Spillard VCAS 200 User manual

Live Vision Detect Control

Vehicle Collision

Avoidance System

VCAS 200 Manual

2 3

Vehicle Collision Avoidance System | VCAS 200 Manual wspillard.com . einf[email protected] . t +44 (0)1902 797930

Contents

Vehicle Collision Avoidance System (VCAS) 4 - 5

Detection zone blind spot comparison 5

Product overview 6

Parts list 7

VCAS limitations 7

Active detection zones 8

Incorrect installation and alignment 8

Instructions 9

The sensor 9

Installation 10

Sensor removal 11

Daily test procedure 12 -13

Disclaimers and warnings 15

VCAS 200 Manual

Last revision July 2020

Spillard Safety Systems, Optronics and their respective logos

are registered trademarks of Spillard Safety Systems Ltd.

The entire content of this manual is copyright 2020 Spillard

Safety Systems. All rights reserved.

=0.5m

Area of detection at 1m high

4 5

Vehicle Collision Avoidance System | VCAS 200 Manual wspillard.com . einf[email protected] . t +44 (0)1902 797930

VCAS 200 Three sensor warning system

An industrialised object detection system monitoring to a

maximum of 4 metres from any sensor at any one time. When

mounted on a vehicle in a predetermined conguration, a 4 metre

primary sensing zone can be achieved, providing eective visual

and audible warnings to the vehicle’s operator, alerting them of

immediate dangers.

nPowerful non-contact sonic sensing technology -

max range = 6 metres.

nSpeech alert, 85db tone sounder and high intensity

LED warnings.

n‘Always on’ transparent operation, eliminates

operator interaction.

nLow maintenance – protected against dust, humidity

and air turbulence.

Vehicle Collision

Avoidance System

Dash Display

nHigh intensity status lights

- Object detected

n Audible warning - speech alarm

- Caution Object Detected

nIP68 Waterproof

VCAS 200 - a vehicle safety enhancement system

that warns operators of immediate dangers within

a predetermined range. The system provides the

assurance of safety when a site dumper’s operation

commences, and cannot be turned o or ignored by

operators unfamiliar with its features.

Detection zone blind

spot comparison

12vDC

sensor

1

sensor

2

sensor

3

SPILLARD

safety system s

6Vehicle Collision Avoidance System | VCAS 200 Manual 7

wspillard.com .einf[email protected] . t +44 (0)1902 797930

VCAS limitations

VCAS is an aid to safety, and should be used in addition to your safe system of work.

n The operator should be aware of the benets and limitations of this system. The daily check

procedure must be followed to determine the operation state of the system before starting

their daily shift.

nAll sensors will not work if an obstruction is covering the sensing face e.g. mud or concrete.

n Sensors detect 4 metres in front of the vehicle. The area covered is dependent upon the

mounting position/angle of each sensor. Dead zones may be created due to sensing shape.

nThe response times from sensors and the operator are reduced when speed is increased.

nDamage to a sensor will start to deteriorate the sensing capabilities of the system.

nThe speaker will not be heard if obstructed or covered.

nAll faults or damage must be reported immediately.

Parts list

1 x VCB205- Display

3 x BVC307- Sensor Housing

+ VMS602Sensor

1 x VFY222 - Cable Assembly

1 x 24mm Grommet

2 x M6 x 15mm set screws

6 x M6 x 25 mm set screws

6 x M6 Nyloc Nuts

12 x M6 washers

1 x 2 amp auto fuse and holder

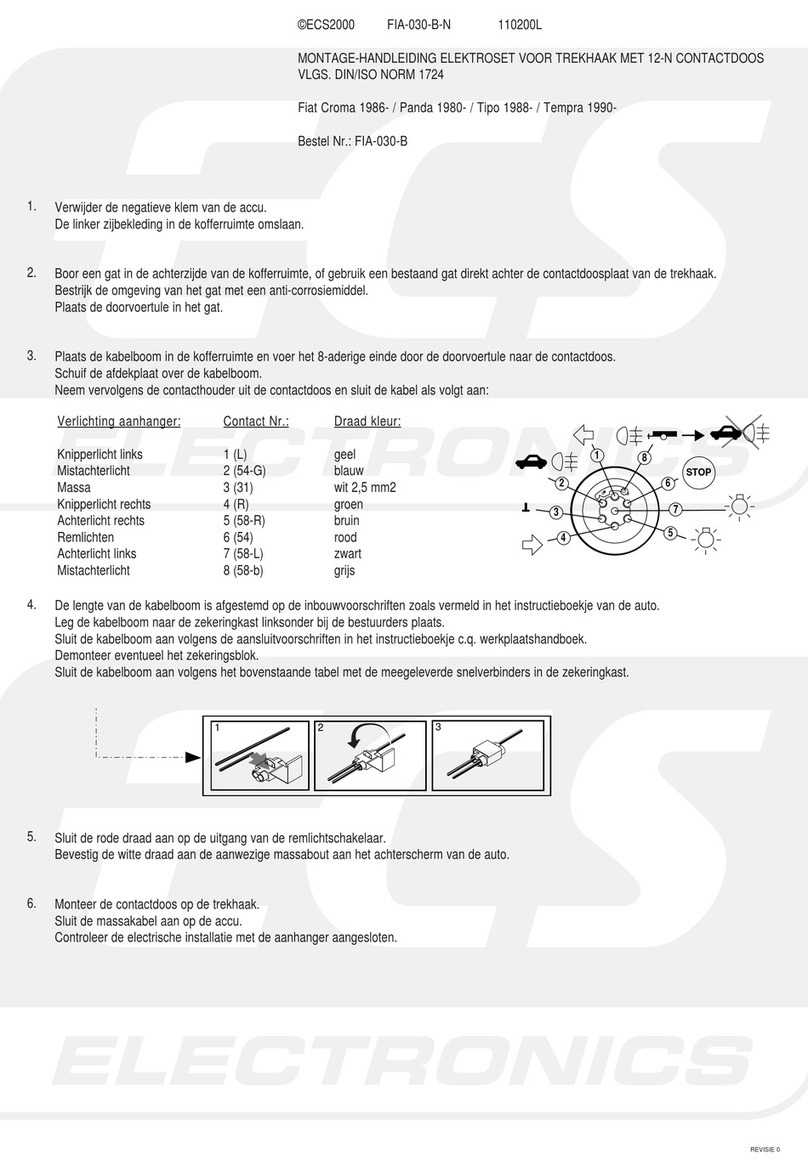

Smooth sloping surface Sound absorbing material

Smooth round object High/low objects

Product overview Parts & Limitations

8 9

Vehicle Collision Avoidance System | VCAS 200 Manual wspillard.com . einf[email protected] . t +44 (0)1902 797930

Active detection zones Instructions

Incorrect installation and alignment

High accuracy round bar Ø27mm

Low accuracy at plate 500mm x 500mm parallel with sensor

Display

The display must be mounted in front of the operator, facing

towards them. When detection is made, the red light on the display

will illuminate and “caution, object detected” will be sounded.

n Connect the main loom cable to the display and run the main

loom cable along the chassis to the front of the machine.

Connect the cables from the sensors to the 3 way block and

apply the heat shrink.

n Connect the power cable blue wire to a suitable earth and

brown positive wire to fuse holder, and then to an ignition

feed.

n Bolt the display to the top of the steering column/

dashboard.

The sensors

The sensors are pre-installed in a protective housing suitable

for your application.

“The display must be mounted in front

of the operator, facing towards them.”

Minimum 400mm800mm

4000mm

10 11

Vehicle Collision Avoidance System | VCAS 200 Manual wspillard.com . einf[email protected] . t +44 (0)1902 797930

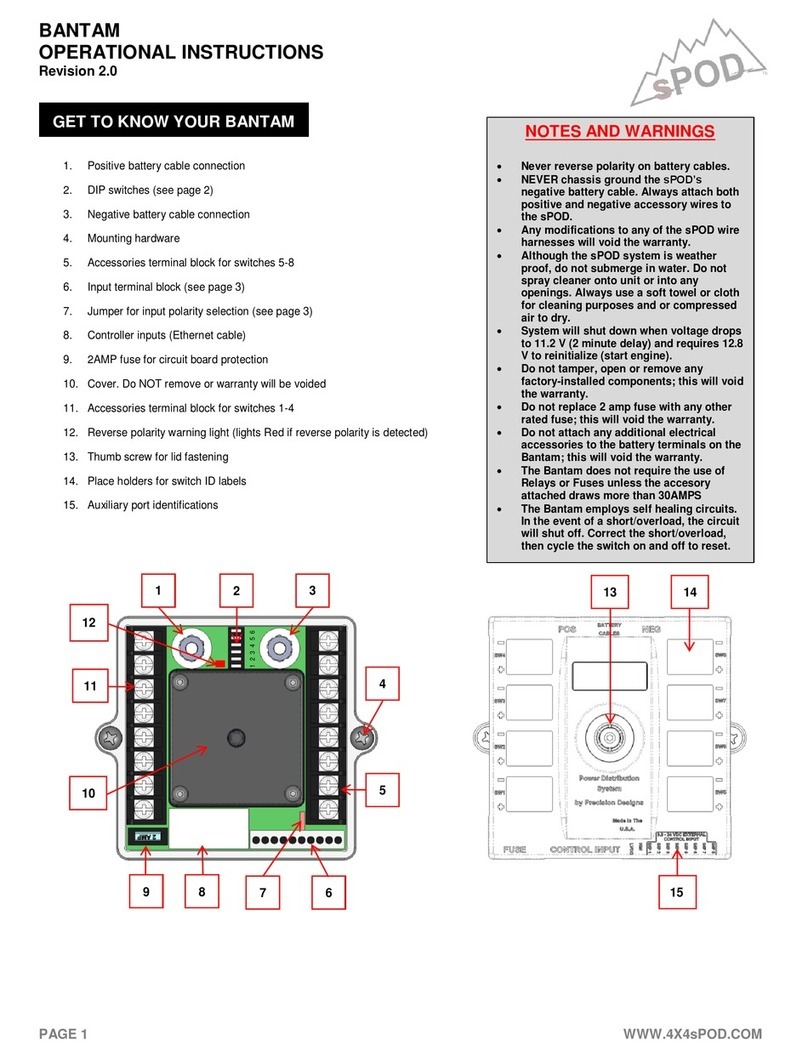

Installation

The 3 Sensors are to be mounted onto the front of the dumper at

even distances apart, to create a forward-facing detection zone.

The sensors are adjustable to ensure no detection is made with

raised iron works or objects wider than the machine.

Sensor removal

If the sensor is to be removed or replaced, to ensure the sensor is

mounted in the correct position within the housing, please follow

the image guidance below.

Mounting

Mount the hanging brackets to the chassis of the machine with the

centre of the brackets 800mm from ground level. (Fig.2)

nThe centre bracket must be mounted in the centre of the

vehicle and will only be adjusted on the vertical plane.

nThe outer brackets should be mounted as wide as possible.

Attach and adjust

Attach the sensor housing to the outer

bracket.

Adjust the top bolt for Left Right toe in to

stop detecting wider than the machine.

(fig.1) (fig.4)

Adjust the rear bolt to angle the sensor face

upwards slightly to detect approx 400mm

off the ground @ 4 metres (fig.3)

IMPORTANT

The sensor cable must only be nger tightened to the sensor and cable tied to the

bracket once looped back with a minimum bend radius of 25mm.

12 13

Vehicle Collision Avoidance System | VCAS 200 Manual wspillard.com . einf[email protected] . t +44 (0)1902 797930

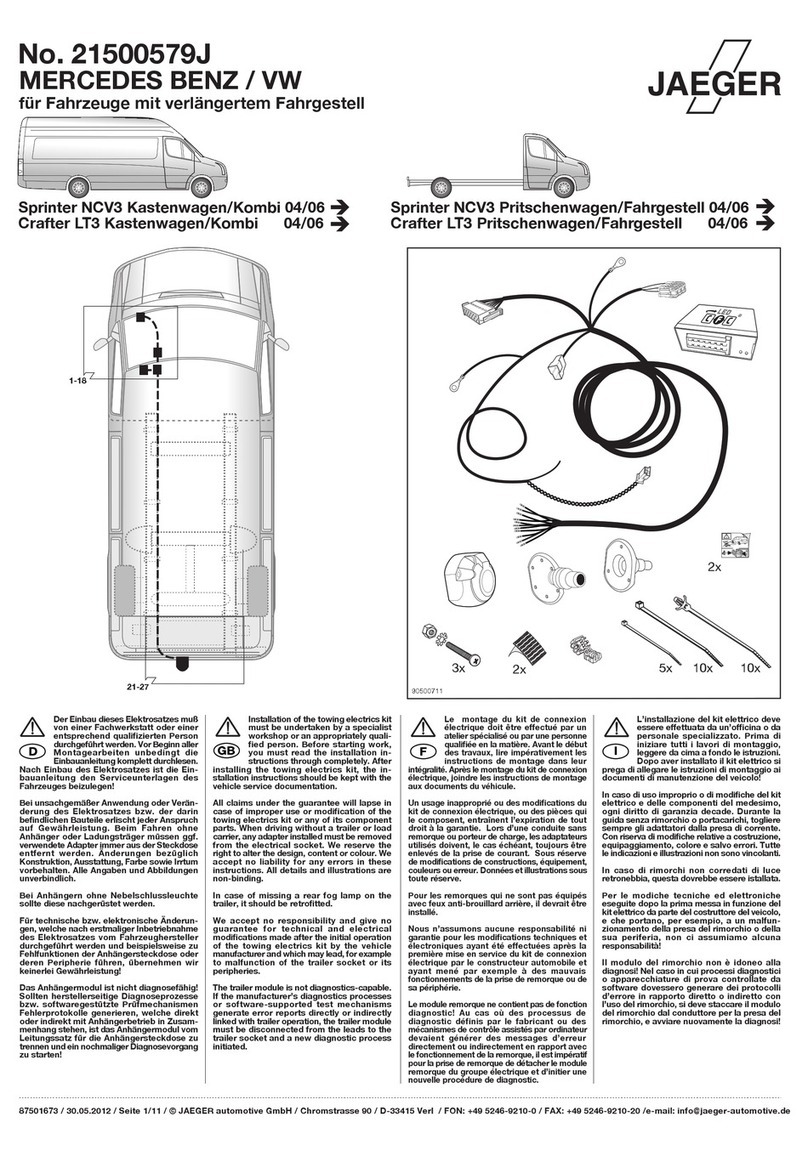

Daily test procedure

Dashboard

1. Place a cone or similar object at the position, approximately 2 metres away

from the front of the skip.

2. Turn the dump truck ignition on - DO NOT START.

3. Ensure the red light is illuminated and the speech alarm can be heard.

Sensors

Leaving the ignition on and NOT STARTED, remove the cone.

Standing at position 2, hold the test target in front of the rst sensor, then hold the

target in front of the second sensor. Repeat the steps standing in position 3, ensuring

there is an audible alert from all sensors.

2

2

3

1

2 3

1

m

Ensure there’s an

audible alert from

ALL SENSORS.

14 15

Vehicle Collision Avoidance System | VCAS 200 Manual wspillard.com . einf[email protected] . t +44 (0)1902 797930

Disclaimers and warnings

A smart construction site

is a safe construction site.

This manual contains important information required for the proper installation of the Spillard Safety

Systems equipment. Please read the manual thoroughly before installation and/or operation of the system.

Spillard Safety Systems cannot assume responsibility for the improper installation of the system.

Although Spillard Safety Systems exercises all reasonable eorts to ensure its products perform properly in

aftermarket and OEM applications, Spillard Safety Systems assumes no responsibility for deciencies in their

installation. It is the installer’s responsibility to consider and avoid possibly hazardous conditions that could result

from the installation of the system. It is the responsibility of the installer to carry out the installation in accordance

with recommended practices outlined in this manual. Spillard Safety Systems cannot assume responsibility for

installations that are performed by end customers or dealers.

Spillard Safety Systems cannot assume responsibility for either the training of operators or for their proper use of this

system. It is the responsibility of the end users to ensure all operators are fully trained regarding the proper use of

the system.

Avoidance of hazards

The suggestions provided in this guide regarding avoidance of

hazardous conditions apply to all applications and are necessarily of

general nature since only the installer is familiar with the details of

his/her installation. The suggestions provided in this guide should

be considered general examples only and are in no way intended

to cover every possible hazard in every installation.

Improper operation, maintenance or repair of this product can

be dangerous and could result in injury or death. Do not operate

or perform any maintenance or repair on this product, until you

have read and understood the operation, maintenance and repair

information.

Most accidents that involve product operation, maintenance

and repair are caused by failure to observe basic safety rules or

precautions. An accident can often be avoided by recognising

potentially hazardous situations before an accident occurs. A

person must be alert to potential hazards. This person should

also have the necessary training, skills and tools to perform these

functions properly.

NOTE:

Spillard Safety Systems cannot anticipate every possible

circumstance that might involve a potential hazard. The warnings in

this publication and on the product are, therefore, not all-inclusive.

If a tool, procedure, work method or operating technique that is not

specically recommended by Spillard Safety Systems is used, you

must satisfy yourself that it is safe for you and for others. You should

also ensure that the product will not be damaged or be made

unsafe by the operation, maintenance or repair procedures that you

choose.

The information, specications, and illustrations in this publication

are on the basis of information that was available at the time

that the publication was written. The specications, adjustments,

illustrations, and other items can change at any time. These

changes can aect the service that is given to the product.

Obtain the complete and most current information before you

start any job. Consult Spillard Safety Systems for the most current

information available.

When replacement parts are required for this product, Spillard

Safety Systems recommends using its own replacement parts or

parts with equivalent specications including, but not limited to,

physical dimensions, type, strength and material. Failure to heed

this warning can lead to premature failures, product damage,

personal injury or death.

Installation precautions

Spillard Safety Systems recommends the system should only be

installed by a competent person.

Spillard Safety Systems recommends the installer seeks advice

from the machine manufacturer before commencing installation,

specically in regard to all electrical connections.

Each system installation might have unique safety considerations

that may or may not relate to items addressed in this document.

Installers should use this and all other resources that may be

relevant to their particular application to determine whether all

reasonably foreseeable hazards have been adequately addressed.

The system should be installed in compliance with any applicable

standards for the application.

Spillard Safety Systems shall not be liable to the buyer for any loss

which may be suered by the buyer should the system fail. The

buyer’s attention is specically drawn to the limitations on liability

contained within clauses 6 and 7 within our Standard Terms and

Conditions of Sale. Copy available on request or at

www.spillard.com/terms

Applies to seat belt:

THE ROLL OVER PROTECTION STRUCTURE (ROPS)

MUST NOT BE DRILLED.

The lap belt should only be used in conjunction with the suggested

electronic buckle. Even if the belt may appear to lock into another

buckle, it may fail in the event of an incident.

Operational precautions*

The system is designed to supplement the machine’s safety during

its operation

*Prior to operating the machine, always conrm the system is operating correctly by using the daily test procedure provided.

Vehicle Collision

Avoidance System

Mining Public Transport Refuse Light GoodsHeavy GoodsConstruction

Mobile safety solutions

that increase awareness

and reduce incidents

Spillard Safety Systems Ltd, Solutions House, Station Road, Four Ashes, Wolverhampton, WV10 7DB

Table of contents