SPI Lasers redPOWER User manual

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 1 FS-S00149-Rev A

redPOWER PRISM OEM

Prism Module Fiber Laser

Quick Start Guide

29/06/2016

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 2 FS-S00149-Rev A

•Customer Requirements Pre Install Water Supply & Fittings.

•Customer Requirements Pre Install Electrical Connections

•Customer Requirements Pre Install RS232/485 Communication...

•Customer Requirements Pre Install 37 Way Dsub Connections

•Customer Requirements Pre Install Protective Conductor (Earth)

•Customer Requirements Pre Install Unpacking & Handling

•Customer Requirements Installing Laser Mounting Laser In ...

•Electrical Connections to Laser

•Start Up/Shutdown Procedure for Prism Laser.

•SPI Service Contacts

Contents

29/06/2016

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 3 FS-S00149-Rev A

Before the redPOWER PRISM OEM laser is delivered to the customer, the customer must ensure that the following

Utilities are available.

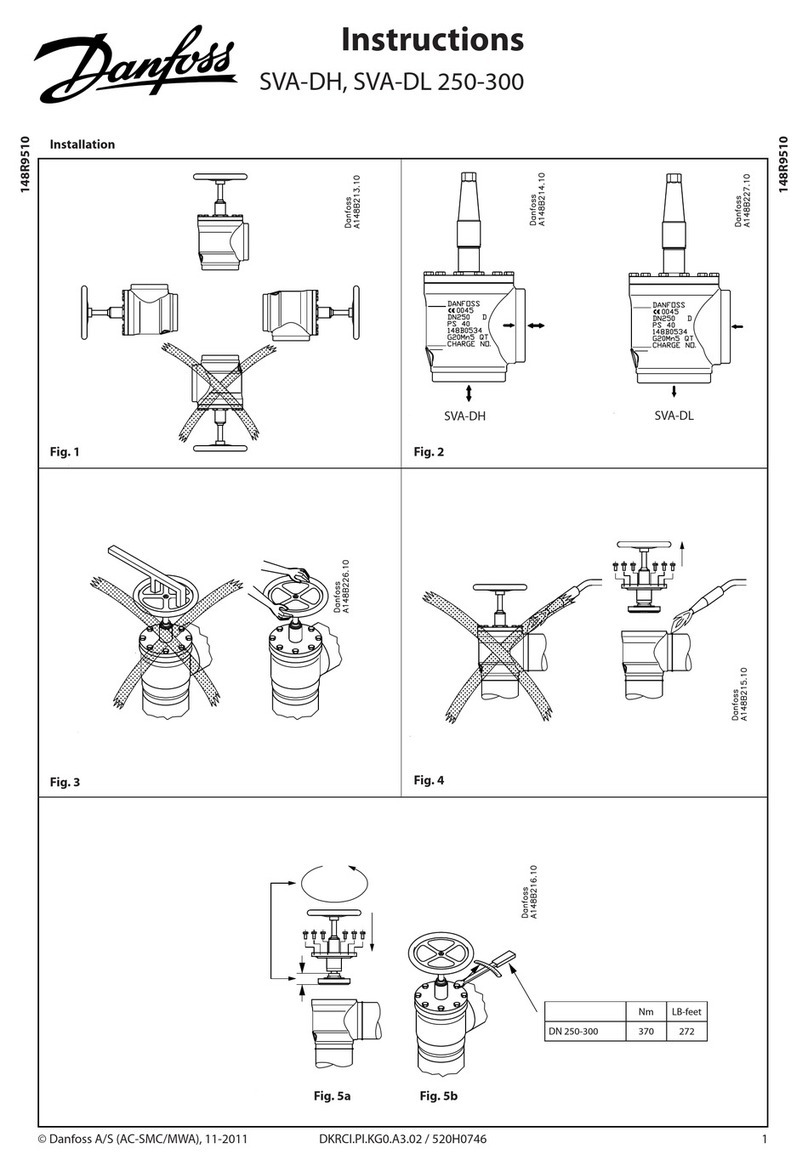

•Water Supply : Cooling Water Requirements

•Integrators must ensure that the water condition meets the requirements set out in the following tables and in

the manual below.

•SM-S00481 redPOWER Prism OEM Fibre Laser Instructions for Use

•Ensure that the hose connections are leak free and tested before electrical operation of the laser .

•SPI recommend that an appropriate filter is installed in line to the flow lines of the laser. The grade of filter is

100µm

•Pre-treated water and additives for prevention of corrosion, scaling and microbial growth are available

commercially, for example from NALCO and Optishield.

•additives may reduce the heat capacity of the water. The flow rate must be increased to compensate.

•The following table will show the specification for the chiller to ensure correct cooling of the OEM and PIPA-Q

BDO head.

Customer Requirements Pre Install

Water Supply & Fittings

29/06/2016

Flow from Chiller

or House Water

Return to Chiller or

House Water

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 4 FS-S00149-Rev A

Customer Requirements Pre Install

29/06/2016

Parameter

Min

Max

Units

Appearance

Clear and without sediment

-

Particle size

-

100

μm

Hardness (mg CaCO3per litre)

-

300

mg/l

Electrical conductivity at 25°C

22

2200

μScm-1

pH

6.5

9.0

-

Cooling Water Requirements

Parameter

Min

Max

Units

Notes

Cooling Water

Temperature

18

30

ºC

It is important that condensation will not occur. Refer to

Section 15.1. of SM-S00481 redPOWER Prism OEM Fibre

Laser Instructions for Use

Input Pressure

-

6

bar

Flow Rate

10

l/min/kW

At 20°C water temperature.

Pressure Drop

Long Module

-

2.5

bar

Pressure Drop

Short Module

-

2.0

bar

Cooling Requirements (Base plate)

Rated Power

300W

500W

750W

1000W

1500W

Units

Chiller Capacity

900

1500

2250

3000

4500

W

Required Chiller Capacity

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 5 FS-S00149-Rev A

Parameter

Min

Max

Units

Notes

Cooling Water

Temperature

15

35

ºC

It is important that condensation will not occur. Refer to Section

15.1. of SM-S00481 redPOWER Prism OEM Fibre Laser

Instructions for Use

Input Pressure

-

6

bar

Flow Rate

0.5

2

l/min/kW

At 20°C water temperature.

Pressure Drop

1.6

5

bar

Chiller Capacity

0.5

-

kW

29/06/2016

Customer Requirements Pre Install

Drinkable tap water is likely to meet the above requirements, and water meeting the requirements of VDI3803,

Appendix B, Table B3 does.

When designing the water cooling system, the Laser Integrator should consider the following:

•Deionised water is not permitted in the cooling circuit as the generally high levels of dissolved O2and CO2in

deionised water cause corrosion.

•Due to the cooling circuit of the laser and BDO incorporate copper, nickel plating and stainless steel, aluminium and

plain carbon or low alloy steels should not be used as galvanic corrosion may occur.

•Bacterial growth, scaling and corrosion will cause low flow rates and reduce heat transfer from the laser therefore

pre-treated water and additives for prevention of corrosion, scaling and microbial growth are available commercially,

for example NALCO and Optishield.

NOTE: Additives may reduce the heat capacity of the water. Therefore the flow rate must be increased to compensate.

Cooling Requirements (PIPA-Q Optical Connector)

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 6 FS-S00149-Rev A

Customer Requirements Pre Install

29/06/2016

•Water Connections PIPA-Q Optical connector.

•The water connections to the PIPA-Q optical connector requires a separate water supply which can be achieved

by using a two channel chiller unit with independent settings for each channel.

•It is essential that the PIPA-Q optical connector is adequately cooled with a source of clean, chilled water in

accordance with the specifications in the table above . Operating the PIPA-Q optical connector without an

adequate flow of cooling water may result in catastrophic damage.

•It is the customers responsibility to provide the fittings and hose for the install of the laser, SPI recommends the

use of John Guest fittings as shown below.

•John Guest 10mm Equal Elbow PM0310E

10mm Equal Straight PM0410E

10mm Locking Clip PM1810R

10mm Plug PM0810R

10mm LLDPE Tubing (Cold Plate) PE-1007-100M-*

6mm LLDPE Tubing (PIPA-Q) PE-0604-0100M-*

10mm Equal Elbow PEM0310W

Tube Cutter TSNIP

•Essentra End Cap FCWA-0095-013

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 7 FS-S00149-Rev A

Customer Requirements Pre Install

Electrical Connections

29/06/2016

Mains DC Power Supply

Electrical power for the pump diodes must be provided by an external DC power supply.

Power for the internal electronics must be provided by a DC auxiliary power supply.

SPI Lasers recommends the following DC power supplies for the pump diode supply

•Customer sourced Power Supply

•Customer must follow Supplier instruction Manual for Parallel Operation if more than one power supply to be used.

•Must conform to the specifications in the following slide for EOL (End Of Life) Current and Voltage.

•TDK Lambda GEN 50-200-3P400

•Aux 24V PSU(0.5A Rated) 24 ±5% Isolating

•MEAN WELL RST-10000-48

•May require additional Capacitive Support for first few

milliseconds of operation. See Figure below.

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 8 FS-S00149-Rev A

Customer Requirements Pre Install

29/06/2016

Parameter

Min

Typ

Max

Unit

Note

Voltage

Adjustment

Range

48

-

51

V

DC

1500W Prism Fibre Laser

Output Current

-

120

135

A

1500W Prism Fibre Laser

Output Load

Regulation

-

-

0.5

%

10% to 90% load variation

Output Line

Regulation

-

-

0.5

%

±10% input variation

Output Ripple

and Noise

-

-

0.5

%

20MHz measurement bandwidth

At full load, nominal input voltage

Power supply to be able to energise

≥4,000µF of load capacitance under

direct on-line load power application

(cold start)

Hold Up Time

5

-

-

ms

At full load, nominal input voltage

Transient

Response

-

-

0.5

%

The input current can change from 0A to

135A in less than 5µs. If the PSU cannot

respond fast enough additional

capacitive support will be required to

ensure that the output power is

maintained over the first few

milliseconds.

Stability

-

-

0.5

%

Over time and temperature

•To ensure compliance with EN

60204-1 Safety requirements for

electrical equipment for

measurement, control and laboratory

use –Part 1: General Requirements,

an external switch or circuit breaker

and external overcurrent protection

device should be fitted.

•Use of an inappropriate pump diode

power supply will invalidate the

warranty on the Prism Fibre Laser.

Further information can be provided

by request from SPI Lasers.

•A power supply capable of providing

0.5Aat 24V DC which is

appropriately approved and protected

is required to power the control and

monitoring circuits in the Prism Fibre

Laser.

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 9 FS-S00149-Rev A

Customer Requirements Pre Install

29/06/2016

37 way Dsub Female connector

The connector is required for the input

and output signals from the Prism OEM

module

9 Way Dsub x 2 for RS232/485 Cable

The RS232 cable is required for the Customer to

communicate with the Prism OEM using the

PrismView Graphical User Interface program

provided with the laser.

M8 Ring Crimp

The ring crimp is used for the DC power supply cables that

the customer must provide between the Buss bars of the

PSU and the OEM module. Cable size recommended for

the DC power supply to OEM is 10mm2

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 10 FS-S00149-Rev A

Customer Requirements Pre Install

RS232/485 Communication Cable

29/06/2016

RS232 Communication Cable

RS485 Communication Cable

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 11 FS-S00149-Rev A

Customer Requirements Pre Install

37 Way Dsub Connections

29/06/2016

NOTE: The integrator safety circuit must include the FCMS such if there is no

continuity between the FCMS pins on the user interface connector the Prism

Fibre Laser is disabled and the industrial laser machine is put in a safe state.

To help the customer the following cable diagram shows the minimum connection that can be achieved which

will operate the laser and allow alarm reset. For the full list of pin outs please refer to the product manual

SM-S00481 Prism OEM Fibre Laser User Manual.

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 12 FS-S00149-Rev A

Customer Requirements Pre Install

Protective Conductor (Earth)Terminals

29/06/2016

37 Way Dsub connector provides the input

for the following supplies.

•External 24VDCAux PSU

•Input /output Logic controls from external

PLC/CNC controller.

•Analogue Control Inputs

All of the above must be connected on the

negative side of the circuit to chassis Ground

single star point.

37 way Dsub Connector

The Bus Bars for the DC input power supply

must be connected from Negative to

Machine chassis Ground Single star point

The Final and most important connection is

the Prism OEM chassis to the Machine

chassis Ground. Leaving this open may

cause the other signals to float due to

insufficient return path to the chassis ground

and closing the ground loop.

For safe operation of the Prism OEM Laser and to comply with

regional electrical codes, grounding of the machine and

equipment is of the highest importance!

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 13 FS-S00149-Rev A

Customer Requirements Pre Install

Unpacking & Handling

29/06/2016

CAUTION: The Prism Fibre Laser is heavy, precautions must be taken when

lifting and moving. Failure to do so may cause serious injury !

On arrival the following actions must be undertaken before removal of the laser from the container.

•Inspect the shipping container for any damage.

•Record all damage for insurance purposes.

The Prism Fiber Laser weighs 33kg without the BDO therefore to avoid risk of personal injury or damage to the

Prism Laser module, SPI advise that the laser must be lifted with two people or by use of a lifting crane. If the laser

is required to move over distance a trolley or similar mechanical assistance is required.

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 14 FS-S00149-Rev A

Once the Prism Laser is removed from the container the following is required.

•Inspect the Prism Laser for any signs of damage.

•Inspect the Optical Connector and the full length of the conduit for any damage

•Confirm all items have been delivered as per the shipping list including items ordered separately.

If any damage is found please take photographic evidence for insurance purposes

Customer Requirements Pre Install

29/06/2016

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 15 FS-S00149-Rev A

Once all inspections have taken place the laser can be mounted in to the machine.

3 ways of Mounting the laser.

•Slide and 19” Rack

•Ensure that the slide rails can take the weight of the Prism unit.

•Bolt the front panel to the cabinet mountings.

•Shelf and 19” Rack

•Ensure the shelf thickness can take the weight of the prism unit.

•Bolt the front panel to the cabinet mountings

•Side Fixing and Rails

•The side of the laser can be mounted to a slide unit

•Customer is required to use all 12 mounting holes to support the weight of the unit

Customer Requirements Installation

Mounting Laser In to the Machine

29/06/2016

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 16 FS-S00149-Rev A

Electrical Connections to Laser

29/06/2016

№

Function

Connector Description

1

Protective Conductor

(Earth) Terminal

M5 female thread

2

Pump Diode PSU +V

Bus Bar with two eyes for

M8 bolts

3

Pump Diode PSU -V

Bus Bar with two eyes for

M8 bolts

4

RS-232 and RS-485

9-way D-Type male

connector

5

User Interface

37-way D-type male

connector

•Connect the protective earth from Item 1 to machine

chassis ground.

•Connect the power supply Negative cable Item 3.

Ensure the negative terminal of the power supply is

also connected to chassis ground

•Connect the power supply Positive Cable Item 2.

•Connect RS232/485 Cable to item 4. Can be used to

monitor the Prism unit using the Prism GUI

Provided.

•Connect the 37 Way Dsub connector Item 5 for input

and output signals, 24V control supply to laser.

•Connect BDO to Process Head ensuring the BDO is

locked in to position.

•Once all of the above is taken care of go to

•start up/Shutdown procedure

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 17 FS-S00149-Rev A

Start Up/Shutdown Procedure for

Prism Laser.

29/06/2016

•NOTE: 24V Aux supply must be turned on before the diode power supply

•Enable line must not be high before turning on the 24V PSU. If enable is high, the laser will not enable and the line must be

cycled for the laser to work correctly.

•Setting Machine & Water controls

•Turn on Machine (Machine may control Chiller or House water)

•Turn on the Chiller or House water if external to machine (Ensure Flow to both Laser and beam delivery optics)

•Turn on 24V Auxiliary Supply to Laser Control

•Turn on Diode Power Supply

•Starting the Operation

•Set ENABLE High

•Laser Ready O/P High

•Set POWER SET High (0.5 to 10V = 5% to 100% Power)

•Set MODULATE High

•EMITTING O/P High (Laser emission status indicator now amber)

•Laser now delivering Output Power as requested.

•Shutting Down the Operation

•Set Modulate to Low

•Set Power Set to 0V

•Set Enable to Low

•Turn off Diode PSU (allow PSU to discharge)

•For a Full Shut Down State

•Turn Off 24V Auxiliary supply for control

•Laser is now in a shutdown state.

•For operation using Analogue Modulation mode consult SM-S00481 Prism Module Fiber Laser User Instructions

•Before following the process as shown, all machine interlocks, emergency stops and Beam Delivery Optics must be

in a safe position.

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 18 FS-S00149-Rev A

In the unlikely event that your laser requires service intervention, please contact your

local service office as stated below

SPI Service Contacts

29/06/2016

SPI Lasers UK Ltd

6 Wellington Park

Tollbar Way

Hedge End

Southampton

SO30 2QU

Tel: +44 (0)1489779696

Option 2

SPI Lasers LLC

4000 Burton Drive

Santa Clara

CA 95054

USA

Tel: +1 408 454 1170

SPI China Office

Room 108

Section B, Building No 3

No 7 Guiqing Road

Caohejing Hi-tech Park

Shanghai 200233

China

Tel: +86 (0) 21617 19474

E. Michael.Lu@spilasers.com

SPI Lasers Korea Ltd.

A-1201 DAEBANG

TRIPLAON Business Tower

1682 Jungsan-dong

Ilsandong-gu Goyang-si

Gyeonggi-do

Republic of Korea

Tel: +82 31 926 7580

E. Dae-Seung.M[email protected]

http://www.spilasers.com/our-locations/

Or Contact your Local Distributor/Integrator

Not to be distributed without prior consent of SPI Lasers UK Ltd.

Slide: 19 FS-S00149-Rev A

29/06/2016

Table of contents

Other SPI Lasers Control Unit manuals