Suggestion

Please register the exposure temperature and the distance of the heating line when

you have an optimum result. In this way, you can repeat the same guidelines for future

work with the same material.

Maintenance

Occasionally remove dirt on the reflector below the heating wire. Heating line should not touch

at any time the walls of the reflector.

If necessary, stretch the heating wire. First, unplug the machine. Subsequently, loosen the hex

screw on one side with an Allen wrench, tighten and retighten.

It could be possible that you have to cut a little heating wire.

Use only original heating wire Ovili., by contacting your provider.

Reparing

Repairs permitted only by a qualified electrician. During guaranty only by Ovili service.

Before opening the control box, please unplug the machine.

Stretching or changing heating lines

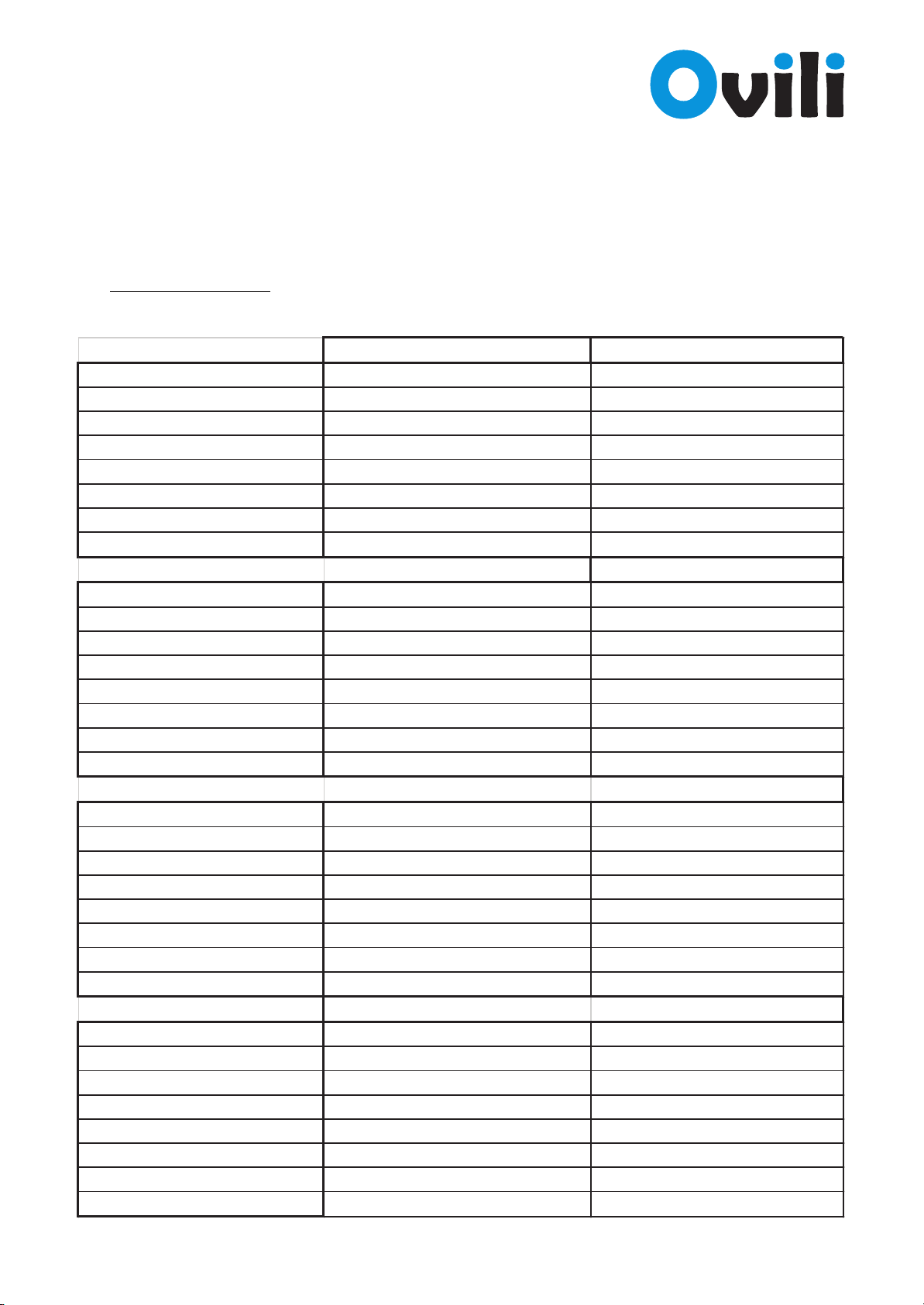

Moving heating lines (4 line unit)

In order to move work place and lines on these units, please use an Allen key.

Untight a little bit the screws under the heating lines (from both parts), move whole

line simultaneously, and adjust exact place. When it is on the place, tight the screws up again.

If necessary, stretch the heating wire to achieve

a regular heating points all over the machine.

First, unplug the machine. Subsequently, loosen

the hex screw on one side with an Allen wrench,

tighten and retighten. It could be possible that you

have to cut a little heating wire.

If you need to change heating line, please loosen

the screws and remove heating line from holder.

Introduce a new heating line in one of the holders

and screw it. Then, straight the line and make

same process in the second holder. The line should

be completely straight before to use the unit.