Theben RAMSES 856 top2 Installation guide

RAMSES

RAMSES 856 top2 OT

Heating controller

8569132

309560 04

GB

RAMSES 856 top2

Installation and

operating guide

OT Box RAMSES top2 OT – Standard box

F

NL

E I

GB

D

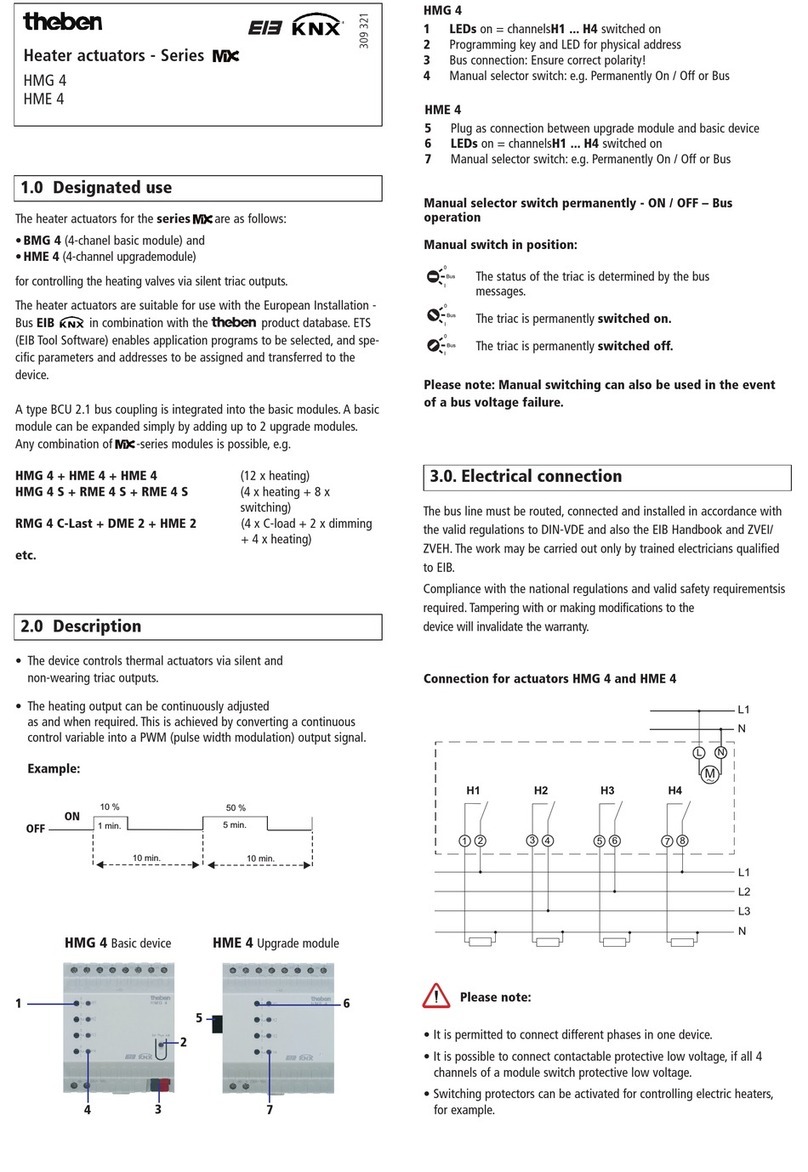

Proper use

The heating controller RAMSES 856 top OT consists of the OT-Box

RAMSES top2 OT as well as the room thermostat RAMSES 850 top2

OT, which transmits the values (target/actual values) via the Open-

Therm bus. The 7-channel regulator regulates 2 heating circuits

with the required circulation pumps and temperature sensors. In ad-

dition, the domestic hot water circulation is maximised via program

control with optional legionella protection function. The range of

functions can be extended via connection of 2 OT boxes.

• The device is intended for wall installation in the boiler room

• Corresponds to Type 1 B in accordance with IEC/EN 60730-1

• The entire system serves the purpose of digital heating

regulation for time-dependent monitoring and control of room

temperature (by means of circulation pumps, burner and/or

motor mixing valve)

• It is used in dry rooms with normal levels of domestic cleanliness

• The controller is suitable only for the Heating-

systems listed. For use in connection with other

systems, contact the service department of Theben AG

• Accessories: optional: RAMSES 850 top2 OT ( (8509132),

feed temperature sensor (9070371), plunge sensor (9070379),

floor sensor (9070321), external temperature sensor (9070459),

additional OT box for system 5 (standard box 9070712)

Disposal

Dispose of equipment in an environmentally sound manner

Contents

Proper use 2

Disposal 2

Safety advice 3

Installation and dismantling 3

Connection 4

Terminal layout 5

Description 6

Start-up with RAMSES 850 top2 OT 7

Set TSP parameters (Transparent Slave Parameters) 8

Set heating curve of second heating circuit on controller 8

Systems/Applications 1–5 9

System 1 10

System 2 11

System 3 12

System 4 13

System 5 – comfort box 14

Switch chimney sweep function on/off 17

Operating hours counter 17

Connect USB/GSM modem 17

Error messages 18

Technical data 19

Service address/Hotline 20

22

Use correct type of fuse for external fuse!

Overload leads to destruction of the relay.

Avoid excessive heat generation.

Safety advice

Danger of death through electric shock or

fire!

Installation should only be carried out by a

qualified electrician!

WARNING

Installation

Remove baffle.

Unlock and remove upper part of OT box RAMSES top2 OT by

turning the bayonet socket 90° anti-clockwise.

Attach base of the OT Box RAMSES top2 to the wall

with enclosed material.

Click terminal into the terminal support and connect cable

with the OT connection terminals.

Power supply line of the OT bus, attach the outputs and

sensors in accordance with the selected connection diagram

to the connection terminals of the base (see connection

diagram on page 9).

3

Put on upper part of the OT-Box RAMSES top2 OT, click in

and secure with bayonet socket.

Afterwards optionally click in baffle or RAMSES 850 top2 OT

in opening.

Connect OT-Box RAMSES top2 to power supply.

Dismantling

Remove RAMSES 850 top2 OT or screen.

Use a screwdriver to unlock upper part, remove and

open device. If necessary take base from wall.

GB

OT terminal

Bayonet socket

10 9

FF

NC

NC N

876 5 43 2 111

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

SELV

1,25 A T

1,25 A T

Connection

Danger of death through electric shock!

Must be installed by qualified electrician!

Disconnect power source.

Cover or shield any adjacent live components.

Ensure device cannot be switched on!

Check power supply is disconnected.

Earth and bypass.

WARNING

Connect all consuming equipment (pumps, etc.) and sensors.

Connect RAMSES 850 top2 OT via OT interface.

Connect mains power between (L) (N) (terminal ).

Inputs and outputs of the OT Box RAMSES top2 OT

4

OutputsInput fault Inputs

Bus bar

earthing

conductor

Input fault

230 V~50 Hz

10 9

FF

NC

NC

1

Terminal layout

Power connection

Outputs

– Heating circuit 1 pump as relay output

– Heating circuit 2 pump as relay output

– Burner as relay output

– Mixer closed (or 2nd burner stage) as relay output

– Mixer closed (or 2nd burner stage) as relay output

– Pump for domestic hot water feed as relay output

– Pump for domestic hot water circulation as relay output

N

876 5 43 2 1

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

SELV

5

GB

6

8

7

5

4

3

2

1

Inputs

– Input fault (see page 4)

– OpenTherm-Slave (Connection RAMSES 850 top2 OT)

– OpenTherm-Master (Connection of second OT-Box)

– Domestic hot water temperature sensor

– Feed temperature sensor (mixer circuit)

– Boiler temperature sensor

– External temperature sensor

– Domestic hot water return temperature sensor

(controls circulation pump)

The connected devices or sensors must be suitable for

SELV or marked with protection class III.

19

18

9 10

17

16

20

13

14

not used

11 12 15

Description

LED for operating state OpenTherm

LED for pump 1

LED for pump 2

LED for burner (or error)

LED for mixer open

LED for mixer closed

LED for domestic hot water (DHW) feed

LED for domestic hot water (DHW) circulation

Button for switching outputs

(for test function without RAMSES 850 top2 OT)

Button and LED for chimney sweep function

USB connection

6

12

12

12

12

12

12

12

1

2

1

2

•The OT box RAMSES top2 can be adapted for the particular

heating system (5 systems) by setting different applications.

•The selection “Weather or room-dependent control” is made

via the sensor connection. If an ambient temperature sensor

is connected, it will be automatically detected and

weather-dependent control will be carried out.

•All applications have a pump protection function.

•Almost all functions are controlled and displayed via

RAMSES 850 top2 OT. The following messages are displayed:

HC Pump on

Burner on/off

Domestic hot water preparation on

Weather-dependent control

Start-up with RAMSES 850 top2 OT

After connection, the messages follow in the display

(see image).

Language, room controls or OT controls, date, time and summer/

winter time can be set in the MODE menu under TIME/DATE or

SERVICE.

To set other functions, see operating manual for

RAMSES 850 top2 OT.

ROOM

CONTROL

EXTERNAL

TEMPERATURE

CONTROL

GERMAN

YEAR

MONTH

DAY

HOUR

MINUTE

ROOM

7

GB

TEMPERATURE

21.6°C

Set TSP parameters

(Transparent Slave Parameters)

The TSP parameters are set in the SETTINGS menu.

Confirm TSP-PARAMETER with OK.

15 parameters can be set (see below).

Parameter 0 includes the 5 systems/applications.

Use + or – keys or rotary control to enter the

value and confirm by pressing OK.

The value is transferred to the OT Box RAMSES top2 OT.

15 parameters are available from 0–14:

0 System selection (1, 2, 3, 4, 5 èdefault 1)

1 Boiler base temperature (10 ... 50 degrees, default 10 = off)

2 Max. feed temperature main circuit

(30 ... 90 degrees, default 80)

3 Max. feed temperature auxiliary circuit (rear mixer)

(30 ... 90 degrees, default 40)

4 Boiler hysteresis (1 ... 15 K, default 5)

5 Domestic hot water hysteresis (1 ... 10 K, default 5)

6 Domestic hot water priority / parallel operation (default ...)

7 Domestic hot water pump switch-off delay (0 ... 20 mins,

default 10)

8 Domestic hot water for frost protection (default ...)

9 Time for domestic hot water circulation pump:

0: Domestic hot water circulation pump only runs

when temperature-controlled

0–99: Domestic hot water circulation pump via ΔT on,

Value is the maximum runtime in s

10 Pump protection time (0 .. 11 pm, default 12)

11 Pump protection duration in s (0…99, default 15,

0 = no pump protection)

12

ΔT for sequence control (5 ... 25, default 15) resolution 0.1 K

13 ΔT1 for pump switch heater 1 (5 .. 15 K, default 5 K)

14 ΔT1 for pump switch heater 2 (5 .. 15 K, default 5 K)

Further information available in product

manual for OT box RAMSES top2 OT at

www.theben.de.

Set heating curve of second heating circuit on controller

The heating circuit is adjusted in the SETTINGS menu.

On the room thermostat RAMSES 850 top2 OT the heating curve for

2 heating circuits can be adjusted (see RAMSES 850 top2 OT oper-

ating guide, page 31). Base point2 and end point2, etc. must be set

on the room thermostat.

Setting range: Base point 10–30 °C, default 20 °C

End point 25-60 °C, default 35 °C

TSP

PARAMETERS

TSP1

1

TSP2

10

8

Systems/Applications 1–5

•For the systems or applications 1-4 the OT-Box RAMSES top2

OT is required. The OpenTherm bus links RAMSES 850 top2 OT

with the OT box RAMSES top2 OT.

•System 5 requires 2 OT boxes (centre box and end box),

which are linked via the OpenTherm bus. RAMSES 850 top2

OT as well as both boxes are linked with one another via the

OpenTherm bus. The centre box must be linked to the 0–10 V

(terminal 15 - 15) input with a wire bridge.

With the RAMSES 856 top2 OT an additional OT box (standard

box 9070712) will be required for this system.

9

GB

RAMSES 850 top2 OT with 2-wire connection to 1 box

RAMSES 850 top2 OT with 2-wire connection to 2 boxes

End box

Centre box

OT

Input

0–10 V

OT

OT

*

* Wire bridge

10

System 1

System 1 consists of a maximum of:

• Burner

• Heating circuit without mixer

• Heating circuit with mixer

• Water storage tank

• Domestic hot water circulation pump

(Domestic hot water return pump)

The individual functions are activated by connecting the

appropriate sensor, i.e. the domestic hot water program is

only executed when the domestic hot water temperature

sensor is connected.

Output configuration

• Heating circuit pump Heating circuit 1

• Heating circuit pump Heating circuit 2

• Burner

• Mixer +

• Mixer –

• Domestic hot water feed pump

• Domestic hot water circulation pump

N

876 5 43 2 1

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

SELV

8

7

6

5

4

3

2

Heizkörper

Fußboden

Frischwasser

Wärmeerzeuger

Brenner

Feed temperature sensor 17

Burner

Heater

Boiler temperature sensor 18

Pump heating

circuit 1 8

Fresh water

Mixer + 5

Mixer – 4

Domestic hot water temperature sensor 14

Domestic hot water return

temperature sensor 20

Pump domestic

hot water feed

3

Pump domestic hot

water circulation 2

Pump heating circuit 2 7

External

temperature

sensor 19

Heating element

Floor

Domestic hot

water tank

Input configuration

• Domestic hot water temperature

• Feed temperature heating circuit 2

• Boiler temperature

• Outdoor temperature

• Domestic hot water return temperature 20

19

18

17

16

Unrequired sensor inputs must be closed off with a

resistor (100 ohm,enclosed).

Power connection 1-

System 2

System 2 (not for AT-dependent control) consists of a

maximum of:

• Burner with 2 stages

• Heating circuit without mixer

• Water storage tank

• Domestic hot water circulation pump

(Domestic hot water return pump)

The individual functions are activated by connecting the

appropriate sensor, i.e. the domestic hot water program is

only executed when the domestic hot water temperature

sensor is connected.

Output configuration

• Heating circuit pump Heating circuit 1

• Burner Stage 1

• Burner Stage 2

• Domestic hot water feed pump

• Domestic hot water circulation pump

11

GB

8

5

4

3

2

N

876 5 43 2 1

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

SELV

Input configuration

• Domestic hot water temperature

• Boiler temperature

• Outdoor temperature

• Domestic hot water return temperature 20

19

18

16

Unrequired sensor inputs must be closed off with a

resistor (100 ohm,enclosed).

Heizkörper

Fußboden

Frischwasser

Wärmeerzeuger

Brenner

Stufe1 Stufe2

Burner

Fresh water

Pump domestic

hot water feed

3

Stage 1 Stage 2

Boiler temperature sensor 18

Pump heating

circuit 1 8

Domestic hot water temperature sensor 16

Domestic hot water return

temperature sensor 20

Pump domestic hot

water circulation 2

External

temperature

sensor 19

Heating element

Service

water tank

Heater

Power connection 1-

System 3

System 3 consists of:

• Burner

• Heating circuit without mixer

• 2. Heater (e.g. solid fuel boiler)

• Buffer storage

• Water storage tank

• Domestic hot water circulation pump

(Domestic hot water return pump)

The individual functions are activated by connecting the

appropriate sensor, i.e. the domestic hot water program is only

executed when the domestic hot water temperature sensor is

connected.

Output configuration

• Heating circuit pump Heating circuit 1

• Burner

• Pump 2. Heater

• Boiler pump (buffer storage feed pump)

• Domestic hot water feed pump

• Domestic hot water circulation pump

12

8

6

5

4

3

2

N

876 5 43 2 1

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

SELV

Heizkörper

Frischwasser

Relais-Brenner

Brenner

Wärmeerzeuger

Burner

Relay burner 6

Fresh water

Heater

Heating element

Feed temperature sensor 17

Boiler temperature sensor 18

Pump heating circuit 1

8

Pump second

heater 5

Boiler pump

4

Domestic hot water temperature sensor 16

Domestic hot water return

temperature sensor 20

Pump domestic

hot water feed

3

Pump domestic hot

water circulation 2

External

temperature

sensor 19

Service

water tank

Input configuration

• Domestic hot water temperature

• Feed temperature heating circuit 2

• Boiler temperature

• Outdoor temperature

• Domestic hot water return temperature 20

19

18

17

16

Unrequired sensor inputs must be closed off with a

resistor (100 ohm,enclosed).

Power connection 1-

13

System 4

System 4 consists of:

• Burner

• Heating circuit with mixer

• 2. Heater (e.g. solid fuel boiler)

• Buffer storage

• Water storage tank

• Domestic hot water circulation pump

(Domestic hot water return pump)

The individual functions are activated by connecting the

appropriate sensor, i.e. the domestic hot water program is only

executed when the domestic hot water temperature sensor is

connected.

Output configuration

• Heating circuit pump Heating circuit 1

• Boiler pump

• Burner

• Mixer +

• Mixer –

• Domestic hot water feed pump

• Domestic hot water circulation pump

8

7

6

5

4

3

2

N

876 5 43 2 1

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

SELV

Heizkörper

Frischwasser

Relais-Brenner

Brenner

Wärmeerzeuger

Burner

Relay burner 6Heater

Fresh water

Boiler pump

4

Heating element

*

*

Feed temperature sensor 17

Return temperature

sensor 20

Boiler temperature sensor 18

Pump heating

circuit 1 8

Mixer + 5

Mixer – 4

Domestic hot water temperature sensor 16

Pump domestic

hot water feed

3

Pump domestic hot

water circulation 2

External

temperature

sensor 19

Service

water tank

GB

Input configuration

• Domestic hot water temperature

• Feed temperature

• Buffer storage temperature

• Outdoor temperature

• Temperature 2. Heater 20

19

18

17

16

Unrequired sensor inputs must be closed off with a

resistor (100 ohm,enclosed).

Power connection 1-

System 5 – comfort box

The Comfort box consists of RAMSES 850 top2 OT and 2 standard

boxes (centre box and end box).

With it additional inputs/outputs are available for the connection

of pumps, etc. Standard box (without RAMSES 850 top2 OT) can

be obtained from Theben.

With the RAMSES 856 top2 OT an additional OT box (standard

box 9070712) will be required for this system.

On the centre box attach wire bridge to input 0–10 V

(terminal 15 – 15) (see figure).

System 5 consists of:

• Burner

• Heating circuit 1 with mixer

• Heating circuit 2 with mixer

• 2. Heater (e.g. solid fuel boiler)

• Buffer storage

• Water storage tank

• Domestic hot water circulation pump

(Domestic hot water return pump)

14

RAMSES top2 OT with 2-wire connection to 2 boxes

End box

Centre box

OT

Input

0–10 V

OT

USB

*

* Wire bridge

15

Output configuration

• Boiler pump

(feed pump buffer storage)

• Mixer + Heating circuit 2

• Mixer – Heating circuit 2

• Pump 2. Heater

6

5

4

3

Output configuration

• Heating circuit pump Heating circuit 1

• Heating circuit pump Heating circuit 2

• Burner

• Mixer + Heating circuit 1

• Mixer – Heating circuit 1

• Domestic hot water feed pump

• Domestic hot water circulation pump

6

8

7

5

4

3

2

GB

Centre box

Power connection

Input configuration

• RAMSES 850 top2 OT

• End box OT

• Wire bridge

• Buffer tank temperature top

• Feed temperature heating circuit 2

• Temperature 2. Heater

• Lower buffer storage temperature 20

18

17

16

13

14

15

End box

Power connection

Input configuration

• Domestic hot water temperature

• Feed temperature heating circuit 1

• Boiler temperature

• Outdoor temperature

• Domestic hot water return temperature 20

19

18

17

16

N

876 5 43 2 1

876 5 43 2 1

N N N NNNN

LL'L'L'

L'L'L'L'

230 V~ 50 Hz

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18 19 20

20

19

18

SELV

Unrequired sensor inputs must be closed off with a

resistor (100 ohm,enclosed).

1- 1-

16

System 5

Comfort box

with centre box

and end box

Frischwasser

Brenner

Festbrennstoff-

Kessel

Heizkörper

Fußboden

Burner

Fresh water

Floor

Burner relay

End box 6

Solid fuel boiler

Pump domestic

hot water feed

End box 3

Pump second heater

Centre box 3

Pump domestic hot

water circulation

End box 2

Boiler

pump 6

Centre box

Pump heating circuit 1

End box 8

Pump heating circuit 2

End box 7

External temperature sensor

End box 19

Sensor feed temperature 1

End box 17

Domestic hot water temperature sensor

End box 14

Domestic hot water temperature

sensor, Centre box 16

Boiler temperature sensor

End box 16

Mixer +

End box 5

Boiler temperature sensor

Centre box 18

Lower buffer temperature

sensor

Centre box 20

Buffer temperature sensor

End box 20

Mixer –

Centre box 4

Mixer +

Centre box 5

Mixer –

End box 4Sensor feed temperature 2

Centre box 17

Connect USB/GSM modem

In the SETTINGS menu the additional sub-menu PIN CODE

appears.

To protect the system, enter the four-digit code

of the SIM card.

Operation via SMS

When you connect a USB/GSM modem to the OT-Box

RAMSES top2 OT, the desired temperature/operating mode

can be set via mobile phone.

1. Room-dependent control

To change the set point value, PIN number and

temperature via SMS send to the USB/GSM modem:

e.g. PIN:1234 Set:21.0 (note format!!)

The USB/GSM modem sends an SMS with:

PIN:Ok Set:21.0 Temp:19.0

To query the current temperature and settings,

send the PIN number to the USB/GSM modem:

e.g. PIN:1234

The USB/GSM modem sends an SMS with:

PIN: OK Set:21.0 Temp:19.0

Switch chimney sweep function on/off

Press button on the OT-Box RAMSES top2 OT x 1. The

LED lights up. The chimney sweep function (burner + pump,

for measurement of emissions by the chimney sweep) is on

(full load).

Press button again; the function is switched off. If not

switched off manually the chimney sweeping function ends

automatically after 30 mins.

In the RAMSES 850 top2 OT, the chimney sweeping function

can also be switched on and off in the SETTINGS – CHIMNEY

SWEEPING.

Operating hours counter

The values burner start and burner hours are determined in the

OT box and displayed on the RAMSES 850 top2 OT.

Press INFO button. The display shows

17

GB

BURNER

START / 10

0 00

BURNER

HOURS / 10

0 00

12

When you receive PIN:xxxx Set:xx,x via SMS,

Replace the x with the correct PIN code/desired

temperature.

2. Weather-dependent control

With the weather-dependent control, you can select the

operating mode by SMS.

Send the PIN number and operating mode via SMS to the

USB/GSM modem: e.g. PIN:1234 Set:2

1 = Frost protection mode

2 = Reduced mode

3 = Comfort mode

The USB/GSM modem sends an SMS with the set operating

mode and current room temperature:

PIN: OK Set:2 Temp:19.0

To query the current temperature and settings,

send the PIN number to the USB/GSM modem:

e.g. PIN:1234

The USB/GSM modem sends an SMS with:

PIN: OK Set:2 Temp:19.0

When you receive PIN:xxxx Set:x via SMS,

Replace the x with the correct PIN code/desired

operating mode.

Error messages

If an error occurs during the adjustment, error codes appear in

the RAMSES 850 top2 OT display. Error codes 20-28 originate

with a sensor error.

Error- Error

code

11 11 NO COMMUNICATION

20 20 EXTERNAL TEMPERATURE ERROR

21 21 FEED ERROR 1

22 22 DOMESTIC HOT WATER ERROR

23 21 FEED ERROR 2

24 24 DOMESTIC HOT WATER RETURN ERROR

25 25 BOILER ERROR 1

26 25 BOILER ERROR 2

27 27 STORAGE ERROR 1

28 27 STORAGE ERROR 2

29 29 EXTERNAL FAULT ERROR

30 ---

31 31 MODEM ERROR

ERROR

23 FEED

ERROR 2

18

19

Technical data

• Operating voltage: 230 V~, +10/–15 %

• Frequency: 50 Hz

• Power consumption: typically 2.7 VA

• Standby: typically 1.1 W

• Switch load: Relay: 5 x max. 2 (1) A 230 V~

(burner, mixer open, mixer closed,

domestic hot water pump, domestic

hot water return pump)

Relay: 2 x 1 A (1 A)

230 V ~

(Heat pump 1, Heat pump 2)

• SELV power circuits: – Sensor inputs

– OT (communication interface)

– USB (data communications

interface)

• Contact material: AgNi

• Contact: 7 x simple working contact

(normally open)

• Permissible ambient

temperature: 0 °C to +50 °C

• Contact position for power reserve: permanently to Off

• Protection class: II in accordance with EN 60730-1

subject to designated installation

• Protection rating: IP 20 in accordance with EN 60529;

IP 65 for remote sensor

GB

• Mode of operation: Type 1 B in accordance with

EN 60730-1

• Pollution degree: 2

• Rated impulse withstand voltage: 4 kV

A detailed manual can be found at

www.theben.de

Service address/Hotline

Service address

Theben AG

Hohenbergstr. 32

72401 Haigerloch

GERMANY

Telephone +49 7474 692 0

Fax +49 7474 692-150

Hotline

Telephone +49 7474 692 -369

Fax +49 7474 692-207

Addresses, telephone numbers etc.

www.theben.de

This manual suits for next models

3

Table of contents

Other Theben Controllers manuals

Theben

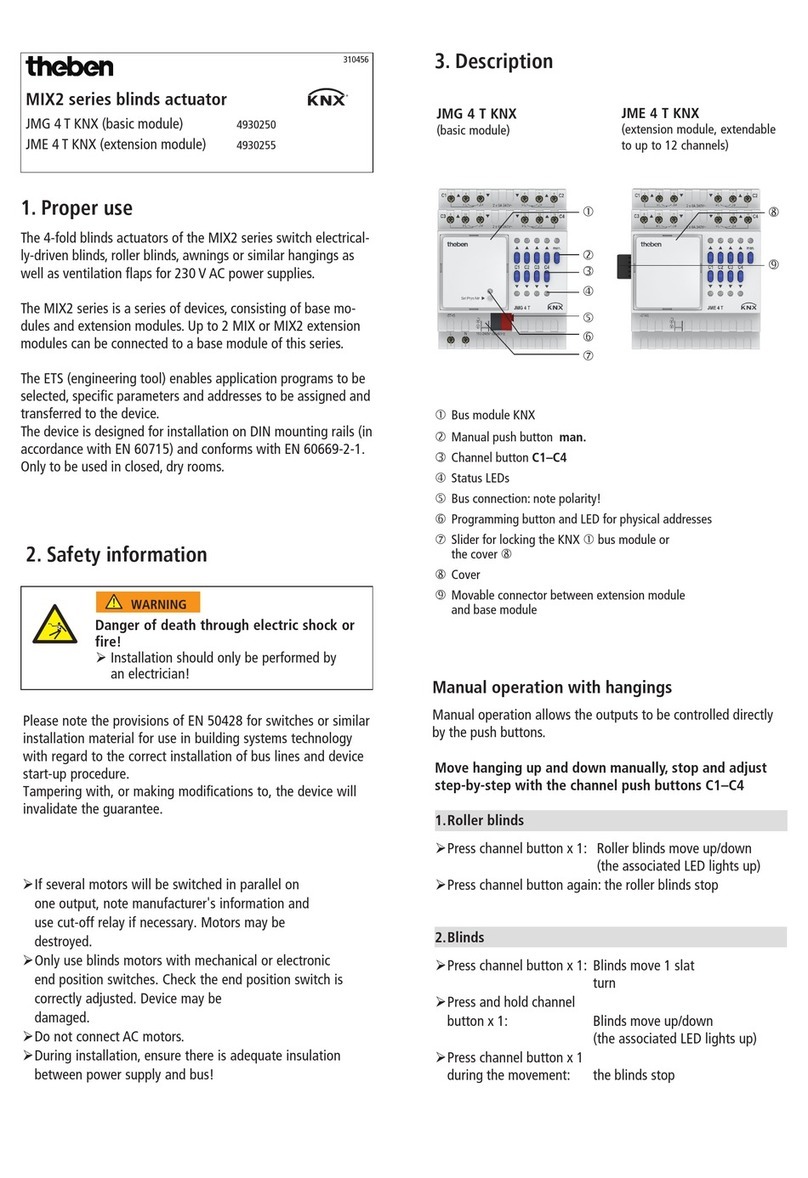

Theben JMG 4 T KNX User manual

Theben

Theben TC 649 E User manual

Theben

Theben Mix Series User manual

Theben

Theben HMG 8 User manual

Theben

Theben PH-II Series User manual

Theben

Theben RM 4 H FIX1 User manual

Theben

Theben DU 1 User manual

Theben

Theben FCA 2 User manual

Theben

Theben RMG 8 User manual

Theben

Theben MIX 2 Series User manual