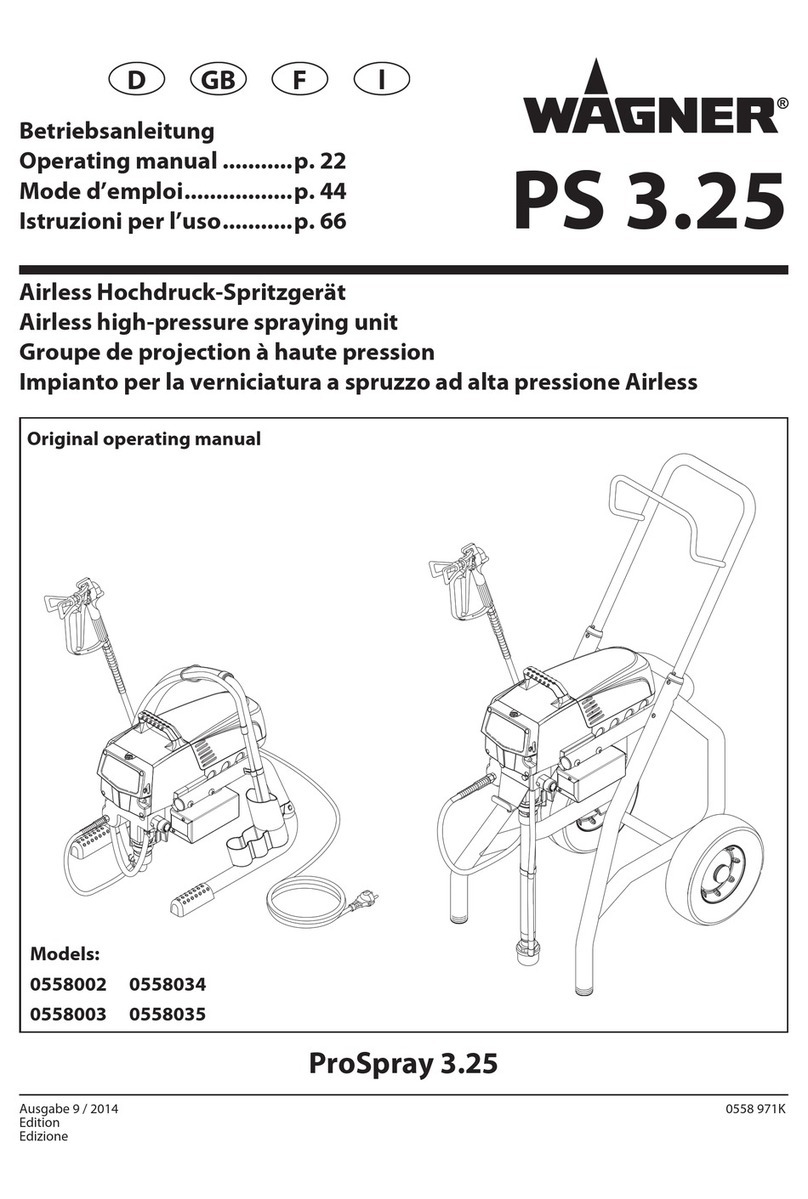

Spray Centre Maxi Spray 21.XL User manual

Edition 9 / 2015 0532 838A

GB

Operating manual

Airless high-pressure

spraying unit

Exclusive Suppliers of

(PS 3.20)

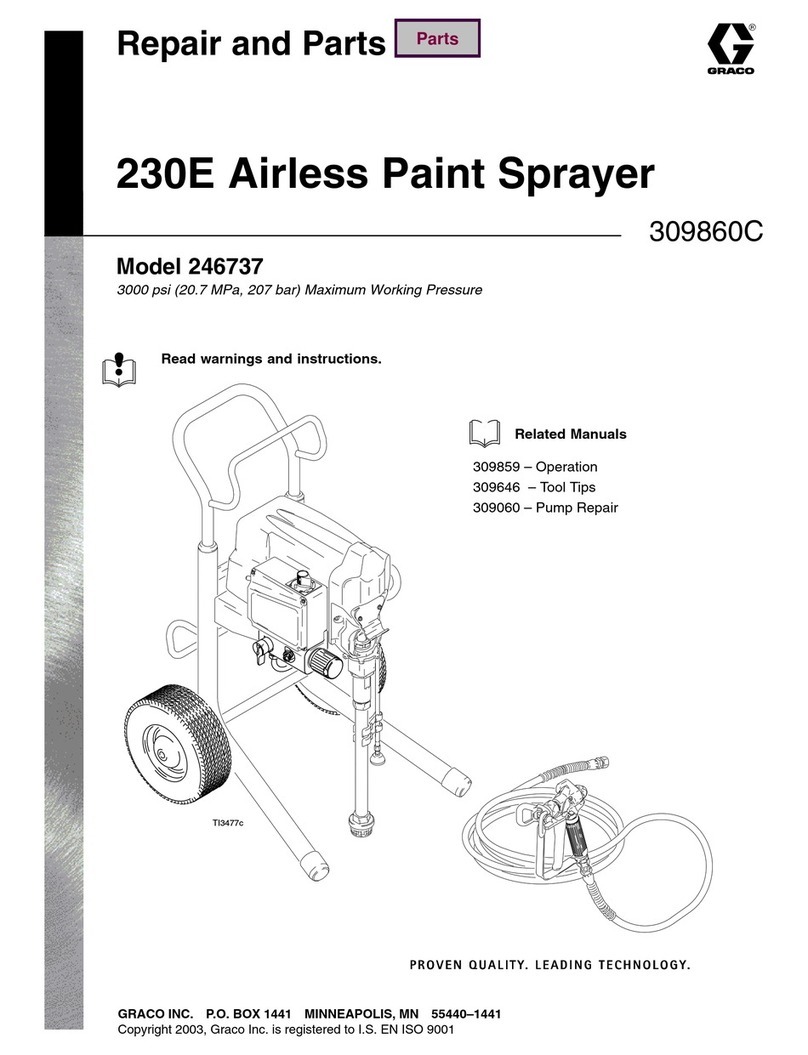

Maxi Spray 21.XL

2 ProSpray 3.20

GB

Warning!

Attention: Danger of injury by injection!

Airless units develop extremely high spraying pressures.

Be safety conscious!

1

2

3

Never put your ngers, hands or any other parts of the body into

the spray jet!

Never point the spray gun at yourself, other persons or animals.

Never use the spray gun without safety guard.

Do not treat a spraying injury as a harmless cut. In case of injury

to the skin through coating materials or solvents, consult a doctor

immediately for quick and expert treatment. Inform the doctor

about the coating material or solvent used.

The operating instructions state that the following points must

always be observed before starting up:

1. Faulty units must not be used.

2. Secure Spray Centre spray gun using the safety catch on the trigger.

3. Ensure that the unit is properly earthed.

4. Check allowable operating pressure of high-pressure hose and

spray gun.

5. Check all connections for leaks.

The instructions regarding regular cleaning and maintenance of

the unit must be strictly observed.

Before any work is done on the unit or for every break in work the

following rules must be observed:

1. Release the pressure from spray gun and hose.

2. Secure the Spray Centre spray gun using the safety catch on the

trigger.

3. Switch o unit.

Original Operating Manual

ProSpray 3.20 1

GB

Contents

Contents

Page

1. Safety regulations for Airless spraying...................................... 2

1.1 Explanation of symbols used.............................................................. 2

1.2 Electric safety............................................................................................ 3

1.3 Electrostatic charging (formation of sparks or ames).............. 3

2. General view of application............................................................. 4

2.1 Application ................................................................................................ 4

2.2 Coating materials .................................................................................... 4

3. Description of unit................................................................................ 4

3.1 Airless process.......................................................................................... 4

3.2 Functioning of the unit ......................................................................... 4

3.3 Legend for explanatory diagram PS 3.20 ....................................... 5

3.4 Explanatory diagram PS 3.20 .............................................................. 5

3.5 Technical data .......................................................................................... 6

3.6 Transportation in vehicle...................................................................... 6

4. Starting operation................................................................................ 6

4.1 High-pressure hose, spray gun and separating oil ..................... 6

4.2 Connection to the mains network .................................................... 7

4.3 Cleaning preserving agent when

starting-up of operation initially........................................................ 7

4.4 Taking the unit into operation with coating material................ 7

5. Spraying technique ............................................................................. 8

6. Handling the high-pressure hose ................................................. 8

7. Interruption of work............................................................................ 8

8. Cleaning the unit (shutting down) ............................................... 9

8.1 Cleaning unit from outside.................................................................. 9

8.2 Suction lter.............................................................................................. 9

8.3 Cleaning the high-pressure lter....................................................... 9

8.4 Cleaning Airless spray gun.................................................................10

Page

9. Remedy in case of faults..................................................................10

10. Servicing..................................................................................................11

10.1 General servicing...................................................................................11

10.2 High-pressure hose...............................................................................11

11. Repairs at the unit ..............................................................................11

11.1 Relief valve...............................................................................................11

11.2 Inlet and outlet valve...........................................................................12

11.3 Packings....................................................................................................13

11.4 Replacing the motor ............................................................................14

11.5 Replacing the gears..............................................................................14

11.6 Replacing the pressure switch / transducer ................................15

11.7 Resetting the pressure switch timing............................................15

11.8 Replacing the circuit board ...............................................................16

11.9 PS 3.20 connection diagram .............................................................16

12. Appendix.................................................................................................17

12.1 Selection of tip .......................................................................................17

12.2 Servicing and cleaning of Airless hard-metal tips.....................18

12.3 Spray gun accessories..........................................................................17

12.4 Airless tip table................................................................................ 18/19

12.5 2Speed Tip table....................................................................................20

12.6 Nozzle cases ............................................................................................21

12.7 TempSpray...............................................................................................22

WAGNER-Service companies.......................................................................23

Spare parts lists .................................................................................................24

Accessories for PS 3.20 ............................................................................... 24/25

Spare parts list for main assembly ................................................................26

Spare parts list for suction system ................................................................26

Spare parts list for drive assembly I ..............................................................27

Spare parts list for drive assembly II.............................................................28

Spare parts list of stand ....................................................................................29

Important notes on product liability ......................................................30

3+2 years guarantee for professional nishing ................................30

2 ProSpray 3.20

GB

Safety precautions

1. Safety regulations for Airless spraying

1.1 Explanation of symbols used

This manual contains information that must be read and understood

before using the equipment. When you come to an area that has one

of the following symbols, pay particular attention and make certain

to heed the safeguard.

This symbol indicates a potential hazard that

may cause serious injury or loss of life. Important

safety information will follow.

At

tention

This symbol indicates a potential hazard to you

or to the equipment. Important information that

tells how to prevent damage to the equipment or

how to avoid causes of minor injuries will follow.

Danger of skin injection

Danger of fire from solvent and paint fumes

Danger of explosion from solvent, paint fumes

and incompatible materials

Danger of injury from inhalation of harmful

vapors

i

Notes give important information which should

be given special attention.

HAZARD: INJECTION INJURY

Attention: Danger of injury by injection! A high

pressure stream produced by this equipment can

pierce the skin and underlying tissues, leading to

serious injury and possible amputation.

Do not treat a spraying injury as a harmless cut. In

case of injury to the skin through coating materials

or solvents, consult a doctor immediately for quick

and expert treatment. Inform the doctor about the

coating material or solvent used.

PREVENTION:

• NEVERaimthegunatanypartofthebody.

• NEVERallowanypartofthebodytotouchtheuidstream.

DO NOT allow body to touch a leak in the uid hose.

• NEVERputyourhandinfrontofthegun.Gloveswillnot

provide protection against an injection injury.

• ALWAYSlocktheguntrigger,shuttheuidpumpoand

release all pressure before servicing, cleaning the tip guard,

changing tips, or leaving unattended. Pressure will not be

releasedbyturningotheengine.ThePRIME/SPRAYvalve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure.

• ALWAYSkeeptipguardinplacewhilespraying.Thetipguard

provides some protection but is mainly a warning device.

• ALWAYSremovethespraytipbeforeushingorcleaningthe

system.

• NEVERuseaspraygunwithoutaworkingtriggerlockand

trigger guard in place.

• Allaccessoriesmustberatedatorabovethemaximum

operating pressure range of the sprayer. This includes spray

tips, guns, extensions, and hose.

HAZARD

: HIGH PRESSURE HOSE

The paint hose can develop leaks from wear, kinking

and abuse. A leak can inject material into the skin.

Inspect the hose before each use.

PREVENTION:

• High-pressurehosesmustbecheckedthoroughlybeforethey

are used.

• Replaceanydamagedhigh-pressurehoseimmediately.

• Neverrepairdefectivehigh-pressurehosesyourself!

• Avoidsharpbendsandfolds:thesmallestbendingradiusis

about 20 cm.

• Donotdriveoverthehigh-pressurehose.Protectagainst

sharp objects and edges.

• Neverpullonthehigh-pressurehosetomovethedevice.

• Donottwistthehigh-pressurehose.

• Donotputthehigh-pressurehoseintosolvents.Useonlya

wet cloth to wipe down the outside of the hose.

• Laythehigh-pressurehoseinsuchawayastoensurethatit

cannot be tripped over.

i

Only use Spray Centre original-high-pressure

hoses in order to ensure functionality, safety and

durability.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

Severe injury and/or property damage can occur.

PREVENTION:

• Donotusematerialswithaashpointbelow38°C(100°F).

Flashpoint is the temperature at which a uid can produce

enough vapors to ignite.

• Donotusetheunitinworkplaceswhicharecoveredbythe

explosion protection regulations.

• Provideextensiveexhaustandfreshairintroductionto

keep the air within the spray area free from accumulation of

ammable vapors.

• Avoidallignitionsourcessuchasstaticelectricitysparks,

electrical appliances, ames, pilot lights, hot objects, and

sparks from connecting and disconnecting power cords or

working light switches.

• Donotsmokeinsprayarea.

• Placesprayersucientdistancefromthesprayobjectina

well ventilated area (add more hose if necessary). Flammable

vapors are often heavier than air. Floor area must be

extremely well ventilated. The pump contains arcing parts

that emit sparks and can ignite vapors.

• Theequipmentandobjectsinandaroundthesprayareamust

be properly grounded to prevent static sparks.

• Useonlyconductiveorearthedhighpressureuidhose.Gun

must be earthed through hose connections.

• Powercordmustbeconnectedtoagroundedcircuit(electric

units only).

• Alwaysushunitintoseparatemetalcontainer,atlowpump

pressure, with spray tip removed. Hold gun rmly against side

of container to ground container and prevent static sparks.

ProSpray 3.20 3

GB

Safety precautions

• Followmaterialandsolventmanufacturer’swarningsand

instructions.Befamiliarwiththecoatingmaterial’sMSDS

sheet and technical information to ensure safe use.

• Uselowestpossiblepressuretoushequipment.

• Whencleaningtheunitwithsolvents,thesolventshould

never be sprayed or pumped back into a container with a

small opening (bunghole). An explosive gas/air mixture can

arise. The container must be earthed.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, and other materials can be harmful

if inhaled or come in contact with body. Vapors can

cause severe nausea, fainting, or poisoning.

PREVENTION:

• Wearrespiratoryprotectionwhenspraying.Readall

instructions supplied with the mask to be sure it will provide

the necessary protection.

• Alllocalregulationsregardingprotectionagainsthazardous

vapors must be observed.

• Wearprotectiveeyewear.

• Protectiveclothing,glovesandpossiblyskinprotectioncream

are necessary for the protection of the skin. Observe the

regulations of the manufacturer concerning coating materials,

solvents and cleaning agents in preparation, processing and

cleaning units.

HAZARD: GENERAL

This product can cause severe injury or property

damage.

PREVENTION:

• Followallappropriatelocal,state,andnationalcodes

governing ventilation, re prevention, and operation.

• Pullingthetriggercausesarecoilforcetothehandthatis

holding the spray gun. The recoil force of the spray gun is

particularly powerful when the tip has been removed and

a high pressure has been set on the airless pump. When

cleaning without a spray tip, set the pressure control knob to

the lowest pressure.

• Useonlymanufacturerauthorizedparts.Userassumesall

risks and liabilities when using parts that do not meet the

minimum specications and safety devices of the pump

manufacturer.

• ALWAYSfollowthematerialmanufacturer’sinstructionsfor

safe handling of paint and solvents.

• Cleanupallmaterialandsolventspillsimmediatelytoprevent

slip hazard.

• Wearearprotection.Thisunitcanproducenoiselevelsabove

85 dB(A).

• Neverleavethisequipmentunattended.Keepawayfrom

children or anyone not familiar with the operation of airless

equipment.

• Donotsprayonwindydays.

• Thedeviceandallrelatedliquids(i.e.hydraulicoil)mustbe

disposed of in an environmentally friendly way.

1.2 Electric Safety

Electric models must be earthed. In the event of an electrical short

circuit, earthing reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with

a cord having an earthing wire with an appropriate earthing plug.

Connection to the mains only through a special feed point, e.g.

through an error protection insallation with INF < 30 mA.

DANGER — Work or repairs at the electrical

equipment may only be carried out by a skilled

electrician. No liability is assumed for incorrect

installation. Switch the unit o. Before all repair

work, unplug the power plug from the outlet.

Danger of short-circuits caused by water ingressing into the electrical

equipment. Never spray down the unit with high-pressure or high-

pressure steam cleaners.

Work or repairs at the electrical equipment:

These may only be carried out by a skilled electrician. No liability is

assumed for incorrect installation.

1.3 Electrostatic charging (formation of sparks or

ames)

Electrostatic charging of the unit may occur during

spraying due to the ow speed of the coating

material. These can cause sparks and ames upon

discharge. The unit must therefore always be

earthed via the electrical system. The unit must be

connected to an appropriately-grounded safety

outlet.

An electrostatic charging of spray guns and the high-pressure hose

is discharged through the high-pressure hose. For this reason the

electric resistance between the connections of the high-pressure

hose must be equal to or lower than 1 MΩ.

4 ProSpray 3.20

GB

General view of application Description of unit

2. General view of application

2.1 Application

The unit performance is conceived so that its use is possible on

building sites for small- to middle-area dispersion work.

Examples of objects of spraying

The sprayer is able for all common varnishing jobs like doors, door

frames, balustrades, furniture, woodencladding, fences, radiators

(heating) and steel parts.

2.2 Coating materials

Processible coating materials

i

Pay attention to the Airless quality of the coating

materials to be processed.

Dilutable lacquers and paints or those containing solvents, two-

component coating materials, dispersions, latex paints, release

agents, oils, undercoats, primers, and llers.

No other materials should be used for spraying without SPRAY

CENTRE’s approval.

Filtering

Despite suction lter and insertion lter in the spray gun, ltering of

the coating material is generally advisable.

Stir coating material before commencement of work.

iAttention: Make sure, when stirring up with motor-

driven agitators that no air bubbles are stirred in. Air

bubbles disturb when spraying and can, in fact, lead

to interruption of operation.

Viscosity

With this unit it is possible to process highly viscous coating materials

of up to around 20.000 MPa·s.

If highly viscous coating materials cannot be taken in by suction, they

mustbedilutedinaccordancewiththemanufacturer’sinstructions.

Two-component coating material

The appropriate processing time must be adhered to exactly. Within

this time rinse through and clean the unit meticulously with the

appropriate cleaning materials.

Coating materials with sharp-edged additional materials

These have a strong wear and tear eect on valves, high-pressure

hose, spray gun and tip. The durability of these parts cane be reduced

appreciably through this.

3. Description of unit

3.1 Airless process

The main areas of application are thick layers of highly viscous

coating material for large areas and a high consumption of material.

A piston pump takes in the coating material by suction and conveys it

to the tip. Pressed through the tip at a pressure of up to a maximum

of 207 bar (20.7 MPa), the coating material is atomised. This high

pressure has the eect of micro ne atomisation of the coating

material.

As no air is used in this process, it is described as an AIRLESS process.

This method of spraying has the advantages of nest atomisation,

cloudless operation and a smooth, bubble-free surface. As well as

these, the advantages of the speed of work and convenience must

be mentioned.

3.2 Functioning of the unit

In the following there is a short description of the technical

construction for better understanding of the function.

Spray Centre ProSpray 3.20 units are electrically driven high-pressure

spraying units.

A gear unit transfers the driving force to a crankshaft. The crankshaft

moves the pistons of the material feed pump up and down.

The inlet valve is opened automatically by the upwards movement

of the piston. The outlet valve is opened when the piston moves

downward.

The coating material ows under high pressure through the high-

pressure hose to the spray gun. When the coating material exits from

the tip it atomizes.

The pressure control knob controls the volume and the operating

pressure of the coating material.

ProSpray 3.20 5

GB

Description of unit

3.3 Legend for explanatory diagram PS 3.20

1 Spray gun

2 High-pressure hose

3 Return hose

4 Suction hose

5 Frame

6 Drip cup

7 Power cord

8 ON/OFF switch

9 Relief valve

Lever position vertical – PRIME ( kcirculation)

Leverpositionhorizontal–SPRAY(p)

10 Pressure control knob

11 Oil cup for EasyGlide (EasyGlide prevents increased wear of

the packings)

12 Pressure gauge

13 Pusher stem

10 3

4

5

6

7

1

2

13

9

8

11

12

3.4 Explanatory diagram PS 3.20

4. Starting operation

4.1 High-pressure hose, spray gun and

separating oil

1. Screw the pressure gauge (1) to the coating material outlet

(Fig. 2, Item 2).

2. Screw the high-pressure hose (3) to the coating material

outlet on the pressure gauge (Fig. 2, Item 4).

3. Screw the spray gun (5) with the selected tip onto the high-

pressure hose.

4. Tighten the union nuts at the high-pressure hoses rmly so

that coating material does not leak.

1

4

2

3

5

5. Fill the oil cup with EasyGlide (Fig. 3). Do not use too much

EasyGlide, i.e. ensure that no EasyGlide drips into the coating

material container.

Attention

EasyGlide prevents increased wear and tear to the

packings.

1

6. Fully depress the pusher stem (Fig. 3, item 1) to make sure the

inlet ball is free.

6 ProSpray 3.20

GB

Description of unit Starting operation

3.5 Technical data

Voltage

220~240VAC,50/60Hzor

100~120VAC,50/60Hz

Max. current consumption

220~240VAC 5.5 A

100~120VAC 12 A

Power Cord

See page 27

Acceptance capacity

1000 Watt

Max. operating pressure

207 bar (20.7 MPa)

Volume ow at 12 MPa (120 bar) with water

1.62 l/min

Max tip size

0.021 inch – 0.53 mm

Max. temperature of the coating material

43°C

Max viscosity

20.000 MPa·s

Weight

13.6 kg

Special high-pressure hose

6,35 mm, 15 m - 1/4” - 18 NPSM

Dimensions (L X W X H)

441 x 324 x 415 mm

Vibration

Spray gun does not exceed 2.5m/s2

Max sound pressure level

80 dB*

* Placeofmeasuring:1mindistancefromtheunitand1.6

m above the oor, 12 MPa (120 bar) operating pressure,

reverberant oor.

3.6 Transportation in vehicle

Secure the unit with a suitable fastening.

4.4 Taking the unit into operation with coating

material

1. Immerse the suction tube (Fig. 4, Item 2) and return hose (1)

into the coating material container.

2. Turn the pressure control knob counterclockwise (3) to

minimum pressure.

3. Open the relief valve (4), valve position PRIME (kcirculation).

4. Switch the unit (5) ON.

5. Wait until the coating material exudes from the return hose.

6. Closethereliefvalve,valvepositionSPRAY(pspray).

7. Trigger the spray gun several times and spray into a collecting

container until the coating material exits the spray gun

without interruption.

8. Increase the pressure by slowly turning up the pressure

control knob.

Check the spray pattern and increase the pressure until the

atomization is correct.

Always turn the pressure control knob to the lowest setting

with good atomization.

9. The unit is ready to spray.

ProSpray 3.20 7

GB

Starting operation

4.2 Connection to the mains network

Attention

The unit must be connected to an appropriately-

grounded safety outlet.

Before connecting the unit to the mains supply, ensure that the line

voltagematchesthatspeciedontheunit’sratingplate.

The connection must be equipped with a residual current protective

device with INF ≤ 30 mA.

iSpray Centre‘s accessories program also includes a

mobile operator protection device for the electronic

supply, which can also be used with other electronic

equipment.

4.3 Cleaning preserving agent when starting-up

of operation initially

1. Immerse the suction tube (Fig. 4, Item 2) return hose (1) into a

container with a suitable cleaning agent.

2. Turn the pressure control knob counterclockwise (3) to

minimum pressure.

3. Open the relief valve (4), valve position PRIME (kcirculation).

4. Switch the unit (5) ON.

5. Wait until the cleaning agent exudes from the return hose.

6. Closethereliefvalve,valvepositionSPRAY(pspray).

7. Pull the trigger of the spray gun.

8. Spray the cleaning agent from the unit into an open collecting

container.

3

1

2

4

5

6. Handling the high-pressure hose

The unit is equipped with a high-pressure hose specially suited for

piston pumps.

Danger of injury through leaking high-pressure

hose. Replace any damaged high-pressure hose

immediately.

Never repair defective high-pressure hoses yourself!

The high-pressure hose is to be handled with care. Avoid sharp

bendsandfolds:thesmallestbendingradiusisabout20cm.

Do not drive over the high-pressure hose. Protect against sharp

objects and edges.

Never pull on the high-pressure hose to move the device.

Make sure that the high-pressure hose cannot twist. This can be

avoided by using a Spray Centre spray gun with a swivel joint and a

hose system.

iWhen using the high-pressure hose while working

on scaolding, it is best to always guide the hose

along the outside of the scaolding.

iThe risk of damage rises with the age of the high-

pressure hose. Spray Centre recommends replacing

high-pressure hoses after 6 years.

iUse only Spray Centre original-high-pressure

hoses in order to ensure functionality, safety and

durability.

7. Interruption of work

1. Open the relief valve, valve position PRIME (kcirculation).

2. Switch the unit OFF.

3. Turn the pressure control knob counterclockwise to minimum

pressure.

4. Pull the trigger of the spray gun in order to release the

pressure from the high-pressure hose and spray gun.

5. Secure the spray gun, refer to the operating manual of the

spray gun.

6. If a standard tip is to be cleaned, see Page 18, Section 12.2.

If a non-standard tip is installed, proceed according to the

relevant operating manual.

7. Depending on the model, leave the suction tube or the

suction hose and return hose immersed in the coating

material or swivel or immerse it into a corresponding cleaning

agent.

Attention

If fast-drying or two-component coating material is

used, ensure that the unit is rinsed with a suitable

cleaning agent within the processing time.

5. Spraying technique

Injection hazard. Do not spray without the tip guard

in place. NEVER trigger the gun unless the tip is

completely turned to either the spray or the unclog

position. ALWAYS engage the gun trigger lock

before removing, replacing or cleaning tip.

The key to a good paint job is an even coating over the entire surface.

Keepyourarmmovingataconstantspeedandkeepthespraygunat

a constant distance from the surface. The best spraying distance is 25

to 30 cm between the spray tip and the surface.

25 - 30 cm

Keepthespraygunatrightanglestothesurface.Thismeansmoving

your entire arm back and forth rather than just exing your wrist.

Keepthespraygunperpendiculartothesurface,otherwiseoneend

of the pattern will be thicker than the other.

Trigger gun after starting the stroke. Release the trigger before

ending the stroke. The spray gun should be moving when the trigger

is pulled and released. Overlap each stroke by about 30%. This will

ensure an even coating.

25 - 30 cm25 - 30 cm

i

If very sharp edges result or if there are streaks in the

spray jet – increase the operating pressure or dilute

the coating material.

8 ProSpray 3.20

GB

Spraying technique Interruption of work

8. Cleaning the unit (shutting down)

A clean state is the best method of ensuring operation without

problems.Afteryouhavenishedspraying,cleantheunit.Underno

circumstances may any remaining coating material dry and harden in

the unit.

The cleaning agent used for cleaning (only with an ignition point

above38°C)mustbesuitableforthecoatingmaterialused.

• Secure the spray gun, refer to the operating manual of the

spray gun.

Clean and remove tip.

For a standard tip, refer to Page 17, Section 12.2.

If a non-standard tip is installed, proceed according to the relevant

operating manual.

1. Remove suction hose from the coating material.

2. Closethereliefvalve,valvepositionSPRAY(pspray).

3. Switch the unit ON.

Attention

The container must be earthed in case of coating

materials which contain solvents.

Caution! Do not pump or spray into a container with

a small opening (bunghole)!

Refer to the safety regulations.

4. Pull the trigger of the spray gun in order to pump the

remaining coating material from the suction hose, high-

pressure hose and the spray gun into an open container.

5. Immerse suction hose with return hose into a container with a

suitable cleaning agent.

6. Turn the pressure control knob counterclockwise to minimum

pressure.

7. Open the relief valve, valve position PRIME (kcirculation).

8. Pump a suitable cleaning agent in the circuit for a few

minutes.

9. Closethereliefvalve,valvepositionSPRAY(pspray).

10. Pull the trigger of the spray gun.

11. Pump the remaining cleaning agent into an open container

until the unit is empty.

12. Switch the unit OFF.

8.1 Cleaning unit from outside

First of all pull out mains plug from socket.

Attention

Danger of short circult through penetrating water!

Never spray down the unit with high-pressure or

high-pressure steam cleaners.

Attention

Do not put the high-pressure hose into solvents.

Use only a wet cloth to wipe down the outside of the

hose.

Wipe down unit externally with a cloth which has been immersed in a

suitable cleaning agent.

ProSpray 3.20 9

GB

Cleaning the unit (shutting down)

8.2 Suction lter

i

A clean suction lter always guarantees maximum

feed quantity, constant spraying pressure and

problem-free functioning of the unit.

1. Screw o the lter (Fig. 5) from suction pipe.

2. Clean or replace the lter.

Carry out cleaning with a hard brush and an appropriate cleaning

agent.

8.3 Cleaning the high-pressure lter

iA high-pressure lter is available as an optional

accessory that can be ordered separately. Clean the

lter cartridge regularly. A soiled or clogged high-

pressure lter can cause a poor spray pattern or a

clogged tip.

1. Turn the pressure control knob counterclockwise to minimum

pressure.

2. Open the relief valve, valve position PRIME (kcirculation).

3. Switch the unit OFF.

Unplug the power plug from the outlet.

4. Unscrewthelterhousing(Fig.6,Item1)withastrapwrench.

5. Turning clockwise, unscrew the lter (2) from the pump

manifold (3).

6. Clean all the parts with the corresponding cleaning agent. If

necessary, replace the lter cartridge.

7. Check the O-ring (4), replace it if necessary.

8. Turning counterclockwise, screw the new or cleaned lter into

the pump manifold.

9. Screw in lter housing (1) and tighten it as far as possible with

the strap wrench.

1

3

2

4

10 ProSpray 3.20

GB

Cleaning the unit (shutting down) Remedy in case of faults

Type of malfunction

A. Unitdoesnotstart

B. Unitdoesnotdrawinmaterial

C. Unitdrawsinmaterial,butthe

pressure does not build up

D. Coating material exits at the top of

the uid section

E. Increased pulsation at the spray

gun

F. Poor spray pattern

G. Unitlosespower

H. Pump over-pressurizes and will not

shut o.

Possible cause

1. No voltage applied.

2. Pressure setting too low.

3. ON/OFF switch defective.

1. ReliefvalveissettoSPRAY(pspray).

2. Filter projects over the uid level and

sucks air.

3. Filter clogged.

4. Suction hose/suction tube is loose, i.e.

the unit is sucking in outside air.

1. Tip heavily worn.

2. Tip too large.

3. Pressure setting too low.

4. Filter clogged.

5. Coating material ows through the

return hose when the relief valve is in

theSPRAY(pspray) position.

6. Packings sticky or worn.

7. Valveballsworn.

8. Valveseatsworn.

1. Upperpackingisworn.

2. Piston is worn.

1. Incorrect high-pressure hose type.

2. Tip worn or too large.

3. Pressure too high.

1. Tip is too large for the coating

material which is to be sprayed.

2. Pressure setting incorrect.

3. Volumetoolow.

4. Coating material viscosity too high.

1. Pressure setting too low.

1. Pressure switch defective.

2. Transducer defective.

Measures for eliminating the malfunction

1. Check voltage supply.

2. Turn up pressure control knob.

3. Replace.

1. Set relief valve to PRIME (kcirculation).

2. Rell the coating material.

3. Clean or replace the lter.

4. Clean connecting points. Replace O-rings if necessary.

Secure suction hose with retaining clip.

1. Replace

2. Replace tip.

3. Turn pressure control knob clockwise to increase.

4. Clean or replace the lter.

5. Remove and clean or replace relief valve.

6. Remove and clean or replace packings.

7. Remove and replace valve balls.

8. Remove and replace valve seats.

1. Remove and replace packing.

2. Remove and replace piston.

1. Only use SPRAYCENTRE original-high-pressure hoses in

order to ensure functionality, safety and durability.

2. Replace tip.

3. Turn pressure control knob to a lower number.

1. Replace tip.

2. Turn pressure control knob until a satisfactory spraying

pattern is achieved.

3. Clean or replace all lters.

4. Thinoutaccordingtothemanufacturer’sinstructions.

1. Turn pressure control knob clockwise to increase.

1. Take unit to a Spray Centre authorized service center.

2. Take unit to a Spray Centre authorized service center.

9. Remedy in case of faults

8.3 Cleaning Airless spray gun

1. Rinse Airless spray gun with an appropriate cleaning agent.

2. Clean tip thoroughly with appropriate cleaning agent so that

no coating material residue remains.

3. Thoroughly clean the outside of the Airless spray gun.

Intake lter in Airless spray gun (Fig. 7)

Disassembly

1. Pull protective guard (1) forward vigorously.

2. Screw grip (2) out of the gun housing. Remove intake lter (3).

3. Intake lter congested or defective – replace.

Assembly

1. Place intake lter (3) with the long cone into the gun housing.

2. Screw in grip (2) into the gun housing and tighten.

3. Slot in protective guard (1).

1

2

3

ProSpray 3.20 11

GB

Servicing Repairs at the unit

10. Servicing

10.1 General servicing

Servicing of the unit should be carried out once annually by the

WAGNER service.

1. Check high-pressure hoses, device connecting line and plug

for damage.

2. Check the inlet valve, outlet valve and lter for wear.

10.2 High-pressure hose

Inspect the high-pressure hose visually for any notches or bulges, in

particular at the transition in the ttings. It must be possible to turn

the union nuts freely.

i

The risk of damage rises with the age of the high-

pressure hose. Spray Centre recommends replacing

high-pressure hoses after 6 years.

11. Repairs at the unit

Switch the unit OFF.

Before all repair work: Unplug the power plug from

the outlet.

11.1 Relief valve

Attention

The valve housing (4) should not be repaired. If

worn, it should always be replaced with a new one.

1. Useadriftpunchof2mmtoremovethegroovedpin(Fig.8,

Item 1) from the relief valve handle (2).

2. Remove the relief valve handle (2) and cam base (3).

3. Usingawrench,removethevalvehousing(4)fromthepump

manifold (6).

4. Ensure that the seal (5) is seated correctly, then screw the

new valve housing (4) completely into the pump manifold (6).

Tighten securely with a wrench.

5. Align the cam base (3) with the hole in the pump manifold (6).

Lubricate the cam base with grease and slide on the cam base.

6. Bring the hole in the valve shaft (7) and in the relief valve

handle (2) into alignment.

7. Insert the grooved pin (1) to secure the relief valve handle in

position.

1

3

2

4

7

5

6

12 ProSpray 3.20

GB

Repairs at the unit

11.2 Inlet and outlet valve

1. Remove the screw that secures the pressure control knob.

Remove the knob.

Remove the three screws in the front cover and then remove

the front cover.

2. Switch the unit ON and then OFF so that the piston rod is

positioned in the lower stroke position.

Danger of crushing - do not reach with the ngers or

tool between the moving parts.

3. Unplugthepowerplugfromtheoutlet.

4. Remove the retaining clip from the connecting bend at the

suction hose and pull o the suction hose.

5. Screw o the return hose.

6. Swiveltheunit90°totherearinordertoworkmoreeasilyon

the material feed pump.

7. Remove the pusher stem clip and slide the pusher housing (7)

from the inlet valve housing (1).

8. Unscrewtheinletvalvehousing(Fig.10,Item1)fromthe

pump manifold (2).

9. Remove the lower ball guide (6), lower seal (5), inlet valve ball

(4), inlet valve seat (3) and O-ring (8).

10. Clean all the parts with the corresponding cleaning agent.

Check the inlet valve housing (1), inlet valve seat (3) and inlet

valve ball (4) for wear and replace the parts if necessary.

1

3

4

5

6

7

2

8

11. Unscrewoutletvalvehousing(Fig.11,Item9)fromthepiston

(10) with adjusting wrench.

12. Remove the upper ball guide (14), crush washer (13), outlet

valve ball (12), and outlet valve seat (11).

13. Clean all the parts with the corresponding cleaning agent.

Check outlet valve housing (9), outlet valve seat (11), outlet

valve ball (12) and upper ball guide (14) for wear and replace

parts if necessary.

14. Carry out installation in the reverse order. Make sure the outlet

valve retainer (9) is reinstalled with the non-threaded “lip”

facing up into the piston. Lubricate O-ring (Fig. 10, Item 8)

with machine grease and ensure proper seating in the inlet

valve housing (Fig. 10, Item 1).

14

10

9

11

12

13

11.3 Packings

Disassembly (Fig. 12)

1. Remove inlet valve housing in accordance with the steps in

Chapter 11.2. It is not necessary to remove the outlet valve.

2. Remove the yoke screw (14) and washer (15) that secures the

dowel pin (16). The dowel pin connects the yoke (17) to the

piston (18).

3. Usingapliers,pullthedowelpin(16)out.

4. Rotate the pump shaft so the piston is in the top dead center

position. Press the yoke (17) against the top bushing (19) with

a screwdriver, for example. This is required to disassemble all

the parts.

5. Remove the piston assembly (18) by pushing down on the

piston near the yoke (17).

6. Unscrewandremovetheupperbushing(19)usingan

adjustable wrench.

7. Remove the worn seals using a at head screwdriver or punch.

Remove the upper packing (20) from the top and the lower

packing (21) from the bottom by pressing against the side

of the seal and popping it out. Be sure not to scratch the

housing where the seals are located.

8. Clean the area where the new packings are to be installed.

Assembly (Fig. 12)

1. Slide the upper packing (20) o the grey sizing/insertion tool

(towards the tip) and install into the top of the pump housing

with the raised lip (23) facing down. Save the upper packing

sizing/insertion tool for use in step 6.

2. Place the upper bushing (19) into the top of the housing and

tighten with an adjustable wrench (torque to 300-360 in-lbs).

This will drive the upper packing (20) into the correct position.

3. Tilt the pump backwards so that it is laying on its back.

Remove the plastic wrap from the lower packing and red pre-

form tool.

Attention

Cut the plastic wrap with a scissors. Do not cut

plastic wrap with a utility knife as damage can occur

to the O-rings.

4. Slide the lower packing (21) o the pre-form tool (towards the

top). Insert the lower packing partially into the bottom of the

pump block so that the beveled edge (24) of the packing faces

up.

5. Thread the inlet valve housing (22) back into the bottom

of the pump housing by hand to drive the lower packing

ProSpray 3.20 13

GB

Repairs at the unit

14

18

19

20

18

20

21

26

22

16

15

17

25

23

24

into place. Once tightened as far as it will go, unthread and

remove again.

6. Place the grey insertion tool over the top of the piston

assembly (18). Coat the piston guide tool and the piston rod

with grease before inserting them into the pump housing.

7. Insert the piston assembly into the bottom of the pump block

and push upward until the hole in the piston is aligned with

the hole in the yoke (17). Discard insertion tool.

Attention

Make sure the piston is inserted precisely through

the middle of the upper and lower packing. Coming

in at an angle will bump the piston into the sides of

the packings and cause damage.

8. Apply any type of household grease to the piston and yoke

area to prolong life. Apply to the holes in the yoke where the

dowel (16) is inserted.

9. Install the dowel pin (16) to connect the yoke (17) to the

piston (18). The piston may have to be moved up or down to

do this.

10. Install the yoke screw (14) and washer (15) to secure the dowel

pin.

11. Turn pump right side up and apply a few drops of EasyGlide or

light household oil between the top nut (19) and piston (18).

This will prolong the seal life.

12. Reinstall the inlet valve assembly (22). Tighten by hand until

it cannot be tightented further, and then tighten another 1/2

turn with a wrench. This will automatically secure the lower

packing (21) into place.

13. If equipped, replace pusher assembly (26) onto inlet valve

assembly.

14. Install front cover and three screws.

15. Reinstall the pressure control knob. Secure with the screw.

16. Reinstall the suction tube and return tube.

iIf the knob bottom (25) has been removed from the

pressure switch assembly, it must be re-calibrated

prior to reinstallation. Follow the “Resetting the

Pressure Switch Timing” instructions.

14 ProSpray 3.20

GB

Repairs at the unit

11.4 Replacing the Motor

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

1. Open the relief valve, valve position PRIME (kcirculation).

SwitchtheunitOFF.Unplugthepowerplugfromtheoutlet.

2. Loosen and remove the four motor cover screws (1). Remove

the motor cover (2).

iThe ON / OFF switch (3) is housed inside the

motor cover. In order to remove the motor cover

completely, you must disconnect all of the wires at

the rear of the switch. Note the position of the wires

before disconnecting.

3. On the back of the motor (4), disconnect the two wires (black

and red) coming from the circuit board (5). Remove the

ground wire from the motor housing.

4. Slide the motor bae (7) o the rear of the motor.

5. Loosen and remove the four motor mounting screws (8).

6. Pull the motor (4) out of the pump housing (9).

7. With the motor removed, inspect the gears in the pump

housing (9) for damage or excessive wear. Replace the gears,

if necessary.

8. Install the new motor (4) into the pump housing (9).

9. Secure the motor with the four motor mounting screws (8).

10. Reconnect the wires (Refer to the Connection Diagram,

section 11.9).

11. Slide the motor bae (7) onto the rear of the motor. The

arrows on the bae should be pointed up.

12. Slide the motor cover (2) over the motor. Secure the motor

cover with the four motor cover screws (1).

1

3

2

8

5

9

6

4

7

11.5 Replacing the Gears

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

1. Open the relief valve, valve position PRIME (kcirculation).

SwitchtheunitOFF.Unplugthepowerplugfromtheoutlet.

2. Loosen and remove the four motor cover screws (1). Remove

the motor cover (2).

iThe ON / OFF switch (3) is housed inside the

motor cover. In order to remove the motor cover

completely, you must disconnect all of the wires at

the rear of the switch. Note the position of the wires

before disconnecting.

3. On the back of the motor (4), disconnect the two wires (black

and red) coming from the circuit board (5). Remove the

ground wire from the motor housing.

4. Slide the motor bae (7) o the rear of the motor.

5. Loosen and remove the four motor mounting screws (8).

6. Pull the motor (4) out of the pump housing (9).

7. Inspect the armature gear (10) on the end of the motor for

damage or excessive wear. If this gear is completely worn out,

replace the entire motor.

8. Remove and inspect the 2nd stage gear (11) for damage or

excessive wear. Replace if necessary.

9. If the armature gear (10) or 2nd stage gear (11) are damaged,

the pump housing (9) must be cleaned of any debris caused

by damaged gears.

10. Reassemble the pump by reversing the above steps.

i

Rell the gear box in the pump housing with ve

ounces of Lubriplate (P/N 314-171).

1

3

2

8

6

7

4

5

9

11

10

ProSpray 3.20 15

GB

Repairs at the unit

11.6 Replacing the Pressure Switch / Transducer

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

iIf the sprayer loses all pressure adjustment, or there

is paint leakage from the front of the sprayer, the

pressure switch and/or transducer may need to be

replaced.

1. Open the relief valve, valve position PRIME (kcirculation).

SwitchtheunitOFF.Unplugthepowerplugfromtheoutlet.

2. Remove the screw (1) that secures the pressure control knob

(2) to the bottom of the pressure control knob (3). Remove

the knob (2).

3. Loosen and remove the three front cover screws (4). Remove

the front cover (5).

4. Remove the screw (7) from the side of the pressure switch.

Remove the bottom of the pressure control knob (3) from the

top of the pressure switch.

5. Remove the pressure switch assembly (6) from the top of the

transducer (8).

6. Unplugthepressureswitch(6)fromthewireconnector(10).

Attention

Do not attempt to pull wires from the inside of the

pressure switch assembly. If the pressure switch

wire connector (10) is not exposed from through

the opening in the pump housing, pull gently on

the wires until the connector is shown through the

opening.

7. Check pressure switch continuity at the connector. If the

switch is bad replace with a new pressure switch assembly.

8. Inspect the transducer (8) for the presence of paint. If there is

paint, replace the transducer. If there is no paint, skip to step

9, below.

a. Usingawrenchonthehexheadofthetransducer,loosenand

remove the transducer assembly.

b. Apply a generous amount of grease to the transducer O-ring

(9). Reinstall the transducer assembly and torque to 70-75 in/

lbs.

9. Reconnect the wires (Refer to the Connection Diagram,

section 11.9).

10. Push pressure switch assembly (6) back onto the transducer

until it bottoms out on the transducer hex head.

11. Replace the screw (7) into the side of the pressure switch.

12. See “Resetting the Pressure Switch Timing”, section 11.7.

1

3

6

8

10

9

7

2

5

4

11.7 Resetting the Pressure Switch Timing

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

i

The components of the pressure switch must be

properly reassembled and adjusted in order for the

pump to operate at the correct maximum pressure.

Perform this procedure using pressure gauge P/N 0521229.

1. Make sure the knob bottom (1) is installed in the pressure

switch (2).

2. Viewingfromthetop,turntheknobbottom(1)counter-

clockwise as far as the teeth inside the pressure switch will allow.

1

3

2

iIf the stop (3) on the pressure switch prevents the

knob bottom from continuing to turn, remove the

knob bottom, re-orient it on the teeth and continue

to turn it counterclockwise until it stops.

3. Re-orient the knob tab against the pressure switch tab stop.

4. Replace the front cover and secure with the three screws.

5. Replace the pressure control knob into the knob bottom but

do not secure with the screw. Turn the knob fully clockwise to

maximum.

6. Connect the pressure gauge to the outlet tting.

7. Connect a high-pressure hose and gun to the pressure gauge.

8. Usingwaterasamedia,followthestepsinsection4.4.Itisnot

necessary to attach a spray tip to the gun. Leave the pressure

set to maximum.

9. The sprayer should now be pressurized at maximum pressure.

The pressure gauge should be reading between 193-207 bar.

10. If the pressure reading is below or above this reading, the

set screw down inside the pressure switch will have to be

adjusted. Adjust it per the guidelines below using a long hex

wrench.

a. If the pressure reading is below 193 bar, turn the set screw

counterclockwise until the pressure gauge reads between 193-

207 bar.

b. If the pressure reading is above 207 bar, relieve pressure by

turning the valve handle to PRIME (kcirculation). While the

sprayer is circulating, turn the set screw clockwise slightly and

thenturnthevalvehandletoSPRAY(pspray). Repeat this

until the pressure reading decreases to a range of 193-207 bar.

11. When the pressure gauge reads between 193-207 bar, the

pressure control knob is now set. Secure the pressure control

knob with the pressure control knob screw.

16 ProSpray 3.20

GB

Repairs at the unit

11.8 Replacing the Circuit Board

i

The following procedure must only be performed by

a Wagner Authorized Service Center.

PerformthisprocedureusingCircuitBoardKit.

1. Open the relief valve, valve position PRIME (kcirculation).

SwitchtheunitOFF.Unplugthepowerplugfromtheoutlet.

2. Loosen and remove the four motor cover screws (1). Remove

the motor cover (2).

3. Disconnect the red and black wires that connect the circuit

board (3) to the motor assembly (4).

4. Disconnect the white wires that connect the circuit board to

the pressure switch.

Attention

Do not attempt to pull wires from the inside of the

pressure switch assembly. If the pressure switch

wire connector is not exposed from through the

opening in the pump housing, pull gently on the

wires until the connector is shown through the

opening.

5. Disconnect the black wire that connects the circuit board to

the circuit breaker (6).

6. Disconnect the white wire that connects the circuit board to

the power switch.

7. Loosen and remove the two circuit board screws (8). Remove

the circuit board (3).

8. Install the new circuit board (3) and secure with the two circuit

board screws (8).

9. Reconnect the wires that were disconnected in steps 3-6

(Refer to the Connection Diagram, section 11.9).

10. Slide the motor cover over the motor. Secure the motor cover

with the four motor cover screws.

1

4

7

5

3

8

6

2

11.9 PS 3.20 connection diagram

Pos. Description

1Power cord

2Power switch

3EMI lter

4Pressure switch

5Circuit breaker

6Motor

7Capacitors

Pos. Description

aBlack / brown

bGreen

cWhite / blue

dBlue

eGreen / yellow

fWhite

gBrown

hRed

iBrown

a

a

d

e

f

g

g

g

g

i

g

h

h

h

f

f

f

f

b

c

1

3

2

4

7

6

5

ProSpray 3.20 17

GB

Appendix

12. Appendix

12.1 Selection of tip

To achieve faultless and rational working, the selection of the tip is of the greatest importance.

In many cases the correct tip can only be determined by means of a spraying test.

Some rules for this:

The spray jet must be even.

If streaks appear in the spray jet the spraying pressure is either too low or the viscosity of the coating material to high.

Remedy:Increasepressureordilutecoatingmaterial.Eachpumpconveysacertainquantityinproportiontothesizeofthetip:

Thefollowingprincipleisvalid: largetip =lowpressure

smalltip =highpressure

There is a large range of tips with various spraying angles.

12.2 Servicing and cleaning of Airless hard-metal tips

Standard tips

Ifadierenttiptypehasbeentted,thencleanitaccordingtomanufacturer’sinstructions.

The tip has a bore processed with the greatest precision. Careful handling is necessary to achieve long durability. Do not forget the fact that the

hard-metalinsertisbrittle!Neverthrowthetiporhandlewithsharpmetalobjects.

The following points must be observed to keep the tip clean and ready for use:

1. Turn the relief valve handle fully counterclockwise (kCirculation).

2. Switch o the gasoline engine.

3. Dismount the tip from the spray gun.

4. Place tip in an appropriate cleaning agent until all coating material residue is dissolved.

5. If there is pressure air, blow out tip.

6. Remove any residue by means of a sharp wooden rod (toothpick).

7. Check the tip with the help of a magnifying glass and, if necessary, repeat points 4 to 6.

12.3 Spray gun accessories

Flat jet adjusting tip

up to 250 bar (25 MPa

Contact protection

for the at jet adjustment tip

Order No. 0097 294

Tip extension

with slewable

knee joint

(without tip)

Tip extension

Length:100cm Order no. 0096 015

Length:200cm Order no. 0096 016

Length:300cm Order no. 0096 017

15 cm, F-thread, Order no. 0556 051 15 cm, G-thread, Order no. 0556 074

30 cm, F-thread, Order no. 0556 052 30 cm, G-thread, Order no. 0556 075

45 cm, F-thread, Order no. 0556 053 45 cm, G-thread, Order no. 0556 076

60 cm, F-thread, Order no. 0556 054 60 cm, G-thread, Order no. 0556 077

Tip

marking Bore mm

Spray width at about 30 cm

removal of spray object

Pressure 100 bar (10 MPa)

Use

Flat jet

adjusting tip

Order No.

15 0.13 - 0.46 5 - 35 cm Paints 0999 057

20 0.18 - 0.48 5 - 50 cm Paints, llers 0999 053

28 0.28 - 0.66 8 - 55 cm Paints, dispersions 0999 054

41 0.43 - 0.88 10 - 60 cm Rust protection paints

- dispersions 0999 055

49 0.53 - 1.37 10 - 40 cm Large-area coats 0999 056

18 ProSpray 3.20

GB

Appendix

12.4 Airless tip table

Wagner

TradeTip 3 tip

up to 270 bar

(27 MPa)

without tip

Fthread(11/16-16UN)

for Wagner spray guns

Order no. 0289391

without tip

Gthread(7/8-14UN)

for Graco/Titan spray guns

Order no. 0289390

i

All of the tips in the table below are supplied

together with the appropriate gun lter.

Application Tip marking Spray

angle

Bore

inch / mm

Spraying

width mm 1)

Gun lter Order no.

Water-thinnable and solvent-based

paints and varnishes, oils, separat-

ing agents

107

207

307

407

109

209

309

409

509

609

10°

20°

30°

40°

10°

20°

30°

40°

50°

60°

0.007 / 0.18

0.007 / 0.18

0.007 / 0.18

0.007 / 0.18

0.009 / 0.23

0.009 / 0.23

0.009 / 0.23

0.009 / 0.23

0.009 / 0.23

0.009 / 0.23

100

120

150

190

100

120

150

190

225

270

red

red

red

red

red

red

red

red

red

red

0553107

0553207

0553307

0553407

0553109

0553209

0553309

0553409

0553509

0553609

Synthetic-resin paints

PVC paints

111

211

311

411

511

611

10°

20°

30°

40°

50°

60°

0.011 / 0.28

0.011 / 0.28

0.011 / 0.28

0.011 / 0.28

0.011 / 0.28

0.011 / 0.28

100

120

150

190

225

270

red

red

red

red

red

red

0553111

0553211

0553311

0553411

0553511

0553611

Paints, primers

Fillers

113

213

313

413

513

613

813

10°

20°

30°

40°

50°

60°

80°

0.013 / 0.33

0.013 / 0.33

0.013 / 0.33

0.013 / 0.33

0.013 / 0.33

0.013 / 0.33

0.013 / 0.33

100

120

150

190

225

270

330

red

red

red

red

red

red

red

0553113

0553213

0553313

0553413

0553513

0553613

0553813

Fillers

Rust protection paints

115

215

315

415

515

615

715

815

10°

20°

30°

40°

50°

60°

70°

80°

0.015 / 0.38

0.015 / 0.38

0.015 / 0.38

0.015 / 0.38

0.015 / 0.38

0.015 / 0.38

0.015 / 0.38

0.015 / 0.38

100

120

150

190

225

270

300

330

yellow

yellow

yellow

yellow

yellow

yellow

yellow

yellow

0553115

0553215

0553315

0553415

0553515

0553615

0553715

0553815

Rust protection paints

Latex paints

Dispersions

117

217

317

417

517

617

717

817

10°

20°

30°

40°

50°

60°

70°

80°

0.017 / 0.43

0.017 / 0.43

0.017 / 0.43

0.017 / 0.43

0.017 / 0.43

0.017 / 0.43

0.017 / 0.43

0.017 / 0.43

100

120

150

190

225

270

300

330

yellow

yellow

yellow

yellow

yellow

yellow

yellow

yellow

0553117

0553217

0553317

0553417

0553517

0553617

0553717

0553817

Rust protection paints

Latex paints

Dispersions

219

319

419

519

619

719

819

919

20°

30°

40°

50°

60°

70°

80°

90°

0.019 / 0.48

0.019 / 0.48

0.019 / 0.48

0.019 / 0.48

0.019 / 0.48

0.019 / 0.48

0.019 / 0.48

0.019 / 0.48

120

150

190

225

270

300

330

385

white

white

white

white

white

white

white

white

0553219

0553319

0553419

0553519

0553619

0553719

0553819

0553919

Flame retardant 221

321

421

521

621

721

821

20°

30°

40°

50°

60°

70°

80°

0.021 / 0.53

0.021 / 0.53

0.021 / 0.53

0.021 / 0.53

0.021 / 0.53

0.021 / 0.53

0.021 / 0.53

120

150

190

225

270

300

330

white

white

white

white

white

white

white

0553221

0553321

0553421

0553521

0553621

0553721

0553821

1)Spray width at about 30 cm to the object and 100 bar (10 MPa) pressure with synthetic-resin paint 20 DIN seconds.

Table of contents