Sperry Rand Univac Universal Terminal System 400 User manual

SECTION

1

INTRODUCTION

1-1.

~

This

book

contains

information

for

installing

the

SPERRY

UNIVAC

Universal

Terminal

System

400

(UTs400).

The

system

consists

of

three

major components: a Master

Terminal

Type

3544,

Slave

Terminal Type

3548,

and a

Controller

Type

8594.

Install-

ation

information

for

each

of

the

system components

is

contained

in

the

following

sections.

Section

2 -

Installation

Section

3 -

Strapping

Section

4 -

De-Installation

Appendix A -

Feature

Installation

Appendix B - Cable Data

Appendix C -

ASCII

Conversion Chart

Appendix D -

Memory

Location

Appendix E -

Foldout

Illustrations

1-2.

REFER.Ei~CE

MATERIAL

The

folloving

books should be

available

as

aids

for

installing

the

terminal

system!

MR6085

HR6087

MR6088

MR6089

MR6090

MR6086

Title

SPERRY

UNIVAC

Universal

Terminal System

400

Preinstallation

Planning

Specifications

SPERRY

UNIVAC

Universal

Terminal System

Functional

Analysis

and

Servicing

SPERRY

UNIVAC

Universal

Terminal System 400 Master Terminal Type

3544

Illustrated

Parts

Breakdown

SPERRY

UNIVAC

Universal

Terminal System 400

Slave

Terminal Type

3548

Illustrated

Parts

Breakdown

SPERRY

UNIVAC

Universal

Terminal System

400

Controller

Terminal

Type

8594

Illustrated

Parts

Breakdown

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

1-1

UTS

400

1-3.

EQt~PMENT

DESCRIPTION

The

SPERRY

UNIVAC

Universal

Terminal System 400

(UTS

400)

is

a

microprocessor-based,

intelligent,

general

purpose

display

terminal

for

use

in

interactive

data

communica-

tions

with

a.

central

processor.

The

basic

areas

of

application

are:

Data

entry

and

accessing

Control and

monitoring

operations

Offline

operations

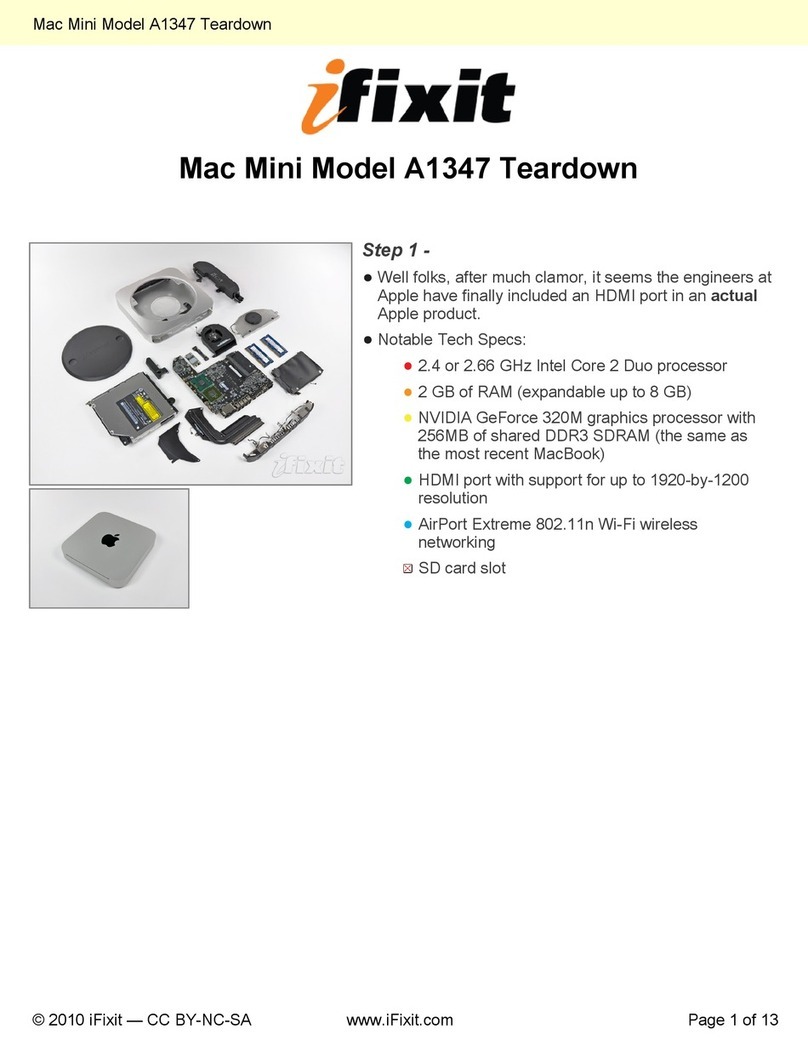

The

UTS

400

consists

of

a

master

terminal,

slave

terminal,

and a

controller

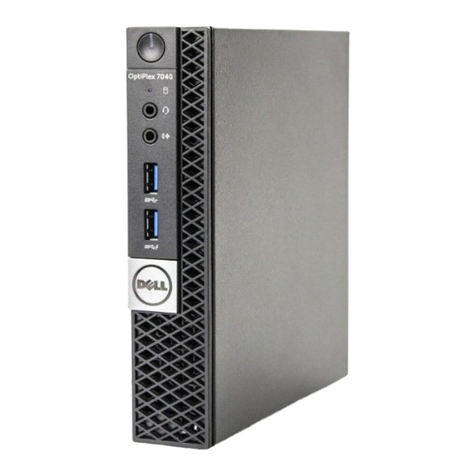

(figure

1-1).

The

system

may

be

configured

as

a

single

master

terminal,

a master with

slaves

(up

to

3),

or

as

a

controller

with

up

to

6

slaves.

The

system

is

designed

to

support

existing

7-bit

interface

devices

such

as

the

SPERRY

UNIVAC

Tape

Cassette

I

System (TCS), and

8-bit

peripheral

devices

such

as

a

freestanding

diskette

subsystem.

The

system

is

also

compatible with

existing

UNISCOPE

display

terminal

software.

SLAVE

TERMINAL

WITH

KEYBOARD

CONTROLLER

MASTER TERMINAL

45718 I

""-------------------------------------_

.........

\

1-2

Figure

1-1.

Universal

Terminal System

400

-System Components

REVISION:

HCB-1

COMPP.NY

CONFIDENTIAL

MR6086

Introduction

1-4.

SPECIAL

TOOrs

AND

SUPPLIES

Common

hand

tools

and

the

following

items

are

required

to

install

and

service

the

terminal

system.

Equipment

Volt-ohmmeter,

triplett

No.

310

or

equivalent*

Test

leads

for

triplett

No.

310*

Printed

circuit

board (module)

extractor*

Module

extender

Extension

cable

(50 conductor)

LED

test

module

Mask,

CPU

Mask,

ROM

Mask,

I/O

Mask,

auxiliary

Alignment

tool

(Hex.)

Alignment

tool

(double ended

hex.)

Crimping

tool

Auxiliary

interface

turnaround

I/O

test

connector

Internal

auxiliary

interface

cable

Internal

communications I/O

cable

1-5.

PLACEM&~T

CONSIDERATIONS

Part

number

3001444-00

920508

2820407-00

2818455-00

2820659-01

2812637-01

2812738-021

2812738-022

2812738-023

2812738-024

2050181-00

2050182-00

2050282-00

2820654-00

2818449-00

2816523-00

2816522-00

The

master

and

slave

terminals

are

designed

to

be

placed

on any

flat

surface

(such

as

a desk

or

table

top)

which

affords

the

operator

comfortable

access

to

the

console

and keyboard and

provides

good

visibility

of

the

display

screen.

Cable

length

between

the

master

~~d

slave

terminals

must

also

be

considered.

A

minimum

of

4

inches

(10.2

cm)

F~st

be allowed

to

the

right,

left,

and

rear

of

the

unit

for

operation.

At

lease

2

feet

(61

cm)

of

clearance

on

all

sides

of

the

master

and

slave

terminals

must be provided

for

maintenance; however,

if

the

minimum

clearance

cannot

be

provided,

leave

sufficient

cable

loop

to

allow

the

terminal

to

be

moved

to

an

area

with

adequate work

space.

Since

an

operator

is

not

required

for

the

controller,

the

controller

may

be

located

in

~~

out-of-the-way

place

and

moved

(with

cables

attached)

for

maintenance

access

if

sufficient

cable

loop

is

provided.

At

least

15

inches

clearance

above

the

controller

must

be

provided

for

removal

of

the

top

cover.

A

minimum

of

5t

inches

clearance

must be provided on

all

sides

of

the

controller.

*These

tools

are

required

for

installation.

MR6086

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

1-3

UTS

400

1-6.

SIGNAL

CABLING

The

master

and

controller

are

connected

to

slave

terminals~

peripheral

devices

s and

communications

devices

by

means

of

the

cables

listed

in

table

1-1,

and

illustrated

in

part

in

figure

1-2.

·(Figure

1-2

is

a sample system

configuration;

additional

configuration

samples

are

provided

in

MR6085

SPERRY

UNIVAC

Universal

Terminal

Sxstem

400

Preinstallation

Planning

Specifications.)

The

circled

reference

num-

bers

in

figure

1-2

correspond

to

the

item

number

listed

in

table

i-1.

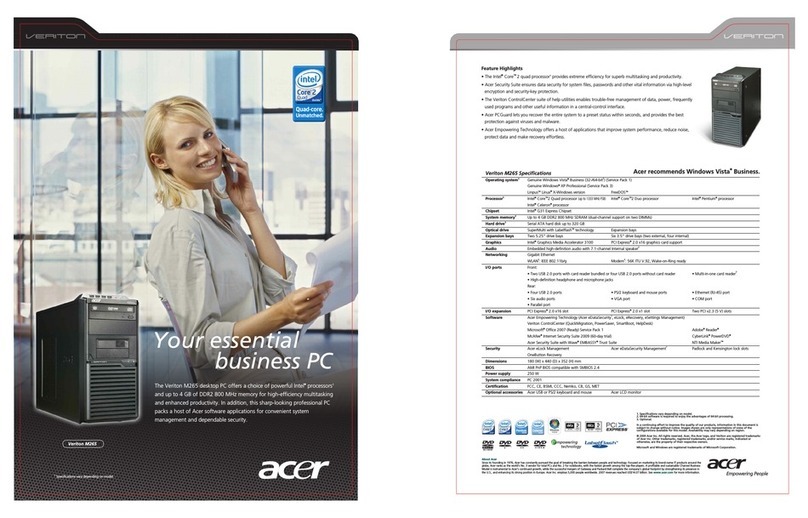

Table 1-1

lists

all

of

the

standard

cables

used

for

interconnecting

.a

master

or

controller

terminal

to

the

system components and communications

devices.

Table

1-2

provides

general

information

about

cable

length

data,

and appendix B

provides

detailed

part

number

suffixes

(dash numbers)

relating

to

the

cables

and

available

lengths.

1-4

PROCESSOR

COMMUNICATIONS

CONTROLLER

15

TERMINALS

MAXIMUM

IOR0

MASTER TERMINAL MASTER TERMINAL

T •

200

FT

20~f

MAX MAX

1PERIPHERALS

'-------'

*USE

CABLEG)WITH

DCM

AND

CABLE

0W1TH

MODEM

Figure

1-2.

Sample System

Configuration

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

45719

MR6086

Item

Part

Number

2805096-XX*

2

2808043-XX

3

2807723-XX

4

5

6 280TI25-XX

7 280TI65-

XX

8 280TI48-XX

9

2807754-XX

10

11

2807868-XX

12 2814419-D:

13 2814880-xx

14

2816519-XX

Introduction

Table

1-1.

System

Signal

Cables

Description

Unshielded,

connects

master

or

controller

ter-

minal

to

multiplexer

or

Direct

Connection Module

(DCM)

• Male

or

female ends.

Maximum

length

is

300

feet

(91.4

meters)

Unshielded,

connects

master

or

controller

ter-

minal

to

multiplexer

or

modem.

Maximum

length

is

50

feet

(15.2

meters).

Unshielded,

connects

master

or

controller

or

multiplexer

**

to

junction

box

(item

4).

One

end open and one

female

end.

Junction

box assembly, used

for

onsite

con-

nections.

Unshielded,

connects

junction

box

to

modem,

multiplexer

or

DCM.

One

end open

and

one

male end.

Shielded,

for

long

distance

runs

between

junction

boxes.

For

serial

or

duct

instal-

lation.

Both ends open.

Shielded,

for

direct

burial

long

distance

runs

between

junction

boxes.

(Junction

boxes_

are

not

buried.)

Both ends open.

Unshielded,

connects

multiplexer"

directly

to

a

Communica-bion

Terminal

Module

(CTMe).

Male

and

female

ends.

Unshielded,

connects

junction

box

to

CTMC.

One

open end and one male end.

Unshielded,

connects

multiplexer**

directly

to

Line Terminal

Controller

(LTC). Male

and

female ends.

Unshielded,

connects

junction

box

to

LTC.

One

open end and one male end.

Shielded,

connects

master

or

controller

to

Communications Output

Printer,

or

connects

Communications Output

Printer

to

a Tape

Cassette

System (TCS). Male and female

ends.

Shielded,

connects

master

or

controller

to

TeS,

or

model 800

terminal

pr5~ter,

or

type

0786

printer.

Male

and

female

ends.

Unshielded,

connects

keyboard

to

master

terminal.

Length

(Table

1-2)

D

B

D

D

A

A

D

D

B

B

c

c

E

*Refer

to

Appendix B

table

B-4

for

instructions

for

converting

cable

2805096-XX

for

U3e

with

modems.

**This

cable

is

also

used

to

provide

direct

connection

to

UNISCOPE

Display

Terminals.

Cannot

be

used

for

direct

connection

to

the

UTS

400.

MR6086

REVISION:

HCB-1

COMPANY

CONFIDL~!A1

1-5

UTS

400

Item

Part

Number

15

2820314-XX

16

2816515-00

11

2820659-00

18

2816509-00

19

6432694

20

6432691

21

2811358

22

2814880-XX

1-6

Table

1-1.

System

Signal

Cables

(Cont)

Description

Shielded,

with

female

BNC

connectors

for

connecting

slave

terminals

to

master

or

controller.

Maximum

length

is

2000

feet.

Shielded,

connects

display

driver

to

additional

slave

terminals.

Unshielded,

connects

display

driver

to

display

control;

required

for

additional

slave

terminals.

Unshielded,

connects

display

driver

to

DC

power

supply.

Unshielded,

connects

General

Communications

System

(GGS)

to

multiplexer.

Unshielded,

connects

GCS

to

item

4.

Shielded,

with

male

and

female

connectors.

Interconnects

DCMs.

Shielded,

with

male

lockscrew

(3011816-o1)

on

connector

P2. Female

lockscrew

on

connector

P1

is-used

for

8-bit

peripheral

connections

to

master

or

controller.

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

Length

(Table

1-2)

I

F

(Internal-

expansion)

(Internal-

expansion)

(Existing

cable)

G

G

H

C

Introduction

Table

1-2.

System

Signal

Cables -

Available

Lengths*

Designation

Available

Len~hs

-

Feet

Available

Lengths -Meters

(Table

1-1)

Length Increments** Length increments.

A 300

to

5000 50

91

..

4

to

152.4

15.2

B 5

to

50 5

1.5

to

15.2

1.5

C 5 and 10

to

200

10

1.5

and 3

to

61

3

D 3 and 5

to

100 5

9.9

and

1.5

to

30.5

1.5

100

to

200

and

10

30~5

to

61

3

200

to

300 20

61

to

91.4

6.1

E 4

to

10

4,

6,

10

1.2

to

3

1.2,1.8,

3

F

10,

25,

50,

75,

as

indicated

.3,

7;6,

15.2,

22.8,

as

indicated

(00

thru

09),

(00

thru

09),

100,-

250,

500,

750,

respectively

3005,

76

0

2,

152.4,

respectively

1

,000

and 2000

228.6,

304.8,

610

G

16.4

to

98.4

16.4

5

to

30

5

H 5

to

100

and

5

1.5

to

30.5

1.5

100

to

200 and 10

30.5

to

61

3

200

to

300 20

61

to

91.4

6.1

*Except

for

item

G,

all

cable

lengths

specified

are

provided

in

foot

lengths

(conversion

to

metric

is

shown). Item G

is

provided

in

metric

lengths

(conversion

to

feet

is

shown).

**See appendix B

for

cable

part

number

suffixes

(dash

numbers)

corresponding

to

all

increments.

MR6086

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

1-7

SECTION

2

INSTALLATION

2-1.

INTRODUCTION

This

section

contains

procedures

for

unpacking,

installing

and checking

the

SPERRY

UNIVAC

Universal

Terminal System

400

(UTS

400).

The

procedures

are

designed

to

allow a Customer Engineer

to

install

and

set-up

the

terminal

system

in

a

minimum

amount

of

time.

2-2.

EgUIPMENT

PLACEMIlIT

The

carrier

is

responsible

for

moving

the

equipment

to

its

approximate

location

in

the

prescribed

area.

The

customer should

be

present

while

the

carrier

is

unloading

the

equipment

to

ensure

that

it

is

not

handled roughly and

that

improper

lifting

devices

are

not

used.

CAUTION

Do

not

use

a

forklift

to

move

equipment

containers.

The

terminal

is

packed

in

a

polystrene

container

which should be handled

with

care.

The

container

can be

easily

penetrated

by

forklift

prongs, and

the

terminal

severely

damaged.

The

customer should

instruct

the

carrier

as

to

initial

unit

placement

at

the

operat-

ing

location.

Correct

placement

at

this

time

will

avoid problems

in

unpacking

later.

After

the

system

is

loaded and

placed

in

the

approximate

operating

location,

inspect

the

container

or

containers

for

signs

of

damage

that

may

have

occurred

during

shipment.

If

damage

is

found,

or

a

portion

of

the

shipment

is

missing,

this

must be

noted

on

the

bill

of

lading.

Also any equipment which

was

handled roughly

or

dropped

during

unloading

or

placement should be so

noted

on

the

bill

of

lading,

even though no

damage

may

be

apparent.

This

aids

in

filing

a

claim

if

damage

is

discovered

during

unpacking.

MR6086

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

2-1

01'8

400

2-3.

YNPACKING

It

is

recommended

that

two customer

engineers

be

available

for

lifting

the

terminal

system

during

unpacking

to

avoid

possible

damage

to

the

units.

The

procedures

for

unpacking

the

master,

slave,

and

the

controller

are

contained

in

tables

2-1,

2-2,

and

2-3,

respectively.

Information

about

the

major

electronic

components

of

the

terminal

system can

be

found

in

MP~087,

SPERRY

UNIVAC

Universal

Terminal System

400

Functional

Analysis

and

Servicing.

2-2

Step

NOTE

Be

sure

to

save

packing

material,

shipping

bags,

and

the

two

packing

container

halves

in

the

event

that

the

system

should

require

shipment

to

a

new

location.

The

number

of

sets

o.r

shipping

material

is

to

be

deter-

mined by

consultation

with

the

customer.

The

procedure

for

repacking

the

components

is

provided

in

Section

4.

Table

2-1.

Master Terminal Unpacking Procedure

Procedure

Remove

master

terminal

container

from

cartun

and

place

on

floor.

2 Cut bands

holding

container

sections

together

and

remove

container

top.

3

Remove

bagged communication

cable

(if

present)

from

top

of

master

terminal.

4

Remove

and unpack

master

terminal

and keyboard.

Check

units

for

visible

damage.

5

Remove

tape

securing

power cord and

front

panel

to

master

terminal.

6

Remove

exterior

casework by

rotating

two

turnlock

fastener

studs

at

rear

of

unit,

then

sliding

case-

work forward

to

clear

the

faceplate,

and

lifting

off.

7 Ensure

that

all

L.E.D.

indicators

are

securely

in

place

in

their

sockets.

8

9

Remove

any

internal

packing

material

from module

cages

A1

and

A5.

NOTE

Detailed

inspection

of

printed

circuit

modules,

to

include

broken

or

missing

ROMs,

is

accomplished

later

in

the

installation

procedure.

Inventory

the

units

and

fill

in

the

appropriate

sec-

tions

of

the

inventory

and

inspection

report

shipped

with

each

unit.

(Use

the

referenced

figures

to

assist

in

inventory

and

inspection

of

the

unit.)

Notify

branch

office

of

any

damage

or

shortage.

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

Reference

Figure

2-1

Figure

2-1

and

Appendix A

MR6086

AlAI

Mod-.lle

A1Al

A1A3

A1A4

AlAS

A1A6

A1A7

A1A8

A5Al

A5A2

A5A3

MR6086

AI

MODULE

CAGE

(MASTER

TERMINAL

.

ONLY)

Color Code

RED

BLK

GRN

BLU

WHT

VEL

VIO

A5A3

Part Number

28l8452-XX

2818483-XX

28l84l4-XX

2818398-XX

28l8443-XX

2818437-05

28184l8-XX

28l8436-XX

2818441-XX

28l8432-XX

AIA3

A2

CRT MODULE

ASSEMBLY

A5A2

A5AI

A5

EXPANSION

MODULE

CAGE

Module Name

CPU

Display Contfol

Communications I/O

7·8it Interfat;e

8·Bit Interface

10K ROM/Switt;h

8K

RAM

Character Generator

Display Driver

Power Supply

45724

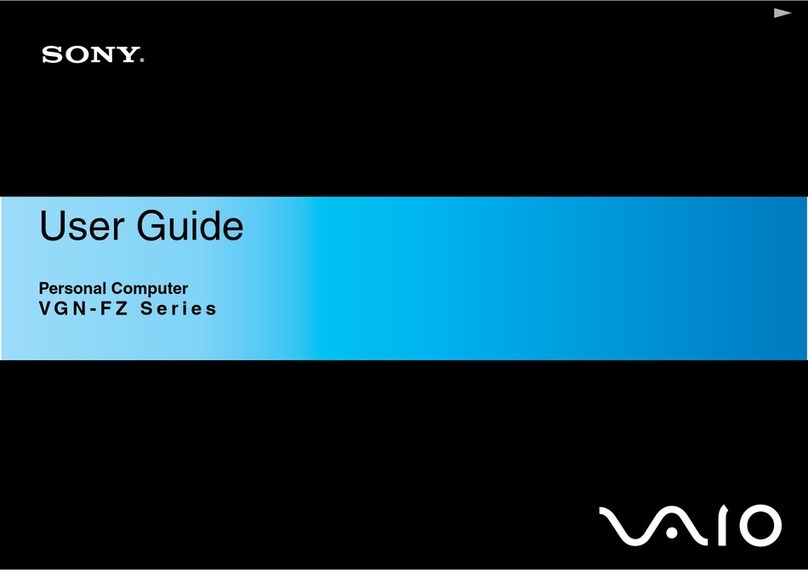

Figure

2-1.

Master Terminal

Module

Locations

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

2-3

UTS

40.0

2-4

Table

2-1.

Master Terminal Unpacking Procedure (Cont)

Step Procedure

10

If

installation

is

to

be completed

at

this

time

proceed

to

table

2-4,

if

not

continue

with

step

11.

11

Replace

exterior

casework and

place

unit

in

a

suitable

place.

Step

Table

2-2.

Slave

Terminal Unpacking Procedure

Procedure

Remove

slave

terminal

container

fr.om

carton

and

place

on

floor.

2 Cut bands

holding

container

sections

together

and remove

container

top.

3

Remove

bagged communication

cable

(if

present)

from

top

of

slave

terminal.

4

Remove

and unpack

slave

terminal

and keyboard.

Check

units

for

visible

damage.

5

Remove

tape

securing

power

cord

and

front

panel

to

slave

terminal.

6

Remove

exterior

casework by

rotating

the

two

turnlock

fastener

studs

at

the

rear

of

the

unit.

Tilt

faceplate

forward by

loosening

screws

at

top

of

unit.

7 Ensure

that

all

sockets

are

securely

in

place

on

the

L.E.D.

indicator.

8

Remove

any

internal

packing

material

from module

ca.ge

A5.·

9

Inventory

the

units

and

fill

in

the

appropriate

sections

of

the

inventory

and

inspection

report

shipped

with

each

unit.

Notify

branch

office

of

any

damage

or

shortage.

10

If

installation

is

to

be completed

at

this

time

proceed

to

table

2-5,

if

not

continue

with

step

11.

11

Replace

exterior

casework and

place

unit

in

a

suitable

place.

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

Reference

Referen-ce.

Figure

2-2

MR6086

Installation

CRT

MODULE

ASSEMBLY

AI

CHARACTER

GENERATOR

NOTE:

Orientation

of

A1

Character

Generator

module

is

shown

for

latest

build

requirements.

Earlier

units

were produced

with

the

module

turned

180

degrees

(speaker

at

the

rear

of

the

terminal).

o

Figure

2-2.

Slave

Terminal -Module

Location

MR6086

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

45728

2-5

UTS

400·

Table

2-3.

Controller

Unpacking Procedure

Step

Procedure

Remove

controller

from

carton

and

place

on

floor.

2 Cut bands

holding

container

sections

together

and

re-

move

container

top.

3

Remove

bagged communication

cable

(if

present)

from

the

package.

4

Remove

controller

top

cover

as

follows:

(a)

Loosen two

retaining

screws on

the

rear

of

the

cabinet

and back

the

screws

out

8

to

10

turns

(about

1/4

inch).

(b)

Tip

the

cover

and

front

panel

toward

the

front

and

lift

off.

5 With

the

cover

removed,

ensure

that

all

L.E.D.

indi-

cators

are

securely

in

place

in

their

sockets.

6

7

Remove

any

internal

packing

material

from

~odule

cages

A1

and

A5.

NOTE

Detailed

inspection

of

printed

circuit

modules,

to

include

broken

or

missing

ROMs,

is

accomplished

later

in

the

in-

stallation

procedure.

InventorJ

the

u.~its

and

fill

in

the

appropriate

sections

of

the

inventory

and

inspection

report

shipped

with

each

lmi

t.

(Use

the

referenced

figures

to

assist

in

inventory

and

inspection

of

the

unit.)

Notify

branch

office

of

any

damage

or

shortage.

8

If

installation

is

to

be completed

at

this

time

proceed

to

table

2-6,

if

not

continue

with

step

9.

9 Replac.e

extericr

casework and

place

unit

in

a

suitable

ph.ce.

2-4.

INSTALLATION

PROCEDL1lliS

Reference

Figure

2-3

Figure

2-3

and

Appendix A

The

procedures

for

installing

the

master

terminal

are

described

in

table

2-4,

the

slave

terminal

in

table

2-5, and

the

controller

in

table

2-6. Table 2-7

provides

the

final

procedures

for

checking

the

system

rold

connecting

the

system

to

a

modem

or

multiplexer.

2-6

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

MR6086

MR6086

AIA6

AlAI

AIA3

A5A3

A5A2

~

~

Part Number

Module

Name

A1Al

RED

2818452-XX

CPU

A1A3

BlK

2818483-XX

Display Control

A1A4

GRN

2818414-XX

Communications

I/O

AlAS

BlU

281

8398-XX

7-Bit

Interface

A1A6

WHT

2818443-XX

8-Bit

Interface

A1A7

VEL

2818437-05

10K

ROM/Switch

AlAS

VIO

2818418-XX

8K

RAM

A5A2

2818441-XX

Display Driver (3)

A5A3

2036465-'-XX Power Supply

Figure

2-3.

Controller

Terminal Module

Locations

REVISION:

HCB-1

COMPANY

CONFID~"TIAL

Installation

45760

2-7

UTS

400

2-8

Step

Table

2-4.

Master

Terminal

Installation

Procedure

Remove

exterior

casework by

rotating

two

turnlock

fastener

studs

at

rear

of

unit,

then

sliding

casework

forward

to

clear

the

faceplate,

and

lifting

off.

2

Roll

master

terminal

on

side

with

power

supply

chassis

supporting

the

unit.

3

4

5

CABLE

CLAMP

Loosen

cable

clamp on bottom

of

unit

and

route

key-

board

cable

(2816519-XX)

thru

opening

in

bottom

of

master

terminal.

Leave

sufficient

cable

in

unit

for

a

cable

loop.

Secure

cable

with

cable

clamp.

Roll

master

terminal

upright

and connect

cable

con-

nector

A5A3P5

to

A5A1J5

on

character

generator

module

in

location

A5A1.

If

keyboard

cable

2816519-XX

is

not

connected

to

keyboard, connect remaining end

of

cable

to

A2J1

on

keyboard.

Figure

2-4.

Master Terminal -Bottom

View

Reference

Figure

2-4

Figure

2-5

Figure

2-6$

Figure

2-7

SCREEN

45722

CHARACTER GENERATOR MODULE

{A5All\

~

REAR

_1

___

~

~~s

400

lLb

t III

fuillt;;;;;;;;;;;;;;1

6

~

A5AIJ5

4572\

Figure

2-5.

Keyboard Cable Connection -

Character

Generator

Module

REVISION:

HCB-1

COMP

ANY

CONFIDENTIAL

MR6086

MR6086

Figure

2-7.

HCB-1

REVISION:

ENTIAL

.ANY

CONFID

COMP

Installation

2-9

UTS

400

2-10

Table

2-4.

Master

Terminal

Installation

(Cont)

Step

Procedure

6 Check

for

broken

or

cracked

connectors

on

terminal

b::>ards, and

bent

or

shorted

connect.or

pins.

Inspect

for

foreign

material.

7

8

Ensure

that

all

push-on

terminals

are

securely

attached

to

their

respective

sYitches,

indicators

and

potentiometers,

etc.

Ensure

that

all

internal

cables

are

properly

routed

and

securely

plugged

into

the

appropriate

connectors.

CAUTION

Two

cables

in

the

UTS

400 system

require

keying.

They

are:

(1)

Keyboard

cable

(W6)

PiN 2816519-XX

(master

and

slave)

Pin

A

is

keyed

on

both

ends.

(2)

Monitor

signal

cable

(W10)

PiN

2816517-XX

Pin

A

is

keyed on

both

ends.

Improper

orientation

of

the

noted

cables

can

cause

equipment damage.

9

Remove

po'ler

supply

module

A5A3

cover.

10 Determine

the

AC

voltage

of

the

operating

location

and

strap

the

power

supply

module

as

described

in

Section

3.

11

Replace power

supply

r.lodule

A5A3

cover.

12

Strap

the

unit

as

described

in

Section

3. While

the

modules

are

removed from

the

unit,

check

for

broken,

loose,

or

missing

ROM

elements,

according

to

the

information

in

appendix

D.

13

Fill

out

Configuration

Descriptions

Record

shipped

yith

each

unit.

Folloy

instructions

on

form.

Keep

a

record

on

reverse

side

of

form

for

all

future

FeOs

installed.

14

Set

POWER

ON/OFF

switch

(front

panel

behind

key-

board)

to

OFF

position.

NOTE

Units

are

shipped

from

the

factory

strap-

ped

for

115

VAC

60

Hz

'with

a Hubbell

5251, 5252,

or

equivalent

power

plug.

On

units

to

be

used

with

other

power

sources,

an

appropriate

primary

power

plug

must

first

be

installed.

15

Use

ohmmeter

to

ensure

that

AC

power

input

leads

are

not

shorted.

16 Connect power

cord

to

primary

AC

power

source.

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

Reference

Figure

2-8

(Foldout)

Figure

2-8,

Figure

2-9

(Foldouts)

Section

3

Section

3 and

Appendix D

Figure

2-10

MR6086

Step

17

Table

2-4.

Master

Terminal

Installation

(Cont)

Procedure

NOTE

The

power-on

confidence

test

is

initiated

by

turning

power

on

to

the

unit.

The

READY

indicator

lights

when

the

test

is

success-

fully

completed;

if

not

successfully

com-

pleted,

the

error

condition

is

displayed

on

the

screen.

Refer

to

SPERRY

UNIVAC

Universal

Terminal System 400

Functional

Analysis

and

Servicing;

MR6087

for

trouble-

shooting

if

an

error

condition

is

displayed.

Set

ro\tlER ON/OFF

switch

to

ON

position.

R>\tlER

ON

indicator

should

light

and

READY

indicator

s~ould

light

at

successful

completion

of

power-on

con-

findenct

test.

SPE~Y1~UNIVAC

UTS

400

MESSAGE

WAITING

@

MESSAGE

INCOMPLETE

~

WAIT

~

POLL

(9

AUXILIARY

BUSY

<.9

READY

@

POWER

ON

<P

INTENSITV@

Installation

Reference

Figure

2-10

.

.L.

..

~

PROTECT

ON

ON

TESTB

OFF

POWER

~

ON

I

rr

I

III~F

I

MR6086

8

MON'TORB

FCC

OFF

"»

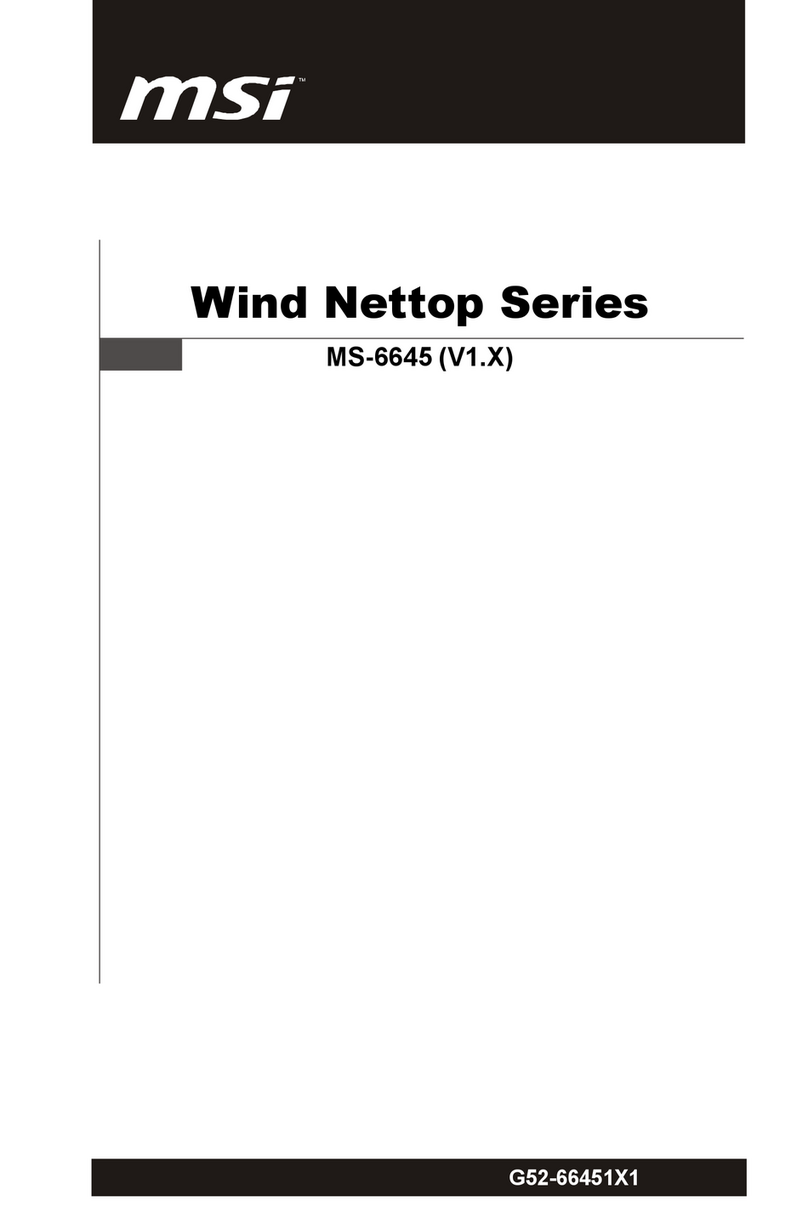

Figure

2-10.

Master

Terminal

Controls

and

Indicators

l@JISIOU:

HCB-1

COMP~~

CONFIDENTIAL

45729

2-11

UTS

400

Step

18

19

20

2-12

Table

2-4.

Master

Terminal

Installation

(Cont)

Procedure

Using volt-ohmmeter, check power supply

voltage

at

following

locations

on

A1

backplane.

Set

POWER

ONI

OFF

switch

to

ON

after

meter

is

connected and

to

OFF

after

each

voltage

check.

NOTE

Terminal

E1

is

not

connected

to

the

6.3

VAC

source.

Terminals

Voltages

Return

Output

E6

(GND)

E2

-10.8

to

·-13.2

E6 E3

-4.2

to

-5.5

E6 E4

+5.0

to

+5.4

E6

E5

+10.8

to

+13.2

If

voltages

are

not

within

tolerance

or

one

or

more

of

the

voltages

are

missing

refer

to

SPERRY

UNIVAC

Universal

Terminal S stem 400 Fu.'1ctional Anal

sis

and

Servicing,

MR

0 7

for

functional

data

on

the

power

supply.

Perform

CRT

module

adjustments

as

required.

Refer

to

SPEFL~Y

UlIIVAC

Universal

Terminal System 400

Functional

Analysis and

Servicing,

MR6087

for

the

adjustment

procedures.

NOTE

A

maximum

of

three

slave

terminals

may

be

corulected

to

the

master

terminal.

The

connection

of

the

three

slave

ter-

minals

requires

modification

of

the

master

terminal

by

installing

featUres

2278-00

(display

driver

module) and

feature

2280-00

(display

control

module and

associated

cables).

The

first

slave

terminal

requires

the

in-

stallation

of

feature

2280-00. Connect-

ing

the

second

slave

terminal

requires

the

installation

of

feature

2278-00.

The

installation

of

a

third

feature

2280-

00

provides

for

the

third

slave

terminal

connection.

See

following

steps.

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

Reference

Figure 2-11

MR6087

MR6087

MR6086

MR6086

Inst.allation

e 0

6 7 8 9

.10.

• • • • • • TA-r

if

n

1"

r

II'

f

'1"

III

·..'

.1

, "

'I

'

ii

I

...

+..

....

1.

"

..

,

1IIIIt

IIIIII1I

+.

+.

+. +.

+..,

+.

••

+ •

-I

-I

-I -I -I

-I

-I

-I

-I -I

o 0 o

EI

E2

E3

..

..

..

6.3VAC

-12V

-5V

E4

E5

~

..

+5V

+12V

NOTE

AI

45730

At

least

one module must

be

plugged

into

the

backplane

to

check

the

-5V,

-12V,

and

+12V

power

supply

voltages

on

A1

backplane.

Figure

2-11.

Power Supply Voltage Checkpoints

REVISION:

HCB-1

COMPANY

CONFIDENTIAL

2-13

This manual suits for next models

1

Other Sperry Rand Desktop manuals