Spitronics TCU Standard User manual

MANUAL Introduction

The manual is written in sequence for the beginner. If you are a first time user spend some time

working through it and understanding where and how the information are put together so that it will

be easy to find what you are looking for. If you are an expert, use this guide to jump to the right

chapter. Is has a lot of information and may be frustrating to find the answers if you don’t know

where to look.

1. SPITRONICS TCU Introduction

This chapter discusses the SPITRONICS TCU as a product, how it is designed, and how it

operates in general.

2. Safety Precautions

This chapter discusses the all the safety precaution to the user and the product. Very important

to read!!

3. Requirements

This chapter discusses the requirements for the TCU to operate the Transmission, and the PC

specifications to communicate with the TCU.

4. Hardware Installation

This chapter discusses the how to do the wiring and physical installation of the TCU. Be sure to

read the precautions during this faze!!

5. Software Installation

This chapter discusses the how to install the software and drivers to connect to the TCU.

6. Software Operation and Setup

This chapter discusses the operation of the tuning software and how to set the parameters up for

each specific Transmission.

7. Driver Operation of the Transmission

This chapter explains how to operate the transmission from the driver side.

8. Startup Procedure

This chapter discusses the basic sequence of actions to prevent damage during the startup faze.

9. Tuning Principles

This chapter discusses tuning information for the Transmission when it operates correctly. This is

to enhance performance and smoothness and correct operation of the TCU.

10. Fault Finding

This chapter discusses the symptoms and remedies of known faults.

11. Specifications

This is a list of specifications for the SPITRONICS TCU.

12. Firmware Programmer

This chapter discusses how to upgrade or change the SPITRONICS TCU Firmware.

SPITRONICS TCU

Welcome

Congratulations on your purchase of the SPITRONICS TCU Transmission Control Unit (TCU). We

are sure that you will be satisfied with this robust, compact and user friendly controller, which was

designed to meet today’s requirements. This TCU was developed around the people involved with

Management Computers. We hope that it will give you years of trouble free operation.

Please read this manual to learn about the safety precautions and design features of your TCU.

Failure to use and install this management system properly may cause injury to people or damage

to equipment. This Manual was written with the novice and professional Transmission tuner in

mind, and we would like to urge you to install the TCU according to our recommendations. This is

the best way to get the most out of your TCU.

Please read the Precautions before and after installation and before

connecting the TCU, to ensure that the correct procedures are followed.

1. SPITRONICS TCU Introduction

The SPITRONICS TCU is an aftermarket Automatic Transmission Control Unit which is designed

to customize shifting and control of many different transmissions. The requirement for this

computer arises mainly for the following reasons. Where existing computers failed and spares are

scarce or none is existing. When modifications to vehicles are done and existing TCU’s do not

shift correctly. For racing and recreational vehicles which must be customized. It is used as a cost

effective replacement for existing TCU’s.

SPITRONICS TCU is a South African made product and can be customized for dedicated

Transmissions and models. It is a reliable compact system which is easy to mount in the driver’s

compartment. No external modules or converter boards are necessary.

The TCU is customized for specific applications and the installer does not have to pay for excess

wires or unused features. Nor does he have to buy separate modules and sensors which will

increase the price. Instead it is compiled with the correct harness and equipment as well as

software and profiles to ease installation and setup. The software will also be calibrated for the

sensors of the specific Transmission.

To make this TCU really versatile it comes with hardware electronics, firmware for the hardware

which is specific to each model of TCU and the powerful user friendly PC Tuning Software.

Hardware

The electronics is designed with inputs to read the sensors and then outputs to control the

solenoids in the transmission. It also has a user interface to select different profiles and operating

features. The main operation required for the transmission is to control the shift solenoids which

activate different gears and then the pressure solenoids which smooth shifting and protect the

clutches in the transmission. It also controls the Torque Converter Clutch to reduce fuel

consumption. In some cases there are features like 4x4 or diff lock selection, reverse block out,

smooth shifting solenoids and lockup clutch pressure control to name a few. The hardware also

consists of two type’s namely common positive and common negative solenoid wiring. This means

that some transmissions require 12 volt and other ground to control these solenoids.

Firmware

This part is not really the concern of the user but it is the operating system of the hardware

electronics. It is custom developed for each type of transmission and is essential for correct

operation and shifting. This firmware is tuned and set up from the PC software to operate the

transmission as it is required by its manufacturer. Once the tuning software is disconnected, this

firmware will take over on its own and control the transmission from there on.

Tuning Software

This software let the user customize the operation of transmission to work exactly as he prefers

the shifting process. The tuner can determines at which RPM’s and speed certain gear changes

must take place. There are also line pressures to control. Then the tuner can select up to four

different profile profiles which can be selected in the vehicle with a rotary switch. These profiles

can be set up for automatic, Tiptronic, towing, off-road driving and low range driving. It is totally up

to the customer and his requirements for his vehicle.

The different models are as follows:

TCU Standard

This is the most basic and cost effective form of the TCU. It is made for common negative

transmissions and has 4 drivers. Signal required are revolution pulse, speed pulse, TPS

signal and inputs from the shifter, Profile Switch and Tiptronic buttons. It has two LED’s to

indicate basic modes and operation. This is mostly for the basic transmissions like the

Lexus A343E auto box.

TCU Intermediate

This TCU is the same as the standard model but has 6 or more drivers for more

complicated transmissions and comes in a common positive and common negative

configuration. This is used for the newer more intelligent automatic transmissions.

All wiring harnesses use screened cables for neatness of installation and to prevent interference

from other electronics or electromagnetic pulses, which may otherwise cause erratic behavior of

the TCU.

1.1 Features

•Up to 4 different profiles for different setups can be loaded like Automatic, Tiptronic, Towing,

Racing, Off Road, and Low Range.

•Internal Drivers up to 6 on existing models.

•Harnesses and drawings included.

•Adjustable gear settings for each gear.

•Adjustable line pressure.

•Speed and RPM signals used for shifting.

•Small Compact South African Design.

1.2 Abbreviations

TCU – Transmission Control Unit

ECU – Engine Control Unit

PCM – Power Train Module

TCC – Torque Converter Clutch

EPC – Electronic Line Pressure

TFT – Transmission Fluid Temperature

TOT – Transmission Oil Temperature

SS1 – Shift Solenoid 1

TPS – Throttle Position Sensor

VSS – Vehicle Speed Sensor

TCS – Transmission Control Switch

MAF – Mass Air Flow

MAP – Manifold Air Pressure

ECT – Engine Coolant Temperature

WOT – Wide Open Throttle

2. Safety Precautions

The following guidelines will ensure proper operation the first time. Failure to install equipment

correctly may damage it or other equipment permanently. These failures will solely be the

responsibility of the installer and no guarantees will be given by Spitronics. Make sure you have

read the Terms and Conditions on the website www.spitronics.co.za before you install this TCU.

By installing the TCU you automatically agree to these conditions. All equipment is tested before it

leaves the factory. We accept no liability for malfunctioning of the equipment, or to injury that may

result from installation or the use of the equipment. We also accept no liability for costs of traveling

of transportation of the equipment or parts or vehicle recovery due to failures of any equipment.

Please read the instructions and drawing and make sure you understand before you begin.

2.1 Operator Safety

•Use only proper tools and products suited for auto installations. Sub standard products and

installation procedures may cause failure to the equipment having your customer break

down in dangerous areas.

•Use correct thickness of wire to carry the entire current requirement for that circuit. Too thin

wires will heat up and may start a fire causing injury.

•Use fuses to protect each circuit separately. Joint circuits require large fuses which may

heat and melt lesser circuits causing fires.

•Solder joints, and cover it with shrink sleeve to prevent loose connections which may cause

fires. Space solder-joints so that they do not sit next to each other minimizing the chance of

a short circuit.

2.2 Equipment Safety

•If you have a firmware programmer, do not load Ver. E1 EMU or Ver. E2 ECU firmware on

the E20 SPITRONICS TCU or visa-versa. It will damage the Micro because they are

different. Make sure if you have E20 hardware to use E20 firmware.

•Never switch the power on, if the TCU enclosure is not grounded properly – this may

damage the TCU or sensors.

•Test the installation with the test procedure before connecting the TCU – this will prevent

damage due to faulty wiring.

•Install the free-wheel Diodes on relays that makes interference to prevent spikes from

interfering with the TCU.

•Break out pins 1,4,6,7,8 & 9 on USB to RS232 converters and on serial cables. These pins

are used for other inputs and outputs of the TCU. It will hang the TCU and damage drivers.

This does not apply to Spitronics USB converters.

•Do not connect screen wires on the Transmission or Engine. The starter will draw current

through them melting the harness.

•The TPS must be connected correctly as it may damage the TCU or TPS permanently.

•Ensure that wires are kept away from hot or sharp parts in the Transmission. Also ensure

that Transmission movement does not put strain on the wires, as metal fatigue will break

the wires in time, resulting in TCU failure.

•Ensure a proper earth between battery negative and chassis and also between battery

negative and the engine. Do not earth the engine on the body or the body on the engine.

•Do not disconnect the battery while engine is running. The alternator will create high

voltage spikes which may damage the TCU permanently. Ensure that all connections from

the battery and alternator are secure. Also connect the alternator charge wire directly to

battery positive and not to the harness somewhere.

•The revolutions trigger input may not be connected to coil negative. The high voltage spikes

on coil negative will damage the unit permanently.

•Whenever it sounds as if clutches are slipping, back off the throttle immediately and

increase the line pressure. These clutches will damage in seconds and destroy the

transmission.

•Leave the 10 way connector disconnected when you switch the TCU on the first time until

the setup is completed. Then connect the 10 way connecter and switch on. Ensure that the

fuse is the minimum required value. Too large fuse will not blow resulting in driver or

solenoid destruction.

•Never engage the lockup clutch under load. It will damage the clutch it very quickly.

•Ensure that the TPS and other signals operate correctly and are calibrated and set up

properly.

•Gearbox parameters are set by the manufacturer. With this software you will be able to

change these settings to your liking. Any wrong settings may damage the transmission and

only you will be responsible. So make sure that the settings are set according to the

guidelines or consult an expert in tuning to prevent damages.

•Do not engage the lockup clutch in the lower gears as it will put unnecessary wear on the

friction plates of the clutch.

•Do not connect 12 Volt directly to solenoids. Some are control solenoids which may

damage in the process. Make sure that the wiring is correct for this reason.

•Solenoid supply voltage must be connected via a relay and fuse for protection.

3. Requirements

3.1 Transmission Requirements

The transmission must be of the electronically controlled type. The older transmissions were

controlled by hydraulic hardware inside the transmission and cannot be converted to computer

control. Also note that the mechanical shifter is still required for some of the transmission

selections like Park, Neutral, Reverse and a mechanical 1,2,3 and Drive setting. There may be a

line pressure cable present on some of the transmissions which must be correctly adjusted

according to the manufacturer specifications. You will require the following:

•The transmission with electronic solenoids

•The connectors on the transmission

•Relevant control signals and sensors (RPM signal, TPS, Speed Sensor)

•A Shifter to select mechanical positions

•Shifter position switches where specified

Notes on RPM Signal

This pulse must be a 12V to ground signal and may not be connected to coil negative. The high

voltage spikes on coil negative will damage the unit permanently.

3.2 PC Requirements

•Pentium 4 Laptop

•Windows XP with service pack 2 or later, Vista or Windows 7. Note that Vista or Windows 7

do not operate with other than the Spitronics USB cable. Vista is also not as stable and

some laptops struggle to communicate with USB converters.

•Serial Port or USB device with USB to RS232 Converter (19200 baud rate)

•Screen Resolution 1024*768

•Ensure that the latest drivers for the PC are installed.

This software is developed under the latest Delphi environment. It requires a lot of processing

speed and may not run on older computers.

4. Hardware Installation

This chapter tells the user how to install and wire the SPITRONICS TCU. Be sure to read

precautions before attempting installation. There are a few do’s and don’ts’ to consider as well.

4.1 Compatibility to the old TCU series

Note that the Ver 3 SPITRONICS TCU may be upgraded to the Ver 20 software. The unit will have

to be sent to the factory for this upgrade at a cost and also an additional profile switch with

harness may be bought separately.

4.2 Harness Selection

The SPITRONICS TCU has different harnesses for all different Transmission configurations. Make

sure that you have the right harness according to the drawing. These harnesses differ mainly as

follows:

•Magnetic or Hall sensors require different voltages and are connected to the TCU on

different pins.

•Different input and output combinations.

4.3 Installing Procedure of the TCU

•Locate a convenient mounting position for the TCU inside the cab for water protection.

Humidity and heavy duty service units are available on request and will be custom made.

•Ensure that the enclosure of the TCU is grounded with at least two metal screws onto the

metal body of the car. If the TCU is not bolted directly onto an earthed metal surface, you

MUST make sure that you run a 4mm2ground wire to one of the TCU’s bolt holes,

otherwise your TCU will not power up. There may flow as much as 20A through the earth

wire.

•Connect the two black wires firmly to the enclosure base. This is the screens of all the

cables.

•Feed all wires of the harness, except the serial cable, through a hole in the firewall. A good

seal around the wiring is necessary to prevent damage and Transmission fumes and water

from entering the cockpit.

•Each cable in the harness is marked to where it has to go. The same name is on the

electrical drawing. Wire colors are marked on the drawing for specific pin connections. Take

special care for TPS wiring as a fault here may damage the voltage regulator on the TCU.

•Pull additional PVC sleeve over the cables for extra protection of the harnesses. This

sleeve is customized on your installation and dependant on routing of the cables.

•The screened cables for the sensors must go to the sensor and connected as close as

possible. Connecting these wires to existing harness on the Transmission will cause the

wires to pick up electrical interference and cause erratic behavior of the TCU.

•No screen wires may be connected or earthed to the transmission or engine. They are

connected on the TCU side to the enclosure.

•Test each harness according to the drawing or to the optional test procedure to ensure

correct wiring, before connecting the TCU. This will indicate installation errors beforehand

which may damage the TCU.

•Plug the harness into the TCU and taking care not to damage the pins and connectors. If it

is sticky do not force it in. Rather move the connector slightly from side to side till it mates

with the TCU connector pins.

•The brown 12Volt supply wire for the solenoids on the common negative controllers must

be wired via a relay circuit directly from the battery with separate fuses in the positive

supply for protection. Do not wire any of these devices directly from the Ignition switch or on

the same circuit as the TCU. This will cause spikes which may damage or influence correct

operation of equipment. Earth connections must be as short as possible to earth and not

connected to a common earth wire which is connected at a distant ground.

•Make sure that the correct wire thickness is used for each power electronic component. If

wires are common ensure that the wire is thick enough to carry the total current. Too thin

wires will heat up and may start a fire. The same goes for relays. Be careful of cheap

relays. They can seize and start a fire. Use 0.5mm2of wire for every 5A of current. Also

check pin numbers of the relays as they differ from one manufacturer to the other. This

mistake may be costly!

•Solder each connection and use shrink sleeve rather than insulation tape. Stagger solder

joins so that they do not sit next to each other. Cover connections and loose wires with PVC

or pigtail sleeve rather than insulation tape.

•Ensure that all electronic settings are correct before connecting the 10Way connecter.

Certain settings may damage equipment if not set to recommendations. Especially the coil

output trigger level. Follow the start-up procedure.

•Ensure a proper ground from battery negative to the body and from battery negative to the

Transmission. This wire must be thick enough to carry the current of all the equipment in

the car.

4.4 Sensors

There are three groups of sensors for speed and rpm sensing. Magnetic, Hall and Optic sensors.

Hall and optic sensors both give a square wave output and are treated exactly the same. They

have electronic components in the sensor which convert the signals to square wave. The Hall

sensor uses magnetic field where optic uses infrared light. In both cases a beam is broken and

detected. Magnetic sensors are just a magnetic coil around a magnet. The metal point passing this

sensor induces a spike which has then to be converted to a square wave so that the processor

can work with it. These sensors have different inputs on the TCU that is why the harnesses differ.

They have different supply voltages which is selectable with jumpers on the PC Board. See the

drawing for correct settings.

4.4.1 Magnetic sensors

1. These sensors provide only a voltage spike to the TCU. The TCU will convert this spike to a

usable square wave to be used by the micro processor.

2. Each sensor has its own positive and negative wire from the TCU. Do not connect

magnetic sensors with common ground wires. The negative is connected to 5V and will

damage the TCU if connected to ground. Disconnect and isolate it first.

3. Make sure that the positives and negatives of the sensors are connected correctly.

4. In certain cases a 1 K ohm resistor may be connected between positive and negative to

reduce spikes in the signal.

5. Connect the screened cables from the TCU as close to the sensor as possible. Do not let

single open wires run along the spark plug wires or the coils as this will induce interference

in the TCU causing erratic firing.

6. Do not connect the screen to the Transmission. It is already connected to the body at the

TCU.

7. Do not connect other devices to this pickup as it will interfere with the signal to the TCU.

Testing a Magnetic sensor

These sensors have a wired coil with a magnet. They normally have two wires. Some do have 3

wires which have an earth which is not connected to the coil. The Coil resistance vary from 150

ohm to 1200 ohm typically. If you swap the tester wires around you would measure the same

resistance value. To test for positive put the meter on milli volts DC. Connect the wires to the coil

of the sensor. Move an iron object to the sensor and look closely at the polarity indicator. If it

indicate positive when moving closer to the sensor and negative when moving away from the

sensor, it means that the red wire of your meter is on the positive of the sensor. If it is the other

way round, then the black wire is on the positive of the sensor.

4.4.2 Hall & Optic sensors

1. These sensors already provide the TCU with a square wave.

2. Hall sensors work with magnetic fields but it does not mean it is a magnetic sensor. Failure

to identify this will cause incorrect wiring and no operation.

3. They have three wires. Each sensor has a positive (12V), earth and signal out pin.

Connecting these wrong may damage the TCU or the sensor permanently. If you are not

sure which pin is which, ask your agent to bench test it first with protection resistors to get

correct pin-outs.

4. The TCU has an extra pull-up resistor of 2.2KOhm set with the jumper. If erratic misfires

occur, another 1K Ohm resister may be connected between the signal and 12V wire on the

sensor.

5. If the sensor requires a resistor in the positive wire to limit current, it must be put in

separately.

Testing a Hall or Optic sensor

•

•These sensors normally have 3 wires. A supply wire, normally 12V, an earth wire and a signal

out. This sensor has electronic components that require power to operate. Connecting this

sensor wrong my damage it permanently. First test for resistance on all the pins and swap the

test leads around to make sure it is not a magnetic sensor. Put the meter on diode test and

measure voltage drops over all the pins. You should get V drops between 0.5V to 1.9V. This is

your indicator that you have an electronic unit.

Bat+

1 K

1 K Sensor

+-

Multi Meter

•Now take 2 x 1K resistors and tie one end of each to the +12V. This will ensure that if you

connect the supply wrong you will not damage the component as the resistor will limit the

current to 10mA. Now put the ground on one pin and the 2 resisters on the other pins. Put the

meter black wire on earth for the remainder of the tests. Connect the meter red wire to any of

the other pins. Now move an iron object to the sensor or in the gap and away. If the signal

varies between 0V and 12V then this pin may be the signal output of the sensor. Now put the

red wire on the other pin and repeat the iron process. This voltage should not change. It may

be less than 12V due to the drop over the resistor. If so then this is the supply pin. With other

words one of the resistor pins should respond rapidly to iron pulses while the other one

remains fairly constant.

•Now change the earth pin to the next and repeat the process. Note that you may get a similar

reaction if you have the earth and the signal pins wrong. The indicator to see which one is

which is to see which pin reacts the most to the iron pulse. That pin is the signal output and the

other one the earth.

•Remember this is a guideline to black box testing and not a failsafe operation. Note point 4

above and rather consult the specifications from the manufacturer or vehicle diagrams.

4.4.3 Throttle Position Sensor

•

•This signal tells the TCU exactly what the driver is thinking.

•The TPS must operate through the whole range of the throttle movement to ensure that the

proper operation of the TCU.

•The TPS is normally connected to the Engine management. In this case only the signal wire

needs to be attached to the TPS signal. Do not connect the positive and negative onto the

ECU wires. This will damage the TCU or the ECU.

•The TPS must be calibrated in the PC software as to operate correctly. This is done in the

setup menu before starting the Transmission. (see TPS calibration under Active Sensors)

•The sensor is connected to 5V, ground and signal input. Connecting it wrong may damage

the TCU or TPS as you may short the 5V to ground. Test it before you connect it to the

TCU.

Testing a TPS for the Correct Pin-Outs

•

Red +5V

Blue

Black / Screen Close

Open

Throttle Position Sensor

C

B

A

1. Test the resistance with an Ohm Meter between 2 pins at a time. Each time move the

throttle open and close. If the resistance do not change and is approx 5000 Ohm, then you

found pin A & C. The remaining pin is B which is the wiper. Mark it as B.

2. Now test the B pin with one of the other pins. If it is below 500 Ohms then that pin is C. If it

is above 4500 Ohm that pin is A.

3. Now to double check. Measure between B & C. if the throttle is closed the resistance is

below 500 Ohm. If you open the throttle the resistance increases to above 4500 Ohm.

4. If you measure between A & C the resistance is around 5000Ohm and does not change

with throttle movement.

4.4.4 Oil Temperature Sensor

Reserved for Future development.

4.6 Additional Wiring

4.6.1 Pin References for the TCU

The TCU has two connectors for all wiring combinations. A 12 way connector for power and

sensors, and a 10 way connector for all the outputs to the Transmission. Note that the TCU

connects to ground via the aluminum enclosure. It is not necessary that all the pins will be used.

There may be additional wires on the drawing that cannot be found on the pin descriptions. This is

due to other connections in the harness to ease with installation. The pin-outs are just for

reference. Please follow the labels on the wiring harness when connecting up your new TCU. All

wires are grouped together for ease of installation.

5

4321

11

10

9

8

7

6

12

Harness Connector

Pin View

Figure shows a view of the 12pin Female Plug on the TCU harness. Note the retaining clip on top

and how the pins are numbered.

12 way

connector

1 Down Shift Button

2 TPS sensor

3 Signal Input

4 Signal Input

5 Speed Hall Sensor Input

6 RPM Sensor Input

7 Up Shift Button

8 Reverse Signal Input

9 5 Volt Output

10 12V Ignition In

11 Speed Mag Sensor Input

12 RPM Mag Sensor Input

5

4321

10

9

8

7

6

Harness Connector

Pin View

Figure shows a view of the 10pin Female Plug on the TCU harness. Note the retaining clip on top

and how the pins are numbered.

10 way

connector

1 Solenoid Driver 1

2 Solenoid Driver 2

3 Solenoid Driver 3

4 GP Out 1

5 Mode LED+ / Solenoid 1

6 Solenoid Driver 4

7 Solenoid Driver 5

8 Solenoid Driver 6

9 +12 Volt Suply for Solenoids

10 Lockup LED+ / Solenoid 2

5. Software Installation

5.1 PC Software installation

The PC Software does not require installation. It is an executable file and can run from any

memory medium except from CD. See PC Requirements however. The software will create a

tcu.ini file in the same directory where your software is run from. This is to save your preferred

settings in the software. When you start the software for the first time, it will prompt you to accept

the Terms & Conditions as laid out by Spitronics Micro Ignitions cc. Read these conditions

carefully and if you agree you may except the terms and continue to work on the ECU. If you press

cancel the program will close. If you load a new manual it will ask you to agree to the terms and

conditions again.

There is also an html help file. When you click on manual button, guide the

software to this file and then you can access the manual from the PC software.

5.2 Spitronics USB driver installation

Go to the Spitronics USB Driver file on the CD. Activate the USB Setup.exe file. The software will

install automatically. It may take a couple of minutes on slower laptops. Now insert the USB cable

into the PC. Windows will detect the cable and install the driver for it. If it does not connect to the

TCU see Changing the Com Port Settings below.

5.3 RS232 Computer to TCU interface

The TCU communicates to the computer via the serial RS232 interface. It operates at 19200 baud

rate. See the drawing for connection diagrams.

Communication can also be achieved by USB via a USB to RS232 converter cable. Ensure that

the drivers for the cable are installed according to manufacturer specifications. When using other

than Spitronics cables, you have to break out pin 1,4,6,7,8 & 9 as they are used for other inputs

and outputs such as for programming the TCU as well as the Profile Switch. See drawing. On a

serial connector provision is made for hardware handshaking on printers etc. It is not used for

these management electronics. For the Spitronics USB converter you do not have to break out the

pins as they are internally disconnected.

15

69

X

XX

XXX

2

3

5

2

3

5

Earth

DB9P Male - Pin View DB9P Extension Cable

Note: These cables are optional and can be bought from the agent, computer shop or made in

some cases.

The settings for the USB cable must be the same as above. Note that the Com port must be Com

1 to 10. Higher numbers will not be detected.

6. Software Operation and Setup

6.1 Button Description

6.2 Connecting a PC to the TCU

6.3 Changing the USB Comport in Windows Device Manager

6.4 Memory Operation of the TCU

6.5 Selecting Different Pages in the Software

This chapter will explain how the software operates and how to set it up for your specific

Transmission. The TCU comes preconfigured so that you don’t have to go through the tedious

process of configuring all the different parameters, to get the Transmission to start. There are

however certain checks on different Transmissions to get the TCU to work properly. Failure to do

this may damage the TCU or components of the Transmission which will solely be your

responsibility. Refer to the drawings of your model to see if your Transmission has a special setup

procedure.

6.1 Button Description

Open a saved profile from the hard disk into the PC Software.

Save profile data from the PC or TCU on the hard disk.

Print profiles to a printer.

Read the profile from the TCU into the PC Software.

Write to TCU – Write de TCU data into the Flash memory to make the changes permanent.

Lock the profiles and change the Customer Code.

Enable or disable the mouse pad for adjustments on the tuning graphs.

Developer and TCU Information.

Quit the Program.

Change the tuning profiles to the active real-time graph.

TCU is Online and can be adjusted.

TCU is offline.

6.2 Connecting a PC to the TCU

Connect the optional serial cable or RS232 converter cable to your laptop or PC and to the TCU.

(Remember to break out pins 1,4,6,7,8 & 9 if it is not a Spitronics USB converter)

Switch the ignition on and check if the yellow LED is on. Open the TCU PC software. If the TCU is

connected, the PC software will detect it on the Com port automatically and connect to it. If it did

not, check your connections again. Note that if you use the USB converter cable, that the com port

must be Com 10 or lower. You can correct this in the Device Manager of Windows XP. You are

now ready to begin with the tuning on your TCU.

6.3 Changing the USB Comport in Windows Device Manager

One some laptops, Windows will install the USB on a Com Port higher than 10. This is a Windows

driver problem and then the Com Port is not detected automatically. You need to change it to

lower than 11. Follow these steps:

1. Left click on Start (left bottom)

2. Right Click on My Computer (or in desktop My Computer)

3. Click on Properties

4. Click on Hardware

5. Click on Device Manager

6. Click on Ports (Com & LPT)

7. Right Click on Prolific USB to Serial Com Port (Com 11or higher)

8. Click on Properties

9. Click on Port Settings

10.Click on Advance

11.Select a Com Port lower than 11 (if all is in use choose 5 to 10 and press OK)

12.Click on OK and close

6.4 Memory operation of the TCU

The figure below indicates how the TCU operates with temporary and permanent memory. When

the TCU is powered up, it will take the data profiles from the permanent FLASH memory and save

it in the temporary RAM memory. This RAM is used by the processor for operation and the Laptop

for tuning. When the user changes the profiles, the processor will immediately start working with

the new data changed in the RAM.

FLASH

Permanent

Storage

Memory

RAM

Tempory

Working

Memory

RAM

Tempory

Working

Memory

Hard Disk

Permanent

Storage

Memory

RS232 TCU

Laptop

Write to TCU

button

Power On

Processor

Maps in Use Outputs & Inputs

Save

Load

Changes

Read from

TCU

6.4.1 Saving data in the TCU

Once the user is satisfied with his changes he must save his changes in the FLASH memory in the

TCU, by pressing the Write to TCU button. Now the data is stored permanently and the

ignition can be switched off. If he does not save this data in flash, all his changes will be lost when

the TCU power is switched off. When data is written to the TCU flash, the processor will cut-out for

about half a second. Remember that each profile is saved separately on the PC and in the TCU.

The laptop memory will have the same information in its RAM when the profiles are uploaded after

the PC software is started. If the car is switched off without saving, the operator may switch the

TCU on and press the Write to TCU button. This will save the copy of the data in the Laptop RAM,

into the TCU FLASH memory. This is also how you can save your profile in another TCU if you

don’t want to save to hard disk first. Remember that each profile is saved separately on the PC

and in the TCU.

6.4.2 Saving a Profile to the PC

The user may also save the Laptop RAM or TCU data to the hard disk so that the profiles maybe

recalled later or if different settings are desired. This is done by pressing the Save Settings

button. Choose the profile in the TCU that you want to save a profile from.

The user has the option of saving the Ram data on the PC or the real-time TCU data. This feature

is useful if you want to change profile data offline. Simply open a profile file, edit it and save it back

to the hard disk. Remember that each profile is saved separately on the PC and in the TCU.

6.4.3 Loading a Profile from the hard disk onto an TCU

First connect to the TCU. Select the profile in the TCU with the profile switch or the buttons, where

you want to load the saved profile into. Then press the Open file button. Press the

button to connect to the TCU. Select Down Load to TCU button and then press the

Write to TCU button. The data will now be written into the TCU flash memory. Note that the

serial number is not written in the process although for this session the serial number is the same

as the profile serial number. Once the software is closed and restarted, the TCU serial number will

be displayed. Also note that if an incorrect version of the profile is loaded, a check box will warn

you of it.

6.4.4 Locking a Profile on the TCU

The tuning profile on the TCU can be locked to prevent other users from copying it or changing

settings on it. This feature is to let Transmission builders install protection settings on the TCU for

guarantee purposes. Note however that you can overwrite the code by loading another profile onto

the TCU. This would however indicate to the agent that tampering took place and may void

warranties.

The Agent has the option of changing the customer code for his reference. He can protect it with a

password and leave the profiles open. It would mean however that the customer cannot lock his

own profiles under the code as they use the same code for protection.

Press the button and enter a password. Select which protection is required. Press Lock, Exit

and then press the Write to TCU button to save it to the Flash memory.

To change the Customer code you need to put in the Agent Password which is only supplied to

the agents by the manufacturer.

To unlock the TCU enter the same password that you used to lock the Code. If you press the

Write to TCU button, the profiles will stay open.

If you changed data and quit the program or switch the TCU off without saving the data in the

flash, the software will prompt you to take action with one of the following blocks so that the data

will not be lost.

6.5 Selecting Different Pages in the Software

6.6 Start (F1)

6.7 Setup (F2)

6.8 Profiles (F3)

6.9 Logger (F4)

6.10 Manual (F5)

Press on any of these buttons to activate the different pages

in the software. By pressing the alt button you will see the hot keys for these buttons.

The hot keys are easier to press during driving.

6.6 Start (F1)

This is where the program will start the first time. On this page all the action events is logged for

information. It will also display the TCU information of the current TCU. Take note of the Warning

as it is important and binding by Law. See the Terms & Conditions on our website.

6.6.1 Version Numbers

The designer reserve the right to do changes to existing designs and harnesses as he keeps on

developing software and hardware. The market change all the time as new ideas submerges. The

TCU has a version number system so that the user knows which drawing and also which tuning

profile goes with which TCU firmware. There is also a document which explains about the

hardware and software changes made between different versions.

TCU Version will indicate the product namely TCU and which model is connected. Model is

Standard, Intermediate or Advance.

Firmware Release is the PC Software, Electronic hardware, Firmware or Protocol version and

software release information. This is very important as it must coincide with the PC software. It is

also written with a permanent marker on the enclosure but this my rub off during installation.

2.20.1.A In the sample means: PC Software Ver. 2, Hardware number 20 (SPITRONICS TCU),

Protocol Ver.1, Firmware Ver. A.

The PC software also has a version number in the name part of

the file or on the Top information bar. Keep older versions for old TCU versions. TCU firmware can

be upgraded by an agent to accommodate changes in the latest PC software. Version 2.20.1.0

TCU must be programmed with Ver. 2.20.1.0 PC software. The alphabetic number if any will

indicate later version changes in the TCU or PC but does not change the protocol of Ver.2.20.1

software. This may differ from software to TCU but does not matter.

Program is a number given to each TCU firmware program to identify them apart. Behind the

number is a short explanation of the type of program. On some programs there is a last letter

indicating a B for Buttons or P for Profile Switch. See the file on CD for a list of these program

numbers available.

Serial Number is to keep track of each TCU sold. It is also engraved on the enclosure of the TCU.

The number for ex PP-PP-999999-15 means as follows:

PP – Agent which this unit was distributed to

PP – Customer which this unit was sold to – this can be changed by the Agent for his own

reference.

999999 – serial number

15 – model function no

TCU model function numbers are as follows:

3 Standard TCU

11 Intermediate TCU

15 Advance TCU

6.7 Setup (F2)

6.7.1 Transmission Setup (Alt 1)

6.7.2 Sensor Setup (Alt 2)

6.7.3 Solenoid Setup (Alt 3)

Click on the setup tab to get information on the configuration of your Transmission. Most

parameters are being preset before the TCU has been shipped. Ensure that these settings are

correct as some may damage components on your Transmission or the TCU itself.

Click on of these icons to adjust different settings in the setup page. Activate the Hot-Key by

pressing the Alt button plus the correlating number as in the icon block.

6.7.1 Transmission Setup (Alt 1)

This manual suits for next models

1

Table of contents

Other Spitronics Control Unit manuals

Popular Control Unit manuals by other brands

Bosch

Bosch Rexroth ctrlX CORE plus X3 operating instructions

VAT

VAT 10.8 Series Installation, operating, & maintenance instructions

Teleco

Teleco TVPLA868CC2EN manual

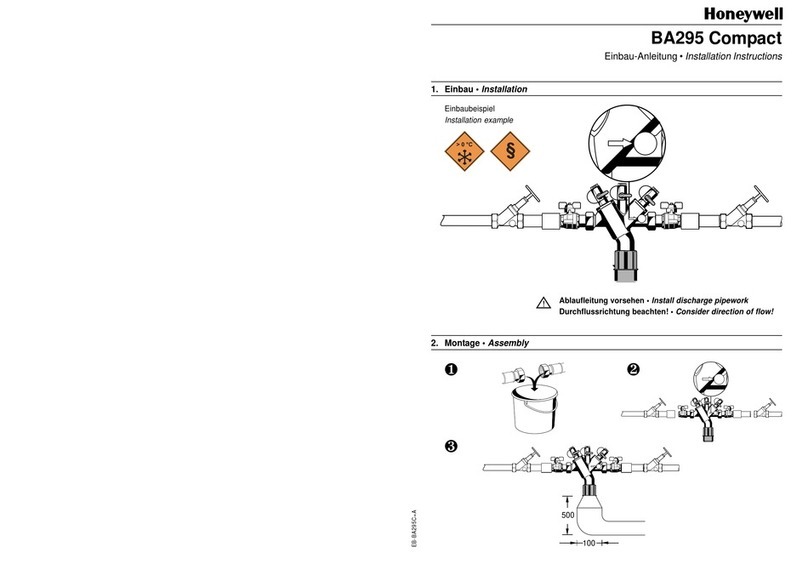

Honeywell

Honeywell NOTIFIER FTM-1 Installation and maintenance instructions

Comelit

Comelit 3360B Technical manual

Tekmar

Tekmar Universal Reset Module 422 Data brochure