ENGLISH

3. ELECTRIC PREPARATIONS

3.1. PEDESTRIAN ACCESS

If the Token Acceptor is used to control the opening of a

pedestrian access you need to remove the shutter from the

token acceptor:

Prepare a 2 x 1 mm² cable between the token acceptor and the

control unit of the gate or barrier.

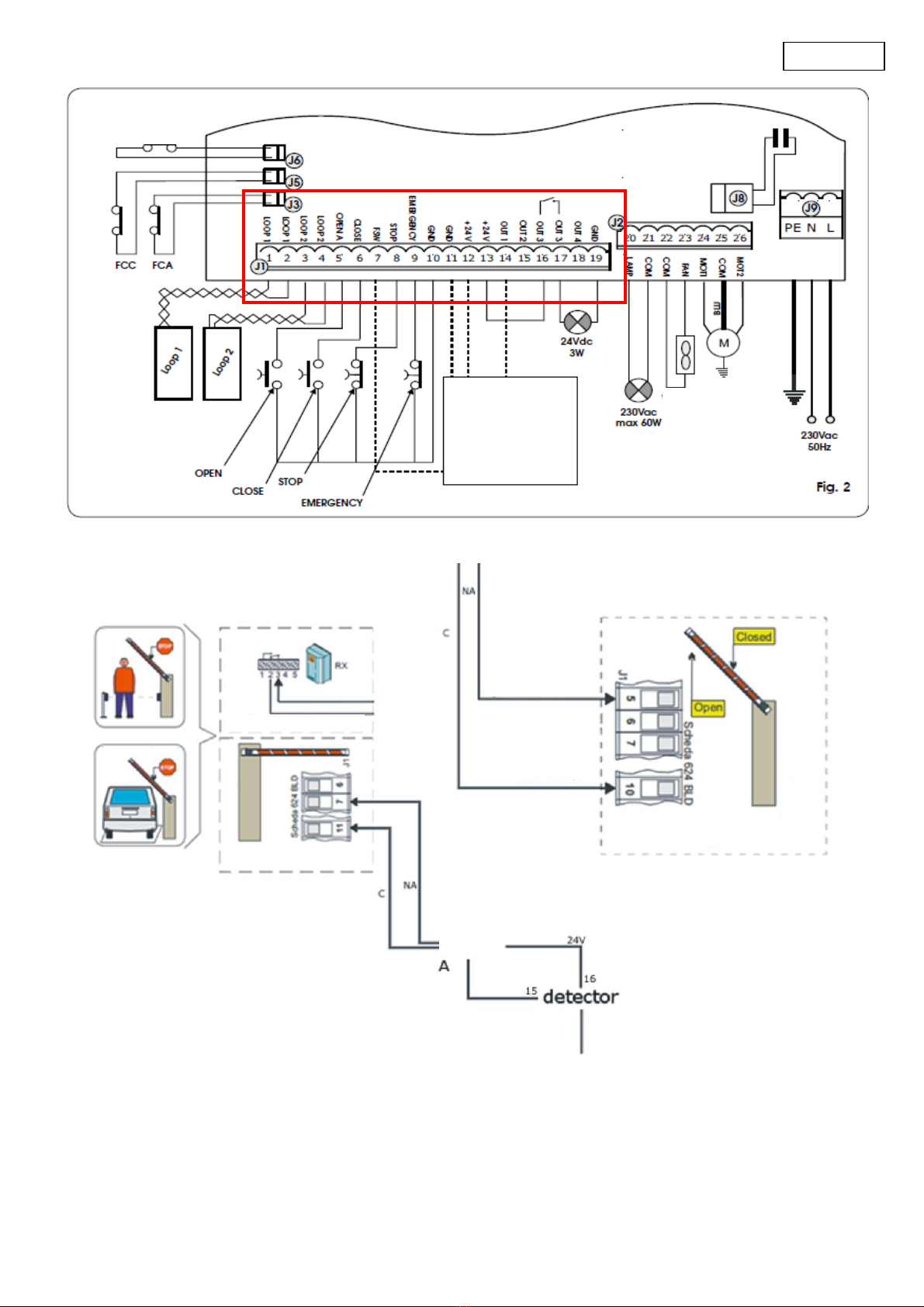

3.2. VEHICLE ACCESS IN LOGIC “A”

If you need to control the opening of a vehicle access only,

without having to control a beam closing contact, operate as

follows:

•add a Single-Channel Detector FG1 (to connect the use of

the Token Acceptor according to the presence of a

vehicle)

•realise a magnetic loop

•provide 24 Vdc –500 mA power supply

•perform the electric preparations as shown in fig.3

3.3. VEHICLE ACCESS IN LOGIC “P”

If the GRS-02 Token Acceptor is used to control a vehicle

access and simultaneously manage the beam closure, you

need to perform the following:

• add the Two-Channel Detector FG2 (to connect the use of

the Token Acceptor according to the presence of a vehicle

and control the beam closure)

• realise two magnetic loops

• provide 24 Vdc - 500 mA power supply

• perform the electric preparations as shown in fig.4

4. INSTALLATION

4.1. PRELIMINARY CHECKS

To ensure safety and an efficiently operating Token Acceptor,

make sure the following conditions are observed:

•The soil must permit sufficient stability of the foundation

plinth.

•There must be no pipes or electrical cables in the plinth

excavation and in the loop areas.

•If the Token Acceptor is exposed to passing vehicles,

install, if possible, adequate means of protections against

accidental impact.

•Check that an efficient earth socket is available for

connecting the housing of the Token Acceptor.

4.2. POSITIONING THE COMPONENTS

4.2.1. PEDESTRIAN ACCESS

Before placing the foundation plate of the GRS-02 Token

Acceptor, make sure the following conditions are observed:

•The Token Acceptor must be installed in such a way not to

expose the user to impact, crushing, dragging risks etc.

due to the movement of the gate or barrier.

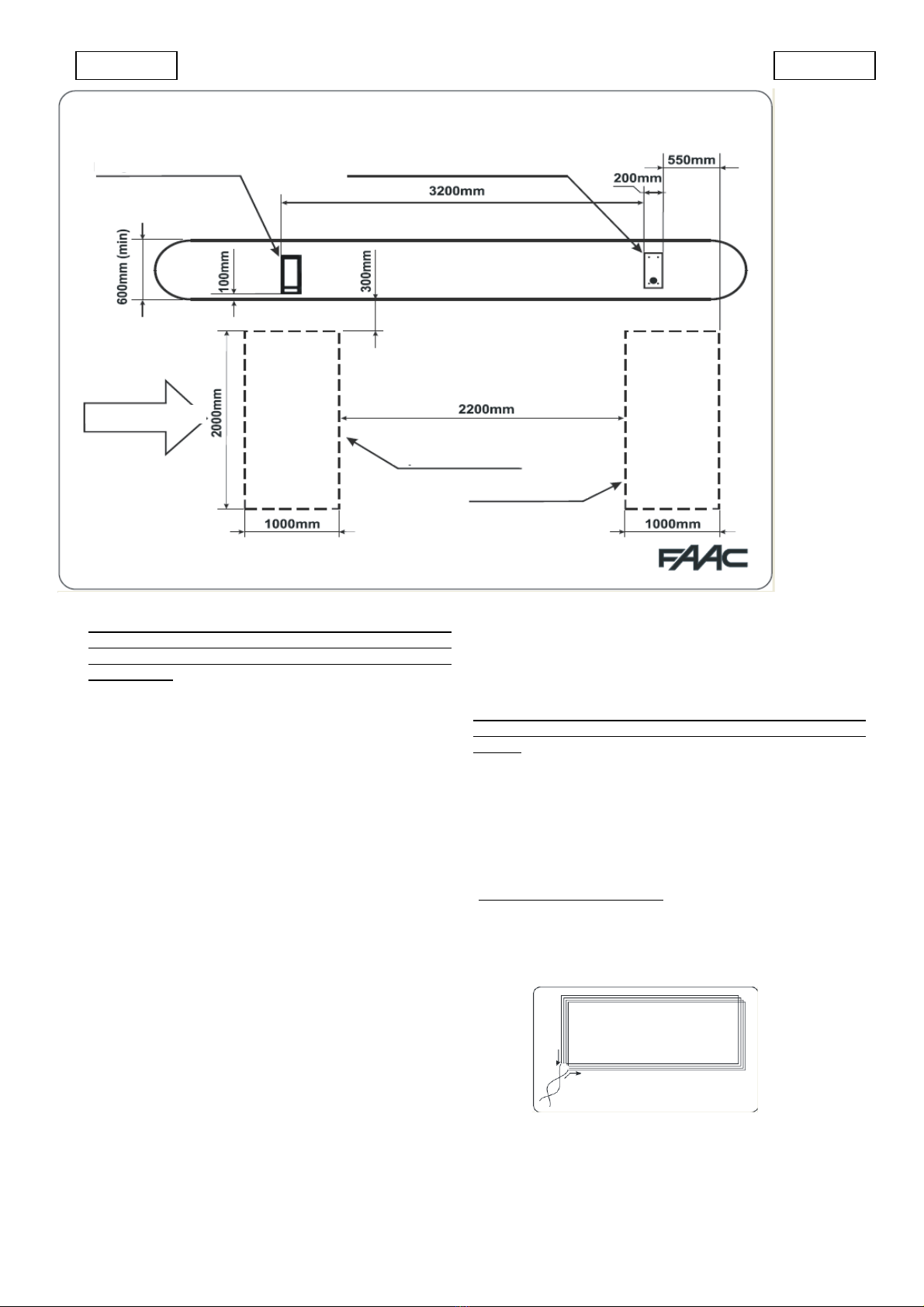

4.2.2. VEHICLE ACCESS

Before placing the foundation plate of the GRS-02 Token

Acceptor, make sure the following conditions are observed:

•The Token Acceptor must be installed in such a way not to

expose vehicles to impact, crushing, dragging risks etc.

due to the movement of the gate or barrier

•Place the Token Acceptor in such a way that the vehicles

coming from various directions can approach the Token

Acceptor enabling the driver to insert the token without any

difficulties.

•Realise the magnetic loop in correspondence with the

Token Acceptor (the loop must be engaged by the vehicle

when the window is in front of the token insertion slot). The

loop must be dimensioned according to the type of vehicle

to detect: observe the dimensions given in fig.5 for

vehicles and vans or the dimensions in fig.7 to detect

heavy vehicles. To realise the loop follow the instructions

in Chapters 4.3. and 4.4.1.

4

Token Acceptor GRS-02 + shutter

+ two-channel detector FG2

1 - Barrier 620

2 –Magnetic loop (see chpt. 4.3.)

3 -Miniservice power pack

To TD 620

1) Token Acceptor GRS-02 +

Single-Channel Detector

FG1

2) Access to control

3) Miniservice power pack

4) Magnetic loop (see chapter

4.3.)