Sperry Rand Univac 1108 User manual

PUNCHED

CARD

SUBSYSTEM

.

UP·7506

This

manual

is

published

by

the

Univac

Division

of

Sperry

Rand

Corporation

in

loose

leaf

format.

This

format

provides

a

rapid

and

complete

means

of

keeping

recipients

apprised

of

UNIVAC

®

Systems

developments.

The

infor-

mation

presented

herein

may

not

reflect

the

current

status

of

the

product.

For

the

current

status

of

the

product,

contact

your

local

Univac

Represent-

ative.

The

Univac

Division

will

issue

updating

packages,

utilizing

primarily

a

page..for-page

or

unit

replacement

technique.

Such

issuance

will

provide

notification

of

hardware

changes

and

refinements.

The

Univac

Division

re-

serves

the

right

to

make

such

additions,

corrections,

and/or

deletions

as,

in

the

judgment

of

the

Univac

Division,

are

required

by

the

development

of

its

Systems.

UNIVAC

is

a

registered

trademark

of

Sperry

Rand

Corporation.

01967

-SPERRY RAND CORPORATION

PRINTED

IN U.S.A.

UP-7506

c

UNIVAC

1108

PUNCHED

CARD

SUBSYSTEM

CONTENTS

1.

INTRODUCTION

2. SUBSYSTEM

DESCRIPTION

2.1.

GENERAL

2.2.

CONFIGURATION

2.3.

SUBSYSTEM

COMPONENTS

2.3.1.

Card

Reader,

Type

0706

2.3.2.

Card

Punch,

Type

0600

2.3.3.

Card

Control

Unit,

Type

5010

2.3.3.1.

Buffer

Memory

3. PROGRAMMING

3.1.

SUBSYSTEM/PROCESSOR

INTERFACE

3.1.1.

Control

Si

gn

al

s

3.1.2.

Communications

Sequence

3.1.2.1.

Translate

(Normal)

Mode

3.1.2.2.

Card

Image

by

Row

Mode

3.1.2.3.

Card

Image

by

Column

Mode

3.1.3.

Ope

rati

on

Type

s

Contents

SECTION:

PAGE:

CONTENTS

1

to

5

1-1

to

1-1

2-1

to

2-9

2-1

2-3

2-3

2-4

2-6

2-8

2-9

3-1

to

3-18

3-1

3-1

3-2

3-2

3-2

3-2

3-4

1

UP-7506

UNIVAC

11.08

PUNCHED

CARD SU8SYSTEM

3.2.

WORD

FORMAT

3.2.1.

Function

Words

3.2.1.1.

Punch

-

Normal

Stacker

(0)

3.2.1.2.

Punch

-

Select

Stacker

(1)

3.2.1.3.

Condition

Punch

for

Translate

3.2.1.4.

Condition

Punch

for

Card

Image

by

Column

3.2.1.5.

Condition

Punch

for

Card

Image

by

Row

3.2.1.6.

Term

in

ate

3.2.1.7.

Transfer

-

No

Trip

3.2.1.8.

Transfer

-

Trip

Fill

3.2.1.9.

Trip

One

-

No

Transfer

3.2.1.10.

Condition

Reader

for

Translate

3.2.1.11.

Condition

Reader

for

Card

Image

by

Column

3.2.1.12.

Condition

Reader

for

Card

Image

by

Row

3.2.2.

Status

Word

3.2.2.1.

Synchronizer

Sequence

Error

3.2.2.2.

Synchronizer

Counter

Error

3.2.2.3.

Normal

Completion

3.2.2.4.

Illegal

Function

Code

3.2.2.5.

Punch

Check

Verification

Error

or

Reader

LighVDark

Error

3.2.2.6.

Inappropriate

Function

Code

3.2.2.7.

Illegal

Character

Code

3.2.2.8.

Interlock

Fault

3.2.3.

Data

Words

3.3.

TIMING

4.

OPERATION

4.1.

OPERATOR'S

RESPONSIBILITIES

4.2.

CONTROLS

AND

INDICATORS

4.2.1.

Card

Reader

4.2.1.1.

Card

Reader

Operator's

Control

Panel

4.2.1.2.

Card

Reader

Operato

r's

Power

Control

Panel

4.2.2.

Card

Punch

4.2.2.1.

Card

Punch

Operator's

Control

Panel

4.2.2.2.

Card

Punch

Power

Control

Panel

4.2.3.

Card

Control

Unit

4.3.

SUBSYSTEM

OPERATION

4.3.1.

Turn

On

Procedure

4.3.1.1.

Card

Reader

Turn

On

4.3.1.2.

Card

Punch

Turn

On

4.3.2.

Turn

Off

Procedure

4.3.3.

I/O

Preparation

4.3.3.1.

Loading

Cards

Contents

SECTION:

3-6

3-6

3-7

3-8

3-8

3-8

3-8

3-9

3-9

3-9

3-9

3-10

3-10

3-10

3-11

3-13

3-13

3-13

3-13

3-14

3-14

3-15

3-15

3-15

3-18

PAGE:

4-1

to

4-23

4-1

4-1

4-1

4-1

4-3

4-3

4-3

4-4

4-6

4-7

4-7

4-7

4-8

4-8

4-9

4-9

2

o

o

UP-7506

c

c

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

4.4.

ERROR

CONDITIONS

AND

CORRECTIONS

BY

OPERATOR

4.4.1.

Interrupts

and

Error

Recovery

4.4.1.1.

Punch

Check

Verification;

Reader

Light/Dark

Check

Error

4.4.1.2.

Inappropriate

Function

Code

(Octal

60)

4.4.1.3.

Illegal

Character

Code

(Octal

70)

4.4.1.4.

Interlock

Fault

(Octal

74)

4.4.2.

Card

Reader

Fault

Diagnosis

4.4.3.

Card

Punch

Fault

Diagnosis

4.5.

OPERATOR

PERFORMED

MAINTENANCE

4.5.1.

Card

Reader

Maintenance

Procedures

4.5.1.1.

Cleaning

and

Inspection

of

Card

Feed

Track

4.5.1.2.

Offline

Operation

Check

4.5.1.3.

Clearing

Reader

Card

Jams

4.5.2.

Card

Punch

Maintenance

Procedures

4.5.2.1.

Emptying

the

Chip

Box

4.5.2.2.

Cleaning

the

Card

Feed

Track

4.5.2.3.

Offline

Operational

Check

4.5.2.4.

Card

J

am

Correction

APPENDICES

APPENDIX

A. SUMMARY

OF

PHYSICAL AND

OPERATIONAL

REQUIREMENTS

APPENDIX

B. SEQUENCE OF OPERATION AND TIMING

FIGURES

2-1.

Punched

Card

Subsystem

Block

Diagram

(Sample

Configuration)

2-2.

Type

0706

Card

Reader

2-3.

Card

Reader,

Block

Diagram

2-4.

Card

Punch,

Type

0600

2-5.

Card

Punch

Feed

Path

2-6.

Type

5010

Card

Control

Unit

3-1.

Function

Word

Format

3-2.

Status

Wo

rd

Format

3-3.

Relationship

of

Data

Word

to

Card

Code

Contents

SECTION:

4-10

4-10

4-10

4-10

4-10

4-11

4-12

4-12

4-13

4-13

4-14

4-14

4-14

4-17

4-17

4-18

4-20

4-20

A-I

to

A-2

B-1

to

B-8

2-3

2-4

2-4

2-6

2-6

2-8

3-6

3-11

3-16

3

PAGE:

Contents

4

UP-7506

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

SECTION:

PAGE:

3-4.

Relationship

of

Data

Words

to

Card

Punches,

Card

Image

by

Columh

" . 3-17 0

>:

'

"ri

3-5.

Relationship

of

Data

Words

to

Card

Punches,

Card

Image

by

Row

3-18

4-1.

Card

Reader

Operator's

Control

Panel

4..,.1

4-2.

Card

Reader

Power

Control

Panel

4-3

4-3.

Card

Punch

Operator's

Control

Panel

4-4

4-4.

Card

Punch

Power

Control

Panel

4-4

4-5.

Card

Control

Unit

Operator's

Panel

4-7

4-6.

Card

Handling

and

Loading

4-9

4-7.

Front

Cabinet

Panel

4-17

4-8.

Chip

Box

4-17

4-9.

Chip

Box

Replacement

4-17

4-10.

Latching

Top

Cover

4-18

4-11.

Details

of

Punch

Interior

4-18

4-12.

Cleaning

the

Punch

Interior

4-19

4-13.

Punch

Interior

with

Cards

Loaded

4-20

c:

4-14.

Card

Jam

Correction

4-21

4-15.

Stacker

Jam

4-23

TABLES

2-1.

Type

0706

Card

Reader,

Capabilities 2-2

2-2.

Type

0600

Card

Punch,

Capabilities 2-2

2-3.

Type

5010

Card

Control

Unit,

Capabilities 2-2

2-4.

Punched

Card

Subsystem

Components

2-3

3-1.

Control

Signals

3-1

3-2.

Standard

Translation:

80-Column

Card

Code

to

Processor

Code

3-3

3-3.

Stan

da

rd

T

ran

sl

ation:

Pro

cesso

r

Code

to

80-Co

lumn

Card

Code

3-4

3-4.

Function

Code

s

for

the

Punched

Card

Subsystem

3-6

3-5.

Status

Codes

3-11

3-6.

Possible

Status

Code

Responses

to

Function

Codes

3-12

4-1.

Card

Reader

Operator's

Control

Panel

4-2 0

UP-7506

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

(~

4-2.

Card

Reader

Power

Control

Panel

" 4-3.

Card

Punch

Operator's

Control

Panel

4-4.

Card

Punch

Power

Control

Panel

4-5.

Card

Control

Unit

Operator's

Panel

4-6.

Operator's

Procedures

for

Reader

Fault

Indication

4-7.

Operator's

Procedures

for

Punch

Fault

Indications

A-l.

Physical

Characteri

sti

cs

A-2.

Environmental

Requirements

A-3.

Allowable

Cable

Lengths

8-1.

Word

Assembly

Time

8-2.

Word

Disassembly

Time

8-3.

Nominal

Timing

Details

for

300

CPM

Punching

Rate

c'

Contents

SECTION:

4-5

4-5

4-6

4-8

4-12

4-13

A-I

A-I

A-2

8-4

8-6

8-8

5

PAGE:

c~

UP-7506

(

PAGE.

1

UNIVAC

1108

PUNCHED

CARD

SUBSYSTEM

S~CTION'

1.

INTRODUCTION

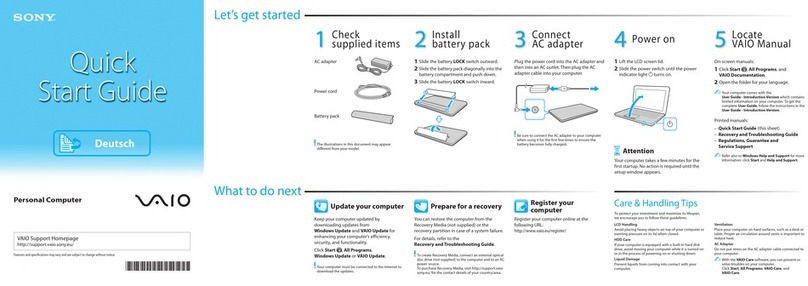

This

manual

contains

information

for

the

programming

and

operation

of

the

Punched

Card

Subsystem

for

the

UNIVAC

1108

Multi-Processor

System.

It

is

assumed

that

both

the

programmer

and

operator

have

sufficient

background

information

on

the

Central

Processor

and

Main

Storage

of

the

UNIVAC

1108

Multi-Processor

System

and

need

only

to

be

instructed

in

the

use

of

the

Punched

Card

Subsystem.

Therefore

material

already

covered

in

the

"UNIVAC

1108

Multi-Processor

System

Processor

and

Storage

Reference

Manual,"

UP-4053

will

not

be

duplicated

here.

This

manual

is

divided

into

three

basic

sections:

•

Punched

Card

Subsystem

Description

This

section

will

acquaint

the

reader

with

the

characteristics

of

the

Punched

Card

Subsystem.

•

Programming

This

section

supplies

the

user

with

the

information

required

for

programming

for

the

Punched

Card

Subsystem.

•

Operation

This

section

contains

the

information

necessary

for

the

operation

of

the

Punched

Card

Subsystem.

Referencing

the

programming

section

within

this

manual

on

a

regular

basis

is

unnecessary

when

appropriate

software

is

available

as

an

interface

to

the

Punched

Card

Subsystem.

1

o

c

UP-7506

(

c

2

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

SECTION:

PAGE:

2.

SUBSYSTEM

DESCRIPTION

2.1.

GENERAL

The

Punched

Card

Subsystem

for

the

UNIVAC

1108

System

consists

of

a

Card

Reader,

Type

0706,

and/or

a

Card

Punch,

Type

0600

and

a

Card

Control

Unit,

Type

5010.

This

latter

unit

communicates

with

the

processor

and

controls

the

operation

of

both

the

Card

Reader

and

the

Card

Punch.

The

Card

Reader

senses

80-column

data

at

the

rate

of

900

cards

per

minute

maximum

and

transfers

the

data,

column-by-column,

to

the

Card

Control

Unit.

The

Card

Punch

receives

data

from

the

Card

Control

Unit

in

the

card

image

format,

row-by-row,

and

punches

and

stacks

cards

at

the

maximum

rate

of

300

cards

per

minute.

The

Card

Control

Unit

decodes

function

words

that

are

transmitted

by

the

processor

as

instructions

for

the

Card

Reader

or

the

Card

Punch.

This

unit

includes

a

buffer

memory

which

collects

the

data

characters

read

by

the

Card

Reader,

translates

and

sends

the

information

to

the

processor.

Likewise,

data

from

the

processor

is

translated

by

the

Card

Control

Unit

and

sent

to

the

Card

Punch.

Some

of

the

important

features

of

the

Punched

Card

Subsystem

are:

•

Stacker

Selection

The

Card

Punch

output

stackers

are

selectable

during

a

punch

operation

by

pro-

grammed

instruction.

The

Card

Reader

is

equipped

with

an

Error

Stacker

which

accepts

cards

should

certain

errors

occur.

•

Translation

Card

Code,

row

binary,

and

column

binary

are

the

modes

of

translation

available

under

program

control.

•

Auto

Recovery

As

an

operator

selectable

option,

the

hardware

of

the

Card

Control

Unit

automatically

repunches

three

cards

of

data

and

maintains

proper

card

sequence

upon

detection

of

a

punch

error.

The

capabilities

and

sklient

features

of

the

individual

units

of

the

subsystem

are

presented

in

Tables

2-1

through

2-3.

1

UP-7506

2

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

SECTION:

2

PAGE:

PARAMETER

SPECIFICATION

o

CARD

ORIENTATION

Fed face down, 9-edge lead ing

CARD

RATE

900 cards

per

minute (maximum)

CARD

CYCLE

66.6 miHiseconds

per

card

cycle

at

900

cpm

IN

PUT

HOPPER

CAPACITY

3000 cards

READ

STATION

SENSING Column-by-column

OUTPUT

STACKER

CAPACITY

STACKER

-Normal 2400 cards

STACKER

-Error 100 cards

Table

2-1.

Type

0706 Card

Reader,

Capabilities

PARAMETER

SPECIFICATION

CARD

ORIENTATION

Fed face down, 9-edge leading

CARD

RATE

300 cards per minute (maximum)

CARD

CYCLE

200

milliseconds

per

card

cycle

at 300

cpm

INPUT

HOPPER

CAPACITY

1000 cards

READ

STATION

SENSING Row-by-row

PUNCH

STATION

PUNCHING Row-by-row

OUTPUT

STACKER

CAPACITY

OUTPUT

STACKER

-Normal 850 cards

OUTPUT

STACKER

-

Select

850 cards

Table

2-2.

Type

0600 Card

Punch,

Capabilities

PARAMETER

SPECIFICATION

COMPUTER

WORD

lENGTH

36

bits

CHARACTER

SIZE 6

bits

MODES OF

OPERATION

Read

and

Punch

DATA

INTERFACES:

CARD

CONTROL

to/from

PROCESSOR

36

bits

parallel

CARD

READER

to

CARD

CONTROL

12

bits

para lieI

CARD

CONTROL

to

CARD PUNCH 8

sequential

transfers,

10

bits

parallel

Table

2-3.

Type

5010 Card Control Unit,

Capabilities

c

UP·7506

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

SECTION:

2

2.2.

CONFIGURATION

Equipment

configurations

for

the

Punched

Card

Subsystem

are

as

follows:

a

Card

Control

Unit

and

either

a

Card

Reader

or

a

Card

Punch

or

both.

A

block

diagram

of

a

sample

configuration

of

the

subsystem

is

shown

in

Figure

2-1.

The

names

and

type

numbers

of

subsystem

components

are

given

in

Table

2-4.

FROM

PROCESSOR

TO

PROCESSOR

CARD

CONTROL

CARD CARD

PUNCH

READER

Figure

2-1.

Punched

Card

Subsystem

Block

Diagram

(Sample

Configuration)

TYPE

NO.

SUBSYSTEM

COMPONENT

60

Cycle

50

Cycle

CARD

READER

0706-99 0706-98

CARD

PUNCH 0600-00 0600·04

CARD

CONTROL

UNIT

5010-00

Table

2-4.

Punched

Card

Subsystem

Components

2.3.

SUBSySTEM

COMPONENTS

Subsystem

components,

described

in

the

following

paragraphs,

include

the

Card

Reader,

Card

Punch,

and

the

Card

Control

Unit.

3

PAGE:

I UP-7506

UNIVAC

1108 PUNCHED CARD SUBSYSTEM

PAGE:

2.3.1.

Card

Reader,

Type

0706

The

Card

Reader,

upon

command

from

the

processor,

reads

cards

into

the

buffer

memory

of

the

Card

Control

Unit

at

a

rate

of

up

to

900

cards

per

minute,

and

then

stacks

the

cards

in

the

same

order

as

originally

fed.

It

is

equipped

with

a

control

panel

which

is

divided

into

two

areas:

the

operator's

control

panel

to

initiate

and

monitor

operation,

and

the

diagnostic

panel

to

diagnose

malfunctions.

See

Figure

2-2.

Figure

2-2.

Type

0706 Card

Reader

The

functional

units

of

the

Card

Reader

are

the

Input

Station,

the

Ready

Station,

the

Read

Station,

the

Error

Stacker

Station,

and

the

Output

Stacker

Station.'

Station-

to-station

card

flow

proceeds

in

the

sequence

given

below

and

is

shown

in

Figure

2-3.

ERROR

STACKER

STATION

Figure

2-3.

Card

Reader,

Block

Diagram

,

SWITCH

4

c

c

---------

-----------------

------------

UP-7506

c

SECTION:

2

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

PAGE:

1.

The

Input

Station

holds

the

cards

to

be

read

and

initiates

their

travel

through

the

reader.

2.

3.

The

primary

components

of

the

Input

Station

are

the

input

hopper,

picker

knife,

and

misfeed

detector.

The

purpose

of

each

of

these

components

is:

•

The

input

hopper

is

of

the

file-feed

type

and

retains

cards

prior

to

being

fed

into

the

Ready

Station.

It

is

readily

accessible

to

the

operator

so

that

cards

can

be

added

while

the

equipment

is

in

use.

The

card

capacity

of

the

hopper

is

3000

cards.

A

card

weight

must

be

placed

on

top

of

the

card

file

to

allow

feeding

of

the

last

card.

•

The

picker

knife

moves

back

and

forth

within

the

input

hopper,

feeding

cards

from

the

bottom

of

the

file

to

the

Ready

Station

upon

receipt

of

a

control

signal

from

the

Card

Control

Unit.

If

there

are

no

cards

remaining

in

the

input

hopper,

the

empty

hopper

switch

energizes

and

places

the

reader

in

the

nonready

state.

•

The

misfeed

detector

is

a

photocell

which

signals

to

the

Control

Unit

whether

a

card

has

or

has

not

been

fed

from

the

Input

Station

into

the

Ready

Station

following

a

feed

signal.

If

a

card

has

not

entered

the

Ready

Station

(a

mis-

feed

has

occurred),

the

Card

Reader

will

be

placed

in

the

nonready

state

and

the

feeding

of

cards

will

be

inhibited.

The

Ready

Station

accepts

the

card

fed

to

it

from

the

Input

Station,

changes

the

direction

of

card

movement,

and

holds

the

next

card

to

be

read.

Once

the

card

has

entered

the

Ready

Station,

the

Card

Control

Unit

issues

a

control

signal

to

activate

the

pinch

roller

(see

Figure

2-3).

The

pinch

roller

transports

the

card

into

the

Read

Station.

The

Read

Station

performs

the

data

sensing

function

in

the

reader.

Its

major

component

is

the

sensing

unit

which

contains

twelve

incandescent

lamps

and

twelve

photocell

assemblies.

When a

card

passes

through

the

Read

Station

(between

the

lamps

and

the

photocells),

the

data

punched

in

the

card

will

permit

the

appropriate

photocells

to

be

activated.

The

sensed

data

is

stored

in

the

Control

Unit's

buffer

memory.

4.

The

Error

Stacker

Station

is

equipped

with

a

card

deflector

which,

when

energized,

intercepts

and

delivers

a

card

to

the

Error

Stacker.

The

Normal

Stacker

accepts

all

cards

not

delivered

to

the

Error

Stacker.

Cards

are

deposited

in

the

Error

Stacker

when

the

card

deflector

is

energized

by

the

detection

of

a

defective

photocell

or

a

damaged

card.

5.

The

Output

Stacker

Station

is

a

2400-card

capacity

stacker

in

which

the

cards

are

stacked

on

end.

The

cards

are

fed

out

of

the

Read

Station

into

the

stacker

mechanism

in

an

upward

arc

and

deposited

on

end

in

the

stacker

tray.

The

stacker

tray

is

readily

accessible

to

the

operator

so

that

cards

can

be

removed

while

the

equipment

is

in

use.

Before

entering

the

stacker,

the

cards

pass

by

a

jam

detector

switch

which

signals

the

control

unit

should

a

jam

occur.

The

stacker

is

also

equipped

with

a

limit

switch

which

closes

to

signal

the

control

unit

of

a

full

stacker

condition.

5

UP-7506

UNIVAC

1108

PUNCHED

CARD

SUBSYSTEM

SECTION.

2

PAGE.

2.3.2.

Card

Punch,

Type

0600

The

Card

Punch

will

feed,

punch,

post-punch

read,

and

stack

80-column

cards

at

a

maximum

rate

of

300

cards

per

minute

on

command

from

the

processor.

It

is

equipped

with

a

control

panel

which

is

divided

into

two

areas:

the

operator's

control

panel

to

initiate

and

monitor

operation,

and

the

diagnostic

panel

to

diagnose

malfunctions

.

.

See

Figu

re

2-4.

Figure

2-4.

Card

Punch,

Type

0600

The

Card

Punch

Feed

Path

is

illustrated

in

Figure

2-5.

NORMAL

~

-~

7

SELECT

(1)

§ff$

OUTPUT

STACKER

STATION

I I

IPOST-PUNCH I

PUNCH

IREAD I STATION

~STATION

I

CJ

-------- --------

JAM B

DETECTOR

o

Note:

Cards are depicted

at

rest

between

consecutive

card punching

cycles.

Figure

2-5.

Card

Punch

Feed

Path

IWAIT I

!STATION2:

I I

JAM A

DETECTOR

WAIT

STATIONl

INPUT

HOPPER

6

o

c

UP-7506

(-

(

2

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM

SECTION:

PAGE:

A

function

word

from

the

processor

causes

the

cards

to

advance

one

station

as

follows:

1.

Input

Station

The

input

hopper

and

the

picker

knife

constitute

the

Input

Station.

The

picker

knife

feeds

cards,

one

at

a

time,

from

the

bottom

of

the

input

hopper

into

the

first

pair

of

feed

rolls.

2.

Wait

Station

1

Wait

Station

1

holds

the

card

for

one

cycle

of

the

clutched

transport

system.

3.

Wait

Station

2

In Wait

Station

2,

two

functions

are

performed:

the

card

is

held

for

another

cycle

of

the

clutched

transport

system,

and

the

position

of

the

card

is

checked.

Upon

entering

Wait

Station

2,

the

leading

edge

of

the

card

is

checked

by a

photocell,

and

the

trailing

edge

is

tested

as

the

card

leaves

Wait

Station

2.

This

is

known

as

JAM A

check.

Any

malfunction

at

this

station

will

light

the

J

AM

A

indicator

on

the

control

panel.

4.

Punch

Station

The

information

received

from

the

Card

Control

Unit's

buffer

memory

is

punched

into

the

card

in

this

station.

As

the

card

emerges

from

the

Punch

Station,

the

JAM B

photocell

checks

the

leading

and

trailing

edge

of

the

card

for

position

or

card

jam.

Any

malfunction

at

this

station

will

light

the

JAM B

indicator

on

the

control

panel.

5.

Post-Punch

Read

Station

In

the

Post-Punch

Read

Station,

the

information

that

has

been

punched

into

the

card

is

sensed

and

sent

to

the

Card

Control

Unit

for

comparison

with

the

in-

formation

contained

in

the

Card

Control

Unit's

buffer

memory

for

the

purpose

of

verification.

6.

Output

Stacker

Station

The

Output

Stacker

Station

consists

of

two

output

stackers

designated

Normal

and

Select.

The

Select

Stacker

is

equipped

with

a

card

deflector,

which

when

energized,

intercepts

and

delivers

a

card

to

the

Select

Stacker

pocket.

The

Normal

Stacker

accepts

all

cards

not

delivered

to

the

Select

Stacker.

The

Punch

function

word

received

from

the

processor

specifies

whether

the

card

goes

to

the

Normal

or

the

Select

Stacker.

7

UP-7S06

UNIVAC

1108

PUNCHED

CARD SUBSYSTEM 2

SECTION:

2.3.3.

Card

Control

Unit,

Type

5010

Figure

2-6.

Type

5010

Card Control

Unit

The

Card

Control

Unit

(see

Figure

2-6)

governs

all

the

operations

of

the

Punch

Card

Subsystem.

Its

principal

functions

are:

PAGE:

•

to

receive

function

words

from

the

processor

that

condition

and

prepare

the

sub-

system

for

different

modes

of

operation

and

for

data

handling.

•

to

synchronize

the

flow

of

data

between

the

processor

and

the

Card

Reader

or

Card

Punch.

•

to

accumulate

the

data

to

be

punched

or

being

read

from

cards

in

its

Buffer

Memory.

•

to

interpret

signals

both

normal

and

abnormal,

from

the

Card

Reader

or

Card

Punch

and

to

notify

the

processor

of

conditions

within

these

units.

8

c

c

UP-7506

(

2

UNIVAC

1108

PUNCHED

CARD

SUBSYSTEM

SECTION:

PAGE:

2.3.3.1.

Buffer

Memory

The

Buffer

Memory

of

the

control

unit

is

divided

into

eight

areas,

as

follows:

•

an

input

sense

area

which

receives

the

data

read

from

cards.

•

an

input

translate

area

which

is

used

as

a

table

look

up

device

for

translation

of

data

read

from

cards

to

processor

code.

•

two

alternating

input

transfer

areas

which

are

used

to

store

data

from

the

input

sense

area

in

translated

form

and

which

are

used

as

the

source

of

data

sent

to

a

word

assembly

register

for

input

to

the

processor.

•

an

output

translate

area

which

is

used

as

a

table

lookup

device

for

translation

of

output

data

(as

it

is

received

from

the

processor)

to

card

code.

•

three

cyclically

rotating

output

transfer

areas

which

are

used

to

store

the

translated

or

formatted

data

received

from

the

processor

following

receipt

of

a

Punch

function,

to

send

data

to

the

punch

station,

and

to

send

data

to

comparison

circuits

to

check

on

the

validity

of

data

read

at

the

post-punch

check

station

of

the

punch

unit.

9

·. ..

,

.,~.

c

c

c

Other Sperry Rand Desktop manuals