Spinner II BN 754081 User manual

Coaxial Two Way Switch (DPDT)

BN 754081

RF Interface 7-16 Female

BN 754082

RF Interface 4.3-10 Female

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

2 / 18

Content

1.Basic Safety Instructions for SPINNER Broadcast Products...................................................................3

2.Intended use.............................................................................................................................................6

3.Improper use ............................................................................................................................................6

4.Function....................................................................................................................................................6

4.1Impulse solenoid drive .............................................................................................................................6

4.2Hypocycloid gear......................................................................................................................................6

4.3Bistable switching property (latching).......................................................................................................7

4.4Manual override........................................................................................................................................7

4.5Visual position indicator ...........................................................................................................................7

4.6Interlock / signal contacts.........................................................................................................................7

4.7Earthing terminal ......................................................................................................................................7

5.Data sheet ................................................................................................................................................8

6.Outline (all dimensions in millimeters)....................................................................................................11

7.Circuit diagram (B24140-CD, Issue D)...................................................................................................12

8.Storage...................................................................................................................................................13

9.Transportation ........................................................................................................................................13

10.Installation ..............................................................................................................................................13

10.1Mechanical installation ...........................................................................................................................14

10.2RF installation.........................................................................................................................................14

10.3Electrical installation...............................................................................................................................14

11.Commissioning.......................................................................................................................................15

12.Operation................................................................................................................................................15

13.Cleaning .................................................................................................................................................15

14.Maintenance...........................................................................................................................................16

15.Repairs ...................................................................................................................................................16

16.Warranty.................................................................................................................................................16

17.Demounting ............................................................................................................................................16

18.Disposal..................................................................................................................................................17

19.Additional endangering (regardless to life cycle) ...................................................................................17

20.Environmental friendly usage period......................................................................................................18

21.Spare parts.............................................................................................................................................18

22.Contacts .................................................................................................................................................18

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

3 / 18

1. Basic Safety Instructions for SPINNER Broadcast Products

The following instructions and safety instructions are to be carefully read and followed!

The Spinner group makes every effort to keep the safety standard of our products up to date to be able to offer our

customers the highest possible degree of safety. Our products are designed and tested in accordance with the relevant

safety standards. Compliance with these standards is continuously monitored by our quality assurance system. The

product described here has been designed and tested in accordance with the respective EU guidelines and has left the

manufacturer’s plant in a condition fully complying with safety standards. To maintain this condition and to ensure safe

operation, observe all instructions and warnings provided. If you have any questions regarding these safety instructions,

the Spinner group will be happy to answer them.

The operator is responsible for using the product in an appropriate manner. This product must not be used in any way that

may cause personal injury or property damage. The operator is responsible if the product is used for an intention other

than its designated purpose or in disregard of the manufacturer's instructions. The manufacturer shall assume no

responsibility for such use of the product.

The product is used for its designated purpose if it is used according to the specifications listed in the product’s

documentation within its performance limits (see data sheet, performance specifications, circuit diagram, the following

safety instructions).

Putting the product into operation requires special technical skills and must be executed by qualified personnel with

reference to “Start-up information” in the product documentation. Keep the basic safety instructions and the product

documentation in a safe place and pass them on to the subsequent users.

Symbols and safety markings

General hazard Warning!

Risk of

electric shock

Warning!

Hot surface

PE terminal Earthing

terminal

Warning!

High weight

Warning!

Non-ionised

electromagnetic

radiation

Pacemaker

hazard area

Use foot guard Use eye

protection

Use safety

gloves

Observe product

documentation

Observing the safety instructions will help prevent personal injury or damage of any kind caused by dangerous situations.

Therefore, carefully read through and adhere to the following safety instructions before putting the product into operation. It is also

absolutely essential to observe the additional safety instructions on personal safety that appear in relevant parts of the

product documentation.

Tags and their meaning

DANGER Indicates a hazardous situation conveying great risk which, if not avoided, will result in death or serious

injury.

WARNING Indicates a hazardous situation conveying moderate risk which, if not avoided, could result in death or

serious injury.

CAUTION Indicates a hazardous situation conveying minor risk which, if not avoided, may result in minor or moderate

injury.

ATTENTION Indicates the possibility of faulty operation that can damage the product.

These tags are in accordance with the standard definition for civil applications in the European Economic Area. Definitions

that deviate from the standard definition may also exist in other economic areas or military applications. It is therefore

essential to make sure that the tags described here are always used only in connection with the related product

documentation and the related product. The use of tags in connection with unrelated products or documentation can result

in misinterpretation and thus contribute to personal injury or material damage.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

4 / 18

1. These products must be operated only under the operating conditions specified in the product documentation. All

instructions for start-up, operation and servicing listed in the product documentation have to be observed.

2. Applicable local or national safety regulations and rules for the prevention of accidents must be observed in all

work performed. Only authorized and specially trained personnel shall work with these products.

3. Operating the products requires special training and intense concentration. Make sure that persons who use the

products are physically, mentally and emotionally fit enough to do so; otherwise, injuries or material damage may

occur. It is the responsibility of the employer/operator to select suitable personnel for operating the products.

4. The product must be installed and operated in operating sites with limited access only. Access for authorized

qualified personnel must be regulated by the operator.

5. Unless otherwise specified, these products are not protected against penetration of liquids, gases, steam, etc. If

this is not taken into account, there exists the danger of electric shock for the user or damage to the product, which

can also lead to personal injury.

6. Never use the product under conditions in which condensation has formed or can form in or on the product, unless

otherwise specified.

7. These products are not explosion protected. They must not be operated in explosion-prone areas.

8. Do not place the product on heat-generating devices such as radiators or fan heaters. The ambient temperature

must not exceed the maximum temperature specified in the product documentation. Product overheating can

cause electric shock, fire and/or serious personal injury or death.

9. Do not place the product on surfaces, vehicles, cabinets or tables that for reasons of weight or stability are

unsuitable for this purpose. Always follow the manufacturer's installation instructions when installing the product

and fastening it to objects or structures (e.g. walls and shelves). An installation that is not carried out as described

in the product documentation could result in personal injury or death.

10. The product may be very heavy. Therefore, the product must be handled with care. In some cases, the user may

require suitable lifting gear to avoid back or other physical injuries.

11. The user is responsible for safe transport, parking and storage of the product. When using auxiliary objects (e.g.

lifting gear, trolleys, shelves), the user has the duty to review their suitability prior to use. Transport and storage of

the product are permitted only in the manufacturer's original packaging.

12. Handles on the product are handling aids and intended solely for people. Therefore, it is not permitted to use the

handles for mounting on or at means of transportation, e.g. cranes, carts etc. Lifting lugs serve for transportation

or lifting with crane.

13. Mains driven products must be operated only from a power distribution system. The operator is responsible for

using an appropriate and sufficiently dimensioned AC power line. The AC power line must be externally fused

according to the product documentation.

14. Operation of products of safety class I is only permitted with sufficient "Protective Earth" connection. Connection

to "Protective Earth" must be done in the way provided and described in the product documentation. The operator

is responsible for inspecting PE continuity by a qualified professional.

15. All connectors on cables from and to the product must be connected firmly. The connectors shall not be dusty or

dirty. Otherwise, danger of fire and/or injuries can occur. Intentionally breaking the protective earth connection

either in the AC power line or in the product itself is not permitted. Doing so can result in the danger of an electric

shock from the product. If extension cables are used, they must be sufficiently dimensioned and checked on a

regular basis to ensure that they are safe to use.

16. Do not overload any sockets, extension cords or connector strips; doing so can cause fire or electric shocks.

17. Operation of the product with a damaged cable is not permitted. All cables must be checked on a regular basis to

ensure that they are in proper operating condition. By taking appropriate safety measures and carefully laying the

power cable, ensure that the cable cannot be damaged and that no one can be hurt by e.g. tripping over the cable

or suffering an electric shock.

18. If the product is equipped with an earthing terminal connection (equipotential connection), the earthing terminal

must be connected sufficiently dimensioned to earth.

19. If a product is to be permanently installed, the connection between the PE terminal on site and the product's PE

conductor must be made first before any other connection is made. The product may be installed and connected

only by a licensed electrician.

20. For permanently installed equipment without built-in fuses, circuit breakers or similar protective devices, the supply

circuit must be fused in such a way that anyone who has access to the product, as well as the product itself, is

adequately protected from injury or damage.

21. Use suitable overvoltage protection to ensure that no overvoltage (such as that caused by a bolt of lightning) can

reach the product. Otherwise, the person operating the product will be exposed to the danger of an electric shock.

22. Any object that is not designed to be placed in the openings of the housing must not be used for this purpose.

Doing so can cause short circuits inside the product and/or electric shocks, fire or injuries.

23. Dangerous voltage must not reach the product over the outer conductor / waveguide.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

5 / 18

24. All externally connected circuits for control, alarm and signalling must be supplied by SELV power sources (SELV

according to DIN EN 60950-1). The current in these circuits must be limited to the values specified in the product

documentation by means on an external fuse.

25. Before applying RF power to the product, it must be ensured that all connecting elements are professionally

connected and all unused ports are terminated. RF connections must have sufficient mechanical strength. If the

product features an interlock system, it must be connected and tested for function in advance.

26. Unless expressly permitted, never remove the cover or any part of the housing while the product is in operation.

Doing so will expose circuits and components and can lead to injuries, fire or damage to the product.

27. Repairs must be carried out by the manufacturer or technical personnel authorized by the manufacturer only.

28. As with all industrially manufactured goods, the use of substances that induce an allergic reaction (allergens) such

as nickel cannot be generally excluded. If you develop an allergic reaction (such as a skin rash, frequent sneezing,

red eyes or respiratory difficulties) when using a SPINNER product, consult a physician immediately to determine

the cause and to prevent health problems or stress.

29. Broadcasting systems or improper use of this product may produce an elevated level of electromagnetic radiation.

Considering that unborn babies require increased protection, pregnant women must be protected by appropriate

measures. Persons with pacemakers may also be exposed to risks from electromagnetic radiation. The

employer/operator must evaluate workplaces where there is a special risk of exposure to radiation and, if

necessary, take measures to avert the potential danger.

30. In the event of a fire, the product may release hazardous substances (gases, fluids, etc.) that can cause health

problems. Suitable measures must be taken, e.g. wearing of protective masks and protective clothing.

31. Products in operation may be hot. Touching them might cause burns.

32. If the product is pressurized, applicable local or national safety regulations for pressure equipment must be

observed.

33. Blocking of constructive openings on the product (ventilation slots, fine leaks etc.) must be prevented to ensure

safe operation.

34. Before cleaning, disconnect the product and all transmitters connected to the product from mains. Use a soft, but

not damp lint-free duster for cleaning. Do not use any chemical cleaning agents.

35. If handling the product releases hazardous substances or fuels that must be disposed of in a special way, e.g.

coolants that must be replenished regularly, the safety instructions of the manufacturer of the hazardous

substances and the applicable regional waste disposal regulations must be observed. Also observe the relevant

safety instructions in the product documentation. The improper disposal of hazardous substances can cause health

problems and lead to environmental damage.

36. The operator is responsible for disposing of the product according to national waste disposal regulations. Improper

disassembly or disposal may be hazardous.

37. SPINNER RF switches are not equipped with separating equipment for safe disconnection from mains. The user

must provide external separation equipment. The mains connector must be de-energized during plugging.

38. Do not actuate RF position Iand RF position II of RF switches simultaneously to avoid RF switch damage.

39. Do not touch or block the emergency manual override during electrical switch over to avoid injuries and switch

damage.

40. Disconnect RF switches from mains before using the emergency manual override of the drive unit to avoid injuries

and switch damage. The emergency manual override serves solely for switching the RF switch manually in a dead

state.

41. Switch over RF switches only without applying RF power to avoid injuries and damage. Hot switching with RF on

is not permitted. Ensure all switches are in the respective end position before applying RF power.

42. Switch off RF power before disconnecting RF connectors to avoid burns, eye injuries and electric shock. Utilize

appropriate devices and methods to prevent accidental energizing.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

6 / 18

2. Intended use

The intended use of the product is switching over (Double Pole Double Through or Single Pole Double

Through) between two coaxial paths of an RF system in indoor applications on operating sites with

limited access. Details and other limits are given in the data sheet of this manual.

The product may only be operated within the specifications given in the data

sheet of this manual. Failure to observe could result in death or serious injury.

3. Improper use

The product is not intended for any other purpose than indicated above.

Do not use

in explosion-prone atmosphere

on operating sites with unlimited access

in outdoor applications

to support mechanical loads

with modifications not authorized by SPINNER

in damaged condition

without correctly connected interlock system

in conditions and environments beyond the specifications given in the data sheet of this manual

interlock loop for safety-related purpose

If the RF switch is not used as intended, safe operation of this product cannot be guaranteed. The user

is responsible for all personal injury and property damage resulting from improper use. Reading the

manual as well as adhering to all the information provided – particularly the safety instructions - is

considered mandatory to comply with the intended use.

4. Function

4.1 Impulse solenoid drive

Switches with impulse solenoid drive generate the torque for the rotor with a rotating permanent

magnet located in a stationary coil. The drive system has two stable switching positions and is locked

in both end positions (latching). Therefore a pulse is sufficient as a control signal (e.g. after switching

no voltage is required). In the event of power failure, or after restarting the system, the last switch

position is retained.

4.2 Hypocycloid gear

The drive and the basic switch element (rotor) are connected by a special gear which has been

developed by SPINNER. With the hypocycloidic gear it is achieved that the torsional moment and

angular velocity changes within the range of rotation.

In the beginning of the changeover procedure there is a high torsional moment whereas the angular

velocity of the rotating breaker is very low. With an increasing angle of revolution the angular velocity

will increase as well while the torsional moment will decrease. On the mid-position of the rotating

breaker this behavior will reverse and the angular velocity is decreasing while the torsional moment

increases.

The drive system is mechanically locked in both end positions.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

7 / 18

4.3 Bistable switching property (latching)

The RF switches show a bistable switching behaviour. Switching takes place from one stable state

into another after applying the control voltage. For this reason, an impulse control signal is sufficient.

The minimum impulse length has to correspond to the maximum switching time (see data sheet of this

manual). After completion of the switching process, the control voltage is no longer necessary. If the

switch is in an end position and the operating voltage fails, the switch remains in the end position. This

also applies to resetting.

The RF switch remains in an undefined switching state, if the operating voltage fails during the

switching process. After reapplying the operating voltage, the RF switch continues the switching

process until it reaches the originally demanded end position.

4.4 Manual override

The switch position can be selected by the user manually with the manual override. The RF switch is

mechanically interlocked in the end position.

4.5 Visual position indicator

The RF switch features a visual position indicator on the drive unit (top side). The position indicators

signal switched RF paths in the respective switch end positions.

4.6 Interlock / signal contacts

WARNING Do not use the interlock loop for personal protection.

ATTENTION Switch off all transmitters before actuating the RF switch.

Do not use the interlock loop for operational switch-off of the transmitters.

Connect all transmitters to the interlock loop to avoid RF switch damage.

Hot switching is not permitted.

Only the interlock contacts open before and close after switching of the RF contacts. Therefore the

signal contacts cannot be used for interlock purposes!

The interlock and signal contacts comply with the requirements for SELV (DIN EN 60950-1).

The maximum permissible voltage is 42.4 V ACpk / 60 V DC. This applies to the loop voltage and the

voltage between signal or interlock contacts and to the earthed casing.

The circuit must be externally limited to 0.5 A.

4.7 Earthing terminal

To ensure equipotential bonding with other plant components, connect the marked earthing terminal

to the main earthing busbar with a copper lead (min 6 mm²).

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

8 / 18

5. Data sheet

Radio frequency characteristics

Interface type (4 connections) BN 754081: 7-16-f (50 Ω)

BN 754082: 4.3-10-f (50 Ω)

Characteristic impedance 50 Ω

Frequency range 690 MHz to 2.69 GHz 3.4 to 3.8 GHz

Return loss, min. 20 dB 20 dB

Isolation, min. 55 dB 50 dB

Insertion loss, max. 0.1 dB 0.1 dB

Average power capability *

at ambient temperature -10 to +45°C

300 W

supports hot switching

Peak voltage capability * 1.0 kV

Intermodulation (IM3)

at 2x 20 W, max. / typ. -165 dBc / -168 dBc

Electrical and mechanical data

Switch type Two way switch, DPDT

Actuator type Solenoid drive, latching, self cutoff

Connector J1 **

for operating voltage, control,

interlock contacts and signaling

25 pole connector according to DIN 41652 / IEC 807-2

Operating

Operating voltage 21.6 to 28 V DC

Operating current, typ. *** 1.1 A

Stand by current, max. *** 25 mA

Nominal fuse The switch must be externally fused by time-delay, 2 A

Control

Control voltage U In LOW = 0 to 4 V DC / -0.7 mA ( 0 - active )

U In HIGH = 8 to 32 V DC

Nominal fuse The circuit must be externally limited to 0.5 A

Interlock contacts

Signal contacts

Lead time typ.***

(only interlock contacts)

5 ms (the interlock contacts open 5 ms before and

close 2 ms after switching of the RF contacts)

Maximum ratings SELV circuits according to IEC EN 60950-1, 42.4 V ACpk / 60 V DC / 0.5 A

Nominal fuse The circuit must be externally limited to 0.5 A

Switching time, typ.*** 100 ms

Command hold time, min. 100 ms (during this time, the voltage at control input must not change)

Switching frequency, max. 30 operations per minute

Life, min. 500,000 operations

Weight, approx. 1.75 kg

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

9 / 18

Environmental conditions

Operational conditions ETSI EN 300 019-1-3 V2.3.2 (2009-1) class 3.1 N

Ambient temperature **** -10 to +60°C

Condensation Not allowed

Relative humidity, max. 95%

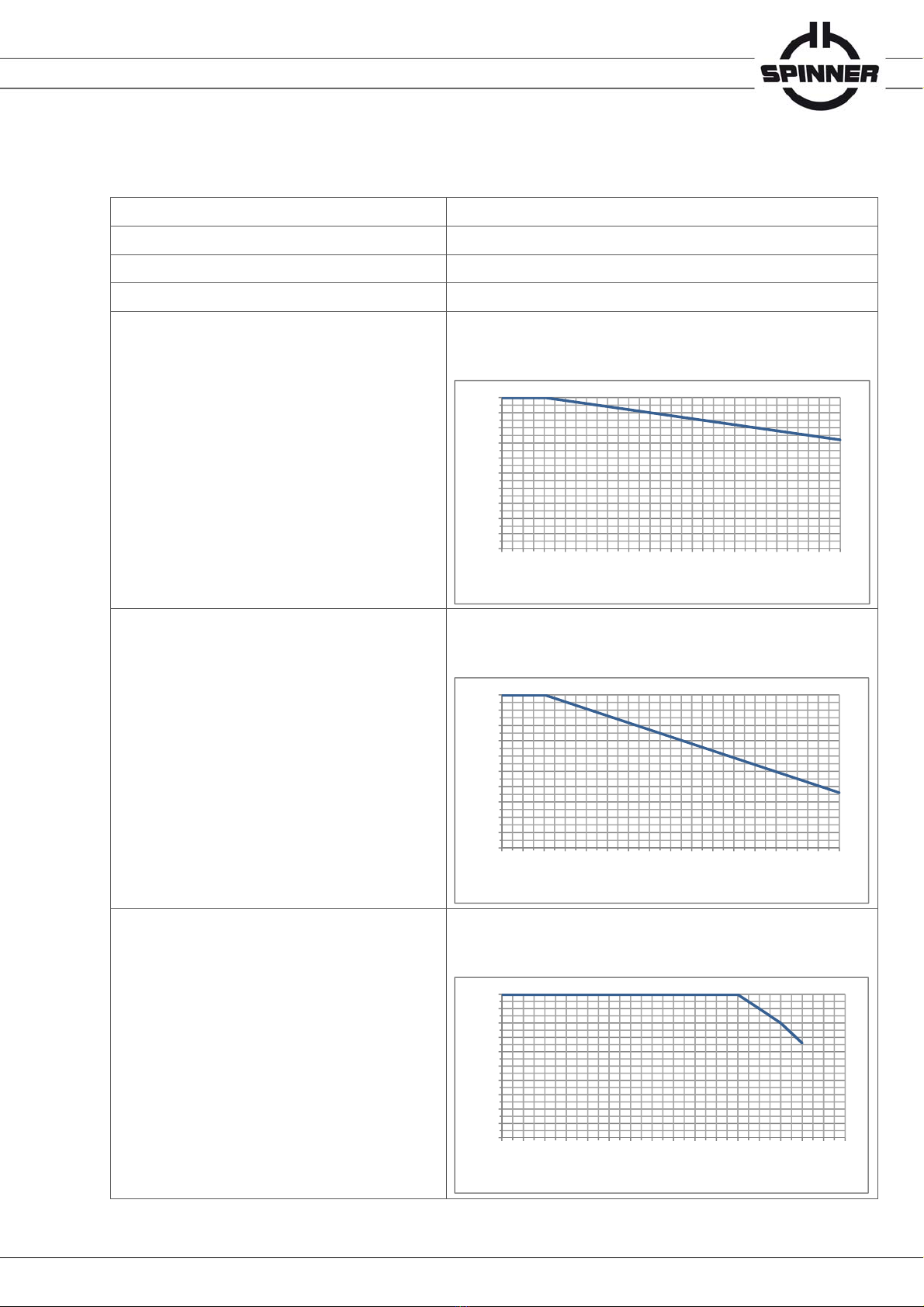

Derating of input power with increasing altitude

The maximum input power can be applied up to 500 m or 1600 ft above

sea level unless noted otherwise in the data sheet.

Above this height the maximum input power must be reduced as shown in

the diagram.

Derating of voltage with increasing altitude

The maximum voltage can be applied up to 500 m or 1600 ft above sea

level unless noted otherwise in the data sheet.

Above this height the maximum input power must be reduced as shown in

the diagram.

Derating of input power with increasing ambient

temperature

The maximum input power can be applied up to +45°C ambient

temperature unless noted otherwise in the data sheet.

Above this ambient temperature the maximum input power must be

reduced as shown in the diagram.

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

0 500 1000 1500 2000 2500 3000 3500 4000

Altitude above sea level [m]

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

0 500 1000 1500 2000 2500 3000 3500 4000

Altitude above sea level [m]

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

-10 0 10 20 30 40 50 60 70

Ambient temperature [°C]

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

10 / 18

Max. altitude above sea level 4,000 m or 13,120 ft according to IEC EN 60664-1

Protection class III according to IEC EN 61140

IP protection level IP40 according to IEC EN 60529

(all interfaces equipped with appropriate gaskets)

Installation position Any

Transport conditions ETSI EN 300 019-1-2 V2.1.4 (2003-04) class 2.2

Ambient temperature -25 to +70°C

Rain, condensation, icing Not allowed

Storage conditions ETSI EN 300 019-1-1 V2.1.4 (2003-04) class 1.2

Ambient temperature -10 to +60°C

Rain, condensation, icing Not allowed

* Standard conditions:

Dielectric: Dry air under standard pressure at sea level (p = 1013 hPa)

Load VSWR, max. 1.0 (no standing wave)

No modulation, sinusoidal carrier only

** Suitable mating connector included

*** At room temperature and nominal voltage 24 V DC

**** Extended temperature range on request

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

11 / 18

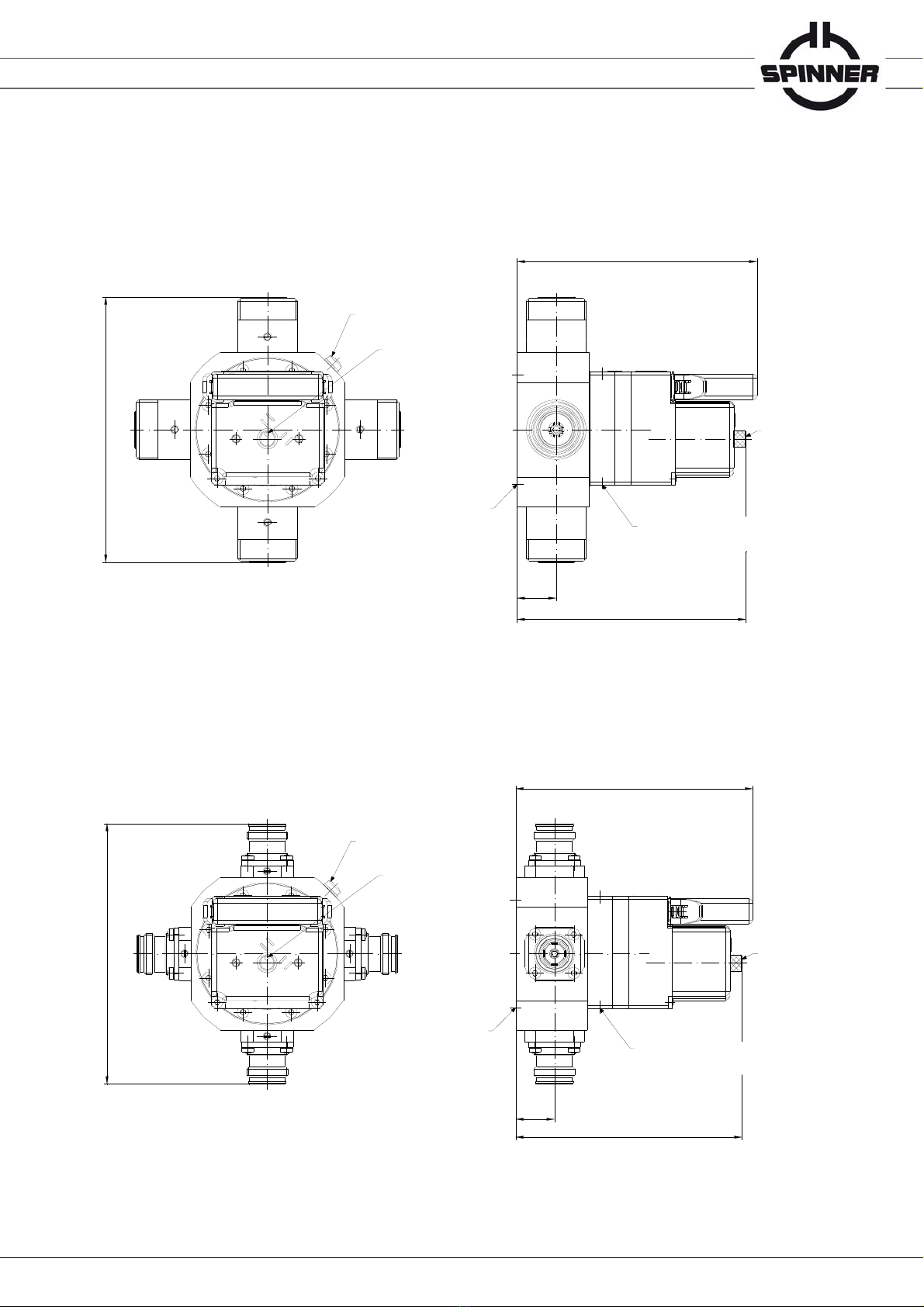

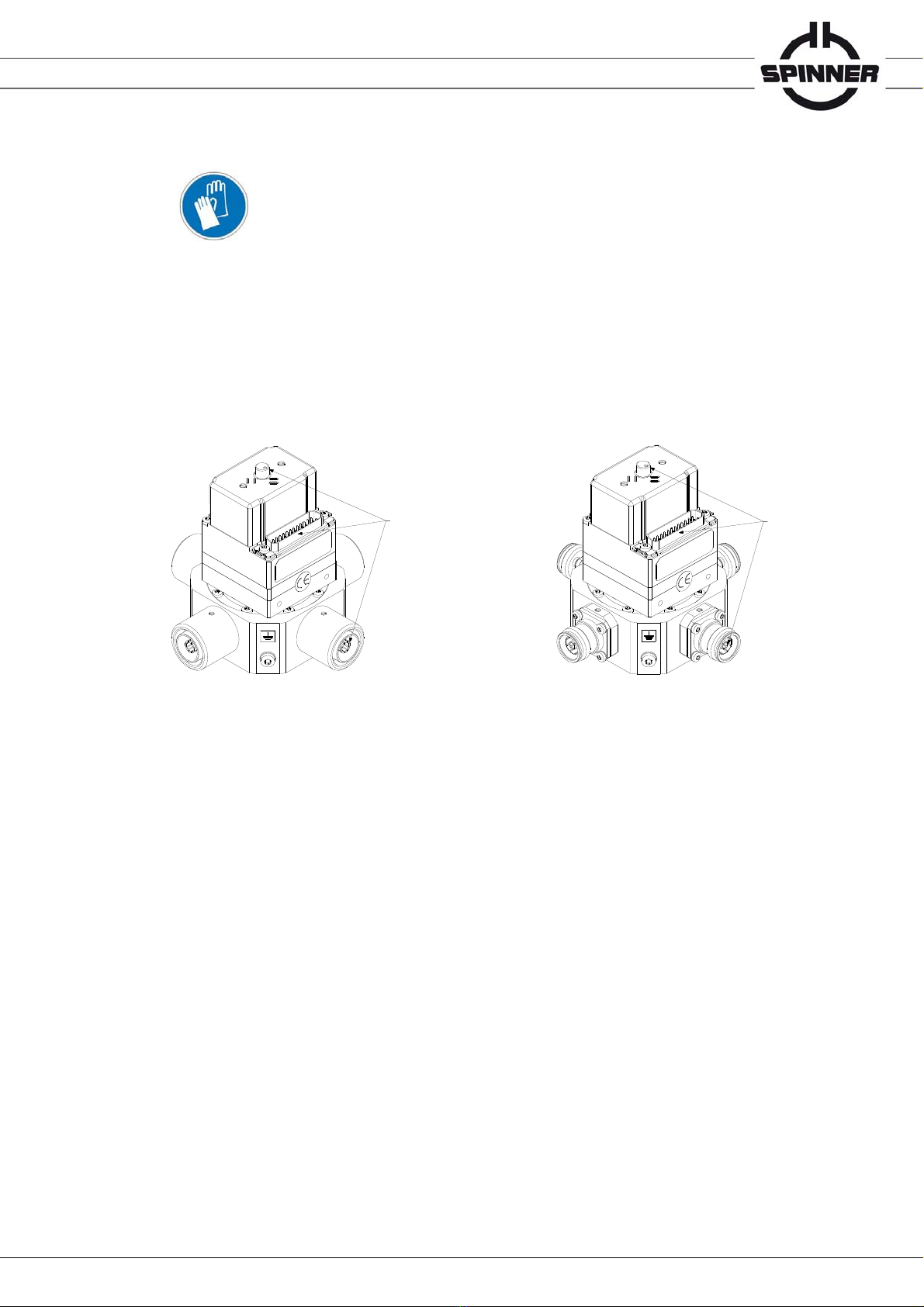

6. Outline (all dimensions in millimeters)

BN 754081:

BN 754082:

(+10 mm to disconnect the connector)

1

2

3

4

RF connection

RF position I: 1-2 / 3-4

RF position II: 1-4 / 2-3

Position indication

128,8±0,5

116,34

111±2

19

Threaded mounting holes

2x M4 / 6 deep on both sides

Ground connection

M4

Manual operation

Threaded mounting holes

4x M4 / 6 deep on Ø75

111

±2

RF connection

RF position I: 1-2 / 3-4

RF position II: 1-4 / 2-3

3

2

1

4

Position indication

Ground connection

M4

Threaded mounting holes

4x M4 / 6 deep on Ø75 Threaded mounting holes

2x M4 / 6 deep on both sides

Manual operation

(+10 mm to disconnect the connector)

116,34

19

128

±0,5

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

12 / 18

7. Circuit diagram (B24140-CD, Issue D)

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

13 / 18

8. Storage

Keep dry and avoid exposure to sudden temperature changes to prevent condensation. Environmental

conditions for storage are specified in the data sheet of this manual. Do not unpack until immediately

prior to installation.

ATTENTION Do not remove any connector transportation locks until immediately prior to assembly

to avoid damage.

9. Transportation

Before you start, ensure to read and understand the attached Basic Safety

Instructions and the additional safety instructions on personal safety that appea

r

in relevant parts of this manual.

WARNING

Crushing Hazard

Falling objects may cause death and serious injury.

Use suitable lifting gear and means of transportation.

Secure the cardboard against tipping or falling.

Do not stand below the RF switch.

Safety shoes are required.

CAUTION

Sharp Edges

Sharp edges may cause cuts and needle stick injuries.

Use safety gloves and handle carefully.

10. Installation

Before you start, ensure to read and understand the Basic Safety Instructions and

the additional safety instructions on personal safety that appear in relevant parts of

this manual. Failure to observe could result in death or serious injury. Only trained

electricians should install SPINNER RF switches in accordance with applicable

national and international safety rules and regulations.

WARNING

Radio Frequency Hazard

Radio Frequency Power can cause burns, eye injuries and electric shock.

Before you start, ensure to disconnect your entire system from the power supply.

Utilize appropriate devices and methods to prevent accidental energizing.

WARNING

Crushing Hazard

Falling objects may cause death and serious injury.

Secure the RF switch against tipping or falling until it is securely bolted to the

mounting rack. Safety shoes are required. If it is necessary to stand below the RF

switch during installation, safety shoes and hardhat are required.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

14 / 18

CAUTION

Sharp Edges

Sharp edges may cause cuts and needle stick injuries.

Use safety gloves and handle carefully.

A

TTENTION The supplied packaging and all protection caps are reusable and required for

transportation. Do not damage or dispose of the packaging.

10.1 Mechanical installation

Install the RF switch in indoor applications on operating sites with limited access only. Do not stress

the connectors and the manual override.

Use the fastening threads on the bottom or the lateral fastening threads to bolt the switch securely to

the mounting rack. Do not clamp the RF switch on the casing. Use a torque wrench to tighten the

bolted connections to 1.2 Nm (bolt material A2-50) / 2.5 Nm (bolt material A2-70).

10.2 RF installation

Remove the protection caps.

Align the system connectors carefully with the RF switch to avoid scratches on the contacts.

Remove any dirt or metallic particles on contact surfaces before connecting.

Ensure sufficient strength of all RF connections.

BN 754081 (RF connection 7-16): Torque all connections to 30 Nm.

BN 754082 (RF connection 4.3-10): Torque all connections to 5 Nm.

Unused ports must be terminated.

Relieve all RF connections from any bending torque, e.g. caused by heavy cables or assemblies.

Avoid sharp bends and tensile load.

10.3 Electrical installation

WARNING Do not use the interlock loop for personal protection.

ATTENTION Do not use the interlock loop for operational switch-off of the transmitters. Connect

all transmitters to the interlock loop to avoid RF switch damage. Hot switching is not

permitted.

do not stress

do not stress

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

15 / 18

Follow the circuit diagram given in this manual and use the supplied connector only to connect

interlock, signal, control and operating voltage.

The interlock and signal contacts comply with the requirements for SELV (DIN EN 60950-1).

The maximum permissible voltage is 42.4 V ACpk / 60 V DC. This applies to the loop voltage and

the voltage between signal or interlock contacts and to the earthed casing. Limit the circuits

externally by means of fuses to 0.5 A.

To ensure equipotential bonding with other plant components, connect the marked earthing

terminal to the main earthing busbar with a copper lead (min 6 mm²).

Use a suitable and amply dimensioned power cord (min AWG 24, max AWG 20) and the supplied

25 pole connector BN 122886 for the electrical connecting. Limit the operating current by means of

an external fuse (time-delay, 2 A).

Relieve all connections to the RF switch from any bending torque, e.g. caused by heavy cables or

assemblies. Avoid sharp bends and tensile load.

11. Commissioning

Before you start, ensure to read and understand the Basic Safety Instructions and

the additional safety instructions on personal safety that appear in relevant parts of

this manual. Failure to observe could result in death or serious injury. Only trained

electricians should commission SPINNER RF switches.

WARNING

Radio Frequency Hazard

Radio Frequency Power can cause burns, eye injuries and electric shock.

Check sufficient strength of all RF connections prior to commissioning.

Unused ports must be terminated. Check proper functioning of the interlock loop

prior to commissioning.

12. Operation

CAUTION

Hot surface

The RF switch heats up during normal operation. Touching it may cause burns.

Do not touch the RF switch while hot. Wait until completely cooled off.

The operator must control the access to the hazardous area.

A

TTENTION Switch off all transmitters before actuating the RF switch to avoid RF switch damage.

Hot switching is not permitted.

A

TTENTION Do not block the manual override during electrical switching to avoid overheating and

RF switch damage.

A

TTENTION Do not place any heat-generating devices such as radiators or fan heaters near to the

RF switch to avoid overheating and RF switch damage.

13. Cleaning

Periodic cleaning of the mounted RF switch is not required. Use a soft, but not damp duster, if cleaning

of the demounted RF switch is required. Do not use compressed air.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

16 / 18

CAUTION

Hot surface

The RF switch heats up during normal operation. Touching it may cause burns.

Do not touch the RF switch while hot. Wait until completely cooled off.

The operator must control the access to the hazardous area.

A

TTENTION Do not use any cleaning fluid to avoid the risk of serious injury at re-commissioning.

14. Maintenance

Periodic maintenance is not required. Carry out at least one switching cycle annually to avoid jamming.

If the switch was not actuated for a period longer than one year (e.g. storage) carry out several

switching cycles before applying RF power.

15. Repairs

Repairs may only be executed by the manufacturer or technical personnel authorized by the

manufacturer.

CAUTION

Hot surface

The RF switch heats up during normal operation. Touching it may cause burns.

Do not touch the RF switch while hot. Wait until completely cooled off.

Do not open the RF switch to avoid the risk of high-frequency radiation and serious

injury.

16. Warranty

Do not disassemble the RF switch. The warranty is void, if the RF switch is modified, improperly

handled or third party intervention or modification has occurred.

17. Demounting

Before you start, ensure to read and understand the Basic Safety Instructions and

the additional safety instructions on personal safety that appear in relevant parts of

this manual. Failure to observe could result in death or serious injury. Only trained

electricians should demount SPINNER RF switches.

WARNING

Radio Frequency Hazard

Radio Frequency Power can cause burns, eye injuries and electric shock.

Before you start, ensure to disconnect your entire system from the power supply.

Utilize appropriate devices and methods to prevent accidental energizing.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

17 / 18

CAUTION

Hot surface

The RF switch heats up during normal operation. Touching it may cause burns.

Do not touch the RF switch while hot. Wait until completely cooled off.

WARNING

Crushing Hazard

Falling objects may cause death and serious injury.

Secure the RF switch against tipping or falling. Safety shoes are required. If it is

necessary to stand below the RF switch during demounting, safety shoes and

hardhat are required.

CAUTION

Sharp Edges

Sharp edges may cause cuts and needle stick injuries.

Use safety gloves and handle carefully.

A

TTENTION The supplied packaging and all protection caps are reusable and required for

transportation. If not available, contact SPINNER before starting demounting.

Do not stress the connectors and the manual override.

Follow the procedure described in chapter 10 in reverse order.

18. Disposal

The user is responsible for disposing of the RF switch in accordance with the national

waste disposal regulations. Improper disassembly or disposal may be hazardous!

19. Additional endangering (regardless to life cycle)

WARNING

Lightning Hazard

Lightning may cause electric shock, burns and serious injury.

Use suitable overvoltage protection to ensure that no overvoltage (such as that caused

by a bolt of lightning) can reach the product. Use a copper lead (min 6 mm²) to connect

the marked earthing terminal to the main earthing busbar.

Data subject to change without notice │M36326 │Issue C

www.spinner-group.com

18 / 18

20. Environmental friendly usage period

表1有害物质名称及含量标识格式

Table1MarkingStylesfortheNamesandContentsoftheHazardousSubstances

Part Name

部件名称

Hazardous Substances

有害物质

Lead

(Pb)

铅

Mercury

(Hg)

汞

Cadmium

(Cd)

镉

Hexavalent

Chromium

(Cr(VI))

六价铬

Polybrominated

biphenyls

(PBB)

多溴联苯

Polybrominated

diphenyl ethers

(PBDE)

多溴二苯醚

Metal parts

金属零件 X O O O O O

This table is prepared in accordance with the provisions of SJ/T 11364.

本表格依据 SJ/T 11364 的规定编制。

O:Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the

limit requirements of GB/T 26572.

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X:Indicates that said hazardous substance contained in at least one of the homogeneous materials used for this

part is above the limit requirements of GB/T 26572.

(Enterprises may further provide in this box technical explanation for marking ”X” based on their actual

circumstances.)

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

(企业可在此处,根据实际情况对上表中打“X”的技术原因进行进一步说明。)

21. Spare parts

22. Contacts

SPINNER GmbH • Headquarters

Erzgiessereistr. 33

80335 München

Germany

Phone +49 8912601-0

Web: www.spinner-group.com

Spinner Telecommunication Devices (Shanghai) Co., Ltd

351 Lian Yang Road

Songjiang Industrial Zone

Shanghai 201613

China

Phone +86 21 5774 5377

Web: www.spcn.cn

Designation Order-No. Qty.

Cable connector (J1, 25 pole) for operating voltage,

control, interlock contacts and signaling BN 122886 1

This manual suits for next models

1

Table of contents

Popular Switch manuals by other brands

MiLAN

MiLAN MIL-SM2401M-STK user guide

ABB

ABB MNS-Up Service manual

IMC Networks

IMC Networks iMcV-FiberLinX-II Operation manual

Spinner

Spinner BN 553064 product manual

Siemens

Siemens RUGGEDCOM RS8000H installation guide

Brocade Communications Systems

Brocade Communications Systems FastIron SX 800 Diagnostic manual