IM-P612-18 ST Issue 3

8

Important - safety note

Before any installation or maintenance procedure, always ensure that all steam or

condensate lines are isolated.

Ensure any residual internal pressure in the product or connecting lines is carefully

relieved. Also ensure any hot parts have cooled to prevent risk of injury from burns. Always

wear appropriate safety clothing before carrying out any installation or maintenance work.

Always use suitable lifting gear and ensure the product is safely secured.

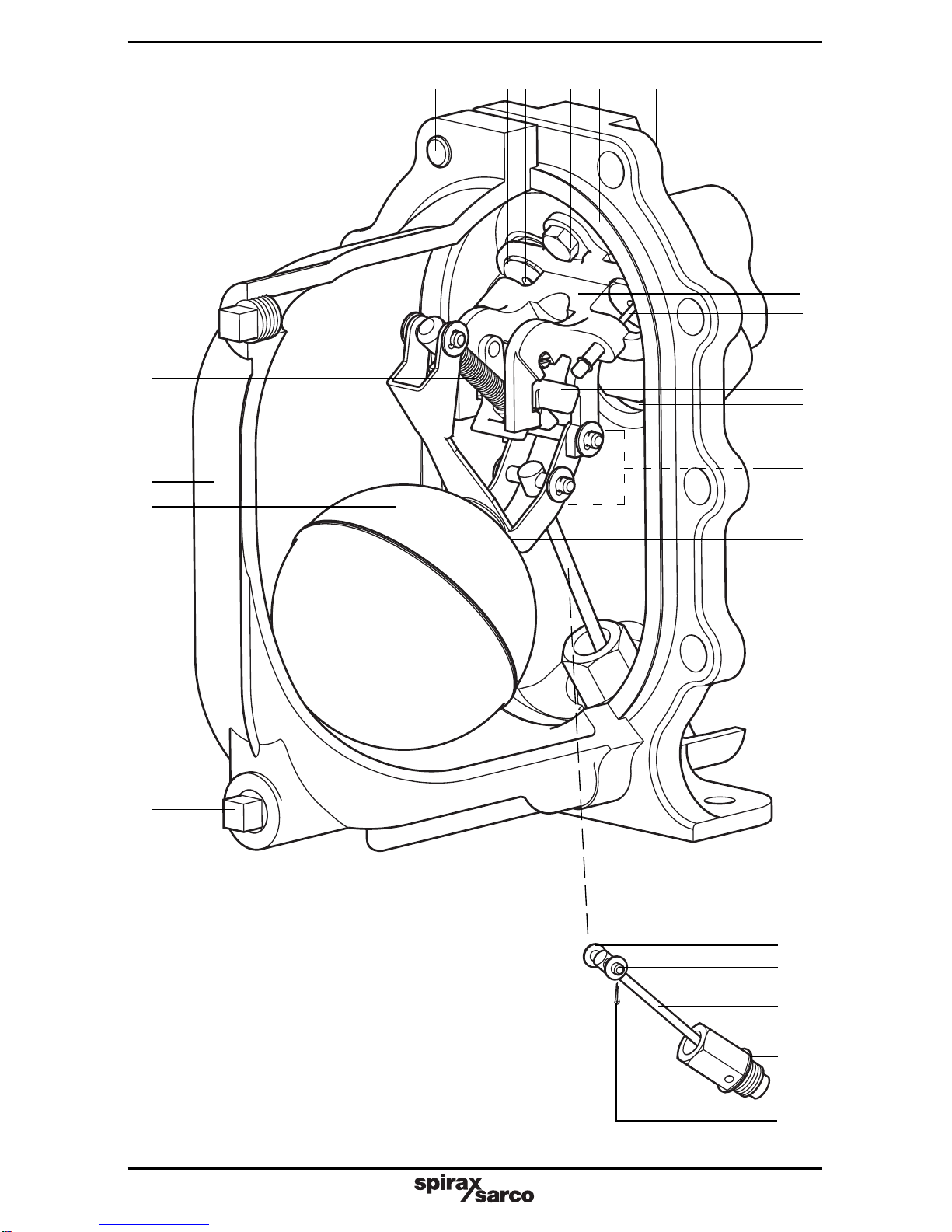

3.1 Inlet piping

To prevent condensate backing up into the equipment being drained, it is recommended that the

inlet pipework is sufficiently sized to accumulate condensate during the pump’s discharge cycle.

Generally a length and diameter of pipe to accommodate 2 litres of condensate will be sufficient.

Itisrecommendedthiscondensatereservoirissituatedatleast1pipediameterbelowtheprocess

outlet but as high as possible above the APT10-2 inlet. It is essential that a Spirax Sarco Y-type

strainer with a maximum 0.8 mm perforation screen size is fitted at the condensate inlet of the

APT10-2, as shown in Fig. 5.

3.2 Recommended installation head

An installation head of at least 0.3 m (12 ins) from the base of the unit is recommended. Minimum

0.2m(8ins)withreducedcapacity.Note:Duringcoldstart-upconditions,itispossibleforhydraulic

pulsingoftheinletcheckvalvetooccur.Itisadvisableinthiscasetoinstallathrottlingisolationvalve

to reduce the filling pressure.

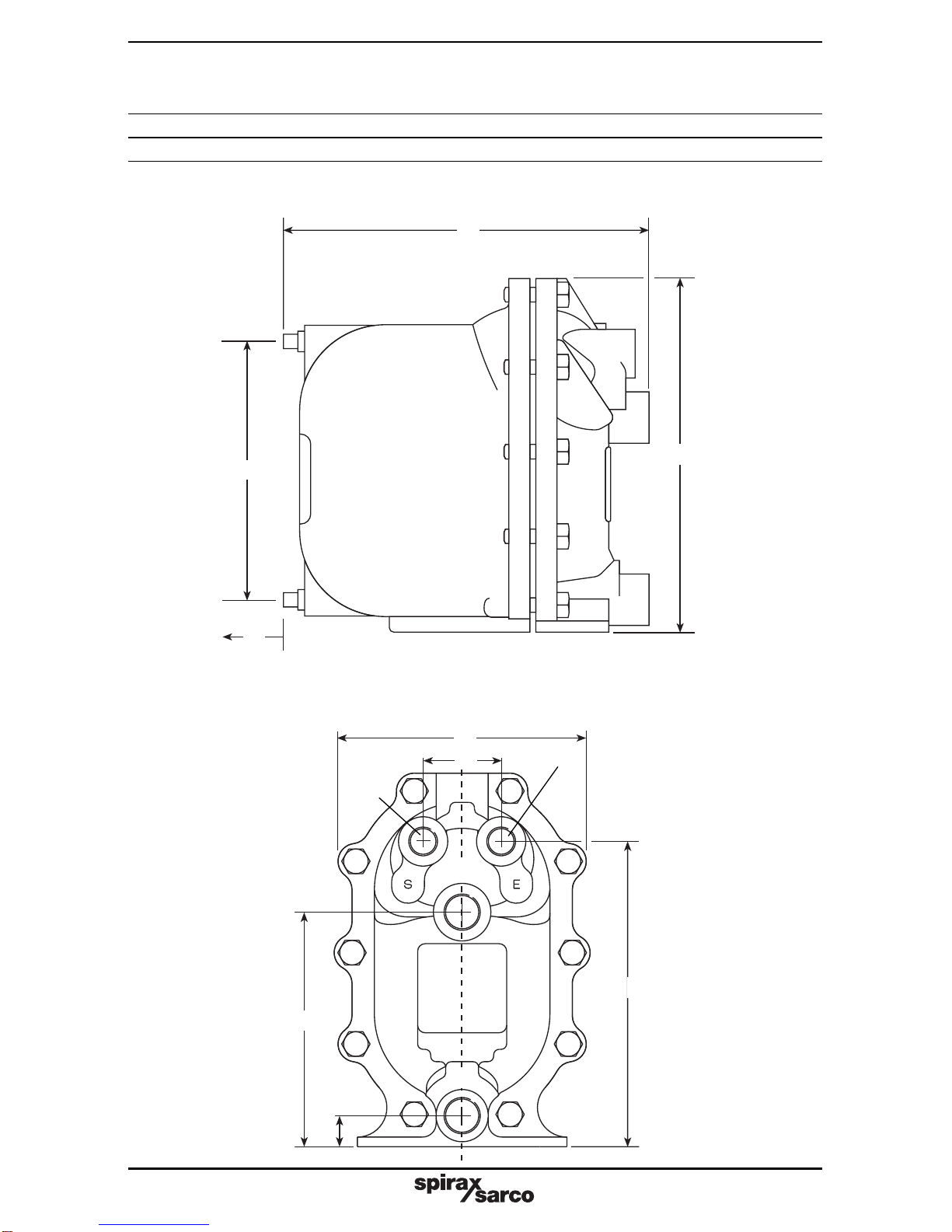

3.3 Connections (refer to installation diagram Fig. 4 opposite)

The APT10-2 has four connection ports. The DN20 (¾") port marked (IN) should be connected to

theoutletoftheequipmentbeingdrained.TheDN20(¾")portmarked(OUT)shouldbeconnected

to the condensate return line. A flow arrow indicates the correct direction of flow. The DN15 (½")

port marked (S) - steam should be connected to a trapped motive steam supply. * It is important

toensure thislineisdrained of condensateatall times usingaSpirax Sarco steamtrapand

filteredusing a 100 mesh strainer. ThescrewedDN15(½")port marked(E)-exhaustshouldbe

balanced back as close as possible to the condensate outlet of the equipment. This balance line

must always be connected to the top of the condensate pipe; as shown in Fig. 5.

Note: The APT10-2 can be secured to a level stable surface using the 2 x Ø12 mm holes drilled

into the base of the cover.

3.4 Outlet piping

It is important for the outlet piping to be correctly sized to prevent excessive back pressure on the

APT10-2.This pipeworkshould be sizedto takeinto accountthe effects offlash steamat theheat

exchangersfullloadoperatingconditions.RefertoTR-GCM-05forSpiraxSarco'smethodofsizing

this pipe.

3. Installation

4. Commissioning

4.1 After ensuring the inlet and outlet pipe connections and steam motive/exhaust connections

arecoupledinaccordancewithFig.4/5,slowlyopenthemotivesteaminletlinetosupplypressure

to the APT10-2. Ensure the exhaust /balance line is open and not restricted in any way.

4.2 Slowly open the isolation valves in the condensate inlet and discharge lines, allowing

condensate to fill the body of the APT10-2.

4.3 The APT10-2 is now ready to operate.

4.4 When the process plant is operational, the APT10-2 will discharge condensate under all

pressure conditions into the return line.

4.4 Ifanyirregularitiesareobserved,rechecktheinstallationaccordingtotherecommendations.

If the unit fails to operate, then consult the fault finding guide Section 9.