6875D Freezer/Mill

1300-87052-1A, REV 1 SPEX SamplePrep LLC Page 4 of 36

1.0 INTRODUCTION

SPEX SamplePrep Freezer/Mills are laboratory mills that cool unconventional materials to

cryogenic temperatures and pulverize them to a powder form without thermal degradation.

Our proven technology uses a dual electromagnetic, grinding chamber that rapidly drives a

steel impactor back and forth against the two end plugs of the sample vial. Since the vial is

securely closed the integrity of its contents is maintained, hazardous or critical samples are

easily controlled, and cross-sample contamination is eliminated. The sample chemical

composition is preserved as a result of the vials being immersed in liquid nitrogen at cryogenic

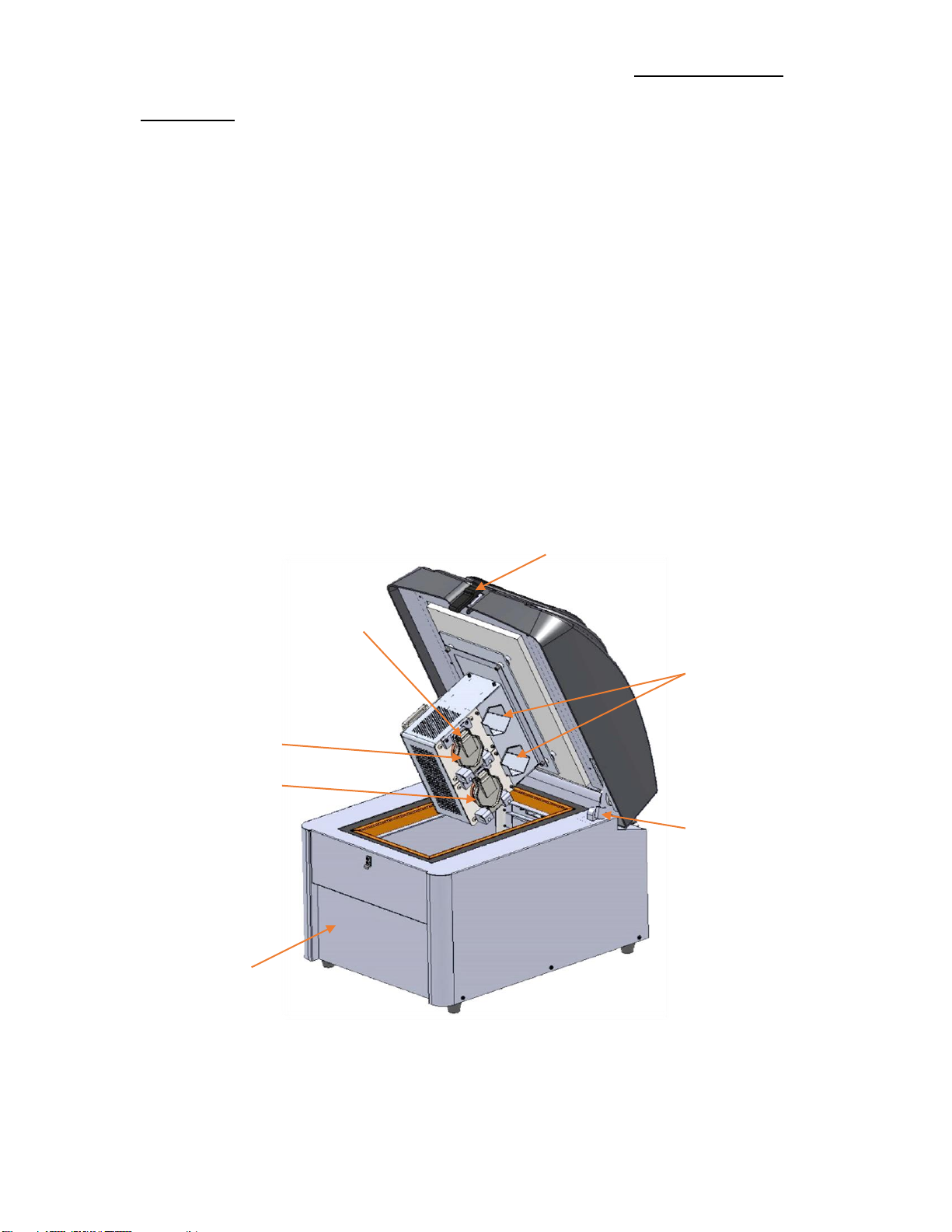

temperatures throughout the grinding process. The 6875D Freezer/Mill expands on this

technology utilizing dual grinding chambers and two additional precooling chambers for

increased sample throughput. The 6875D Freezer/Mill has been re-engineered with a liquid

nitrogen Auto Fill feature which comes standard in every unit. The preference to Manual Fill

the unit with liquid nitrogen is optional. These unique aspects have made SPEX SamplePrep

Freezer/Mills the most effective cryogenic mills in the world. They are the “mills of first choice”

for many abnormal materials, or samples whose composition or structure cannot be ground

using conventional grinding methods.

NOTE: Do not operate the 6875D Freezer/Mill until you have read the Operating Manual and

are familiar with the controls and operation.

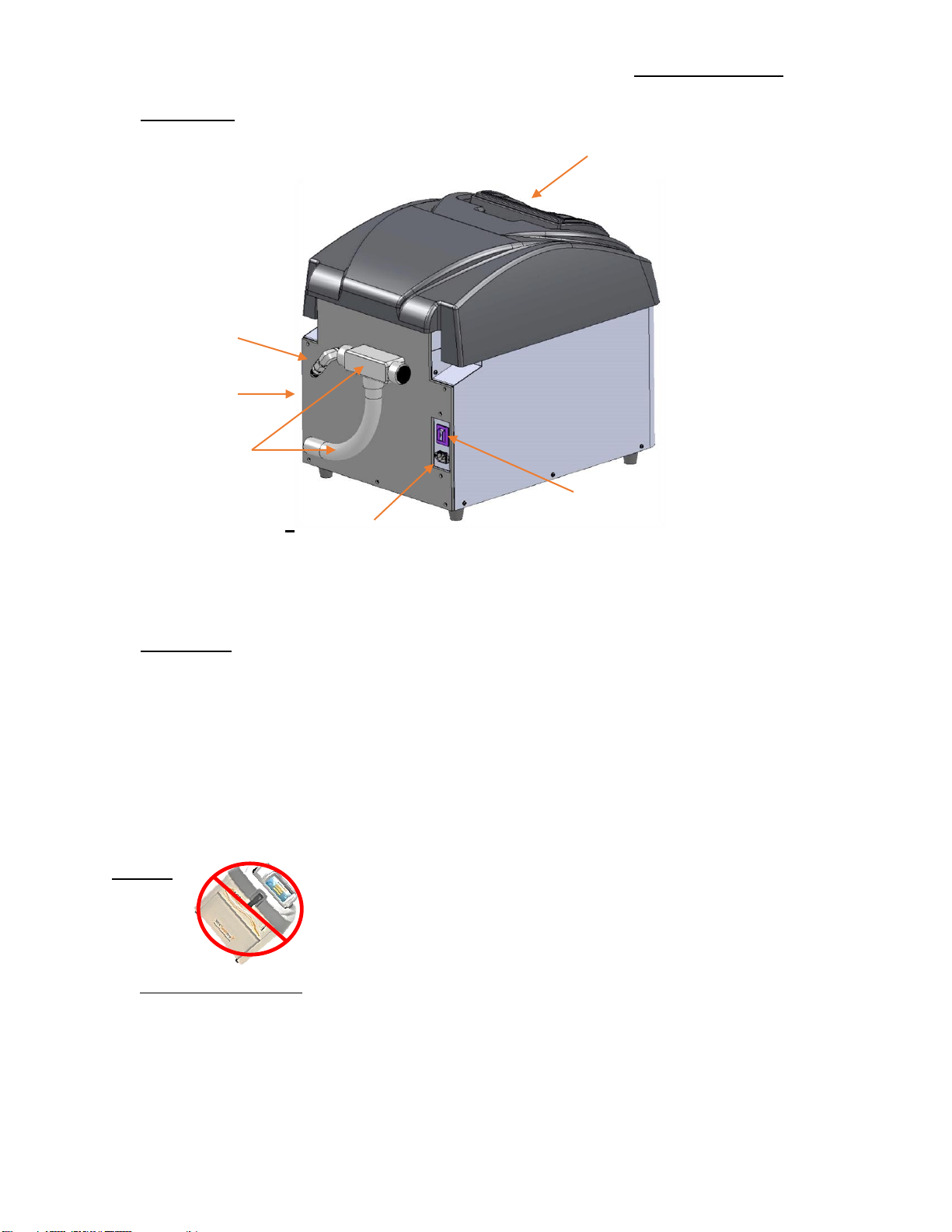

OPERATING CONDITIONS: Do not set up the 6875D Freezer/Mill in an insulated or confined

space. The Freezer/Mill should be run on an open countertop, in ambient air, with

recommended maximum relative room humidity 70% from 5°C - 31°C (40°F - 88°F). If the entire

mill is chilled during operation, components such as the gas springs, controller, and display

screen can fail. This damage is not covered by the Freezer/Mill warranty. During operation,

water vapor in the air will condense on parts of the unit. For this reason, it is important not to

place any moisture-sensitive equipment near the Freezer/Mill.

VERY IMPORTANT: Liquid nitrogen(LN) not only makes samples brittle through severe chilling

and making them “grindable,” but it also cools the magnetic coils which powers the 6875D

Freezer/Mill. If the unit is operated in the optional Manual Fill mode the liquid nitrogen level

should be visually checked during extended runs as well as topped off before every run.

Operating the unit without liquid nitrogen for a period of one minute will cause the coils to

become very hot and may sustain permanent damage. The 6875D Freezer/Mill has a LN sensor

that will shut down the unit when the liquid nitrogen gets too low to cool the coils. The

Freezer/Mill warranty does not cover damage to the coils caused by operating the mill with

little or no liquid nitrogen. We recommend operating the unit in Auto Fill mode with LN Tank.

SAFETY: Liquid nitrogen (LN) can be hazardous. Its boiling point is -195.8°C (-320.4°F). When

working with liquid nitrogen directly or indirectly, the LN Tank valve or hose, or chilled

Freezer/Mill components, cryogenic gloves must be worn to protect hands. A face Shield is also

recommended to protect eyes from possible splashing. Wear the proper protection equipment

PPE).