Hyundai H5699100 User manual

Universal Park Distance Aid System Installation Instructions issue 1.0 – 01/12/03

Park Distance Aid Part No. H5699100

Prior to installation carry out a pre installation inspection

check.

•Interior/Exterior condition

•Electrical ancillary equipment operation

•Battery disconnection prior to commencing the

installation and note any security codes.

•This system REQUIRES SET UP following

installation (See page 5)

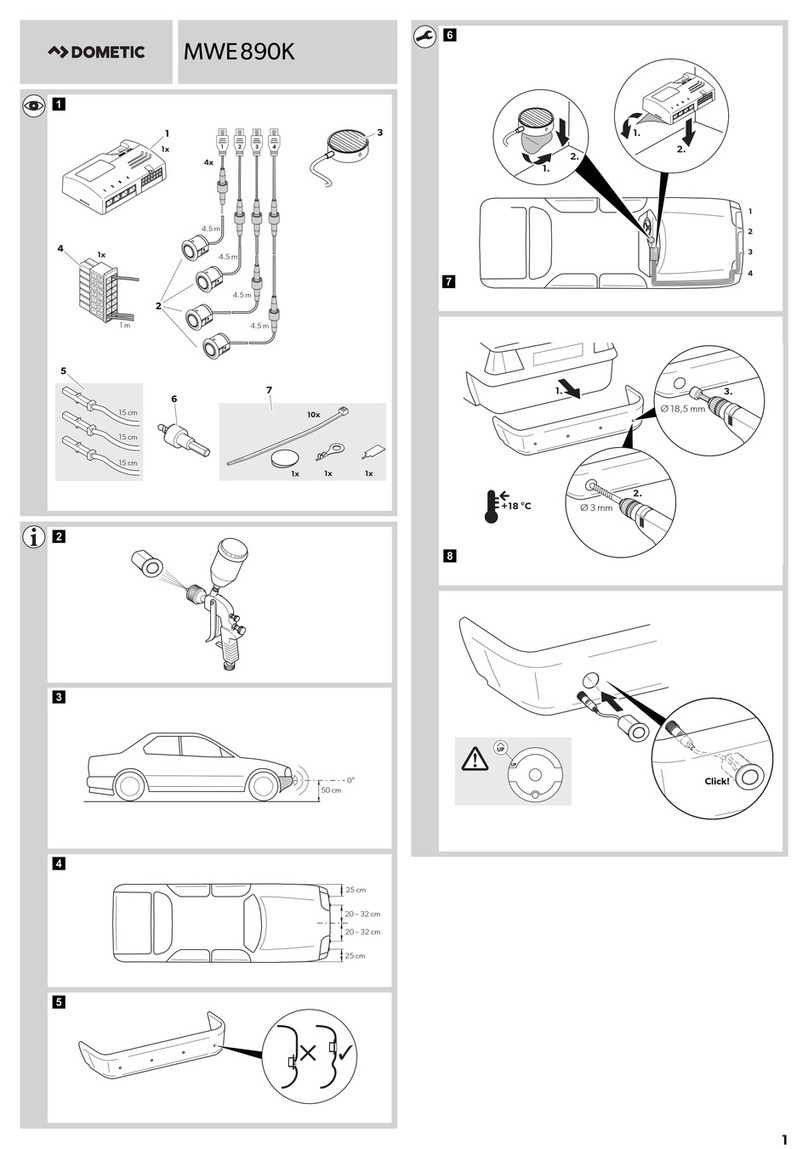

KIT CONTENTS

OPERATION

The PARK DISTANCE AID is activated automatically

when reverse gear is selected. The sensor eyes emit an

acoustic field around the rear of the vehicle. The system

then evaluates the waveforms and calculates the

distance from objects around the bumper area; these

signals are in turn converted instantly to an audible

beeper hidden within the vehicle.

Diagram 1.

•The system beeps once when an obstacle is

between 200cm & 120cm away, safety zone)

•A repeated beeping begins when an obstacle

is between 120cm & 30cm away and

increases in frequency as the obstacle

becomes closer Alert zone)

•A constant beep is emitted when the vehicle

enters the maximum alert zone) between

30cm & 0 from an obstacle.

KEY POINTS OF THE INSTALLATION

A. Prior to routing the sensor leads ensure the white

“identification collar tabs” around the sensor leads

are secured in position with insulation tape. This

will prevent the collars being trapped behind

grommets etc during routing. Each lead is

numbered and will require identification when

connecting to the numbered ports on the ECU.

B. NOTE: The two inner sensor leads 2 & 3) are 2

metres in length and the two outer sensor leads

1 & 4) are 2.5 metres in length.

C. The leads to each sensor eye must be run in

numerical order 1,2,3 & 4 across the bumper from

left to right.

D. Ensure that the small spot on the front of each

sensor eye is located at the top.

E. Do not apply tension to the leads during routing, as

this may result in disengagement and possible

damage to the sensor eye.

F. Should the sensor eyes require spraying to body

colour, please refer to the section “Spraying The

Sensor Eyes” at the rear of this manual.

G. Ensure that the holes drilled to accommodate the

sensor eyes are exactly 20mm Ø and there is at

least 23mm depth.

H. Following installation, carry out the “System Set up

Procedure” on Pg 5. NOTE: In the event the

system does not set up satisfactorily, reconnect the

two Blue wires from the ECU back together again

and carry out the system set up again. Ensure the

vehicle is parallel with the wall and 50cm away.

I. During System Set up, avoid walls with drainpipes

or other surface objects that may adversely

influence set up.

J. When deciding the mounting position of the ECU,

ensure it is within reach of the shortest sensor lead.

K. The set up procedure must be repeated if one of

the sensor eyes is replaced.

L. To avoid faulty operation, snow, ice, and dirt must

be cleaned from the sensor eye.

M. In certain circumstances, low or very thin obstacles

may not be detected. Also undulations in the

ground may give rise to sporadic detection

patterns.

N. For information concerning the minimum and

maximum distances permissible between sensors,

refer to diagrams 1 8

Document Part No: MKHYUUNI1203

1

NB. If it is not possible to maintain the dimensional protocol as shown in diagrams 1 – 7, contact the help-line on Pg 5

PARK DISTANCE AID – Universal Installation Manual

Universal Park Distance Aid System Installation Instructions issue 1.0 – 01/12/03

When installing on particularly wide vehicles do not

exceed the recommended maximum overall width of

1600mm from each outer sensor eye.

Diagram 1.

When installing on particularly narrow vehicles do not

go below the critical minimum overall width of 900mm

from each outer sensor eye.

Diagram 2.

Always observe the recommended (ideal) sensor

locations points as indicated in diagram 3A. Try to

maintain a straight horizontal line across the bumper.

Example

Diagram 3.

The sensors ideally should be mounted between

450mm & 550mm from the ground.

Diagram 4.

The outer sensors ideally should be mounted at least

150mm from the extreme edge of the vehicle.

Diagram 5.

If the sensor eyes require staggering due to mouldings

within the bumper or number plates, spare wheels etc,

do not exceed a 100mm drop or rise.

Diagram 6.

Should the inner sensor eyes require a wider width than

the outer sensor eyes due to number plates etc, do not

exceed a gap of 700mm between the 2 inner sensors

2 & 3. As a result of the wide inner width, try to maintain

a gap of (Ideally) of 300mm or up to 450mm between

sensors 1 &2 / 2 & 3

Document Part No: MKHYUUNI1203

2

550mm

450mm

100mm

1/8

1/4

1/4

1/4

1/8

1/2

1/2

150mm

300mm

Minimum

300mm

Minimum

700mm

Maximum

Maximum Overall Width

1600mm

Minimum Overall Width

900mm

194

388

388

388

194

776

776

1552mm

Overall Width

A

B

Universal Park Distance Aid System Installation Instructions issue 1.0 – 01/12/03

Diagram 7.

The coverage of the sensor is dependent on the height

and angle of the sensor from the ground. If the sensor

is pointing down or mounted to low on the bumper, the

system may suffer from “Ground Affect”, (Reflection

from undulations in the ground) or “Erratic Detection”.

Angled Spacer sleeve

Diagram 8.

GENERAL

Divide the total width of the vehicle as shown in

diagram 9.

Diagram 9.

These measurements are the optimum position for the

sensors. Observe the spacing measurements between

the sensors whenever possible, however sometimes

the contours and features of the of the bumper

moulding etc can dictate particular mounting points.

See Diagrams 1 8

Check for protrusions at the rear of the vehicle e.g. Tow

Bars, overhanging bumpers etc. If these items are in

the sensors 60o cone detection area the system will not

operate correctly, therefore allowances should be made

and the installation positions vary accordingly.

When determining the dimensional position of the

sensors, ensure the vehicle is at its normal ride height.

DRILLING THE HOLES

Ensure that there is at least 23mm depth directly behind

the sensor eye prior to drilling.

NOTE: Some vehicles have foam protection directly

behind the bumper, this foam can cause cone cut tools

to drift during drilling and elongate the hole. It is

recommended a 20mm Ø hole saw & arbor is used to

drill all holes.

Identify a panel that is flat and vertical to the ground at

the rear of the vehicle for the sensors to be mounted.

This position ideally should be no less than 450mm and

no higher than 550mm from the ground. (The vehicles

bumper is normally the ideal position).

Try to establish a flat surface for the sensor eyes as

excessive curves will separate from the sensor lip edge.

Apply the template stickers exactly in poison and

ensure that any lines drawn on the bumper are done so

using a marker that can be wiped away without trace.

Always take additional measurements from fixed

moulding points on the vehicles bumper and not items

such as number plates as the location may not be

symmetrical.

Should an inner skin or panel be directly behind the

mounting hole, caution should be taken prior to drilling.

If you are unsure of any aspect of the installation,

remove the bumper and investigate. Do not drill steel

reinforcement members.

When the position of each sensor is determined; Drill a

2mm Ø pilot hole through the bumper moulding at the 4

location points.

Open out the 4 holes to exactly 20mm Ø using a

holesaw & arbor see diagram 10. Alternatively a

stepped cutter may be used however, never use a

stepped cutter when drilling bumpers with foam support

to the rear as this will cause the stepped cutter to drift &

elongate the hole.

Document Part No: MKHYUUNI1203

3

Requires

Angled

Spacer

Standard Sensor eye.

From 0° – 5° maximum.

NOTE: as the angle

increases the mounting

height from the ground

must increase

retrospectively

15° Spacer sleeve must be

used on all sensors mounted

with 5° 15° angle.

NOTE: 15° maximum angle

550mm

1/8

1/4

1/4

1/4

1/8

1/2

1/2

Universal Park Distance Aid System Installation Instructions issue 1.0 – 01/12/03

Diagram 10.

Often, when using hole saws, it is possible to continue

to cut out any foam support directly behind the bumper

to accommodate the sensor eye, however, take care

not to cut any cable or any other obstacle that may be

in the way.

Using a small file cut a small keyway in the top of the

20mm Ø diameter hole to accommodate the locating tab

on the top rear of the sensor pod

Diagram 11

This will ensure the small spot at the top front of the

sensor eye is located at the top.

Remove any foam directly behind the sensor eye and

just under the rear of the sensor location so as to

accommodate the connector, which protrudes down

and away from the rear of the eye.

CONNECTING THE SENSOR EYE LEADS

Insert the numbered lead of each sensor through their

respective holes, numbered 1 – 4 (1=Outer Left,

4=Outer Right).

Connect the sensor leads to the rear of the sensors

eyes, ensure the connectors click into place, and fit the

rubber sealing boots.

Insert the sensor into the bumper, (it should locate in

position with a little pressure) and verify the rear

locating tab and front spot is at the top.

SENSOR CABLE ROUTE

NOTE: Each of the sensor leads have numbers on

small white identification tabs located around the sensor

collar, it is essential each lead are allocated the correct

location point in the Park Distance Aid ECU (See

Diagram 12.) Taping the identifying number tabs to the

lead will assist when routing the leads through.

Try to use an existing grommet such as the number

plate light grommet when routing the leads.

Secure the leads at regular intervals within the bumper

chamber using cable ties. Ensure a small coil of cable is

left within the bumper chamber in order to facilitate any

future removal of the bumper at a later date.

MOUNTING THE BUZZER

Mount the buzzer (using the adhesive pad provided) on

a flat horizontal surface if possible. Ensure the buzzer is

clearly audible to the driver when the engine is running.

Route the lead through to the main ECU and connect in

place. Cable tie any surplus wire in position.

NOTE: Heating the adhesive pad and corresponding

mounting panel with a hot air gun will increase the

adhesive bonding process.

ELECTRICAL CONNECTIONS

Diagram 12.

FIXING THE ECU BLACK GROUND WIRE

The Black Ground wire from the ECU is equipped with a

ground ring terminal. Try to utilize existing ground

points whenever possible or a nut or bolt on the bulk

panels.

Avoid using the mounting nuts & bolts holding the light

assemblies in place, these are often mounted through

Document Part No: MKHYUUNI1203

4

Cut a small

keyway with a

triangular file

20mm Ø

Blue Loop Wire

Set-Up

ECU

Buzzer

4xNumbered

Sensor Eye

Ports

Black Wire

Ground

4xSensor

Eyes

4xNumbered

Sensor Leads

Red Wire

Reverse

Light

Supply

Universal Park Distance Aid System Installation Instructions issue 1.0 – 01/12/03

rubber sleeves and consequently provide poor ground

points.

If no suitable ground point is available use the ground to

the rear light assembly.

FIXING THE ECU RED LIVE WIRE

Cut the Red wire from the ECU to length and splice in

place to the reversing light switched 12v positive. (Wire

that becomes live when reverse gear is selected)

located at the light assembly.

Splice/solder in position and protect the soldered joint.

NOTE: Use a metre or test light to verify the reverse

light switched positive is correct prior to connection.

MOUNTING THE ECU

Identify a mounting point inside the vehicles boot area

behind a panel, near the sensor leads entry point and

reverse light connection.

Mount in position (horizontally if possible) using the

adhesive pad provided.

SET-UP PROCEDURE

Confirm all electrical connections are correct prior to

reconnecting the battery terminal.

1. Position the rear bumper of the vehicle,

parallel, exactly 50cm from a wall.

2. Turn the ignition on and select reverse gear.

(Do not turn the engine over)

3. A DOUBLE TONE will be emitted followed

within 100 seconds (evaluation time) by a

single CONSTANT tone. N TE: If a single

intermittent tone is emitted at this point, (or no

tone at all) during the 100-second evaluation

time, the set-up has not been successful and

must be repeated. Refer to pages 6 “ ystem

set-up & fault diagnosis”

4. Following the constant tone, turn the ignition

off and cut the blue loop wire on the harness

going into the ECU.

5. The system is now “Set up”

Insulate the two cut ends of the blue loop wire and

secure to the harness.

CUSTOMER HANDOVER

Ensure a responsible member of staff fully explains the

operation of the Park Distance Aid System and provides

the customer with the user instructions.

SPRAYING THE SENSOR EYES OPTION)

The sensors inner transducer eye itself is made from

Aluminium (Pre Coated) while the outer sensor sleeve

ring is made from "PBT" / Valox material.

The plastic masking rings must be put over the central

silicon absorber before painting. The reason for this is

to prevent paint coating this part, as it would reduce the

vibration capability of the transducer itself.

Insert the 4 sensor eyes in the cardboard spraying try

provided, and place on a flat horizontal surface. Protect

the table or bench surface around the tray.

Insert the spacer rings provided securely in position.

It is important to apply the spray in even thin coats from

various angles approximately 300mm from the sensors.

Use more than one coat if required, applying too much

spray at one time will form ripples or gather to one

edge.

1. Apply an appropriate primer spray to each

sensor. And immediately REMOVE THE

MASKING RINGS. NOTE: If the masking rings

are removed when the paint is dry, it will

fracture the paint surface around the silicon

band.

2. Allow 20minitues to dry

3. Apply the paint following the details described

above, Remember to use thin even strokes

and more than one coat with an appropriate

drying period between coats.

4. Once again REMOVE THE MASKING RINGS

whilst the paint is still wet to prevent cracking.

5. Depending on the type of vehicle body paint, it

may be necessary to apply a lacquer to the

surface paint.

Document Part No: MKHYUUNI1203

5

Table of contents

Other Hyundai Automobile Electronic manuals

Popular Automobile Electronic manuals by other brands

DRG

DRG LC 120 installation instructions

Blue Ox

Blue Ox BX8848 installation instructions

Dometic

Dometic MAGICWATCH MWE890K Installation and operating manual

Honeywell

Honeywell Thor VM3A user guide

Waeco

Waeco MagicWatch MWE250 Installation and operating manual

GoldCruise

GoldCruise GC90Ci installation manual