Speed Clean CoilJet CJ-200E Installation and operation manual

SpeedClean®

Innovative Maintenance Tools.

OPERATING & MAINTENANCE INSTRUCTIONS

U.S. Patent: 9,381,549

MODEL

CJ-200E

CoilJet®Portable

HVAC Coil

Cleaning System

CJ-200E

2Model CJ-200E Operating and Maintenance Manual

This unit has been carefully tested and inspected and is warranted

to be free from defects in material or workmanship. The company

will, under this warranty, repair or replace any parts which prove,

upon examination, to be defective. This warranty is valid for one

year from date of purchase by original purchaser.

This warranty excludes accessories, unusual wear, abuse, damage

resulting from an accident, or unreasonable use of this machine. It is recommended that any

repairs be done by SpeedClean as improperly performed repairs will void the warranty.

For repairs or warranty information DO NOT contact the place of purchase. Call SpeedClean

Customer Service at (888) 700-3540.

To obtain warranty service a proof of purchase is required and the unit must be returned freight

prepaid. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state. SpeedClean reserves the right to improve products. Contact

the factory for the latest configuration and uses.

Table of Contents

Limited Warranty

CJ-200E

Limited Warranty ...................................................................................................................2

Important Safety Instructions................................................................................................3

Grounding Information .........................................................................................................3

Parts Breakdown ...................................................................................................................5

Common Optional Accessories .......................................................................................5

Operating Instructions ..........................................................................................................6

Pre-Operation Checklist ...................................................................................................6

Normal Coil Cleaning Operation.....................................................................................6

Chemical Dilution Ratios...................................................................................................6

Water Sources....................................................................................................................6

Warnings ............................................................................................................................7

General Maintenance and Storage....................................................................................7

Specifications ........................................................................................................................7

Troubleshooting.....................................................................................................................8

Problem..............................................................................................................................8

Probable Cause ................................................................................................................8

Solution ..............................................................................................................................8

Plumbing and Wiring Diagram .............................................................................................8

Wiring Diagram......................................................................................................................8

CJ-200E

Thank you for purchasing this SpeedClean CJ-200E CoilJet®Portable HVAC Coil

Cleaning System. We appreciate your business and look forward to serving you in the

future. As with all SpeedClean products, you can be assured that the finest quality

components and workmanship have gone into this unit.

Please take a few minutes to read the following Operating and Maintenance Instructions.

By carefully following these instructions, you will obtain years of trouble free service from

this product. Please pay particular attention to the safety instructions and exercise

caution when using this product.

© 2019 All Rights Reserved. 3

Table of Contents

Read and understand all instructions before using the unit. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

Save these Instructions!!

• Always check the unit, hoses, fittings, etc. before each use.

• Do not fill with gasoline or any other flammable liquid. Do not operate in explosive

atmospheres, such as in the presence of flammable liquids, gases or dust.

• Make sure that there is adequate ventilation in the work area.

• Stay alert, watch what you are doing and use common sense when operating this unit.

• Keep bystanders, children, and visitors away while operating this unit.

• Turn unit off and relieve pressure in the hose when done.

• Do not use while tired or under the influence of drugs, alcohol, or medication.

• Be careful — a fully filled unit is heavy! Do not make any sudden movements when using

this unit with the shoulder strap.

• Do not overreach or stand on unstable support. Keep proper footing and balance at all times.

• Wear rubber gloves, rubber boots, goggles or face-shield, etc. Detergents and

chemicals may cause injuries to the eyes and skin. Protect yourself from direct skin

contact with the chemicals and debris found in the coil cleaning environment.

• Do not use any acid or cleaners that contain sodium or potassium hydroxide! Call

SpeedClean to check compatibility before using any chemical in the CoilJet®.

• Do not mix chemicals! Mixing incompatible chemicals may cause damage to the unit or

cause dangerous, life-threatening chemical reactions.

• Do not use the unit if it does not operate properly or has been damaged. Do not try to

service the unit yourself — call SpeedClean for assistance. Service must be performed

only by qualified repair personnel. Service performed by unqualified personnel could

result in a risk of injury and voids the warranty.

• Never point the spray gun at anyone. Do not direct stream at eyes or mouth.

• Always turn machine off after use or when tank is empty. Do not spray the unit with

water or chemicals.

• Do not allow the unit to freeze or leave in freezing temperatures.

• Do not use water with a temperature of more than 140°F (60°C).

• Use only approved accessories and replacement parts.

• Follow maintenance procedures outlined in this manual.

Important Safety Instructions

CJ-200E

Grounding Information

CJ-200E

This product must be grounded. If it should malfunction or break down, grounding provides

a path of least resistance for electric current to reduce the risk of electric shock. This product

is equipped with a cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

DANGER: Improper connection of the equipment-grounding conductor can result in a risk of

electrocution. Check with a qualified electrician or service personnel if you are in doubt as to

whether the outlet is properly grounded.

DO NOT USE ANY TYPE OF ADAPTOR WITH THIS PRODUCT.

CJ-200E

4Model CJ-200E Operating and Maintenance Manual

GUIDE TO GRAPHICAL SYMBOLS

Read all instructions Eye protection required High Pressure Output. Direct spray

away from persons, pets, equipment,

and electrical outlets.

Grounding Information

Ground Fault Circuit Interrupter Protection

The COILJET®is provided with a ground fault circuit interrupter (GFCI) built into the power

supply cord. This device provides additional protection from the risk of electric shock. Should

replacement of the plug or cord become necessary, use only identical replacement parts that

include GFCI protection.

Extension Cords: Use only 3-wire extension cords that have 3-prong grounding-type plugs and

3-pole cord connectors that accept the plug from the product. Use only extension cords that

are intended for outdoor use. These extension cords are identified by a marking, “Acceptable

for use with outdoor appliances; store indoors while not in use.” Use only extension cords having

an electrical rating not less than the rating of the products. Do not use damaged extension

cords. Examine extension cord before using and replace if damaged. Extension cords are not

protected by the GFCI. A GFCI must be present on the power cord or a GFCI must be present

in the outlet.

Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away

from heat and sharp edges. Always disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

WARNING: To reduce the risk of electrocution keep all connections dry and off the ground. Do

not touch plug with wet hand.

Wear proper clothing: Protect yourself! Wear rubber gloves, rubber boots, etc. Wear eye

and face protection, goggles or face-shield. Coil cleaning chemicals may cause injuries

to the eyes and skin. Protect yourself from direct skin contact with the chemicals found in

this environment. Remember that water splatter can send these chemicals toward you, so,

again, protect yourself.

Environment: Make sure that there is adequate ventilation into the work area. Do not operate

machine in areas where flammable gases or liquids are present.

Changing hoses and/or nozzles: ALWAYS turn machine off when changing hoses or nozzles.

Never hold onto nozzle or point it at anyone with machine turned on. High-pressure water

streams can cause serious bodily injury.

Job completion: Always turn machine off before disconnecting water supply. Running a water

pump “dry” may cause serious damage.

Maintenance: Keep machine clean and dry to maximize performance and longevity. Follow

maintenance outlined in this manual, such as checking for weak spots, leaks, slices or cuts in

hose, replace nozzles when worn. Keep antifreeze in hose & pump when storing in freezing

temperatures. Additional maintenance details follow in this manual. If the machine does not

operate properly or has been damaged or exposed to water, call the factory for assistance —

do not try to service the unit yourself.

© 2019 All Rights Reserved. 5

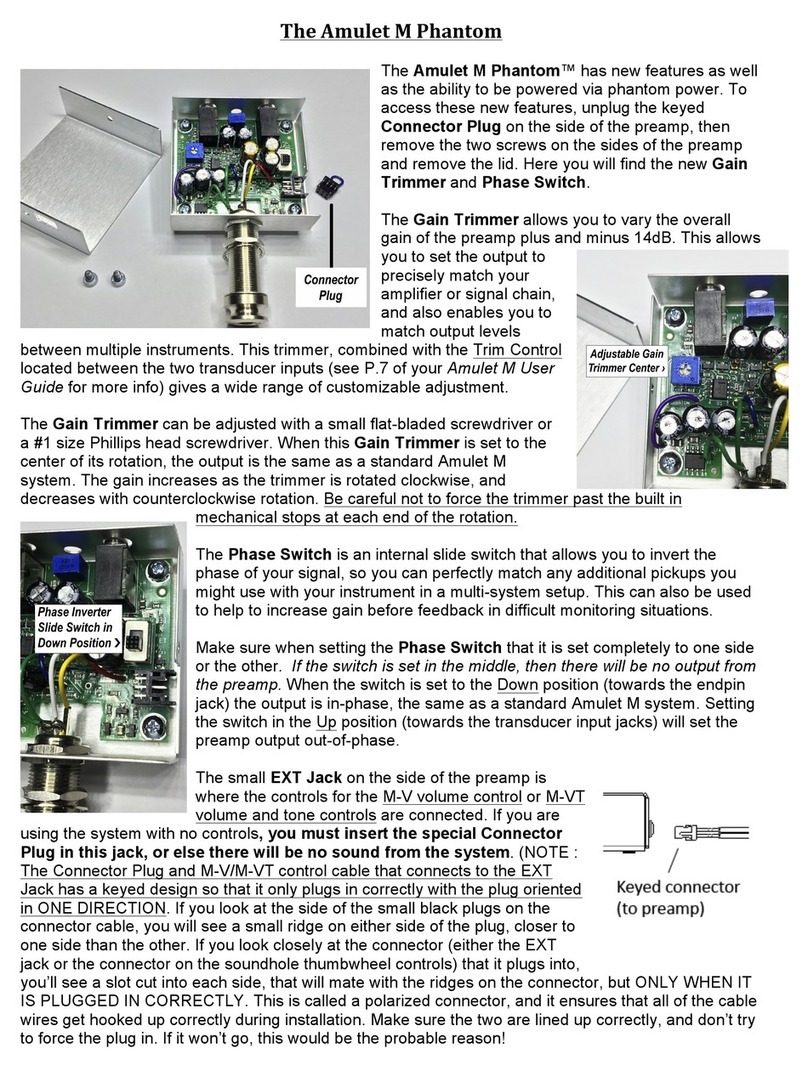

Parts Breakdown

Common Optional Accessories

CJ-200E

1. 9647-1-G Cap

2. CJ2-01-S Water/

Chemical Tank

3. CJ2-14-S-ASSM

Shoulder Strap

4. 8940-200E-20FT

20 ft (6 meters)

Self-Coiling Hose

5. CJ2-22 Power Switch

6. 8943-RB Spray

Gun with

Quick Connect

7. Spray Nozzles:

Yellow: 15˚ Fan

CJ-QDN-15025Y

Green: Soap Nozzle

CJ-QDN-2508G

8. 8933-ASSEMBLY

Chemical Valve

Assembly

1

2

3

5

6

4

7

8

90º SPRAY WANDS

8945-24 24” (61 cm)

8945 36” (91 cm)

8945-48 48” (122 cm)

8945-60 60” (152 cm)

8945-FLEX-24 Flexible 24” (61 cm)

OPTIONAL NOZZLES ACCESSORIES

CJ-QDN-0003-R Size 3 Pinpoint

CJ-QDN-90 90˚ Adapter

CJ-QDN-45 45˚ Adapter

OTHER ACCESSORIES

CJ2-05-115 Motor/ Pump

CJ2-07 Chemical Check Valve

CJ2-07-1 Water Check Valve

CJ-200E

6Model CJ-200E Operating and Maintenance Manual

Pre-Operation Checklist

• Check for adequate water and chemical cleaner supply (use only mild cleaners).

• Check spray nozzles and make sure orifice is not blocked or worn to excess.

• Check pressure hose for wear or kinks.

• Check all connections, fittings, screws and fasteners.

Normal Coil Cleaning Operation

1. The COILJET

®

is a very versatile machine and has two operational modes. It is equipped

with an Auto-Shut-Off function. When the trigger is released the pump turns off and comes

on when the trigger is pulled. Please remember to turn main switch off when done.

2. Fill the water and chemical tanks. Before priming the pump, make sure chemical valve is

fully closed.

3. The COILJET

®

is equipped with a two position water valve. Set the chemical valve to the

“Off” position and set the water valve to “Tank” for on-board water or “Garden Hose”, as

appropriate.

4. Plug the 3-prong male GFCI plug into a normal AC power outlet (110-volt, 60 hertz) and

depress the GFCI reset button. The COILJET

®

will be ready to operate when you flip the

power switch to the “On” position.

5. For best results and maximum self-contained operation time, it is advisable to fully prime the

pump before normal operation. Remove any nozzle that may be attached to the spray gun.

Squeeze the spray gun trigger to prime the pump until steady flow of water appears.

6. NOTE: If you are having trouble priming the pump, make sure the water tank is fully filled

or garden hose is attached to it, place the unit on a table or support, hold the spray gun

below the level of the pump and squeeze the trigger until a steady flow of water appears.

7. When switching between “Garden Hose” and “Tank”, it is best to re-prime the pump.

8. Fully open the chemical valve (counter-clockwise). Squeeze the spray gun trigger

repeatedly until chemical is primed.

9. The COILJET

®

comes with 2 quick-connect nozzle attachments:

• Yellow Rinsing Nozzle – a 15° fan-spray high-flow rinsing nozzle.

• Green Soap Nozzle – a 25° nozzle to apply soap to coils.

10. Attach nozzle to spray gun.

11. Apply water/chemical solution evenly to coils.

12. Close the chemical valve finger tight (clockwise). Do NOT overtighten.

13. If possible, let foaming coil cleaner solution sit for the recommended dwell time (according

to chemical instructions) to penetrate into coils.

14. Rinse coils with clean water.

15. *NOTE: There may be a ten second delay for the chemical to be removed from the hose.

16. When done using the COILJET

®

, make sure the power switch is in the “Off” position. This is to

prevent accidental discharge from the spray gun.

17. After shutting off the power, always relieve the pressure by pointing the spray gun lance in

a safe direction and squeezing the spray gun trigger.

18. Adjust chemical valve to desired dilution ratio (see table below).

Operating Instructions

Chemical Dilution Ratios

Turn Chemical Valve counter-clockwise to open, clockwise to close.

1 Turn Open = 30:1

2 Turns Open = 20:1

2.5 Turns Open = 10:1

Water Sources

The CJ-200E give you the option to use either on-board water supply or garden hose supply.

To use the on-board water supply, turn the knob to the “Tank” position as shown. Fill the tank

with water, then prime the unit and then equip the nozzle necessary for cleaning. (Please see

Normal Coil Cleaning Operations for priming instructions).

3 Turn Open = 6:1

Full Open = 4:1

© 2019 All Rights Reserved. 7

General Maintenance & Storage

CJ-200E

1. When done using the unit, run clean water through the pump.

2. Protect unit from freezing temperatures. Do not store unit outdoors.

3. The unit can be stored above freezing temperatures for short periods of time (less than 1

week) with liquid in the tanks.

4. To protect the unit from damage, chemical and water should be drained from the tanks

and the pump and chemical valve flushed with clean water before the unit is placed in

long term storage.

5. If the unit is to be stored for an extended period of time in an unheated location, pour

about 1 quart of RV antifreeze into the tanks. Open the chemical valve and run the pump

until antifreeze exits the spray gun. Turn unit off and relieve pressure. IMPORTANT: Use only

RV Antifreeze. Normal Antifreeze is corrosive and may damage the pump.

6. When using the unit after long term storage, flush with clean water before use.

CJ-200E

Motor Power 0.2 HP

Input Power 115V 50/60Hz 1.5A 230V 50/60Hz 0.8A

Water Requirements On-Board

Output Water Pressure 200 PSI (13.8 bar)

Output Water Flow 0.40 – 1.10 GPM (1.5 - 4.1 liters)

Pump Positive displacement diaphragm

Water Tank 3.3 gallons (12.5 liters)

Soap Tank 1.75 quarts (1.6 liters)

Noise Level 66 dBA

Dimensions: 19” high x 18” wide x 10” deep (48.2 cm x 45.7 cm x 25.4 cm)

Weight: 22 lbs (10 kilos) net dry; 52 lbs (12.5 liters) at 3.3 gallons water and

1.75 quarts (1.6 liters) chemical

Specifications

To use the garden hose water supply, turn the knob

to the “Garden Hose” position as shown. Securely

connect the garden hose to the garden hose fitting

on the side of the unit, then turn on the water supply.

Prime the unit and equip the nozzle necessary

for cleaning. (Please see Normal Coil Cleaning

Operations for priming instructions).

Warnings

The motor is equipped with an automatic shut-off

that disconnects power when the spray gun trigger

is released. The unit may appear to be “off” (not

running), but if the power switch is on or the system

pressure is not relieved the unit will discharge when the

spray gun trigger is squeezed. Do not leave the unit in

automatic shut-off condition for more than 10 minutes.

The cords, wires, and/or cables supplied with this product may contain chemicals, including

lead or lead compounds, known to the State of California to cause cancer and birth defects

or other reproductive harm. Always wash hands after using.

Water Tank

General Maintenance & Storage

Troubleshooting

PROBLEM PROBABLE CAUSE SOLUTION

Inconsistent and/or

erratic pressure

• Nozzle worn

• Nozzle clogged

• Water/chemical is low

• Air sucked into system

• Air in pump

(not properly primed)

• Vacuum lock

(cap vent clogged)

• Water temp too high

• Replace nozzle

• Clean nozzle orifice

• Add water and/or chemical

• Fill Tank(s)

• Remove nozzle, prime pump

• Clean cap air vent

• Add cold water to reduce temp

Motor continues to run

even though trigger is

released

• High pressure system or

pump hydraulic circuit

not watertight

• Air in system

• Tank(s) empty

• Garden hose off

• Check for leaks at spray gun

and pump

• Re-prime the unit

• Fill tank(s)

• Turn valve on

Motor stops abruptly • Power switch off

• Thermal breaker tripped

• Plug not connected properly

• GFCI was tripped

• Turn switch on

• Turn off, let unit cool

•

Place plug completely into receptacle

• Reset GFCI

Motor buzzes but fails

to start or does not start

at all

• Problems with pump

auto shut-off

• Unit in disuse for

extended time

• Pressure needs to be relieved

• Contact factory

• Contact factory

• Squeeze trigger and

relieve pressure

water tank not priming air block in the line Prime machine through the garden

hose side. Prime the tank with the

garden hose still attached then take

off the garden hose.

Plumbing and Wiring Diagrams

CJ-200E

Pump

HWP-38FNPT-25B

CJ2-Y-BRB-025

CJ2-GHC

1006

1006

Garden

CJ2-SPHN-38MNPT

CJ2-08

Tank

CJ2-07

Tank

Chemical

9608

Water

Hose In

933

CJ2-05-115

CJ2-08

CJ2-25B25NPT

CJ2-3WAY-VALVE

Out to Spray Gun

In Out

CJ2-07-1

8933

CJ2-07-1

Plumbing Diagram

Breaker

Power Switch

Circuit

120VAC

L2

L2 = White

L1

L3 = Ground

L3

L1 = Black

Pump

~

Wiring Diagram

P/N: MNL-CJ200E 0119

PO Box 110301, Stamford, CT 06911-0301

(888) 700-3540 www.speedclean.com

CJ-200E

SpeedClean is a registered trademark of Crossford International.

SpeedClean reserves the right to improve products;

contact the factory for the latest configuration and uses.

Table of contents

Other Speed Clean Other manuals

Popular Other manuals by other brands

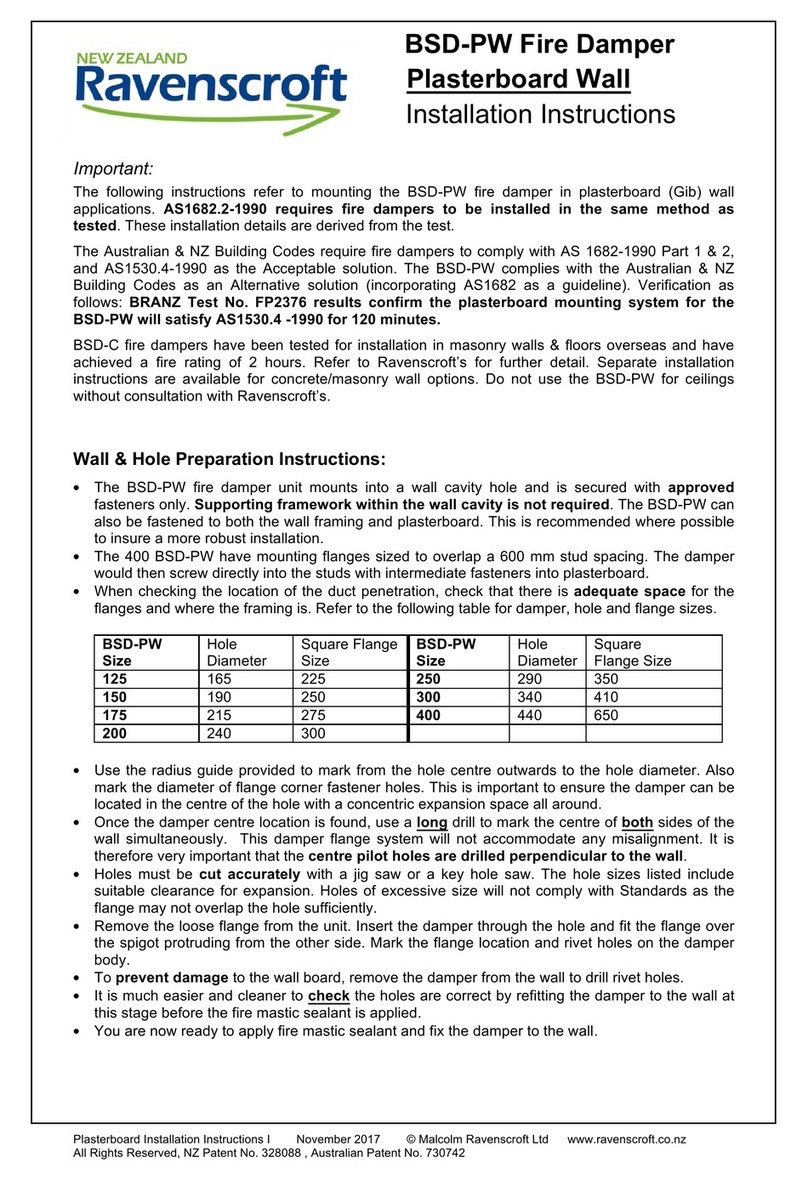

Ravenscroft

Ravenscroft BSD-PW installation instructions

Fisher Engineering

Fisher Engineering HD2 installation instructions

Kohler

Kohler VEIL K-5402A-0 Homeowner's guide

COXREELS

COXREELS C-L335-3516-X Installation and maintenance manual

Toshiba

Toshiba TDDP7011ES2 user manual

K&N

K&N 77 series installation instructions