Speck pumps BADU Vac 1 User manual

Swimming Pool Technology

Swembadtegnologie

BADU®Vac

I

Automatic Pool Cleaner

Fast Start-up,

Safely Operate and

Efficiently Clean.

Installation and

Operation Manual

I. Preparation of Your Pool

Before assembling and installing your cleaner, your pool should be clean and algae-free so as not to

inhibit the cleaner’s traction. If necessary, make the following preparations before proceeding:

1. Chemically balance the pool water.

2. Brush pool and let the debris settle.

3. Hand vacuum thoroughly.

4. Clean filter and pump strainer basket.

II.Assembly

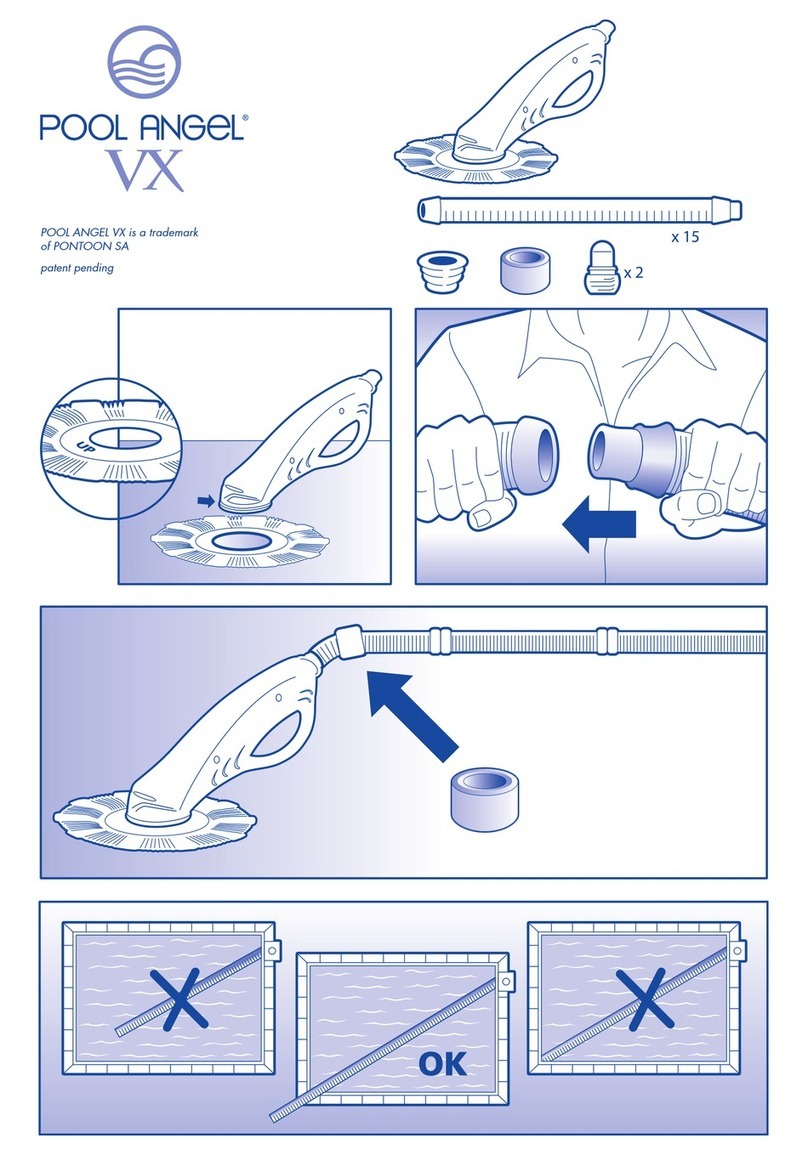

Remove the body and all of its parts from the box and check to make sure that all components were

included. Refer to Figure 1.

Components Check List

1. Body

2. Dive float restrictor

3. Eyeball diverter and

outer ring (Optional extra)

4. Hose weights (Set of 3)

(Optional extra)

5. Automatic regulator valve

(Optional extra)

6. Regulator Valve 2” (50mm)

Hose Cone (Optional extra)

7. Roller bumper strap

8. Pleated skirt

9. Hose-10 meters total length

(not shown)

1

Figure 1

Step 1. Attach the Skirt

To install the skirt locate the words “Up” and

face them towards the main body, slip the

skirt over the foot pad-(flat side down towards

pool floor)-and full gently until it seats itself

on the other side in its groove as illustrated

in Figure2. Skirt must be installed flat side down,

pleated side up.Once in place, the skirt should rotate

and turn freely.

The skirt is not reversible. The raised pleats on the

pleated skirt must face upward. The flat side of the

skirt should face down to rest against the pool surface.

Step 2. Attach the Roller Bumper Strap

Snap the roller bumper strap into the lower U-shaped

brace between the dive floats. Make sure the locking

tabs on both sides of the roller bumper strap snap

securely into place. See Figure 3.

Step 3. Attach The Dive Float Restrictor

Insert the bottom end of the strap into the slot

provided on the main body. Insert the top end of the

strap into the locking clip attached to the swivel head.

See Figure 4.

2

Figure 3

Figure 4

Figure 2

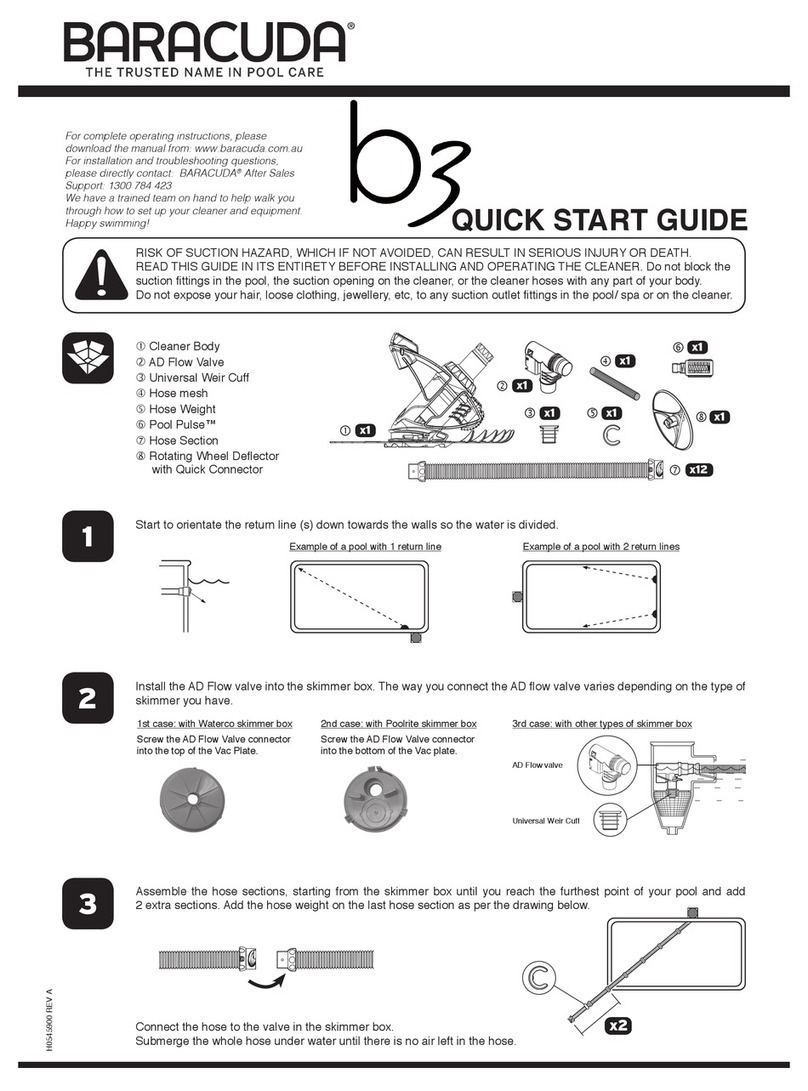

Step 4. Attach the Hose Weights

and Assemble the Hoses

The cleaner hose comes in sections which

must be assembled. You’ll need enough sections

to reach from where the cleaner is connected,

to the farthest part of your pool, plus one section.

You will also have to attach hose weights to the hose

to neutralize the hose’s buoyancy in water.

The number of hose weights required is determined by

the maximum depth of your pool. The deeper your

pool, the more weights is needed. The number of

hose weights appropriate for your pool are explained

in Table A.

Note: Not all pools will require the hose weights.

Twist and push the female ends onto the male ends

after dipping the ends into the pool to wet them.

See Figure 5. Continue until you’ve connected all the

sections you need. After connecting the hose weights

to the hose as described in “Table A”, then connect the

hose to the cleaner. See Figure 6.

One of the hose sections has 2 female ends and a hose protector. This section should be fitted last

with one end attached to the pool’s vacuum connection (the weir or automatic regulator valve)

and the other side attached to your first hose.

Your fully assembled cleaner should look like this.

3

Figure 5

Figure 6

Pool depth

1,2m or less

More than 1,2m,

but less than 2,1m

More than 2,1m,

but less than 3,6m

More than 3,6m

Weight Placement

1 weight: 4 to 12 inches

from body’s swivel head.

2 weights: one 4 to 12

inches and one 6 feet

from the swivel head.

3 weights: one 4 to 12

inches and one 6 feet

and one 10 feet from the

swivel head.

4 weights: * one 4 to 12

inches, one 6 feet, one 10

feet, and one 12 feet from

the swivel head.

Table A

III. Installation

The cleaner is designed to work in wide variety of swimming pools. That’s why we’ve included certain

items (such as a 2” hose cone and valve cap for the automatic regulator valve) with your cleaner.

These may or may not be needed, depending on the particular features of your pool.

Both the standard in-skimmer installation and an optional vacuum line installation are covered in this

manual. Check to see which most closely fits your pool configuration and follow the directions.

Standard Installation

For pools with one skimmer, using the automatic

regulator valve.

The advantage of this installation is that the automatic

regulator valve automatically balances the water flow

between the skimmer and the cleaner. We strongly

recommend the use of automatic regulator valve

for maximum safety and performance. The valve

automatically adjusts to changes in the amount of water

flow to provide the cleaner with the power necessary

to ensure proper cleaning performance.

1. Switch the pool pump off.

2. Close the main drain and all suction lines, except

the line from the skimmer to which the cleaner

will be connected.

3. Remove skimmer basket.

4. Press the 2” (50mm) Hose Cone into the vacuum

connection in the bottom of the skimmer, as shown

in figure 8.

5. Press the automatic regulator valve into the

2” (50mm) Hose Cone.

The end of the valve that is marked “Attach Hose This End” must point up. See Figure8.

6. Place the cleaner into the pool and allow it to sink to the floor. Continue to feed the hose

vertically down into the pool until it is completely filled with water and purged of air.

7. Insert the end of the hose through the skimmer opening and connect the hose directly

onto the automatic regulator valve.

4

Figure 8

Figure 7

IV. Adjustments

After completing the installation, turn the pool pump on. Allow the pump to run for a couple of minutes

to ensure all air cycles out of the system. The cleaner should be moving about the pool at a rate of

3-4 meters per minute. Check each of the following initial adjustments to the cleaner at this time.

Hose Length

IMPORTANT: The pump must be on when you check the hose length. The hose contracts when the

pump is operating and will be longer when the pump is off.

With the cleaner operating, position it at the furthest point of the pool from where it’s attached.

(It is easy to position the cleaner the pool by moving it about with your pool pole and brush.)

The cleaner’s hose should be long enough to reach the end of the pool, plus one hose section.

If necessary, remove extra hose sections from the center portion of hose. Removing center hose

sections avoids having to disturb the hose weight placements. Save extra hose sections for use as

needed for replacement. NOTE: Turn pool pump off when adding or removing hose sections.

Hose Balance

To determine correct hose balance, turn the pump off and observe the cleaner. Hose balance is

correct when the cleaner’s seal rests flat on the pool floor and the diver tubes make a 45° angle

with the floor, as shown in Figure 9. The cleaner achieves the best cleaning coverage when the hose

neither weights down nor pulls up on the unit. Adjust hose weights one inch at a time as needed,

until proper hose balance is achieved. In pools with both shallow and deep areas, adjust hose

weights first in the deep area and then in the shallow area.

1. Hose Too Light.

If the hose rises towards

the surface at an angle

greater than 45°, move the

weights closer to the

cleaner, or move the first

two weights closer to each

other.

2. Correct Hose Balance.

3. Hose Too Heavy.

If the hose sags downward

to an angle less than 45°,

move the weights away

from the cleaner, or

separate the first two

weights away from each

other.

5

Figure 9

Return Line Water Flow

IMPORTANT: The water flow from your return line can push the cleaner’s hose and affect its

performance. It may cause the cleaner to steer away from the end of the pool where the return line

is located, or it may cause the cleaner to remain in one section of the pool. To correct this, use the

eyeball diverter (optional extra) included with your cleaner, or point your return line fitting in another

direction.

To install the eyeball diverter:

• Note: The eyeball diverter does not fit all pool return line fittings!

• Firstmakesureyourpool pump is off. Remove the original eyeball from the return line at

the pool by unscrewing the lock ring.

• ReplacetheoriginaleyeballwiththeBADU®Vac

I

eyeball diverter.

• Replacethelockringandtighten.Makesuretheopeningoftheeyeballdiverterpointsin

the proper direction before tightening fully. See “Eyeball Diverter positions”.

Eyeball Diverter Positions

Position the diverter opening to redirect the return line

water flow so it does not interfere with the cleaner’s

movement.

Try different positions to see which works best in

your pool:

• Flowdirectedalongthesideofpool(thetileline).

• Flowdirecteddownward.

• Flowdirectedagainstthehosewillhelpsteerthe

cleaner away from obstructions such as

stairs and ladders.

After installing the eyeball diverter, turn the pool pump on. The BADU®Vac

I

should begin moving

across the pool floor vacuuming up debris in its path.

6

Figure 10

VI. Troubleshooting

Because of the individual characteristics of your pool, some additional adjustment may be required

to get the best performance from your BADU®Vac

I

.

If there seems to be a problem, check these common causes of cleaner problems.

Is bottom main drain closed? Close the drain

Is filter clean? Clean the filter

Is pump strainer basket clean? Clean the basket

Is debris blocking the bottom

of the cleaner? Remove the debris

Are there any leaks/cracks in the hose? Replace the leaky/cracked sections

Is automatic regulator valve

free of debris? Clean the valve

7

SOLUTIONSCHECKS

8

SOLUTIONS

1. If the cleaner is working slowly,

runs then stops or not moving

or not pulsating at all.

• Checktoensurethatthemaindrainand

all suction lines are closed, except for the

suction line to which the cleaner is

attached.

• Checkfordebrisintheweirorpump

basket and check that all the baskets are

in a good condition and are not broken.

• Checkfordebrisinthecleaner’shammer.

Debris may prevent hammer movement or

restrict flow.

• Poolpumpandfiltersystemmaybetoo

small (incapable of providing 75 L per

minute water flow). Consult your pool

professional.

• Checkthatthevacuumlidisflushwith

the weir and not damaged.

• Checkthatthefilterhasbeenback

washed and rinsed thoroughly.

PROBLEMS

2. If the cleaner stays in one end

of the pool.

• Checkthereturnlinewaterflowand

redirect as necessary with and eyeball

diverter.

• Checkthathoseislongenoughto

reach to end of pool.

• Checkthatthecleanerhasproper

hose balance.

3. If the cleaner stays on the main

drain.

• Checktoensurethatmaindrainis

closed. A pool professional may need to

assist you.

• Checktoensurethatamaindraingrate

is installed.

• Ifmaindrainisnotflushwiththepool

floor, consult your pool professional.

SOLUTIONS

4. If the cleaner slows or stops and

air bubbles enter the pool at the

return line.

Find and correct the air leak that is causing the

pump to lose its prime by doing the following:

• Checkthehosestoensurethereareno

leaks.

• Checkthevacuumlidattheautomatic

regulator valve connection. It should be

submerged in the water so no air enters

the system. Top up the water level if it is

neccesary.

• Checkthepumplidforlooseness,cracks,

and worn or missing O-rings. If you need

assistance, contact your pool professional.

PROBLEMS

5. It the cleaner pulls air from, or

remains at, the water surface.

• Checktoensurethedivefloatmechanism

is operating freely and the dive float

restrictor is installed. (See page 2 for how

to install dive float restrictor.)

• Checktheautomaticregulatorvalvefor

its proper installation and ensure it is not

clogged with debris.

• Makesurethewaterlevelisatleast

7-8 cm’s below the pool deck.

• ChecktoinsuretheBADU®Vac

I

is

operating at the proper speed of

2-4 meters per minute.

6. If the cleaner stays at the shallow

end steps.

• Checkthereturnlinewaterflowand

re-direct as necessary with an eyeball

diverter.

• Checktheautomaticregulatorvalvefor

its proper installation and ensure it is not

clogged with debris.

• Checkthatthehosesarelongenoughto

reachthefurthest point ofthe pool,including

the pool steps.

• Checkthatthecleanerhasproperhose

balance in the shallow end.

9

10

SOLUTIONS

6. Continued • Checkthatthecleanerhasproperhose

balance in shallow end.

• Checktoensureyourcleaneris

operating at the proper speed of

2-4 meters per minute.

• Checktoensurethedivefloatmechanism

is operating freely and the dive float

restrictor is installed. (See page 2 for how

to install dive float restrictor.)

• Shortenthedivefloatrestrictorby1cm.

(Pull out upper end of the restrictor from

the locking end clip attached to the

swivel head. Cut 1cm off, then return the

restrictor into the locking end clip.)

PROBLEMS

7. When the cleaner tracks in a

repetitive pattern.

• Checktheswivelonthetopofthe

cleaner. It should turn freely.

• Checkthereturnlinewaterflowand

re-direct as necessary with an eyeball

diverter.

• Checkthecleaner’shosestoensureithas

not become bent or kinked. It only takes

one bent or kinked hose section to hinder

the cleaning coverage. One way to check

for kinks in your hose is to lay each

section flat on your pool’s deck (or other

flat surface). The hose should be

perfectly straight and flat. Do not coil the

hose when taking your cleaner out of

the pool because it will retain the coil

shape, forming a bend or kink.

11

SOLUTIONS

8. The pool cleaner climbs above

the water level.

• Checkifthereistoomuchsuction.

• Checkiftheautomaticregulatorvalveis

free of debris.

• Adjusttheautomaticregulatorvalvesetting.

PROBLEMS

9. The pool cleaner does not climb

the walls easily.

• Checkifthereissufficientsuction.

• Adjusttheautomaticregulatorvalvesetting.

• Checkthatthefilterandbasketsare

clean.

10. The pool cleaner falls on it’s side. • Checkthatthehammerchamberisfree

of debris.

• Checkthattheswivelheadofthepool

cleaner is moving freely.

To Remove Debris from the Hammer.

• Sometimesdebrismayclogthebottomofthe

cleaner and prevent hammer movement or restrict

flow. The hammer is located inside the main body

and must move freely at all times.

You can see the hammer through the opening in

the hammer cover, when you turn the cleaner

upside down as shown in Figure 11.

Jiggle the hammer with your finger or flush the

cavity with a hose to fore out any debris lodged

inside the main body.

• Ifdebrisisstilllodgedinside,youmustremovethehammer. First, remove the pleated skirt.

Unscrew the hammer cover and then remove it from the main body.

In succession, take out the screw from the hammer cover. Lastly, remove the hammer from

the main body. See Figure 12.

• Oncethedebrisisdislodged,insertthehammerbackintothemainbodyandsnapthe

hammer cover back into position. Be sure that it is securely in place and tighten the screw.

Do not over tighten the screw, you might damage the hammer cover. See Figure12.

Figure 11

Figure 12

12

VII.Maintenance

The cleaner requires almost no maintenance. Visually inspect your cleaner from time to time to make

sure that:

• Thehammerismovingfreelyandisnotobstructedbydebris.

• Thefootpadisnotexcessivelyworn.Whenthetractionpadsonthebottomhaveworndown,

it is time for replacement.

When storing the cleaner, do not coil the hose.Lay the hose flat in an area protected from direct

sunlight. If hose sections are disconnected, try not to disturb the hose weight locations.

The BADU®Vac

I

hoses is specially designed to ensure optimum performance from the cleaner.

Should replacement be required, insist on genuine BADU®Vac

I

hoses.

Disclaimer of Liability - About your Pool and the Cleaner

There are a multitude of factors that contribute to the life of your pool. The BADU®Vac

I

Automatic

Pool Cleaner is very passive product that will have no impact on pool life.

Please be aware that over time, deterioration, discoloration and brittleness of any pool finish can be

caused separately by, or in combination with, age, an imbalance in pool water chemistry, improper

installation and other factors. An automatic pool cleaner, such as the BADU®Vac

I

, will not remove

or cause wear on “good” pool plaster. In fact, the opposite is true – pool plaster will eventually cause

wear on the cleaner.

The same situation holds true for vinyl-lined in ground swimming pools, because vinyl liners are

also affected by environment and factors such as pool water chemistry, sunlight and the pool’s

surroundings. Therefore over time, vinyl can become brittle and weak. In addition, vinyl-lined pools

are affected by the workmanship, composition and installation of the liner and the workmanship

and quality of construction of the supporting walls and pool base. These are all factors which can

contribute to liner failure. The existence of any of these type of conditions in your pool is not caused

by the use or operation of the BADU®Vac

I

. The manufacturer and Speck Pumps SA Pty Ltd as the

distributor disclaims any liability for repairs or replacement to any of these structures or components

of the customer’s pool.

The pool owner must assume all responsibility for the condition and maintenance of the pool’s

surface, water and deck.

13

Parts List

14

8013000016

8013000002

8013000018

8013000008

8013000004

8013000007

8013000005

8013000009

8013000010 8013000012 8013000015

8013000011

8013000013

8013000014

8013000006

WARRANTY CARD

BADU®Vac

I

Your BADU®Vac

I

Automatic Pool Cleaner is guaranteed to be free of defects in workmanship

and materials for a period of 1 year from the date of purchase.

The warranty is limited to the replacement or repairs of defective parts only and excludes:

• Allwearingpartswhichmustberegularlycheckedandreplacedwhenworn.

These include the foot pad, dive float restrictor, skirt and hammer plate.

• AnydiscolorationorfadingofBADU®Vac

I

parts.

• AnydamagetotheBADU®Vac

I

resulting from improper or abnormal use or

conditions, inadequate care and maintenance, and all such acts or omissions

beyond our control.

The warranty is not transferable and replaces all other guarantees, representations,

or warranties whether expressed or implied relating to the BADU®Vac

I

including its

merchantability and fitness for purpose.

This warranty is valid only within the border of the Republic of South Africa.

NAME:

ADDRESS:

CODE:

TEL. NO.: ( )

NAME OF DEALER:

DATE OF PURCHASE:

SERIAL NUMBER:

15

EAST RAND BRANCH

P.O. Box 2425

Bedfordview, 2008

4 Bart Street

Wilbart

Germiston, 1609

Tel: +27 11 455-4300

Fax: +27 11 455-1949

CAPE TOWN BRANCH

P.O. Box 14703

Kenwyn, 7790

Cnr. Clifford Street &

Harris Drive, Sunset Park

Ottery, Cape Town, 7800

Tel: +27 21 704-1143

Fax: +27 21 703-4374

DURBAN BRANCH

P.O. Box 267

Pinetown, 3600

Unit 1 & 2, Goodwood Park

10 Goodwood Road

Westmead, Pinetown, 3610

Tel: +27 31 700-8005

Fax: +27 31 700-8006

PRETORIA BRANCH

P.O. Box 2425

Bedfordview, 2008

Unit 4, 123 Mosaic Street

Silvertondale, Pretoria

0184

Tel: +27 12 804-1294

Fax: +27 12 804-1295

WEST RAND BRANCH

P.O. Box 2425

Bedfordview, 2008

80 Schooner Street

Lazer Park, Honeydew

2040

Tel: +27 11 794-5212

Fax: +27 11 794-8142

www.speck-pumps.co.za [email protected]

Table of contents

Other Speck pumps Swimming Pool Vacuum manuals