Spedo 2600 User manual

1 - Spedo 2600 Service Manual SP 007 011

Spedo 2600 Forms Cutter

SERVICE MANUAL

Issue 2

Part Number SP 007 011

76 Woolmer Way

Bordon

Hampshire GU35 9QF

ENGLAND

Telephone

National: 01420 487442

International: +44 01420 487442

Facsimile

National:

01420 477827

International: +44 01420 477827

2 - Spedo 2600 Service Manual SP 007 011

Spedo 2600 Forms Cutter History Sheet

Manual Issue Date Changes Incorporated

1 July 2012 First Edition

2 January 2013 Change of Address

3 - Spedo 2600 Service Manual SP 007 011

Spedo 2600 Forms Cutter

Published by Spedo UK Limited

Unit 5, Riverwey Ind. Park

Newman Lane

Alton,

Hampshire GU34 2QL

ENGLAND

Copyright

Spedo UK Limited 2012

All Rights Reserved.

No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of Spedo UK Limited.

Unpack

Unpack the equipment and examine it thoroughly to ascertain whether any damage

has occurred in transit. Report immediately any such damage to the agent or

manufacturer. Retain the packing should further transportation be necessary.

All Goods

All goods manufactured by the Company are guaranteed to the extent hereafter

mentioned against defects arising from faulty material or workmanship subject to

the goods not having suffered maltreatment or interference. The Company's liability

under this guarantee is limited to replacing any part or parts found defective within

a period as laid down in Company instructions after the date of delivery or

installation.

Other Goods

If goods not of the Company's manufacture are ordered, the guarantee of that

company is to be accepted.

Descriptive Matter

Descriptive matter, illustrations, dimensions and weights issued by the Company are

typical and shall not be held as binding.

Patterns and Designs

The Company reserves the right to alter patterns and designs without notice.

First Published

March 2012

We have taken every care in the preparation of this manual. If there are any

inaccuracies, ambiguities or omissions, Spedo UK Limited and its consultants and

distributors cannot accept responsibility for any loss or damage these errors may

cause.

4 - Spedo 2600 Service Manual SP 007 011

Safety Measures

This instruction manual contains certain WARNING and CAUTION notices which must be

followed by the user to ensure safe operation and to retain the equipment in a SAFE condition.

All users of the equipment described in this manual

MUST have received adequate training in its

use and application in order to ensure SAFE AND PROPER USE.

Any adjustment, maintenance or repair of the opened apparatus under voltage shall be carried out

only by a skilled person who is AWARE OF THE HAZARD INVOLVED.

5 - Spedo 2600 Service Manual SP 007 011

Spedo 2600 Forms Cutter

Table of Contents

History Sheet................................................................................................................... 2

Copyright ........................................................................................................................ 3

Safety Measures.............................................................................................................. 4

Table of Contents............................................................................................................ 5

Maintenance Procedures

WARNINGS ............................................................................................................. 7

Electrical................................................................................................................ 7

Clothing & Jewellery............................................................................................. 7

Cutting Blades ....................................................................................................... 7

MAINTENANCE INTERVALS................................................................................ 8

OPERATOR MAINTENANCE PROCEDURES ...................................................... 9

SERVICE ENGINEER PROCEDURES.................................................................... 9

Section 1 – Edge Trimmer Units.................................................................…...11

Section 1a - Edge Trimmer Unit Removal……………………………….……...11

Section 1b - Edge Trimmer Unit Strip……………………………………….….12

Section 1c - Edge Trimmer Unit Rebuilt…………………………………….….14

Section 2 – Centre Cutter Unit...........................................................................17

Section 2a- Centre Cutter Lower Hub Removal………………………….……..17

Section 2b – Centre Cutter Arm Service………………………………………...17

Section 2c – Centre Cutter Lower Hub Blade Change………………………….19

Section 2d – Centre Cutter Arm Adjustment…………………………………....20

Section 2e – Centre Cutter Setting………………………………………………21

Section 3 – Cross Cut Blades........................................................................…...22

Section 3a – Cross Cut Blade Guard Removal…………………………………..22

Section 3b – Cross Cut Blade Removal………………………………………….23

Section 3c – Blade Guide Preparation…………………………………………...24

Section 3d – Lower Blade Preparation…………………………………………...27

Section 3e – Upper Blade Preparation……………………………………………28

Section 3f – Lower Blade Adjustment…………………………………………...28

Section 3g – Advanced Lower Blade Adjustment..........................................…...29

Section 3h – Upper Blade Adjustment…………………………………………...30

Section 4 – Drive and Pressure Head Units........................................................36

Section 4a – Drive Wheel Assembly Removal………………………………...…36

6 - Spedo 2600 Service Manual SP 007 011

Section 4b – Drive Wheel Replacement……………………….……………….37

Section 4c – Drive Wheel Assembly Installation.........................................…...38

Section 4d – Pressure Head Assembly Removal……………………………….38

Section 4e – Pressure Head Assembly Strip…………………………………....39

Section 4f – Pressure Head Assembly Rebuild………………………………...41

Section 4g – Pressure Head Assembly Setting………………………………....43

Section 5 – Blade Drive System……………………………………………….45

Section 5a – Blade Drive Belt Renewal……………………………...…………45

Section 5b – Blade Sensor Set-up………………………………………...…….47

Section 6 – In feed Section................................................................................. 49

Section 6a – In feed Brush Element Renewal……………………………….….49

Section 6b – OMR Sensor Set-up……………………………………………….49

Section 7 – Trouble Shooting Guide ................................................................ 51

SCHEMATIC DIAGRAMS

SP006 034 Operator Switch Assembly ............................................................... 53

SP006 844 Control PCB – Internal I/O............................................................... 54

SP006 844 Control PCB – External I/O.............................................................. 55

7 - Spedo 2600 Service Manual SP 007 011

Maintenance Procedures

WARNINGS

Electrical

Before starting any maintenance, ensure that the forms cutter has been disconnected from the main

electrical supply.

Clothing & Jewellery

Never operate the forms cutter when wearing items of loose clothing or other decorative jewellery,

such as necklaces or bracelets as they could become entrapped in the machinery and cause injury.

Cutting blades

The putting into operation of the machine, especially the actuation of the cross-cut forms cutter

blade pre-supposes that the forms cutter has been correctly installed by a Spedo trained technician.

The first time that the cross-cutting blade is to be actuated, it must only be carried out manually by

a Spedo trained technician.

The angular blades on the edge trimmers, the centre cutter and the cross-cutter are extremely sharp

and care should be taken to protect fingers when the protective cover has been opened.

The manufacturer is not liable for damage caused by non-observance of the procedures given in this

manual. Never touch the working area of the longitudinal cross-cutting blade. This is applicable

especially when standing at the stacker end, when the motor is running. If any malfunction occurs,

contact the Customer Services Department of Spedo or their agent for assistance. DO NOT

ATTEMPT to correct any mechanical malfunction that occurs unless qualified to do so.

8 - Spedo 2600 Service Manual SP 007 011

Maintenance Intervals

Operator Maintenance procedures

This section must be completed by a competent operator or maintenance engineer

Service Engineer's procedures

This section must only be completed by a fully trained Spedo technician

Section 1 – Edge Trimmer Units

Section 2 – Centre Cutter Unit

Section 3 – Cross Cut Blades

Section 4 - Drive & Pressure Head Units

Section 5 – Blade Drive System

Section 6 – In-feed Section

Section 7 – Fault Finding

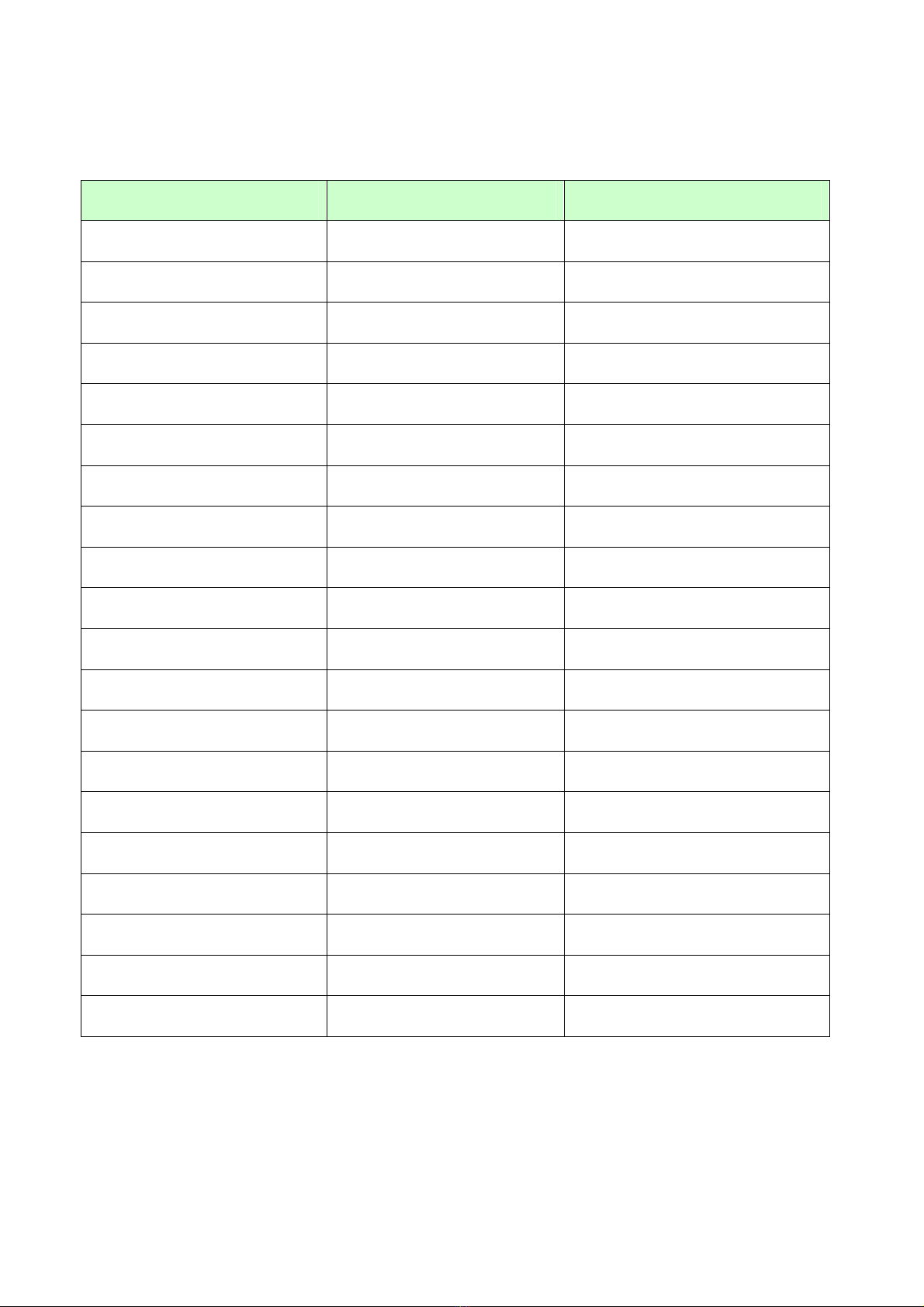

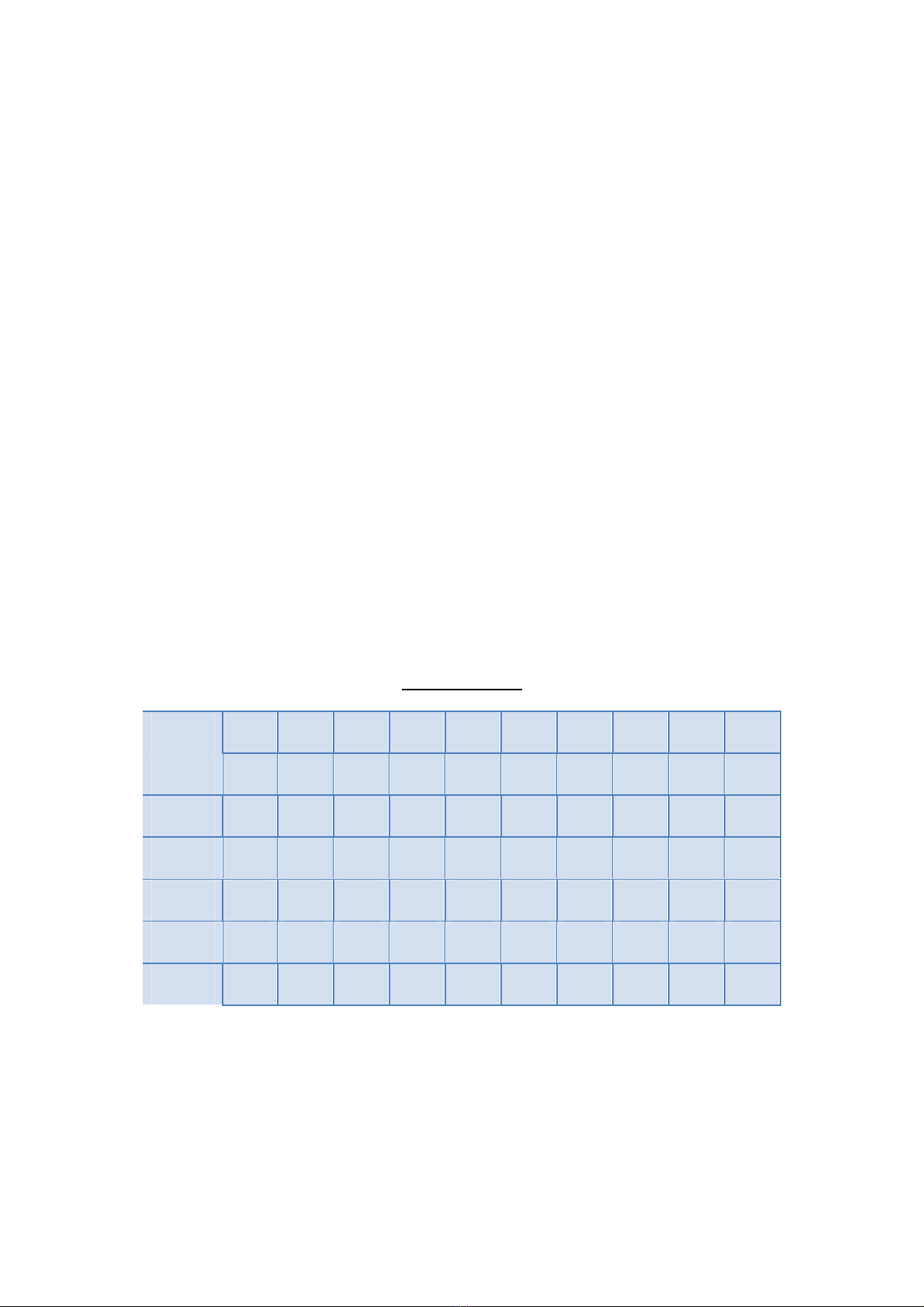

The following table shows which sections of the ‘Service Engineers Tasks’ are to be completed

at each 5 million cycle interval. Once 50 million cycles are reached, start again from 5 million

Service Table

Section

5m 10m

15m

20m

25m

30m

35m

40m

45m

50m

1 * * * * * * * * * *

2 * * * * * * * * * *

3 * * * * * * * * * *

4 * *

5 * *

6 * * *

9 - Spedo 2600 Service SP 007 011

Operator Maintenance procedures

To maintain your machines optimum performance the following tasks must be completed daily.

Please read this complete section before starting.

WARNING The machine must be isolated from its power supply before starting any

maintenance procedure.

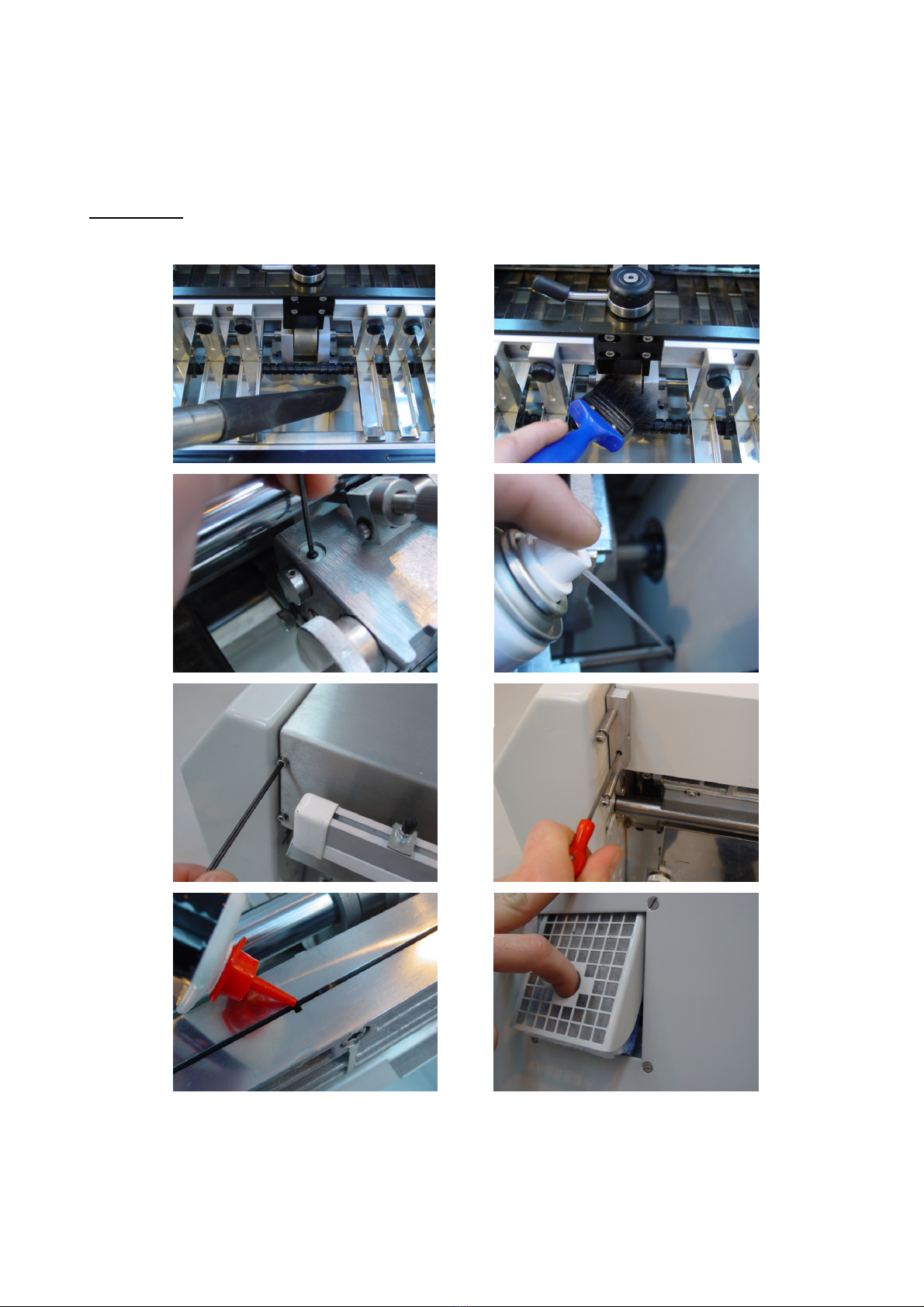

1. Open the safety cover to gain access to the paper feed section. Using a vacuum cleaner to

remove any build-up of dust. (Fig .1)

8

7

6

5

4

3

1

2

10 - Spedo 2600 Service Manual SP 007 011

Operator Maintenance procedures (continued)

2. With a soft hair bush, remove any compressed paper dust build-up on the drive wheel.

(Fig. 2) If the build-up of dust is so compressed that a soft hair brush alone will not

remove it, you can use a soft grade brass wire brush. NOTE: Do not use a steel wire

bush or any form of abrasive to clean the drive wheel surface.

3. Remove, and lubricate the edge trimmer oil wicks (one per edge trimmer) with light

machine oil. Refit the oil wicks once oil has soaked in. (Fig. 3) NOTE: Do not over oil

the wicks as this may cause marks on the edges of the forms.

4. Lubricate the drive wheel drive shaft bush. We recommend using light machine oil, in an

aerosol form to ease application. (Fig. 4)

5. Remove the blade guard. (Fig. 5) WARNING Exposed blades proceed with caution.

6. Loosen the two grub screws which retain the pressure head mount plate, (Fig. 6) and lift

the assembly clear of the machine.

7. Apply only one drop of light machine oil into each of the oil channels on the blade guide.

(Fig. 7) NOTE: Do not over oil the guide as this may cause marks on the end of the

forms.

8. Remove the fan filter, (Fig. 8) and clean using a vacuum cleaner. WARNING Do not

immerse the filter in water to clean.

11 - Spedo 2600 Service Manual SP 007 011

Service Engineer's Procedures

To prevent excess component wear and damage to motors and drivers, the tasks shown in the

service table must be completed at each 5,000,000 cycle interval

Please read this complete section before starting.

WARNING The machine must be isolated from its power supply before starting any

maintenance procedure

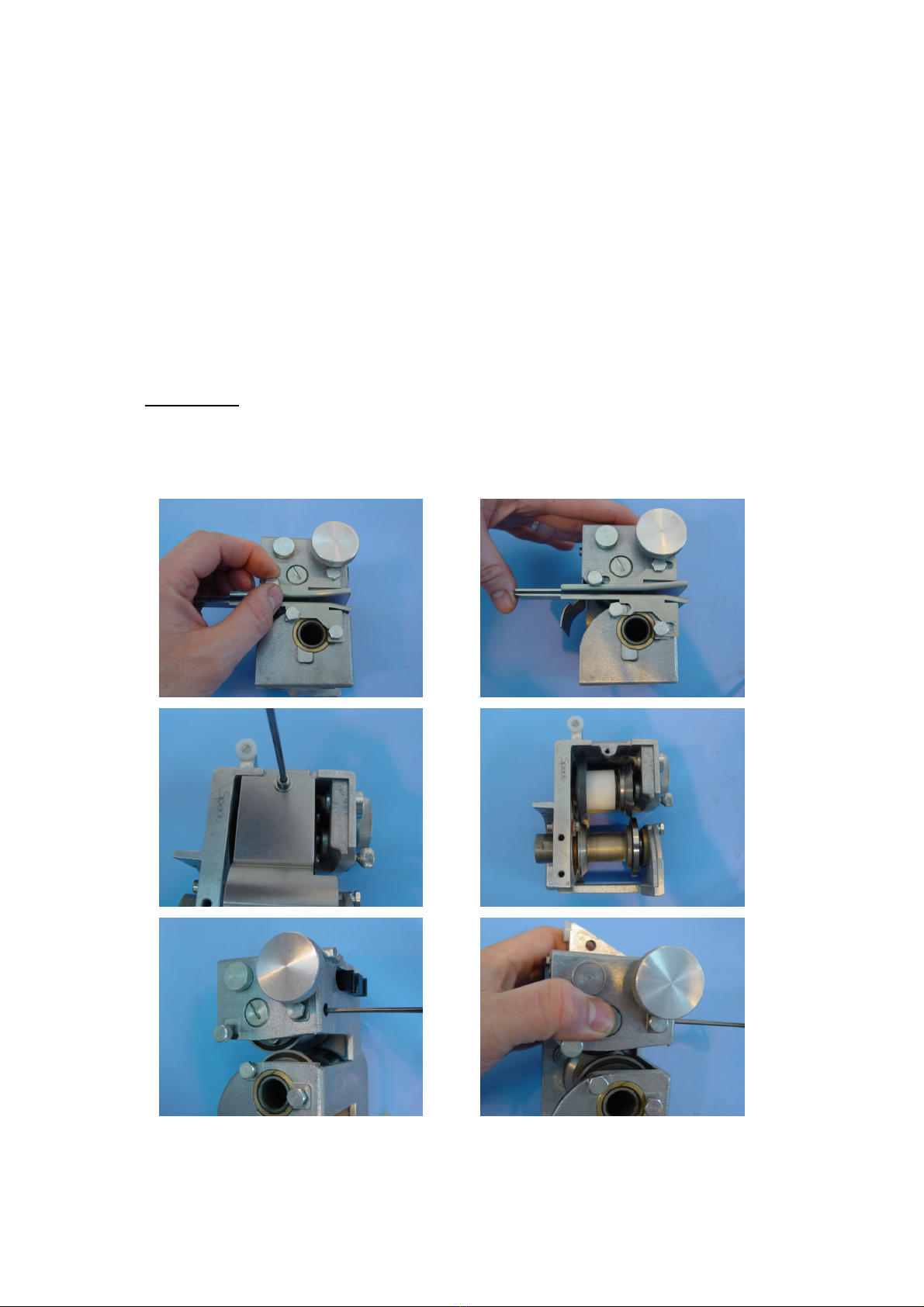

Section 1a – Edge Trimmer Unit removal

1

2

3

4

5

6

7

8

12 - Spedo 2600 Service Manual SP 007 011

Section 1a – Edge Trimmer Unit removal (continued)

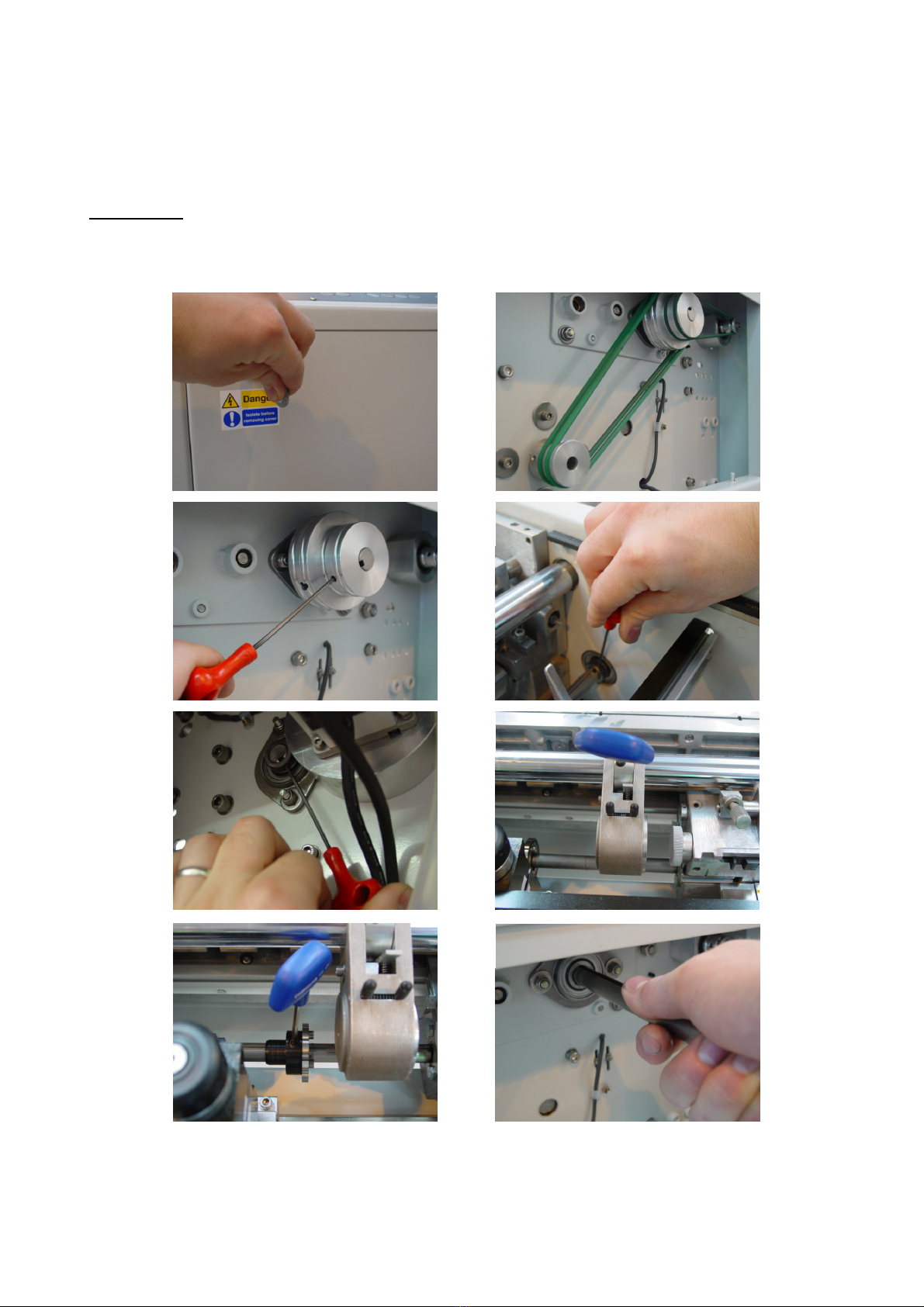

1. Remove the outer service door. (Fig. 1)

2. Remove the edge trimmer and kick-out roller drive belts (Fig. 2) and pulleys. (Fig. 3)

3. Loosen the grub screw that retains the edge trimmer shaft into the bearings, there is one

at each end of the shaft. (Fig. 4 & 5)

4. Loosen the grub screw that holds the centre cutter arm, slide the arm to one side allowing

clear access to the lower centre cutter hub. (Fig. 6)

5. Loosen the lower centre cutter hub and slide it clear of its support. (Fig. 7)

6. Carefully remove the edge trimmer drive shaft by gently pulling it towards you. The

edge trimmer units and centre cutter lower hub will need to be supported during this

process. Failure to do so may result in the shaft becoming difficult to remove. (Fig. 8)

WARNING Do not force the drive shaft in either direction. If the shaft is proving

difficult to remove, examine the shaft for damage.

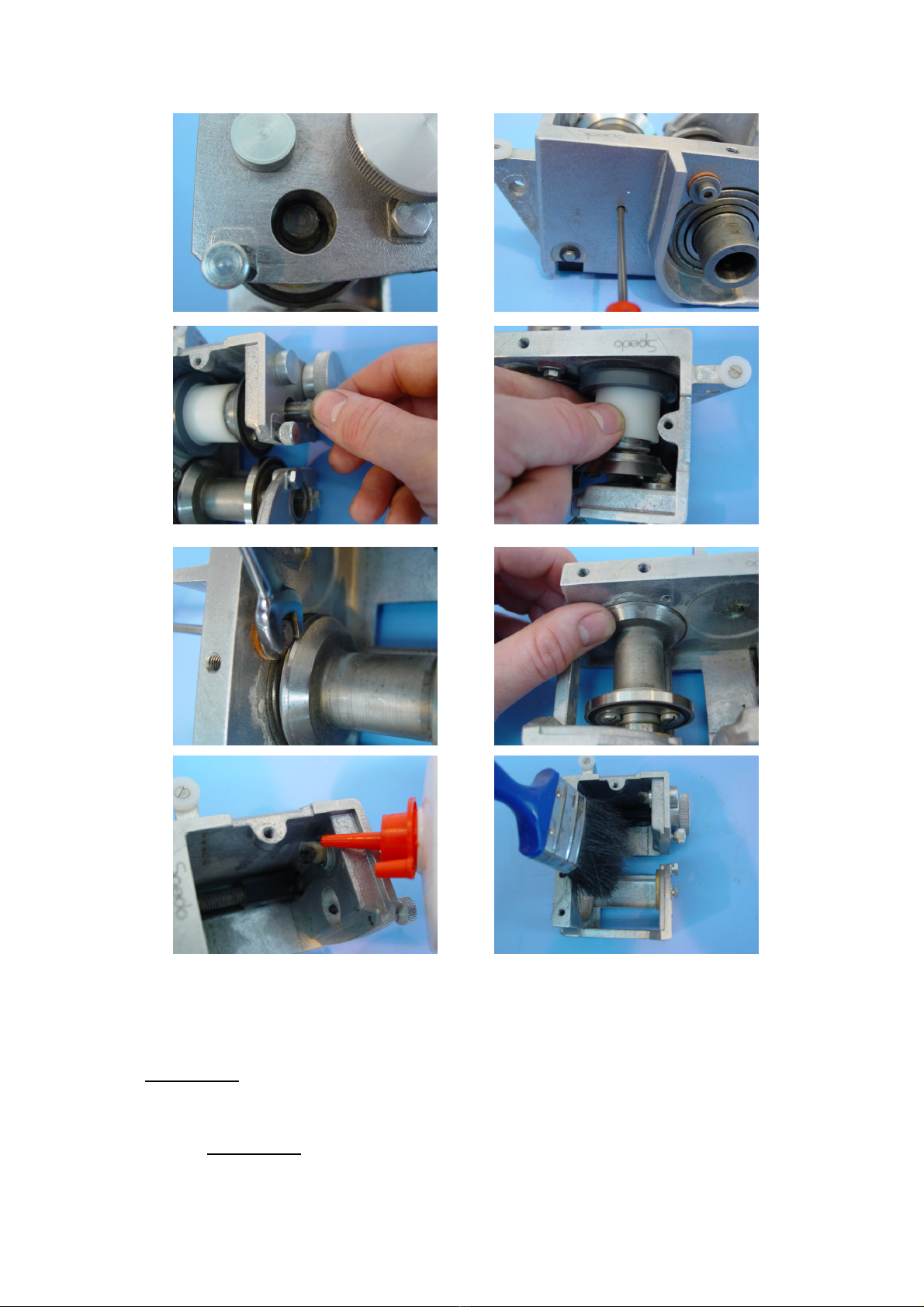

Section 1b – Edge Trimmer Unit strip

1

2

3

4

5

6

13 - Spedo 2600 Service Manual SP 007 011

Section 1b – Edge Trimmer Unit strip (continued)

1. Remove the paper guide by loosening the knurled screw and push the guide out from the

rear. (Fig. 1 & 2)

2. Remove the paper deflector plate to expose the edge trimmer blades. (Fig. 3 & 4)

WARNING Even blades that have been used may still be sharp so proceed with

caution.

3. Loosen the grub screw in the front of the edge trimmer which retains the eccentric bush.

(Fig. 5) WARNING The eccentric bush is spring loaded so you must keep your thumb

over the top while removing the grub screw.(Fig. 6)

7

8

9

10

11

12

13

14

14 - Spedo 2600 Service Manual SP 007 011

Section 1b – Edge Trimmer Unit strip (continued)

4. Once the eccentric bush and spring have been removed, you are able to see the upper hub

axle. (Fig. 7)

5. The axle is removed by pushing it out from the opposite end. You may have to apply a

small amount of pressure, using a pin punch. (Fig. 8)

6. Once the end of the axle is exposed you will be able to remove it from the edge trimmer

unit. (Fig. 9) WARNING The upper hub is no longer retained and may fall out.

7. Carefully remove the upper hub. (Fig. 10)

8. Remove the lower hub retainer and carefully remove the hub. (Fig. 11) You may need to

apply a small amount of pressure to the drive edge of the lower hub. (Fig. 12)

9. Apply a small amount of light machine oil to the blade wick. (Fig. 13)

10. Remove any dust build up in the casting with a soft hair brush, or airline. (Fig. 14)

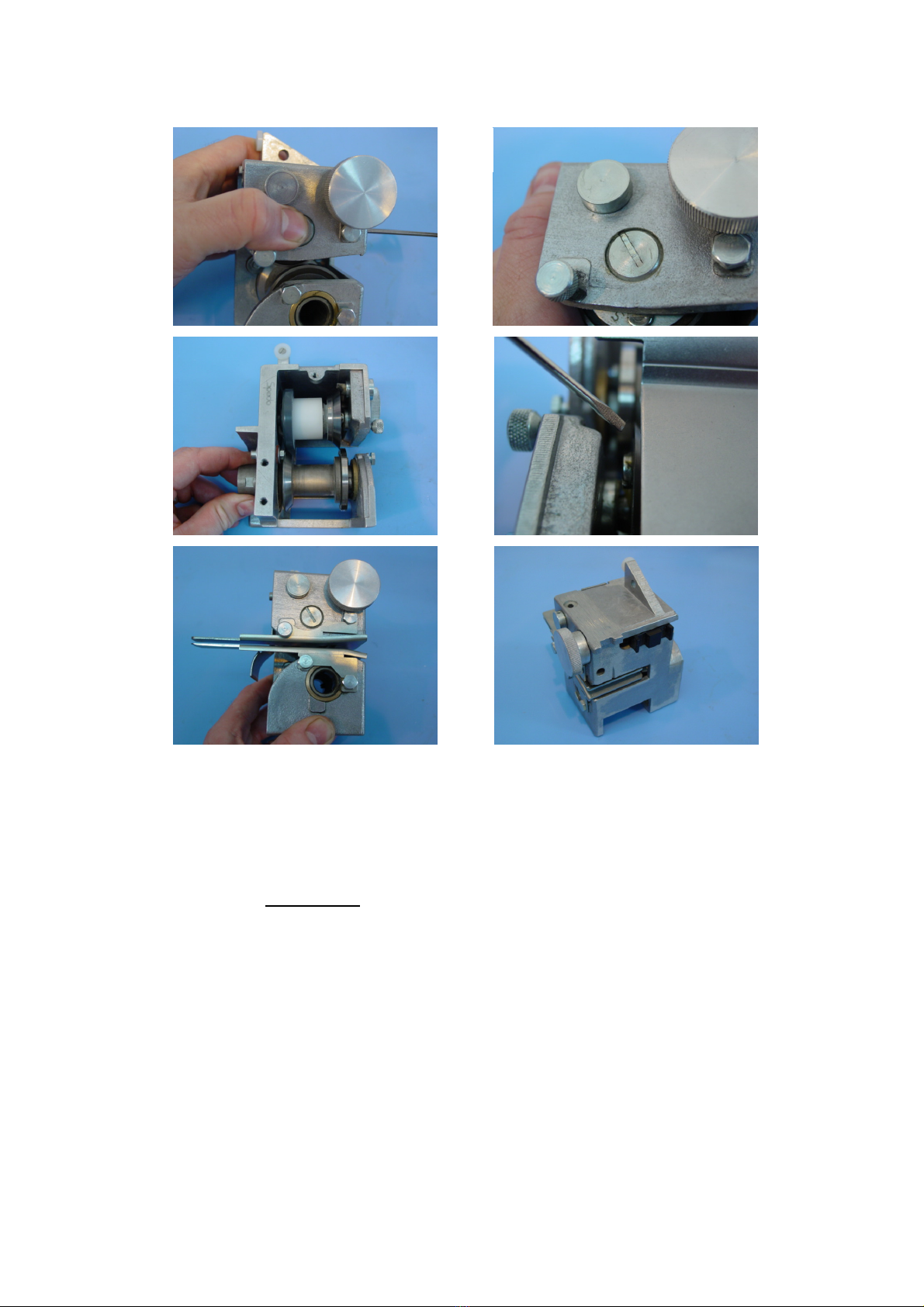

Section 1c – Edge Trimmer Unit rebuild

1

2

3

4

5

6

15 - Spedo 2600 Service Manual SP 007 011

Section 1c – Edge Trimmer Unit rebuild (continued)

7

8

10

11

12

13

14

15

16

9

16 - Spedo 2600 Service Manual SP 007 011

Section 1c – Edge Trimmer Unit rebuild (continued)

1. Remove the lower edge trimmer blade. (Fig. 1) This blade has two cutting faces. If one face

is good, turn the blade so that the good face is to the inside. (Fig. 2)

2. Remove the friction hub, (Fig. 3) and the pressure springs. (Fig. 4) Then refit the friction

hub, (Fig. 5) this will give you something to hold as you undo the upper edge trimmer

blade. (Fig. 6) WARNING Hold the blade as shown, failing to do so may result in

injury.

3. Replace the upper blade. Always fit a new upper blade if you either turn, or replace the

lower blade (Fig. 7)

4. Apply a small amount of light machine oil to the upper hub wick. (Fig. 8)

5. Refit the springs and friction hub to the upper hub. (Fig. 9)

6. Apply HMP grease to the bearing surface of the lower hub. (Fig. 10)

7. Refit the lower hub and lower hub retainer. (Fig. 11 & 12)

8. Apply HMP grease to the upper hub axle. (Fig. 13)

17

18

19

20

21

22

17 - Spedo 2600 Service Manual SP 007 011

Section 1c – Edge Trimmer Unit rebuild (continued)

9. Compress the upper hub and fit into position within the edge trimmer housing. With the

upper hub still compressed insert the axle. This can be very tricky and may take several

attempts. (Fig. 14) WARNING The upper blade is very sharp. Care must be taken

when refitting the upper hub.

10. With the upper hub still compressed, move the upper hub down behind the lower hub to

create an overlap. (Fig. 15)

11. Refit the eccentric bush and spring. Once the bush is located into the edge trimmer housing,

you can release the upper hub. Keep your thumb over the eccentric bush as the spring will

try to dislodge it. (Fig. 16)

12. With your thumb still positioned over the eccentric bush, tighten into place. (Fig. 17)

13. Loosen the grub screw holding the eccentric bush by approximately ¼ turn. Then with a

screw driver adjust the eccentric bush to the position shown. Retighten the grub screw. The

head of the eccentric bush should now be approximately flush with the side of the edge

trimmer housing. (Fig. 18)

14. Cycle the edge trimmer unit by hand. There should be no binding or stiffness in the

operation. (Fig. 19) WARNING Keep your fingers clear as you cycle the blades.

15. Refit the paper deflector plate. (Fig. 20) NOTE the deflector should be positioned

approximately 1mm from the blade cutting edge.

16. Refit the paper guide. (Fig. 21)

17. The edge trimmer units can now be fitted back into the machine. To refit the edge trimmer

units complete Section 1a ‘Edge Trimmer Shaft Removal’ in reverse order. NOTE: It is

recommended that anti-fret compound is used on the shaft as it is reinserted into the

bearings either end of the drive shaft.

Section 2a – Centre cutter lower hub removal

Please read this complete section before starting.

WARNING The machine must be isolated from its power supply before starting any

maintenance procedure.

1. Remove the lower centre cutter hub by completing Section 1a ‘Edge Trimmer Shaft

Removal’

Section 2b – Centre cutter arm service

1

2

18 - Spedo 2600 Service Manual SP 007 011

Section 2b – Centre cutter arm service (continued)

3

4

5

6

7

8

9

10

11

12

19 - Spedo 2600 Service Manual SP 007 011

Section 2b – Centre cutter arm service (continued)

1. Remove the centre cutter adjustment plate. (Fig. 1) WARNING The upper hub is no

longer retained and may fall out.

2. Remove the upper centre cutter hub. (Fig. 2) WARNING Even blades that have been

used may still be sharp so proceed with caution.

3. Remove the centre cutter blade. (Fig. 3 & 4)

4. Remove one of the circlips on the upper centre cutter hub. (Fig. 5) WARNING Safety

goggles must be worn when removing circlips.

5. The bearing assembly should now slide out of the upper centre cutter hub. (Fig. 6)

6. Inspect the condition of the bearing surface on the inside of the upper centre cutter hub. It is

normal for there to be a small number of marks on the bearing surface. However if there are

any deep scores this will affect the centre cutter operation. (Fig. 7)

7. Remove the circlip from the bearing assembly, (Fig. 8) and remove the axle. (Fig. 9) Check

the bearings for signs of wear, then lubricate the springs and axle with HMP grease, and

reassemble into the hub. (Fig. 10)

8. Refit the centre cutter blade. This blade has two cutting faces. If one face is good, turn the

blade so that the good face is on the side that the centre cutter is adjusted to cut on. (Fig. 11)

See Section 2d ‘Set the Centre Cutter’ for instruction on how to change the side the centre

cutter cuts on.

9. Refit the centre cutter adjustment plate. If you haven’t changed any settings on the

adjustment plate, then you will be able to simply refit, without further adjustment. (Fig 12)

Section 2c – Centre cutter lower hub blade change

1

2

3

20 - Spedo 2600 Service Manual SP 007 011

Section 2c – Centre cutter lower hub blade change (continued)

1. Remove the blade from the lower centre cutter hub. Use a cloth to wrap the blade to protect

your hand. (Fig. 1 & 2) WARNING Even blades that have been used may still be sharp

so proceed with caution.

2. Refit the centre cutter blade. This blade has two cutting faces. If one face is good, turn the

blade so that the good face is on the side that the centre cutter is adjusted to cut on. (Fig. 3)

See Section 2d ‘Set the Centre Cutter’ for instruction on how to change the side the centre

cutter cuts on.

Section 2d – Centre cutter arm adjustment

1. To adjust the centre cutter arm to cut on the right side of the lower centre cutter blade. First

loosen the two grub screws marked (Fig. 1). Tighten the rear grub screw all the way in then

loosen by ¼ turn. Then retighten the two marked grub screws. This will angle the blade as

shown in Fig. 2.

2. To adjust the centre cutter arm to cut on the left side of the lower centre cutter blade. First

loosen the two grub screws marked (Fig. 3). Tighten the top grub screw all the way in then

loosen by ¼ turn. Then retighten the two marked grub screws. This will angle the blade as

shown in Fig. 4.

1

2

3

4

Other manuals for 2600

1

Table of contents

Other Spedo Cutter manuals