Figure 4-13 Removing retainers and 0-ring from

fluid body.

Figure 4-14 Removing check valves from fluid

body.

5.7 Check outside diameter (OD) of

fluid piston (16 or 27) and the inside

diameter (ID) of the fluid body (21) to

determine wear clearance between the

two parts. See Table 5-1. Remember

that the operating efficiency of the

pump depends on maintaining the

close tolerance dimension between

the piston and the body. Note: When

checking the ID of the fluid body and

the OD of the piston, check at several

points around and up and down the

bore of the body and the circum-

ference of the piston.

5.0 INSPECTION

5.1 Wash all metal parts in solvent.

Dry parts thoroughly with air or with

lint-free cloth. Remove hardened sedi-

ment with a soft bristle brush. Do not

scrape parts with a metal tool.

5.2 Under a light, and preferably under

magnification, visually inspect parts

for cracks, pitting, scoring, corrosion

or galling.

5.3 Inspect all threaded parts for chipped,

crossed or stripped threads.

5.4 Inspect and measure the free (re-

laxed) length of springs:

a. Detent springs (8), 7/8 inches

(22.23 mm);

b. Check valve springs (25), 3/4

inches (19.05 mm);

c. Check valve springs (34), 11/16

inches (17.45 mm);

d. Shuttle spring (4E), 1 5/16

inches (33.5 mm).

5.5 Roll springs over a flat surface to

check for wobble.

5.6 Check tube assembly (48) for kinks,

breaks or defective tube flares.

8

5.8 Check for smooth movement of shut-

tle assembly within air valve body.

Check contacting surfaces of shuttle

and bore of body for dirt, scratches

or galling. Check rings (4C) on shuttle

for wear, particularly at the tips. Check

o-rings (4B) under seal rings for

general condition and inspect detent

pins (9) for worn condition.

5.9 Inspect inlet and outlet check valve

seating surfaces in the fluid body (21)

for nicks, burrs or excessive wear.

Inspect valve bodies, poppets, springs

and seats for nicks, burrs, excessive

wear or rust.

6.0 REPAIR AND REPLACEMENT

6.1 Polish metal parts to remove minute

imperfections, minor scratches or

scoring. Use wet-or-dry paper grit

#600.

6.2 Check fluid piston (16 or 27) and fluid

body (21). If there is any evidence of

galling, replace both piston and body.

Carefully polish piston to remove mi-

nor scratches or nicks. Use grit #600.

Polish fluid body bore with hone to

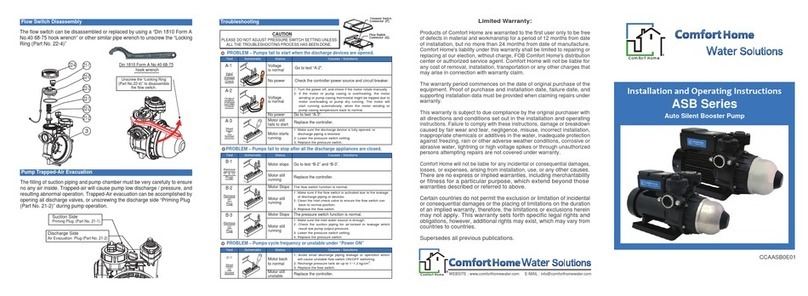

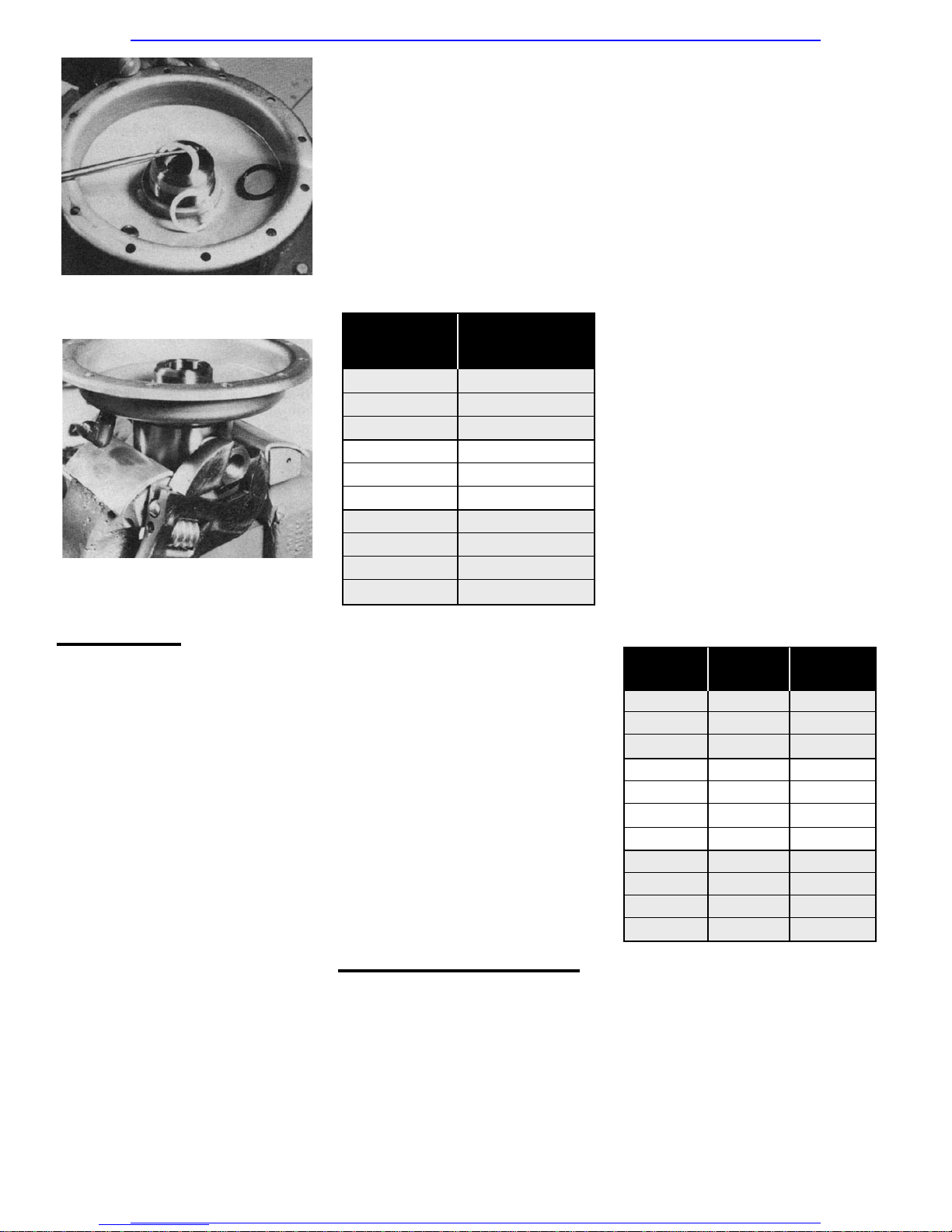

Table 5-1 In-service wear limits, fluid piston to

fluid body.

ALLOWABLE MAX.

PUMP RATIO CLEARANCE

AND DASH NO. INCH MM

10:1 - 10 0.010 0.254

20:1 -20 0.008 0.203

30:1 -30 0.007 0.178

35:1 -35 0.005 0.127

60:1 -60 0.005 0.127

100:1 -100 0.004 0.102

125:1 -125 0.004 0.102

150:1 -150 0.003 0.076

200:1 -200 0.002 0.051

300:1 -300 0.001 0.025

remove minor imperfections. Use a

very fine polishing stone. Recheck

for wear clearances as described in

paragraph 5.7 and Table 5-1. If im-

perfections cannot be easily removed,

replace piston and body as a matched

set. Note: The replacement piston-

body set also includes the lower

housing and gasket.

6.3 Check air valve and upper housing

assembly. Polish out minor imper-

fections as described in paragraph

6.2. Keep polishing and honing to

an absolute minimum to prevent an

increase in wear clearance and result-

ing loss of air. If imperfections

cannot be easily removed, replace the

entire air valve and upper housing

assembly.

6.4 Clean all repaired parts in solvent as

described in paragraph 5.1.

6.5 Replace all metal parts that fail to

pass inspection or are damaged or

worn beyond simple repair.

6.6 Replace all o-rings, packing retainers,

gaskets, springs and detent pins at

each pump overhaul. Overhaul kits

from Sprague Products conveniently

contain all necessary parts to prop-

erly overhaul or service the pump.

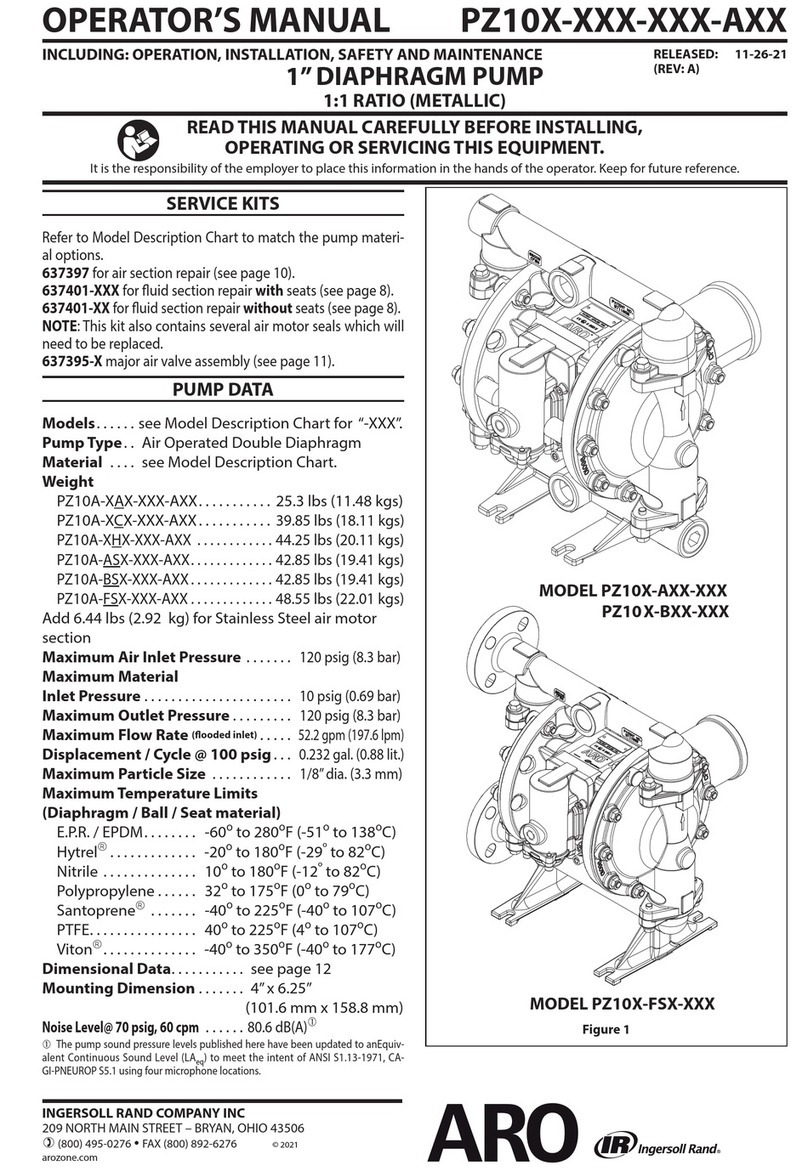

See Figure 6-1.

These listed kits contain nitrile seals. Kits

can also be ordered with neoprene, viton,

and EPR seal material. Refer to catalog

SCC-0693 for kit descriptions and specific

ordering information.

Figure 6-1 Overhaul Kits.

PUMP REFERENCE OVERHAUL

MODEL NO. NO. KIT

S-216-J-10 79293-11 90680-11

S-216-J-20 77894-11 90680-21

S-216-J-30 77894-21 90680-31

S-216-J-35 77895-81 90680-41

S-216-J-60 77895-11 90680-51

S-216-J-100 77895-21 90680-61

S-216-J-125 77895-61 90680-01

S-216-J-125 77895-61001 90680-01001

S-216-J-150 77895-31001 90680-71001

S-216-J-200 77895-41001 90680-81001

S-216-J-300 77895-51001 90680-91001

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.