SPI Lasers redPOWER FVCU User manual

redPOWER

FiberView Control Unit

FVCU

Instructions for Use

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

2

Safety Notes

This FiberView Control Unit (FVCU) does not in itself present a hazard but may be used to

control redPOWER PRISM Fiber Lasers which are potential hazards.

The safety information provided in the Instructions for Use for redPOWER PRISM Fiber

Lasers must be observed.

Throughout these Instructions for Use warning messages are given in contexts in which a

hazard may occur.

General Hazard Information

WARNING: Ensure that all Users are fully aware of all safety

implications identified in these Instructions for Use before

attempting to install, operate or maintain this FVCU.

WARNING: This FVCU has no safety control functionality and as

such all safety functionality, including electrical and laser safety

functionality, is the responsibility of the Laser Integrator.

WARNING: Attempts to modify or alter this FVCU or the use of

controls or adjustments or performance of procedures other than

those specified in these Instructions for Use may render this FVCU

unsafe.

Attempts to modify or alter this FVCU or the use of controls or adjustments or performance of

procedures other than those specified in these Instructions for Use additionally will invalidate

the warranty and may result in patent infringement.

Laser Integrators are not authorized to modify this FVCU.

Electrical Hazard Information

CAUTION: This FVCU must be grounded for safety and to comply

with regional electrical codes.

Failure to do so may result in incorrect operation of the FVCU.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

3

CONTENTS

1Structure and Scope of these Instructions for Use 7

2Definition of Symbols and Terms 8

3Health and Safety 9

3.1 General 9

3.2 Intended Use of the FVCU 9

3.3 Hazards 10

3.4 Compliance 10

3.5 Labelling 11

4Document References 12

5redPOWER FVCU Tour 13

5.1 Key Features 13

5.2 Software Tools 15

6Getting Started 16

6.1 Receiving and Inspection 16

6.2 Unpacking and Handling 16

7Installation 17

7.1 Safety and Compliance During Installation 17

7.2 Location and Environment 17

7.3 Mounting 17

7.4 FiberView Installation 17

7.5 Electrical Connections 18

8Operating Instructions 35

8.1 Before Operation 35

8.2 Powering the FVCU Up and Down 35

8.3 Alarms and Warnings 36

9The FVCU and FiberView for Laser Control 37

9.1 Overview 37

9.2 Basic Operation 37

9.3 Parameter Sets 40

9.4 Process Cycles 44

9.5 Other Settings 46

10 Basic Control Using Serial Communication 48

10.1 Overview 48

10.2 Functionality 48

10.3 Protocol Message References 50

11 Machine Interface Reference 51

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

4

11.1 Overview 51

11.2 Default Input Functionality 51

11.3 Default Output Functionality 72

11.4 Protocol Message References 77

12 Alarm and Warning Messages 78

12.1 Alarm Code Definitions 78

12.2 Warning Code Definitions 80

13 Maintenance 84

13.1 Periodic Inspection 84

13.2 General Cleaning 84

14 Disposal 85

15 Specifications 86

15.1 Operating Conditions 86

15.2 Non-Operating Conditions 86

15.3 Utility Requirements 87

15.4 Mechanical Specifications 87

16 General Information 88

16.1 Trade Marks 88

16.2 Software 88

16.3 Warranties 88

16.4 Copyright 88

16.5 Changes 88

17 Contact Information 89

18 Customer Service 90

FIGURES

Figure 1 WEEE Symbol........................................................................................................................... 10

Figure 2 FVCU in Packing Case ............................................................................................................. 16

Figure 3 Interface Connectors................................................................................................................. 19

Figure 4 Star Earthing Configuration....................................................................................................... 20

Figure 5 Machine Interface Connections Circuits.................................................................................... 24

Figure 6 PL5 Programmable Inputs ........................................................................................................ 25

Figure 7 PL5 Programmable Outputs...................................................................................................... 26

Figure 8 Fiber Laser Connection Dialog.................................................................................................. 38

Figure 9 FiberView Overview Screen...................................................................................................... 39

Figure 10 FiberView Parameter Editor.................................................................................................... 42

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

5

Figure 11 Shape Editor Window.............................................................................................................. 44

Figure 12 Steps Grouped into Process Cycles ....................................................................................... 45

Figure 13 FiberView Process Cycle Editor.............................................................................................. 45

Figure 14 State Transition Diagram ........................................................................................................ 49

Figure 15 Moving to STANDBY in Remote Control................................................................................. 53

Figure 16 Moving to OFF in Remote Control .......................................................................................... 53

Figure 17 Entering Remote Control (OFF State, Laser Start Set) .......................................................... 54

Figure 18 Entering Remote Control (STANDBY or ON State, Laser Start Clear)................................... 54

Figure 19 Entering Remote Control (STANDBY or ON State, Laser Start Set)...................................... 55

Figure 20 Moving to ON in Remote Control ............................................................................................ 57

Figure 21 Moving to STANDBY in Remote Control (No Ramp Down Time Configured)........................ 58

Figure 22 Moving to STANDBY in Remote Control (Ramp Down Time Configured) ............................. 58

Figure 23 Moving to ON state in Remote Control Before the State has Moved to the STANDBY State 59

Figure 24 Entering Remote Control (STANDBY State, Laser ON Input Set).......................................... 59

Figure 25 Entering Remote Control (ON State, Laser ON Input Set) ..................................................... 60

Figure 26 Entering Remote Control (ON State, Laser ON Input Clear, No Ramp Down Time Configured)

................................................................................................................................................................. 60

Figure 27 Entering Remote Control (ON State, Laser ON Input Clear, Ramp Down Time Configured) 61

Figure 28 Starting a Process Cycle in Remote Control........................................................................... 61

Figure 29 Stopping a Process Cycle in Remote Control (No Ramp Down Time Configured in Active

Step Parameter Step).............................................................................................................................. 62

Figure 30 Stopping a Process Cycle in Remote Control (Ramp Down Time Configured in Active Step

Parameter Step) ...................................................................................................................................... 62

Figure 31 Starting a Process Cycle in Remote Control Before the State has Moved to the STANDBY

State ........................................................................................................................................................ 63

Figure 32 Entering Remote Control (STANDBY State, Process Cycle Start Input SET)........................ 63

Figure 33 Entering Remote Control (Process Cycle Active, Process Cycle Start Input Set, No Ramp

Down Time Configured in Active Step Parameter Step)......................................................................... 64

Figure 34 Entering Remote Control (Process Cycle Active, Process Cycle Start Input Set, Ramp Down

Time Configured in Active Step Parameter Step) ................................................................................... 64

Figure 35 Entering Remote Control (STANDBY State, Process Cycle Start Input Set) ......................... 65

Figure 36 Entering Remote Control (Process Cycle Active, Process Cycle Start Input CLEAR, No Ramp

Down Time Configured in Active Step Parameter Step)......................................................................... 65

Figure 37 Entering Remote Control (Process Cycle Active, Process Cycle Start Input CLEAR, Ramp

Down Time Configured in Active Step Parameter Step)......................................................................... 66

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

6

Figure 38 Advancing Process Cycle Steps in Remote Control............................................................... 67

Figure 39 Advancing Process Cycle Steps in Remote Control (Before Process Cycle Wait Is Set) ...... 68

Figure 40 Alarm Reset............................................................................................................................. 69

Figure 41 Alarm Reset When in the ON state......................................................................................... 70

Figure 42 Edge Trigger Operation(Pulsed Output Only)......................................................................... 71

Figure 43 Gated Trigger Operation (Pulsed Output)............................................................................... 72

Figure 44 Gated Trigger Operation (CW Output).................................................................................... 72

TABLES

Table 1 Safety, Explanatory and Compliance and Information Labels ................................................... 11

Table 2 Laser Integrator Supplied PC –For Operating FiberView.......................................................... 18

Table 3 Interface Connectors.................................................................................................................. 19

Table 4 Serial Port Connections.............................................................................................................. 21

Table 5 PL5 Machine Interface Pin Out .................................................................................................. 22

Table 6 Laser Inputs................................................................................................................................ 27

Table 7 Laser Status Outputs.................................................................................................................. 29

Table 8 BDO Integrity Circuit Connections (When Option Specified) ..................................................... 32

Table 9 Minimum Interface Connection................................................................................................... 33

Table 10 Parameter Set Attributes.......................................................................................................... 40

Table 11 Process Cycle Step Attributes.................................................................................................. 46

Table 12 Default Configuration of Machine Interface Inputs................................................................... 51

Table 13 Default Configuration of Machine Interface Outputs ................................................................ 51

Table 14 Environmental Operating Conditions........................................................................................ 86

Table 15 Non-Operating Conditions........................................................................................................ 86

Table 16 Electrical Requirements ........................................................................................................... 87

Table 17 Dimensions and Weight............................................................................................................ 87

Table 18 Contact Information.................................................................................................................. 89

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

7

1 Structure and Scope of these Instructions for

Use

These Instructions for Use for SPI Lasers’ redPOWER®FiberView Control Unit (FVCU)

contain all the information that Users needs to know for its safe and efficient use. This

information is important. These Instructions for Use should be read before installing and using

the FVCU and made available for reference at the location where the FVCU is being used.

Additional or replacement copies are available from SPI Lasers.

These Instructions for Use are divided into the sections below which provide Users with health

and safety information before introducing the FVCU and then guiding them through its

installation, operation, maintenance and disposal. Lastly it provides other useful information

and the FVCU’s specifications.

1

Structure and Scope of these Instructions for Use

2

Definition of Symbols and Terms

3

Health and Safety

4

Document References

5

redPOWER FVCU Tour

6

Getting Started

7

Installation

8

Operating Instructions

9

The FVCU and FIberView for Laser Control

10

Basic Control Using Serial Communication

11

Machine Interface Reference

12

Alarm and Warning Messages

13

Maintenance

14

Disposal

15

General Information

16

Contact Information

17

General Specifications

18

Mechanical Specifications

19

Customer Service

The FVCUs covered by these Instructions for Use have order codes:

SP

-

FVCU

-

1

4

The order code can be found on a label on the front panel of the FVCU. The last digit indicates

whether the FVCU can control one (1), or from one to four (4) PRISM Fiber Laser Modules.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

8

2 Definition of Symbols and Terms

This general warning symbol emphasizes important information

needed during installation and operation

This symbol identifies the protective conductor terminal (ground

point)

WARNING:

Indicates a hazard with a medium level of risk which, if not avoided,

could result in death or serious injury

Warnings must be observed to prevent personal injury to yourself

and others.

CAUTION:

Indicates a hazard with a low level of risk which, if not avoided,

could result in minor or moderate injury

Cautions must be observed to prevent personal injury and damage

to or destruction of equipment or loss of operational effectiveness.

FVCU:

FVCU as used herein means the item that was procured from SPI

Lasers.

This FVCU is not a consumer product and is not to be sold on or

made available as such.

Laser

Integrator:

Any person, company or organisation who integrates this FVCU

into equipment, or any person, company or organisation who uses

this FVCU in the form as supplied by SPI Lasers.

A Laser Integrator is skilled in and understands the integration

issues surrounding the use, design and supply of laser products to

end users in the end markets which it supplies.

User:

Individuals or organizations that use this FVCU. User includes the

Laser Integrator and the end user

Authorised

Personnel:

Those who have attended official Training Courses and have been

certified as competent.

SPI Lasers:

SPI Lasers UK Ltd.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

9

3 Health and Safety

3.1 General

This section gives information on the hazards which may be encountered during installation,

operation and maintenance of this FVCU and steps to reduce the risk. Also included is

information on laser and electrical safety compliance. All safety instructions, including those in

the Safety Notes and those in other sections of these Instructions for Use, must be followed.

Not following safety instructions may constitute a hazard to Users and third parties or cause

damage to property and the FVCU.

Only Authorised Personnel who have been instructed in, and fully understand, the necessary

safety procedures should operate this FVCU. Access must be restricted to Authorised

Personnel.

Any local safety requirements for the operation of this equipment must be complied with.

Throughout the documentation, ‘WARNING’, and ‘CAUTION’ paragraphs appear. It is the

responsibility and duty of all Users who operate and maintain this equipment to fully

understand the WARNING and CAUTION and act in order to reduce or eliminate hazards.

3.2 Intended Use of the FVCU

This FVCU has been designed exclusively for incorporation or integration into other equipment

for controlling from one to four SPI redPOWER PRISM Fiber Lasers.

Operating the device within the limits of its designated use requires the user to:

observe the instructions set out in these Instructions for Use and in the PRISM Fiber

Lasers Instructions for Use

install and use this FVCU in compliance with international, national and local

regulations regarding laser safety, for example IEC/EN 60825-1 and 21 CFR 1040.10.

install and use this FVCU in compliance with international, national and local

regulations regarding the safety of electrical equipment, for example BS EN 60204

wire and connect the electrical lines to this FVCU in compliance with international,

national and local regulations regarding electromagnetic compatibility (EMC), for

example the relevant sections of IEC/EN 61000 and FCC CFR47

not move this FVCU when it is switched on

carry out necessary inspection and maintenance work

This FVCU is not intended for controlling lasers other than SPI redPOWER PRISM Fiber

Lasers.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

10

SPI Lasers cannot be held liable for any damage resulting from use other than the intended

use. The risk lies entirely with the User.

3.3 Hazards

3.3.1 Laser Hazards

This FiberView Control Unit (FVCU) does not in itself present a hazard but may be used to

control redPOWER PRISM Fiber Lasers which are potential hazards.

The safety information provided in the Instructions for Use for redPOWER PRISM Fiber

Lasers must be observed.

3.4 Compliance

Within the EU, the FVCU is CE marked and is supplied with a Declaration of Conformity. The

standards which SPI Lasers declares that the FVCU is in conformity with, and the directives

which SPI Lasers declares that the FVCU complies with the requirements of are listed in the

Declaration of Conformity.

Within the USA, the FVCU is shipped with an appropriately completed FDA 2877 form.

It is the responsibility of the Laser Integrator to ensure that the integrated laser system

conforms with the appropriate standards and complies with the appropriate directives.

Nonetheless, many of the electronic and labelling requirements have been incorporated into

the FVCU to facilitate compliance.

3.4.1 Europe: WEEE Directive

Figure 1 WEEE Symbol

This symbol indicates that, at end of life, this FVCU should be separately collected from

unsorted waste.

3.4.2 Europe: RoHS Directive

This FVCU is in conformity with European RoHS Directive. Compliance is demonstrated

through conformance with this standard which is harmonised to the RoHS directive:

BS EN 50581:2012

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

11

3.4.3 Europe: EMC Directive

This FVCU falls outside the scope of the EMC Directive as it is intended exclusively for an

industrial assembly operation for incorporation into other apparatus. However SPI Lasers

recognises that Laser Integrators may require the integrated laser system to comply with the

directive. SPI Lasers has therefore designed for compliance to parts of the standards listed

below which are harmonised to the EMC Directive:

BS EN 50370-1:2005

BS EN 55011:2009+A1:2010..

3.4.4 USA: CFR Title 47, Federal Communications Commission

This FVCU is designed for compliance with:

FCC CFR47: §15.109 Radiated emission limits.

3.5 Labelling

Labels are placed on the rear panel of the FVCU to warn of potential hazards and to provide

other useful information.

Table 1 below shows the labels and give their locations.

Table 1 Safety, Explanatory and Compliance and Information Labels

Protective conductor terminal

indicator

Identification

Address, WEEE and CE label

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

12

4 Document References

Document number

Description

FS-S00131

PRISM Rack Fiber Laser Installation Drawing

SM-S00482

PRISM Fiber Laser Serial Interface Manual

SM-S00499

redPOWER Fiber Laser Serial Communications Protocol

These documents may be downloaded by going to 'Customer Login' at the top right of SPI

Lasers’ home page: www.spilasers.com.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

13

5 redPOWER FVCU Tour

The redPOWER FVCU builds on many years of experience of SPI Lasers in designing,

developing and supplying control systems for fiber lasers into a wide range of industrial laser

processing applications. It gives laser integrators the capability to control fiber lasers in

industrial laser machines with maximum output power levels from 300W up to many kilowatts.

5.1 Key Features

The FVCU allows the individual PRISM FL modules to be controlled as a single Fiber Laser

either by using the Laser Integrator’s interface or by using SPI Laser’s FiberView software.

The FVCU also takes the inputs from the sensors in the PRISM HPC Module and the

individual PRISM FL modules and generates alarm and warning signals and also the pierce

detection signal.

Pulse Shaping

An integrated pulse generator in the FVCU allows precise and accurate control of the laser

power over time. When cutting complex features, this allows fine control of laser power.

When welding and additive manufacturing, control of the power throughout the process,

but particularly at the start and end, can produce dramatic improvements in the quality of

the finished part. For example, this can be very evident when welding crack sensitive

aluminium alloys, where a controlled cooling of the melt pool will reduce occurrence of

cracks and leave a much stronger weld.

Within the FVCU Parameter Sets are used to define the desired energy output. The FVCU

can store up to 50 Parameter Sets in its onboard memory for fast access when switching

between Parameter Sets during processing. The Parameter Editor will set up the desired

repetition rate, peak power and pulse length, choosing from a library of pulse shapes and

waveforms. However, any arbitrary pulse shape can be defined using the Shape Editor.

The Shape Editor works graphically to produce and edit dimensionless shapes that are

then saved as a particular User Defined pulse shape. This pulse shape can be used in any

parameter set, where it is scaled to the peak power and pulse width associated with that

pulse shape.

Process Cycles

Process Cycles are an automation feature implemented in the FVCU that can dramatically

reduce the load and complexity needed for the system controller, by transferring a number

of control functions directly to the laser controller. They allow a programmed sequence of

Parameter Sets to be output using minimal input to control an entire process sequence, for

example when a single part has to be processed with different types of spot and seam

welds at different positions around the part. Process Cycles are constructed from one or

more elements known as Steps. Each Step holds a Parameter Set reference and control

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

14

attributes. A Process Cycle can be programmed to execute fully automatically from start to

finish, or to require a simple external trigger input / serial command to change between

programmed Steps, or any combination of automatic and manual control.

The FVCU has the capacity to store up to 1000 steps which can be grouped into up to 50

Process Cycles. The Process steps can be given meaningful names when being stored

within the laser.

Pierce Detection

Pierce detection is an aid in cutting processes. The back reflected light from the work

piece is detected in an High Power Combiner (HPC) Module and interpreted to determine

when the work piece has been fully pierced. Completion of the pierce is signalled by a

output on the Machine Interface and in the FiberView control software. An HPC module is

required to implement this feature.

As different materials and processes have different back reflections, the feedback from

different process will vary. Therefore a set of configuration parameters are made available

to the Laser Integrator in order for them to hone their process.

Machine Interface

The Machine Interface allows total operational integration of the laser into a production line

or cell. Options include Power Control, Parameter Selection and Alarm Reporting. The

function of each of the seven input and seven output signal lines can be configured by the

user. See Section 7.5.6. for more details.

Indicators

Coloured LED indicators are fitted to the front panel to show whether there is DC power,

the state of the PRISM Fiber Laser –one of the six states: OFF, STARTING, STANDBY,

RAMPING UP, ON or RAMPING DOWN, and whether there is an alarm or warning.

oPower (white, marked ‘~’)

Indicator is lit if DC power is connected.

oEmission Indicator (yellow, marked with laser warning triangle)

Indicator is flashing if the PRISM Fiber Laser is in the STARTING state.

Indicator is lit if the PRISM Fiber Laser is in the STANDBY, RAMPING UP, ON

or RAMPING DOWN state.

Indicator is not lit if the PRISM Fiber Laser is in the OFF state.

oFault (red, marked ‘?’)

Indicator is flashing if there is an Alarm condition. The PRISM Fiber Laser will

be in the OFF state

Indicator is lit if there is an active Warning.

Indicator is not lit when there are no alarms or warnings present.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

15

5.2 Software Tools

SPI Lasers’ Graphical User Interface, FiberView, allows Users to control this FVCU over a

serial interface. Operation of the FVCU using FiberView is described in Section 9.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

16

6 Getting Started

6.1 Receiving and Inspection

Before installing or operating this FVCU, you should:

Inspect the shipping container for damage

Inspect the FVCU for signs of damage

Confirm that the shipping carton contains all items on the shipping inventory list

Retain all packaging materials until the FVCU has been commissioned. If anything is missing

or defective contact SPI Lasers. See Section 16 for contact details.

6.2 Unpacking and Handling

To avoid the risk of personal injury or damage to the FVCU when lifting or moving, follow good

manual handling practice.

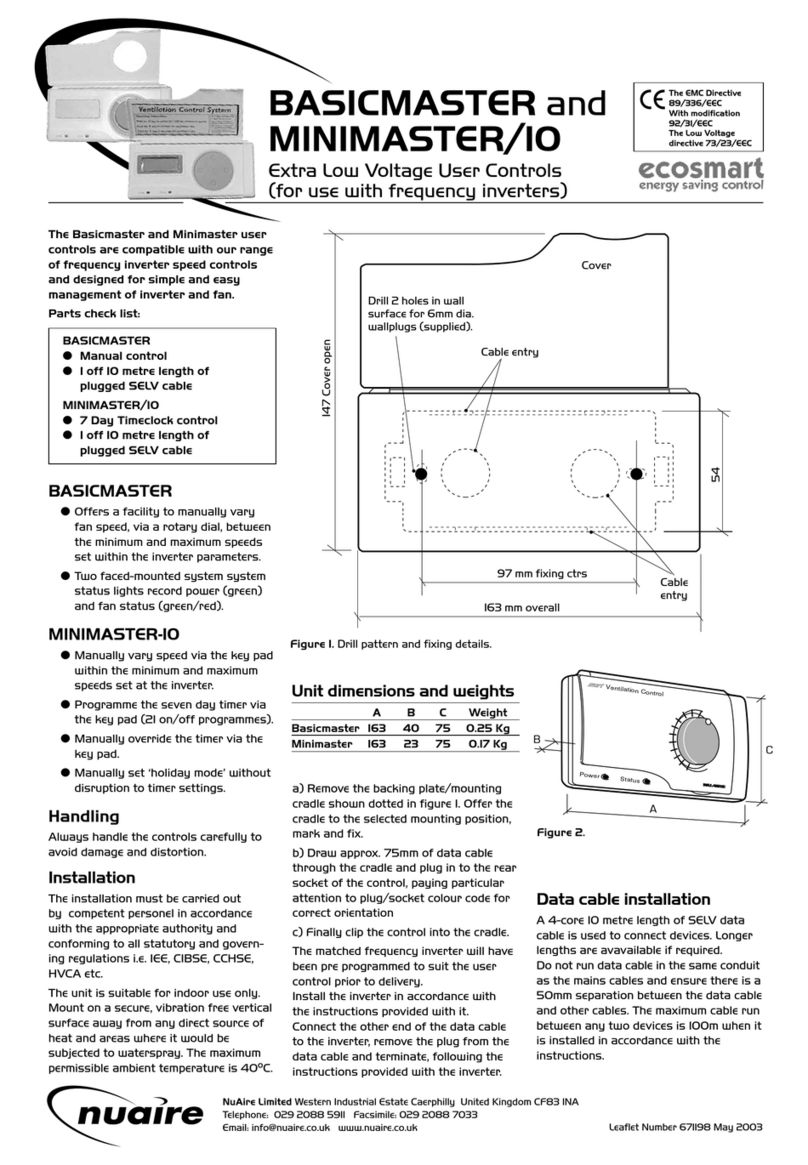

Figure 2 FVCU in Packing Case

1. Open the packing case and open up the flaps.

2. Remove the FVCU with the foam packing pieces.

3. Remove the cables.

4. Remove the foam packing pieces from the FVCU. Put the packing pieces into the

empty packing case and store for future use.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

17

7 Installation

7.1 Safety and Compliance During Installation

Before installation reference should be made to Section 3 regarding laser safety, electrical

safety, EMC and compliance. When installed, the FVCU, the PRISM Fiber Laser and the

additional equipment required to operate them should not obstruct access to safety devices or

impair their operation.

It is recommended that installation is done in the sequence of the following sections, with

water connections to the PRISM Fiber Lasers made and checked before electrical

connections are made.

7.2 Location and Environment

This FVCU is designed for operation within the environment specified in Table 14. Operating

the FVCU beyond the limits of the environmental specification may lead to accelerated

component ageing and performance degradation.

This FVCU must not be installed in a corrosive atmosphere. The FVCU must not be exposed

to high levels of optical radiation, for instance radiation from materials processing.

This FVCU is sealed against dust and water ingress to IP52 to BS EN 60529:1992+A2:2013

with the exception of the electrical connectors which are rated IP50. The laser integrator

should ensure that when installed the FVCU is not likely to be exposed to water, for instance

from coolant leaks.

At least 120mm clear space must be provided behind the FVCU to allow the electrical cables

to be routed correctly.

7.3 Mounting

The total weight of the FVCU is given in Section 15.4. The width of the FVCU enables it to

fitted into a standard 19” rack cabinet.

7.4 FiberView Installation

Insert the medium supplied, which has the FiberView software on it, into the computer which

will be used to control the FVCU. Run setup.exe. This will install FiberView and necessary

support programs.

Note: Check PC setting as follows: Control Panel –Regional & Language Options –

Advanced Tab –Language for non-Unicode Programs. Set this to English in drop down box.

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

18

Table 2 Laser Integrator Supplied PC –For Operating FiberView

Parameter

Requirement

Operating System:

Windows 7 and above

Minimum Hardware Specification:

Processor 1GHz

-

Hard drive with 250MB free space

2GB RAM

CD Drive

RS-232 Interface Port or RJ45 Network Port

Up to 57,600 Baud.

Minimum screen resolution 1024 x 768

Interconnect cable connections

RS-232:9-pin D-type, Null Modem

(Pins connected 2-3, 3-2, 5-5)

Ethernet: Cross-over cable for direct

connection to PC, Standard cable for LAN

connection.

PC settings

Control Panel –Regional & Language

Options –Advanced Tab –Language for non-

Unicode Programs

English

7.5 Electrical Connections

CAUTION: This FVCU must be grounded for safety and to comply

with regional electrical codes.

Failure to do so may result in incorrect operation of the FVCU.

For safe operation of the FVCU the electrical connections given in the following sections need

to be made. All electrical connections should use cables of the shortest practical length.

For safety, the FVCU must be connected to an external protective earthing system before any

other electrical connections are made. The FVCU is not ‘hot pluggable’: all electrical

connectors should be mated and secured in place before power is applied.

All figures in this section indicate the pin positions when looking at the connector on the rear

panel of the FVCU.

To operate a PRISM Fiber Laser using this FVCU a power connection must be made to the

PRISM FL Module and to the FVCU, and a control connection must be made from the FVCU

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

19

to the PRISM FL Module, and a control connection, which can be serial (Ethernet, RS-232 or

RS-485) or analogue and logic, must be made to the FVCU.

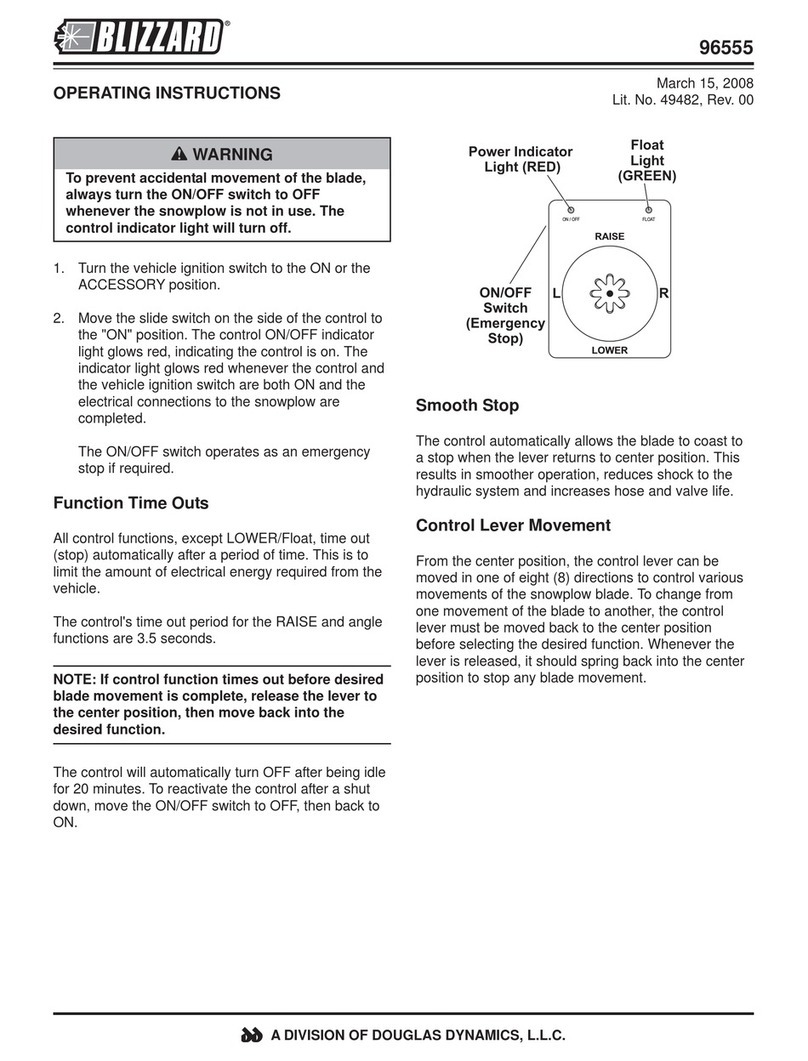

The connectors mounted on the rear panel of the FVCU, as shown in Figure 3 with

connections to a PRISM FL Module, are described in more detail in Table 3.

Figure 3 Interface Connectors

Table 3 Interface Connectors

Connector

ID

Function

Connector

Description

Reference

-

RS-232 and RS-485 (PRISM FL

Module)

9-way D-Type male

connector

Section

7.5.2

PL1

RS-232 Serial Port Control Interface

9-way D-Type female

connector

Section

7.5.4

PL5

Machine Interface

25-way D-Type male

connector

Section

7.5.6

PL9

Reserved for future expansion

SK2

Ethernet

RJ-45

Section

7.5.5

SK11

Software Shutdown

-

Section

7.5.7

SK12

Reserved

-

-

© 2017 SPI Lasers UK Ltd.

Commercial in Confidence

SM-S00530 Revision A 17 February 2017

redPOWER FVCU Instructions for Use

20

Connector

ID

Function

Connector

Description

Reference

SK41

PRISM FL Module Control Interface

37-way D-type male

connector

Section

7.5.3

SK91

Fiber Continuity Monitoring System

9-way D-Type female

connector

Section

7.5.8

SK99

SPI Lasers use only

-

-

TB1

Auxiliary Power Supply

Terminal Block

7.5.10

Protective Conductor (Earth) Terminal

M8 x 20 Stud

Section

7.5.1

7.5.1 Protective Conductor (Earth) Terminal

Figure 4 Star Earthing Configuration

The grounding and bonding of the FVCU and PRISM FL Module to a suitable low impedance

safety and EMC earth point is necessary to ensure safety in fault conditions and to minimise

the effects of electrical noise during normal operation. The FVCU and PRISM FL Module

should be connected as shown schematically in Figure 4. The earth connection from the

PRISM FL Module to the FVCU should be as short as possible. A longer, missing or incorrect

earth connection will increase susceptibility to electrical noise and could impair proper

operation.

The protective conductor shall support the maximum short-circuit current of the pump diode

PSU.

Table of contents

Other SPI Lasers Control Unit manuals

Popular Control Unit manuals by other brands

Elk Products

Elk Products ELK-100 manual

DeZurik

DeZurik APCO AVV-140 instructions

BRONKHORST

BRONKHORST VDM Series instruction manual

Blizzard

Blizzard 96555 operating instructions

Mitsubishi

Mitsubishi Q68RD3-G user manual

Sierra Wireless

Sierra Wireless AirPrime MC7330 Product Technical Specification & Customer Design Guidelines