45oElbow

14

Concrete or Gunite Installation - continued

5. Keep all parts not being used now in original box. Store in a safe place until needed.

NOTE: An extension ring and longer square cover screws (part #9/5) are available (upon request) for applications where the

housing is recessed into the pool wall.

6. Once the concrete or gunite is fully cured and pool wall is completed, install the square cover (part #8) using the four (4)

M6 x 25mm square cover screws (part #9/1).

NOTE: In tile installations, the tile thickness can be compensated for by first installing the clamping ring gasket (part #12)

and clamping ring (part #3) before installing the square cover. The clamping ring and clamping ring gasket are installed using

the eight (8) clamping ring screws (part #9/2, 9/3, or 9/4).

The air regulator can be located in the tile above the

water level or in the deck. When tiling the pool, adjust

the air regulator location so it is 3”-4” ABOVE the water

level. Place and set with hydraulic cement. The air

regulator holder (part #17) should finish flush with the

inner pool wall. Drill a 1/2” hole in the tile line even with

the center hole of the air regulator holder. Tile over the

air regulator holder. CAUTION: DO NOT plug the center

hole of the air regulator holder.

Insert the M10 x 80 mm brass screw (part #24) through

the bottom part of the air regulator (part #23), the 42

x 11 x 2 mm and the air regulator gasket (part #26).

Thread the M10 x 80 mm brass screw into the center of

the air regulator holder (part #17). Tighten with a flat

head screw driver.

B.

C.

D.

Figure 12

Air Regulator Assembly

Install the hose ring (part #25) and snap the top part of the air regulator (part #22) into place. See Figure 12 for air

regulator assembly.

Figure 13 Figure 14

Installation in Concrete or Gunite Pools BaduStream in Concrete or Gunite Pool.

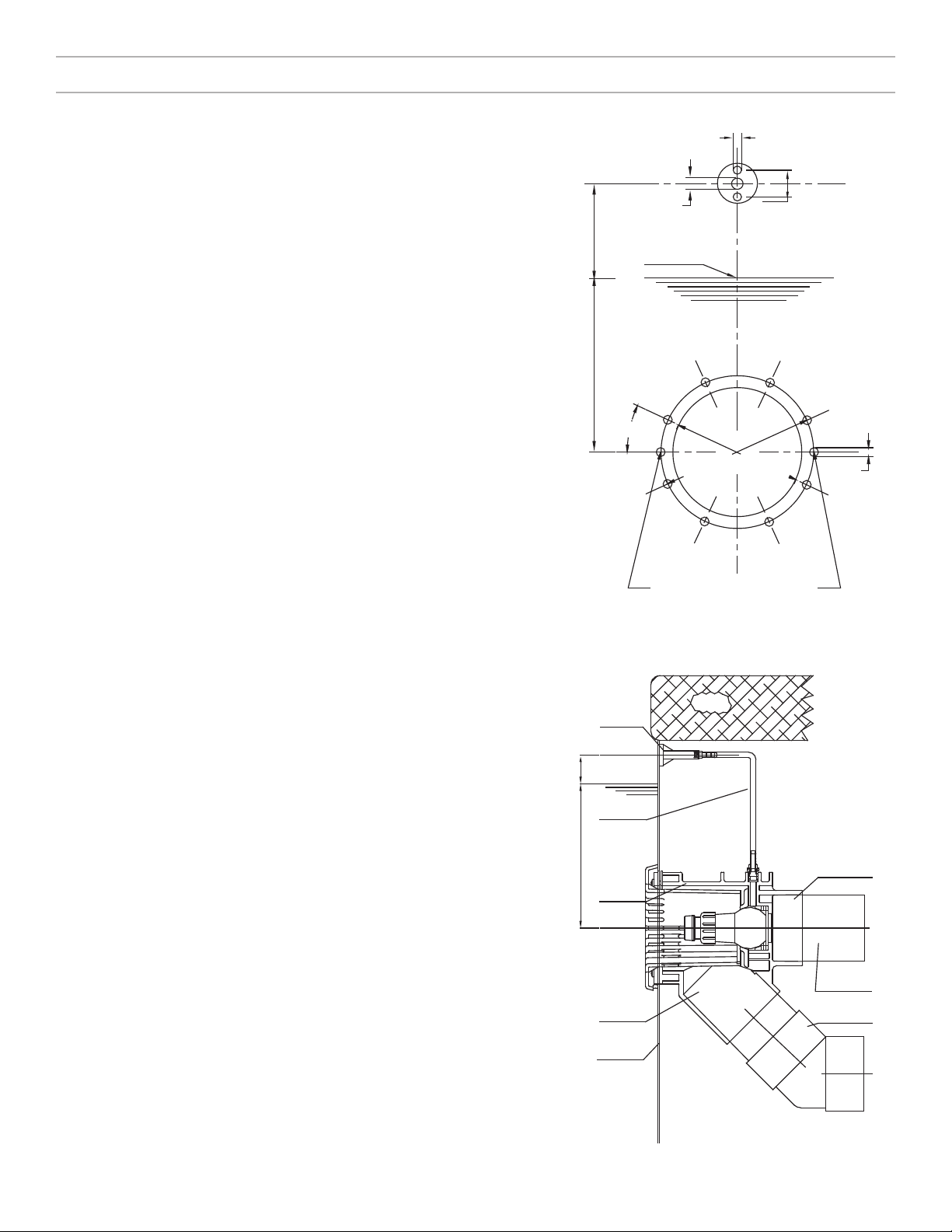

1. Using the clamping ring (part #3) as a template, drill holes

in the pool wall for installation. The center line of the clamping

ring should be 12” BELOW the water level (See Figures 15 &

16). Two additional holes will need to be drilled at the 3 and

9 o’clock positions for installation of the jet housing (part #7).

The four brass inserts in the clamping ring should be at the 2,

4, 8 and 10 o’clock positions (See Figure 15).

2. Mount the housing (part #7) and one clamping ring gasket

(part #12) on BEHIND the pool wall using two (2) #14 x 1”

counter sunk screws (part #27). Install the screws from the

inside of the pool wall through the holes drilled at 3 and 9

o’clock positions. (See Figure 15)

3. Install the clamping ring (part #3) and a second clamping

ring gasket (part #12) in FRONT of the pool wall using eight

(8) M6 screws (part # 9/2, 9/3, or 9/4). Screw lengths vary

depending on the installation. NOTE: A good RTV silicone may

be used with the gasket when mounting the jet housing, but in

most cases is not necessary. Installer should decided whether

or not the silicone is necessary.

NOTE: When installed properly, the center of the housing (part

#7) will be 12” BELOW the surface of the water and the air

regulator hose nipple (part #14) will be at the top center of

the jet housing.

CAUTION: When installing the BaduStream Cover (part #8).

Use a Phillips head screw driver and tighten to 1.5 Nm or hand

tight. DO NOT use electrical or air drills. (NOTE: The square

cover, part #8, will have an uneven appearance if the housing

is not installed properly.)

4. For the air regulator assembly, one 1/2” hole must be

provided, preferably along the vertical axis, approximately

3-4” ABOVE the water line. (See Figures 15 & 16). Using the

60 x 11 x 2mm air regulator gasket (part #21), mark and drill

two 1/4” mounting holes (See Figure 15). Use the two (2) 1/4 -

20 air holder screws (part #18) and two 1/4-20 air holder nuts

(part #19) to mount the air regulator holder.

NOTE: Part #18 & Part #21 go in FRONT of the pool wall; Part

#19 & Part #17 go BEHIND the pool wall.

5. Keep all parts not being used now in original box. Store in a

safe place until needed.

6. Once the pool is complete, install the square cover (part #8)

using the four (4) square cover screws (part #9/1).

For Liner Pools Only: Install the jet housing and air regulator

prior to installation or replacement of the pool liner.

For Steel Walled Pools: An optional butterfly gasket (part

#12.1) maybe purchased to replace the two (2)clamping ring

gaskets (part #12). Increase the jet housing hole in Figure 15

from 5.59” to 5.75” for installation.

12”

Housing

Discharge

Deck

Air Regulator

Air Line

3”

Minimum Water Level

Suction

Liner &

Wall

Fitting 4”

Pipe

Fitting 4”

45oElbow

Water Level

0.5” 1.70”

0.25”

12”

3”

Minimum

0.3”

25o

6.54” dia

5.59” dia

For Liner & Fiberglass Pools Only

(Jet House Mounting Holes)

15

Liner and/or Fiberglass Pool Installation

Figure 15

Figure 16

Cutout Pool Wall for BaduStream housing.

BaduStream in Liner or Fiberglass Pool.

16

Removal of Liner

Electrical - SPECK Controller Installation

When replacing liner or removing liner for repairs; remove the four (4) screws (part #9/1) which hold the square

cover (part #8) to the jet housing. Remove all screws (part #9/2, 9/3 & 9/4) except the top two, which hold the

clamping ring (part #3) and gasket (part #12) to the jet housing. Back out the two remaining screws approximately

halfway and check for any movement of the jet housing from the wall. (NOTE: If the two counter sunk screws

(part #27) which hold the jet housing to the wall were installed, the jet housing should not move, and the two

remaining screws can be removed.) Remove one of the remaining two screws and slide the clamping ring (part

#3) to the side. Replace all the screws before removing the last screw. Remove or replace the liner. Reverse the

process to install liner.

NOTE: When replacing the clamping ring and screws: locate screw heads under liner, make a small cut on the liner

at the screw heads and push the liner over the screw head.

WARNING: The wiring of the pool motor and control box should be done by a licensed electrician in accordance with all

local, state, and federal codes. Be certain that the motor frame and control box are properly grounded. Motor name plate lists

voltage, phase, amp draw, and other information as well as wiring connection instructions.

This section concerns the electric motor and control box for BaduStream II swimjet system.

CAUTION: Before installing the Speck Pump, read the entire pump owner’s manual found in the pump box.

Consult local codes for minimum distance between pump and pool. Locate pump as close to the pool as practical.

CAUTION: There is 50ft of cable included with the touch button. If a longer distance to the control box is required, a junction

box can be installed above the water line to splice additional cable as required.

NOTE: The System ON/OFF LED touch button is installed in a 1-1/2” threaded housing. This housing may be installed

in any 1-1/2” return fitting, either below the water line or above the water.

BONDING: As required by National Electrical Code, the pump motor must be electrically bonded to the pool structure

(reinforced bars, etc.) by a solid copper conductor not smaller than No. 8 AWG via the external copper bonding lug on the

pump motor.

GROUNDING: Permanently ground the pump motor and control box using a conductor of appropriate size.

CAUTION: DO NOT connect to electric power supply until the unit is permanently grounded.

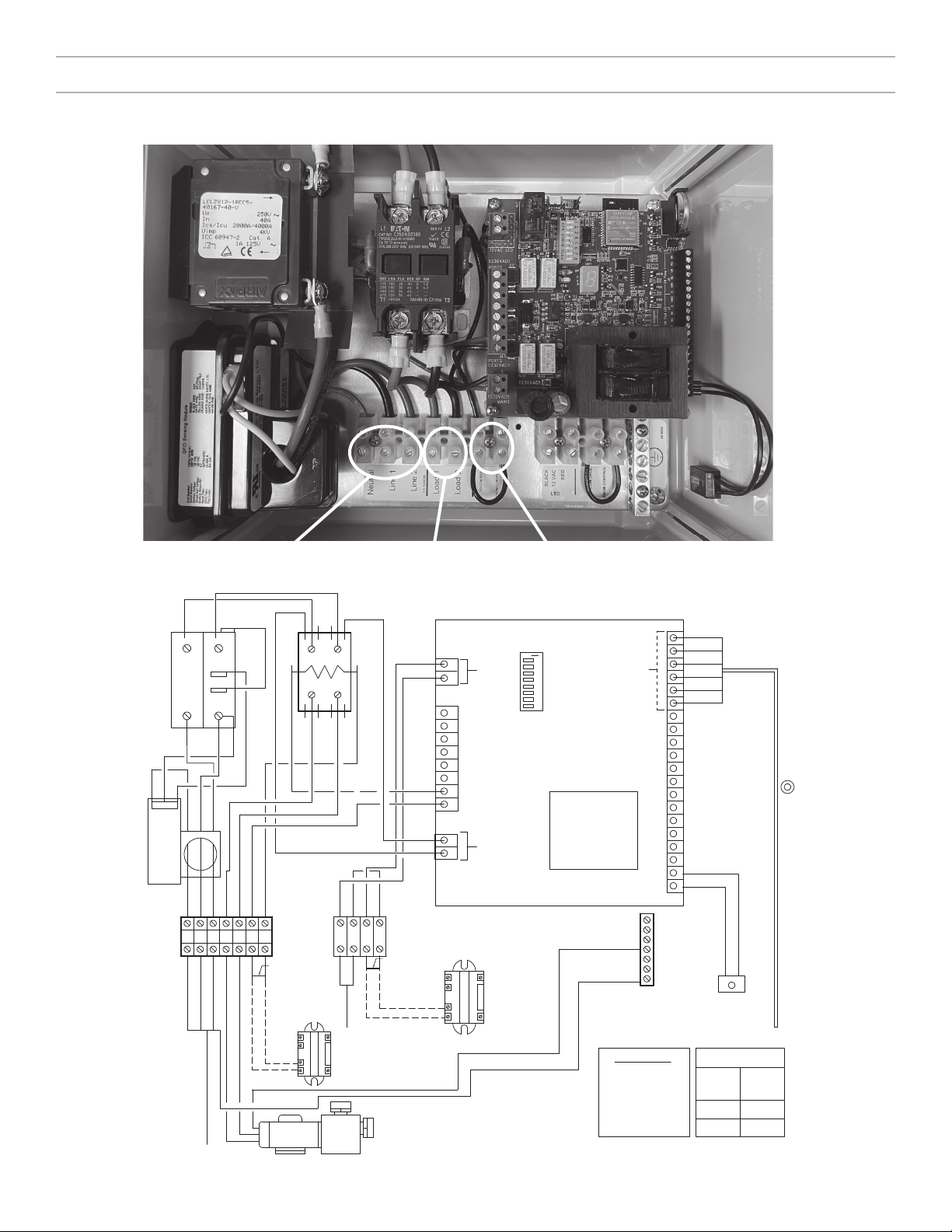

NOTE: Single phase control boxes equipped with GFCI are shown on pages 17-18. Other options are available. Please contact

the factory (800) 223-8538 for assistance.

Connecting the SPECK controller to a WiFi network for the FIRST TIME:

1. Before connecting the SPECK controller to the WiFi network, stand where the SPECK equipment is located and with your

mobile device in-hand assure that the signal strength to the WiFi network is good to excellent (weak signals will cause

problems).

2. Make sure the power to the SPECK Device is turned ON. There is a green indicator on the controller board to indicate power.

A small “o” will be flashing on the LED display.

3. Give the homeowner the BADUConnect app manual and allow them to finish the App setup. For more information, Call

(800) 223-8538 or visit www.baduconnect.com for additional copies of the BADUConnect App instructions.

Pump Motor: Connect to the #10 green headed ground screw provided inside the motor terminal box.

Control Box: Connect to the aluminum grounding terminal strip on the inside of the control box enclosure.

n

n

TORQUE DATA

8 CU 10

14-10 CU 7

Torque

in.-lbs.

Wire

Range

BJC RATING

1 - Circuit 28 Amps

208-240 Volts

60 Hz, 1 Phase

4-Wire Service

GFCI Protected

ON/OFF Controls

NOTE: Use TO & FROM Control for

remote operation of equipment.

Ground

Terminal

Motor

Ground

Service

Ground

WiFi Reset Button

Cable For Pump ON/OFF Button

On-Board Transformer

DIP Switches

BKRDGRBLSW1G

SW Pump 1

BLACK

RED

GREEN

BLUE

WHITE

YELLOW

Controller Power

12V Light

CONTACTOR

ON

1 2 3 4 5 6 7 8

Coil

230V

RED-5

RED-4

RED-4

RED-6

RED-2

BLK-7

BLK-2

BLK-4

BLK-5

BLK-4

ORG-0

YEL-0

ORG-0

YEL-0

BLK-2

RED-2

RED-5

BLK-6

BLK-3

RED-3

BLK-0

BLK-1

BLK-0

RED-1

WHT-1

40A Shunt

Tr p w/ AUX

Switch

C rcuit

Breaker

GFCI Module

BLK-7

BLK-1

RED-6

BLK-6

BLK-5

BLK-3

RED-3

RED-1

WHT-1

Black

Red

REMOVE JUMPER

FOR REMOTE

CONNECTION

REMOVE JUMPER

FOR REMOTE

CONNECTION

LOAD 2

From Control

LOAD 1

LINE 2

LINE 1

NEUTRAL

To Control

From Control

To Control

12VAC LED

Remote Relay

Remote Relay

Single

Speed

Motor

SERVICE

4-WIRE

1 PHASE

Terminal

Strip

43 6 752

18 9 10 11

17

Electrical - SPECK Controller Installation - Continued

Power from main panel (230 VAC):

Neutral, Line 1, Line 2

Power to pump motor (230 VAC):

Load 1, Load 2

Connection for remote relay

(Remove Jumper)

Figure 17

Control Box Wiring

TORQUE DATA

8-6 CU 10

14-10 CU 7

Torque

in.-lbs.

Wire

Range

BJC RATING

1 - Circuit 28 Amps

208-240 Volts

60 Hz, 1 Phase

4-Wire Service

GFCI Protected

ON/OFF Controls

NOTE: Use TO & FROM Control for

remote operation of equipment.

Ground

Terminal

Motor

Ground

Motor

Ground

WiFi Reset Button

Cable For Pump ON/OFF Button

On-Board

Transformer

DIP Switches

BKRDGRBLSW1G

SW Pump 1

BLACK

RED

GREEN

BLUE

WHITE

YELLOW

Controller Power

12V Light

CONTACTOR

ON

1 2 3 4 5 6 7 8

Coil

230V

RED-4

RED-8

RED-2

BLK-9

BLK-2

BLK-4

BLK-4

ORG-0

YEL-0

ORG-0

YEL-0

BLK-2

RED-2

RED-7

RED-7

RED-6

BLK-8

BLK-8

BLK-7

BLK-3

BLK-5

RED-3

RED-5

BLK-0

BLK-1

BLK-0

RED-1

WHT-1

50A Shunt

Trip w/ AUX

Switch

Circuit

Breaker

GFCI Module

BLK-3

BLK-6

BLK-5

BLK-7

RED-3

RED-5

RED-1

WHT-1

REMOVE JUMPER

FOR REMOTE

CONNECTION

LOAD 2

LOAD 3

LOAD 4

From Contro

LOAD 1

LINE 2

LINE 1

NEUTRAL

To Contro

Remote Relay

SERV CE

4-W RE

1 PHASE

Term na

Str p

43 6 7521 8 9

Service

Ground

To Motor 2

To Motor 1

BLK-1

CONTACTOR

Coil

230V

RED-4

RED-6

BLK-6

RED-8

BLK-9

18

Power from main panel (230 VAC):

Neutral, Line 1, Line 2

Power to pump motor 1

(230 VAC): Load 1, Load 2

Power to pump motor 2

(230 VAC): Load 1, Load 2

Connection to remote relay

(120 VAC)

Electrical - SPECK Controller Installation - Continued

Figure 17A

Control Box Wiring

PATTERN ON LED DISPLAY CONDITION

Flashing Dash (-) with an interval of ~200ms Ideal with no Relay/Pump on

Flashing ‘P’ with the interval of ~200ms No WiFi connection, Wrong Wifi Password

Flashing ‘O’ (Capital O) with an interval of

~200ms

No cloud connection due to server down or no internet

Flashing ‘o’ (Small o ) with an interval of 200ms Device has not been set up to connect to WiFi

Flashing ‘ ’ (triple bars) with an interval of 200ms The device is doing OTA Firmware update

Flashing ‘E’ with an interval of ~200ms Hardware error

Flashing ‘L’ with an interval of ~200ms Pool light error

Steady 2 Port 2 is on manually (No Timer/Schedule)

Steady 3 Port 3 is on manually (No Timer/Schedule)

Steady 4 Port 4 is on manually (No Timer/Schedule)

Steady 5 Port 5 is on manually (No Timer/Schedule)

Steady 1 with flashing dot.

The dot will flash with an interval of ~100ms

Port 1 is on a schedule based on Time of Day.

Steady 2 with flashing dot.

The dot will flash with an interval of ~100ms

Port 2 is on a schedule based on Time of Day.

Steady 3 with flashing dot.

The dot will flash with an interval of ~100ms

Port 3 is on a schedule based on Time of Day.

Steady 4 with flashing dot.

The dot will flash with an interval of ~100ms

Port 4 is on a schedule based on Time of Day.

Steady 5 with flashing dot.

The dot will flash with an interval of ~100ms

Port 5 is on a schedule based on Time of Day.

Flashing 1 with the interval of ~100ms Port 1 is on a countdown timer

Flashing 2 with the interval of ~100ms Port 2 is on a countdown timer

Flashing 3 with the interval of ~100ms Port 3 is on a countdown timer

Flashing 4 with the interval of ~100ms Port 4 is on a countdown timer

Flashing 5 with the interval of ~100ms Port 5 is on a countdown timer

Blue light is ON Touch Button LED: When Port 1 or 2 is OFF

Green-light is ON Touch Button LED: When Port 2 is ON in manual mode

Green light is Flashing

1 second interval flashing when time remaining is more

than 2 minutes otherwise flashes with 0.5 second

Touch Button LED: When Port 1 or 2 is ON in Timer or

schedular mode

Red light is flashing Touch Button LED: When there is an error with the

Swimjet Light (Port 2)

Table 2

LED Codes & Meanings

Table 1

COLOR MEANING

Solid BLUE SwimJet System is OFF

Flashing GREEN every 1 second SwimJet System is ON with 2 hour timer

Flashing GREEN every 1/2 second This is a 2 minute warning on the 2 hour timer.

Once the 2 minutes have passed the swimjet

system will automatically turn OFF.

LED Touch Button Color Codes

19

Electrical - SPECK Controller Installation - Continued

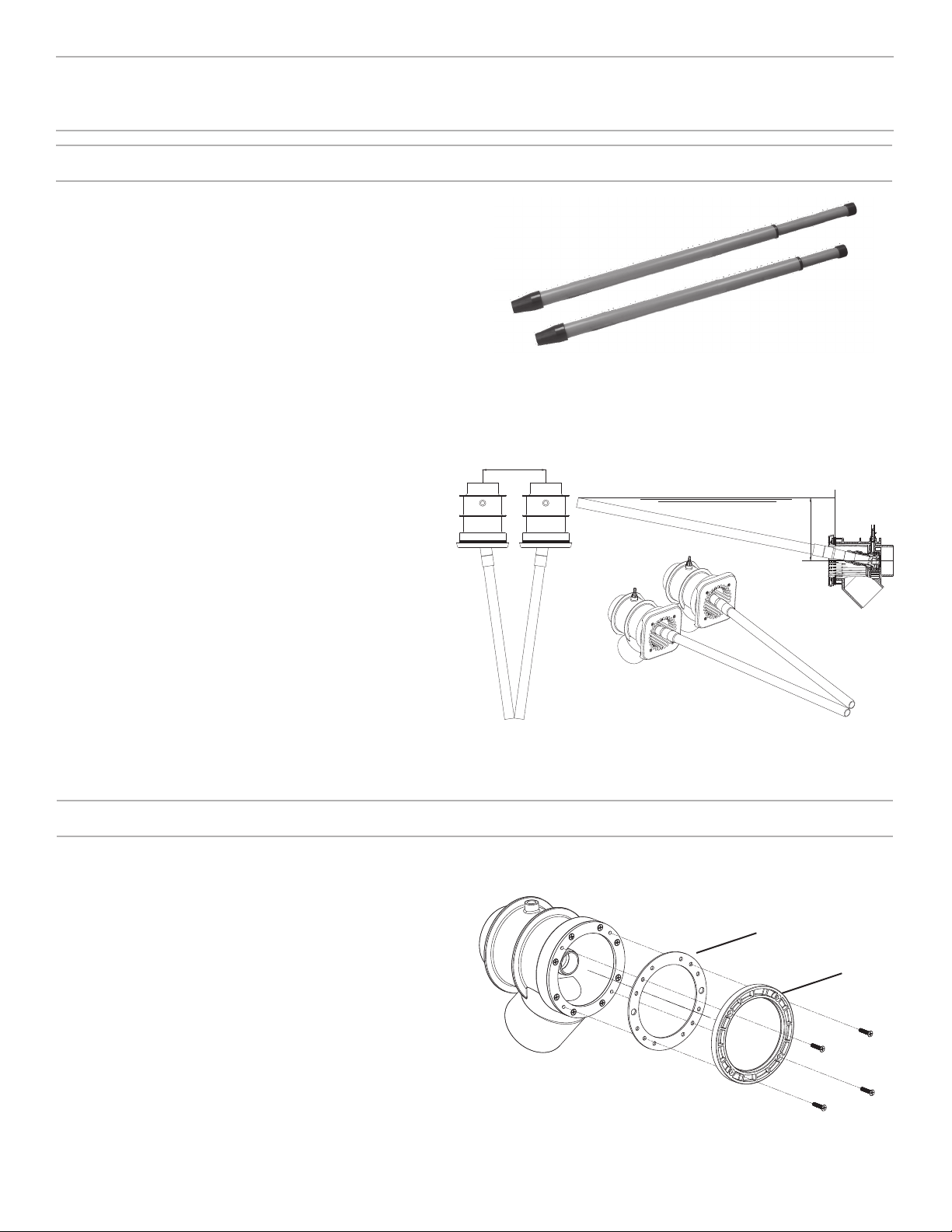

The BaduStream System is provided with a set of nozzle

adjustment tools. These tools will allow the user to set

the jet nozzles into position for optimum performance.

When setting the nozzles for basic swimming, it is

recommended that you set the nozzles in such a way

that each nozzle intersects 4 feet away while breaking

the surface at the same time. To help set the nozzles

in position for best performance, please follow these

instructions:

1. Extend the nozzle adjustment tool to full length.

2. Place each nozzle adjustment tool into the jet nozzles

on the BaduStream housing.

3. Once that is complete, bring the blue nozzle tool up to

where the end of the nozzle tool breaks the surface of

the water. Then bring the two nozzles tools together to

meet. (See Figure 16)

Nozzle Adjustment Tools

NOTE: Though the nozzle adjustment tools are designed for

outdoor use, it is advised to protect them from continuous

direct heat.

20

4 Service and Maintenance

Nozzle Adjustment

Perspective View

Water Level

~10”

Side View

Top View

10”

Figure 16

BaduStream Nozzle Adjustment

Winterizing

In areas subject to freezing water temperatures, you

should protect your equipment. We recommend you

purchase a winter cover kit part #2308752006K. This

kit includes one (1) winter plate, one (1) gasket and

four (4) screws.

Also, you can protect your swimjet system as follows:

Drain pool until water level has dropped below

the anti-entrapment cover. Then protect pump by

removing drain plug and red filler plug (or lid).

Figure 5

Winter Cover Kit

Gasket

Winter Plate

Other manuals for Badu Stream II

4

Table of contents

Other Speck pumps Lighting Equipment manuals

Speck pumps

Speck pumps BaduJet super-sport II Installation and operating instructions

Speck pumps

Speck pumps Badu Stream II Service manual

Speck pumps

Speck pumps BADU JET User manual

Speck pumps

Speck pumps Badu Stream II Service manual

Speck pumps

Speck pumps Badu Stream II Service manual

Speck pumps

Speck pumps BADU JET Service manual

Speck pumps

Speck pumps Badu Stream II User manual