3

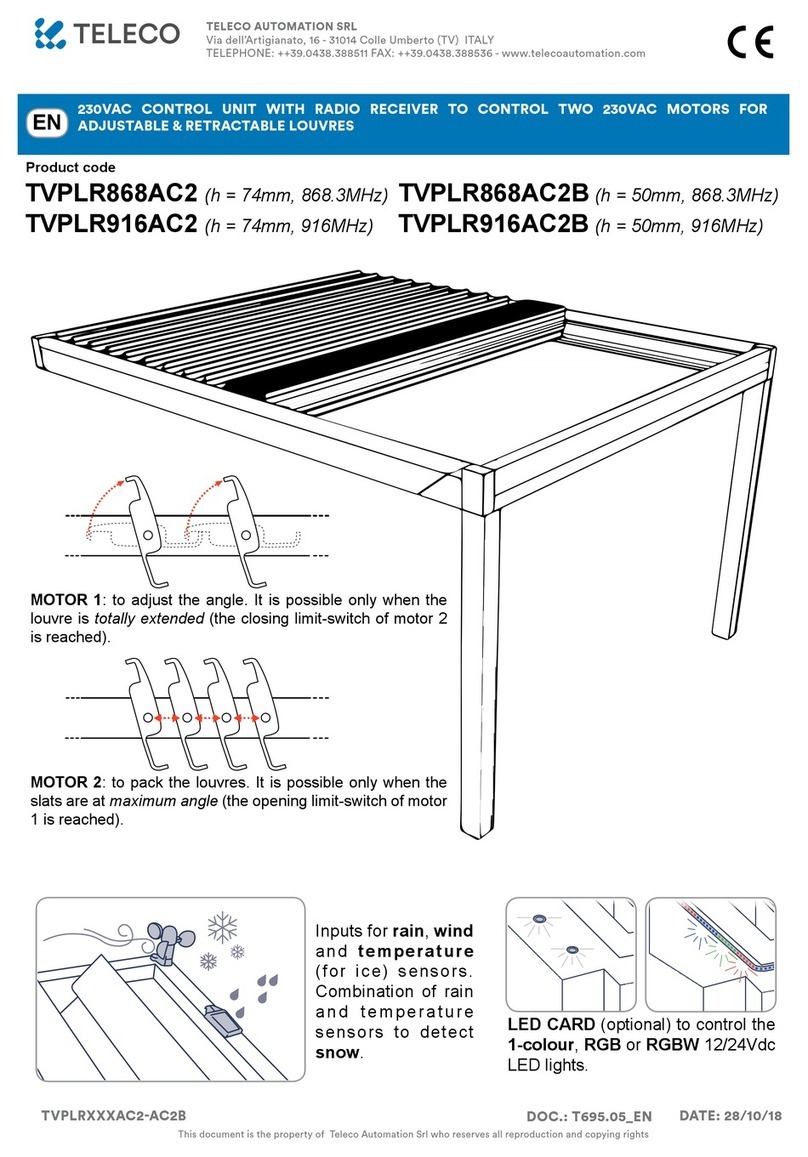

M1

M2

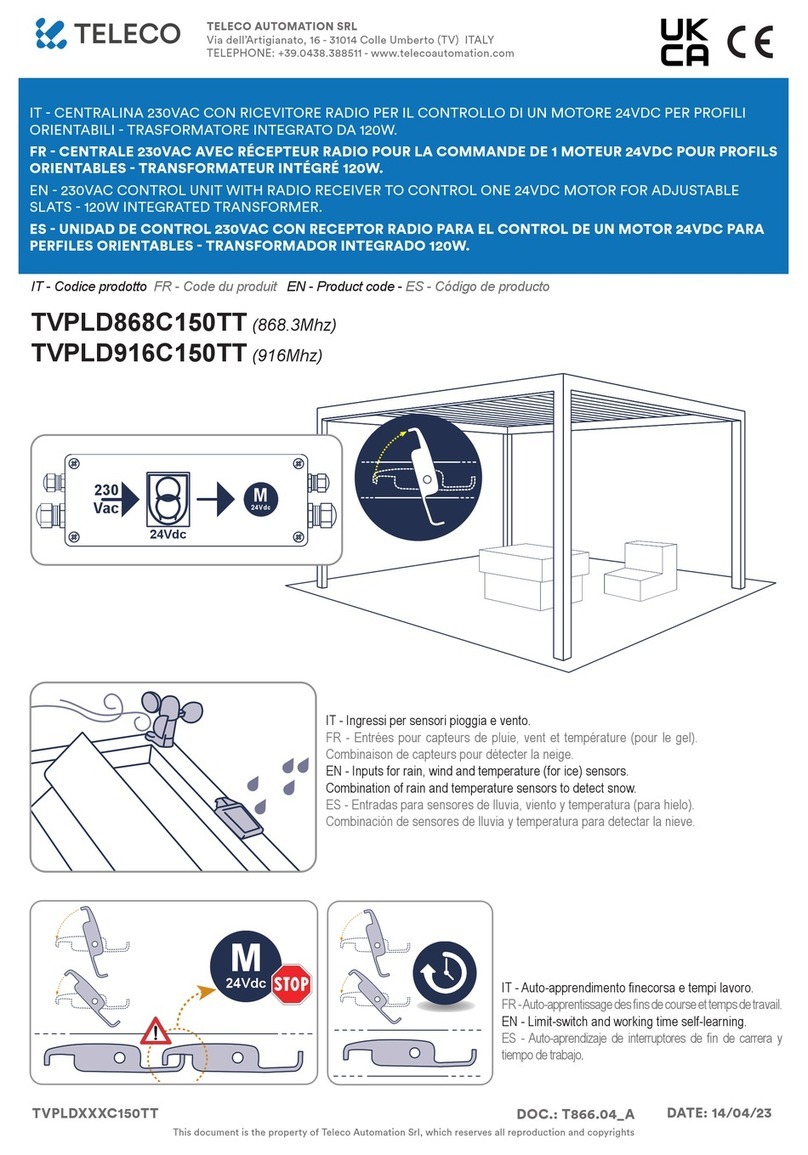

1+24V POWER SUPPLY

2 POWER SUPPLY GND

3 MOTOR 1 (OPEN)

4 MOTOR 1 (CLOSE)

5 MOTOR 2 (OPEN)

6 MOTOR 2 (CLOSE)

7 WIND SENSOR (BROWN)

8 WIND SENSOR (BLUE)

9RAIN SENSOR (WHITE, +12V )

10 RAIN SENSOR (BLUE, SIGNAL)

11 RAIN SENSOR (YELLOW, GND)

12 AERIAL RF

13 AERIAL GND

14 TEMPERATURE SENSOR (BLACK)

15 TEMPERATURE SENSOR (WHITE)

16 ENCODER M2 (VDD)

17 ENCODER M2 (Signal A)

18 ENCODER M2 (Signal B)

19 ENCODER M2 (GND)

20 ENCODER M1 (GND)

21 ENCODER M1 (Signal B)

22 ENCODER M1 (Signal A)

23 ENCODER M1 (VDD)

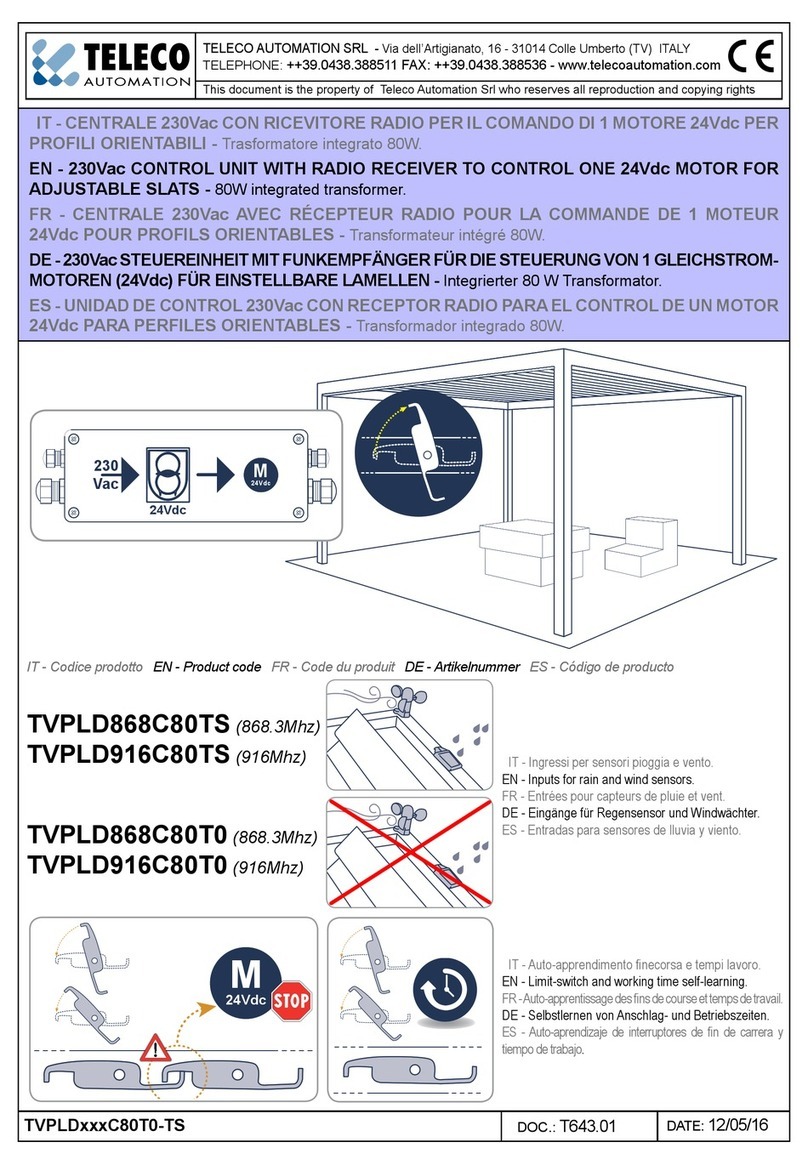

LED COLOUR STATUS MEANING

L1 RED ON until next manoeuvre MOTOR 1: Limit switch or alarm

Flashing during movement MOTOR 1 moving with encoder communication

L2 RED ON until next manoeuvre MOTOR 2: Limit switch or alarm

Flashing during movement MOTOR 2 moving with encoder communication

L3 BLUE ON Synchronized mode activated

One ash every second Synchronized mode activated (during conguration)

One ash every 2 s Independent mode activated (during conguration)

L4 RED One ash every 10 s Water draining alarm (par. 4.4, page 12)

Two quick ashes every 10 s Rain alarm (par. 4.4, page 12)

Three quick ashes every 10 s Ice / Snow alarm (par. 4.2 - 4.3, pages 11-12)

Four quick ashes every 10 s Wind alarm (par. 4.1, page 11)

Five quick ashes Unexpected absorption of one motor in synchronized mode

Six quick ashes Built-in motor limit switch activated

Seven quick ashes Motor stopped by current absorption over the threshold

Eight quick ashes Safety limit switch

Nine quick ashes Encoder signal error. The motor stops.

Ten quick ashes One motor is short-circuited

Twelve quick ashes Encoder signal disturbed. Abnormal motor operation.

One ash every 2 s Rain sensor is deactivated

One ash every 3 s Temperature sensor is deactivated

L5 RED ON Power ON

L3

Optional LED CARD

(only in TVPLAxxxCC2EN version)

Memory

10A Fuse

24V

Power supply

-

+

2

1

6

5

4

3

14

15

13

12

8

7

11

10

9

RAIN

sensor

WIND

sensor

Aerial

P1 P2

TEMP.

Sensor L2

L1

L5

DIP switch

ATTENTION! The electronic

board is protected by a 10A

fuse. The maximum allowed

power, including the plug-in

LED controller board, is 240W.

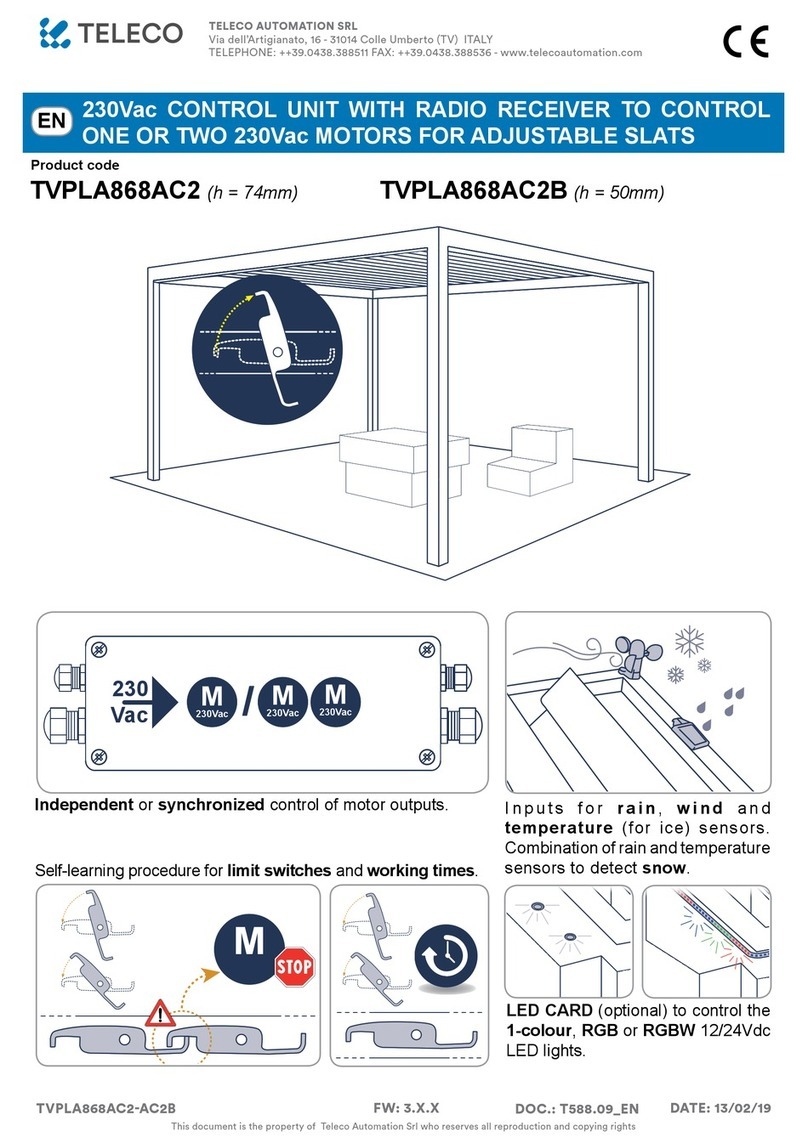

= Weather sensor alarms (from LOW to HIGH priority)

FIRST POWER ON: at rst power-on, the system is waiting

to be programmed with the memorization of at least one

transmitter (par. 3, page 8) and the conguration of the

motors and relative working time (see next pages).

1CONNECTIONS, ADJUSTMENTS AND CONTROL UNIT WARNINGS

= It takes effect DURING conguration

DIP MEANING

1 - 2 - 3 Setting of wind sensor threshold (see par. 4.1, page 11)

4 - 5 Motor control mode (see pages 4…7)

6Maximum motor current threshold set during conguration

(see par. 2.4, page 7)

not

used

L4

16 17 18 19

20 21 22 23

Encoder M1

Encoder M2

= MOTOR alarms