SPX FLOW Votator II User manual

FPO

INSTRUCTION MANUAL

Votator® II

SCRAPED SURFACE HEAT EXCHANGER

FORM NO.: 95-03057 REVISION: 06/2023 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

Information contained in this manual is subject to change

without notice and does not represent a commitment on the

part of SPX FLOW, Inc. No part of this manual may be

reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and

recording, for any purpose, without the express written per-

mission of SPX FLOW, Inc.

Copyright © 2019 SPX FLOW, Inc.

All Rights Reserved.

Revision Date: 06/2023

Publication: 95-03057

SPX FLOW, Inc.

611 Sugar Creek Road

Delavan, WI 53115 USA

Tel: (800) 252-5200 or (262) 728-1900

Fax: (800) 252-5012 or (262) 728-4904

E-mail: [email protected]

Web site: www.spxflow.com

Votator® II Scraped Surface Heat Exchanger Table of Contents

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 3

Warranty ..................................................................................................................................... 6

Shipping Damage or Loss ..............................................................................................................6

Warranty Claim ...............................................................................................................................6

Safety .......................................................................................................................................... 7

Care of Component Materials ................................................................................................... 8

Stainless Steel Corrosion ...............................................................................................................8

Elastomer Seal Replacement Following Passivation .....................................................................8

Introduction ................................................................................................................................ 9

Models and Specifications ..............................................................................................................9

Cylinder Assembly ..........................................................................................................................9

Product Side and Jacket Pressure Ratings ....................................................................................9

Machine Serial Number ..................................................................................................................9

Votator II Media Configurations ....................................................................................................10

Special Considerations for Vertical Votator II ...............................................................................10

................................................................................................................................ Installation 11

Site Selection Considerations .......................................................................................................11

Foundation & Drainage ....................................................................................................11

Clearances ...................................................................................................................................11

Leveling the Unit ...........................................................................................................................11

Electrical Power Connections .......................................................................................................11

Mutator Rotation Check ................................................................................................................12

Mechanical Seals ........................................................................................................................12

Single Mechanical Seal ...................................................................................................12

Double Mechanical Seal ..................................................................................................12

2005 Mechanical Seal Design .........................................................................................13

2012 Mechanical Seal Design .........................................................................................13

Flush Fluid Requirements ................................................................................................14

Piping ............................................................................................................................................14

Guidelines for Piping .......................................................................................................14

Suggested Media Piping for Steam ..............................................................................................14

Suggested Media Piping for Water or Liquid ................................................................................15

Refrigeration Piping Installation ....................................................................................................16

Liquid Line Installation .....................................................................................................16

Suction Line Installation ...................................................................................................16

Hot Gas Line (if required) ................................................................................................16

Pressure Relief Line ........................................................................................................16

Refrigeration Valves .....................................................................................................................17

Liquid Feed Solenoid Valve .............................................................................................17

Dual Pressure Regulating Valve ......................................................................................17

Sporlan Level Master Control (LMC) or Level Switch ......................................................17

Refrigerant Return Valve .................................................................................................17

Flow Control Valves .........................................................................................................18

Hot Gas Pressure Regulating Valve ................................................................................18

Pressure Relief Valve ......................................................................................................18

Suggested Media Piping for Liquid Over Feed Refrigeration .......................................................19

Suggested Media Piping for Gravity Refrigeration .......................................................................20

Electrical Equipment .....................................................................................................................22

Refrigeration Wiring Schematics ..................................................................................................23

Freeze Protection Components .......................................................................................23

Gravity Refrigeration with Level Master Control (LMC) ...................................................24

Gravity Refrigeration with Level Switch ...........................................................................25

Liquid Overfeed Refrigeration System .............................................................................26

Media System Check ....................................................................................................................27

Special Considerations for Vertical Votator II ...............................................................................27

Minimum Height - Vertical Votator II ................................................................................27

Working Access – Vertical Votator II ...............................................................................27

Mounting Pole - Vertical Votator II ...................................................................................27

Table of Contents Votator® II Scraped Surface Heat Exchanger

Page 4 Waukesha Cherry-Burrell®95-03057, 06/2023

Mounting Scrape Cylinders - Vertical Votator II .............................................................. 28

Hydraulic System - Vertical Votator II ............................................................................. 28

Gravity Refrigeration System - Vertical Votator II ........................................................... 30

Typical Dimensional Data and Hydraulic Lift System 31

Votator II General Assembly ........................................................................................... 31

Horizontal Refrigeration Assembly .................................................................................. 32

Vertical Refrigeration System .......................................................................................... 33

Horizontal Frame Options ............................................................................................... 34

Vertical Mounting Suggestions ........................................................................................ 35

Vertical Cylinder Mounting .............................................................................................. 36

Vertical Mounting Pole/Hydraulics .................................................................................. 37

Vertical Hydraulic Schematic .......................................................................................... 38

Operation .................................................................................................................................. 39

Pre-Startup Check ........................................................................................................................ 39

For Refrigeration Units Only ............................................................................................ 39

Pre-production Run Setup ............................................................................................................ 39

Startup Procedure ........................................................................................................................ 40

Heating/Liquid Cooling Applications ................................................................................ 40

Refrigeration Applications - Pumped and Gravity Systems ............................................ 40

Shutdown Procedure .................................................................................................................... 41

Preventing Tube Scoring .............................................................................................................. 41

Maintenance ............................................................................................................................. 42

Routine Maintenance - Horizontal Votator II ................................................................................ 42

Routine Maintenance - Vertical Votator II .................................................................................... 43

Scheduled Maintenance ............................................................................................................... 49

Preventive Maintenance ............................................................................................................... 49

Mutator Shaft Bearing .................................................................................................................. 50

Extra Heavy Duty Votator II Shaft Bearing ...................................................................... 50

Shafts ........................................................................................................................................... 50

Gear Drive .................................................................................................................................... 50

Blades .......................................................................................................................................... 51

Mechanical Seals ......................................................................................................................... 51

Tubes ........................................................................................................................................... 51

Care of Heat Exchanger Tube ..................................................................................................... 51

Product Side ................................................................................................................................. 52

Inspection of Chrome Plated Nickel or Stainless Steel Tubes ..................................................... 53

Inspection of Stainless Steel Tubes ............................................................................................. 53

Jacket Side ................................................................................................................................... 53

For Units Using Steam, Water, Or Liquid ........................................................................ 53

For Units Using Refrigerant ............................................................................................. 53

Cleaning the Flanges ................................................................................................................... 53

Leak Testing ................................................................................................................................. 54

Scraper Blade Maintenance ......................................................................................................... 54

Blade Inspection .............................................................................................................. 54

Scraper Blade Removal & Replacement ......................................................................... 54

Scraper Blade Wear ........................................................................................................ 54

Blade Sharpening ............................................................................................................ 54

Maintenance of Horizontal Votator II ............................................................................................ 55

Shaft Removal - Horizontal Unit ...................................................................................... 55

Shaft Installation - Horizontal Unit ................................................................................... 56

Heat Exchanger Tube Removal - Horizontal Unit ........................................................... 58

Heat Exchanger Tube Installation - Horizontal Unit ........................................................ 59

Maintenance of Vertical Votator II ................................................................................................ 60

Shaft Removal - Vertical Unit .......................................................................................... 60

Shaft Installation - Vertical Unit ....................................................................................... 61

Heat Exchanger Tube Removal -Vertical Unit ................................................................ 62

Mechanical Seal Maintenance ..................................................................................................... 64

Single Mechanical Seal ................................................................................................................ 64

Votator® II Scraped Surface Heat Exchanger Table of Contents

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 5

Seal Head Insert Removal and Installation .....................................................................64

Seal Body Insert (Rotating Seal Face) Used Before 2012 ..............................................64

Single Mechanical Seal Installation .................................................................................65

One-Piece Single and

Double Mechanical Seals 66

Primary/Secondary Seal Head Insert Removal and Installation ......................................66

2012 Primary/Secondary Seal Head Insert Removal and Installation .............................66

One-Piece Primary Seal Body (Rotating Seal Face) .......................................................67

Removable Seal Body Insert (Rotating Seal Face) .........................................................67

Assembly of Removable Primary Seal Body ...................................................................67

Assembly of 2012 Primary Seal Body .............................................................................68

Seal Assembly Installation on Shaft ................................................................................68

Servicing Mechanical Seals - Vertical Votator II ..............................................................70

Parts Lists ................................................................................................................................. 72

Latch .............................................................................................................................................72

Product Heads ..............................................................................................................................72

Votator II Blades ...........................................................................................................................73

Labels ...........................................................................................................................................73

Cylinder Assembly ........................................................................................................................74

Cylinder Assembly - Shaft ............................................................................................................76

Cylinder Assembly - Removable Tube 77

2012 Single and Double Mechanical Seal ....................................................................................79

One-Piece Single & Double Mechanical Seal, 2005-2012 ...........................................................81

Two-Piece Single & Double Mechanical Seal, 2000-2004 ...........................................................83

Two-Piece Single Mechanical Seal (with flushing lip seal), 1997-2004 ........................................85

Two-Piece Single Mechanical Seal

(Retrofit of the One-Piece Design - 2005) .......................................................................87

Two-Piece Double Mechanical Seal

(Retrofit of the One-Piece Design - 2005) .......................................................................89

Vertical Refrigeration Piping .........................................................................................................90

Vertical Frame/Hydraulics ............................................................................................................92

Shaft Heater (Optional) .................................................................................................................94

Troubleshooting ....................................................................................................................... 95

Unthawing A Frozen System ........................................................................................................98

Water and Air in Refrigeration System .........................................................................................98

Warranty Votator® II Scraped Surface Heat Exchanger

Page 6 Waukesha Cherry-Burrell®95-03057, 06/2023

Warranty

LIMITED WARRANTY: Unless otherwise mutually agreed to in writing, (a) SPX FLOW US, LLC (SPX FLOW)

goods, auxiliaries and parts thereof are warranted to the Buyer against defective workmanship and material for

a period of twelve (12) months from date of installation or eighteen (18) months from date of delivery, which-

ever expires first, and (b) SPX FLOW services are warranted to Buyer to have been performed in a workman-

like manner for a period of ninety (90) days from the date of performance. If the goods or services do not

conform to the warranty stated above, then as Buyer’s sole remedy, SPX FLOW shall, at SPX FLOW’s option,

either repair or replace the defective goods or re-perform defective services. If Buyer makes a warranty claim

to SPX FLOW and no actual defect is subsequently found, Buyer shall reimburse SPX FLOW for all reason-

able costs which SPX FLOW incurs in connection with the alleged defect. Third party goods furnished by SPX

FLOW will be repaired or replaced as Buyer’s sole remedy, but only to the extent provided in and honored by

the original manufacturer’s warranty. Unless otherwise agreed to in writing, SPX FLOW shall not be liable for

breach of warranty or otherwise in any manner whatsoever for: (i) normal wear and tear; (ii) corrosion, abrasion

or erosion; (iii) any good or services which, following delivery or performance by SPX FLOW, has been sub-

jected to accident, abuse, misapplication, improper repair, alteration (including modifications or repairs by

Buyer, the end customer or third parties other than SPX FLOW), improper installation or maintenance, neglect,

or excessive operating conditions; (iv) defects resulting from Buyer’s specifications or designs or those of

Buyer’s contractors or subcontractors other than SPX FLOW; or (v) defects resulting from the manufacture,

distribution, promotion or sale of Buyer’s products; (vi) damage resulting from the combination, operation or

use with equipment, products, hardware, software, firmware, systems or data not provided by SPX FLOW, if

such damage or harm would have been avoided in the absence of such combination, operation or use; or (vii)

Buyer’s use of the goods in any manner inconsistent with SPX FLOW’s written materials regarding the use of

such product. In addition, the foregoing warranty shall not include any labor, dismantling, re-installation, trans-

portation or access costs, or other expense associated with the repair or replacement of SPX FLOW goods.

THE WARRANTIES CONTAINED HEREIN ARE THE SOLE AND EXCLUSIVE WARRANTIES AVAILABLE

TO BUYER AND SPX FLOW HEREBY DISCLAIMS ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ANY PERFORMANCE OR PROCESS OUTCOME DESIRED BY THE

BUYER AND NOT SPECIFICALLY AGREED TO BY SPX FLOW. THE FOREGOING REPAIR, REPLACE-

MENT AND REPERFORMANCE OBLIGATIONS STATE SPX FLOW’S ENTIRE AND EXCLUSIVE LIABILITY

AND BUYER’S EXCLUSIVE REMEDY FOR ANY CLAIM IN CONNECTION WITH THE SALE AND FURNISH-

ING OF SERVICES, GOODS OR PARTS, THEIR DESIGN, SUITABILITY FOR USE, INSTALLATION OR

OPERATIONS.

Shipping Damage or Loss

If equipment is damaged or lost in transit, file a claim at once with the delivering carrier. The carrier has a

signed Bill of Lading acknowledging that the shipment has been received from SPX FLOW in good condition.

SPX FLOW is not responsible for the collection of claims or replacement of materials due to transit shortage or

damages.

Warranty Claim

Warranty claims must have a Returned Material Authorization (RMA) from the Seller or returns will not be

accepted. Contact 800-252-5200 or 262-728-1900.

Claims for shortages or other errors must be made in writing to Seller within ten (10) days after delivery. This

does not include transit shortage or damages. Failure to give such notice shall constitute acceptance and

waiver of all such claims by Buyer.

Votator® II Scraped Surface Heat Exchanger Safety

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 7

Safety

READ AND UNDERSTAND THIS MANUAL PRIOR TO INSTALLING, OPERATING, OR

SERVICING THIS EQUIPMENT

SPX FLOW recommends users of our equipment and designs follow the latest Industrial Safety Standards. At

a minimum, these should include the industrial safety requirements established by:

1. Occupational Safety and Health Administration (OSHA)

2. National Fire Protection Association (NFPA)

3. National Electrical Code (NEC)

4. American National Standards Institute (ANSI)

WARNING

Severe injury or death can result from electrical shock, burn, or unintended actuation of equipment.

Recommended practice is to disconnect and lockout industrial equipment from power sources, and release

stored energy, if present. Refer to the National Fire Protection Association Standard No. NFPA70E, Part II and

(as applicable) OSHA rules for Control of Hazardous Energy Sources (Lockout-Tagout) and OSHA Electrical

Safety Related Work Practices, including procedural requirements for:

• Lockout-tagout

• Personnel qualifications and training requirements

• When it is not feasible to de-energize and lockout-tagout electrical circuits and equipment before working

on or near exposed circuit parts

Before putting SPXFLOW equipment into operation, the operator shall analyze the application for all foresee-

able risks, their likelihood to occur and the potential consequences of the identified risks as per ISO 31000 and

ISO/IEC 31010 in their actual current version.

Locking and Interlocking Devices: These devices should be checked for proper working condition and capa-

bility of performing their intended functions. Make replacements only with the original equipment manufac-

turer’s OEM renewal parts or kits. Adjust or repair in accordance with the manufacturer’s instructions.

Periodic Inspection: Equipment should be inspected periodically. Inspection intervals should be based on

environmental and operating conditions and adjusted as indicated by experience. At a minimum, an initial

inspection within 3 to 4 months after installation is recommended. Inspection of the electrical control systems

should meet the recommendations as specified in the National Electrical Manufacturers Association (NEMA)

Standard No. ICS 1.3, Preventative Maintenance of Industrial Control and Systems Equipment, for the general

guidelines for setting-up a periodic maintenance program.

Replacement Equipment: Use only replacement parts and devices recommended by the manufacturer to

maintain the integrity of the equipment. Make sure the parts are properly matched to the equipment series,

model, serial number, and revision level of the equipment.

Warnings and cautions are provided in this manual to help avoid serious injury and/or possible damage to

equipment:

DANGER

Immediate hazards which WILL result in severe personal injury or death.

WARNING

Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which COULD result in minor personal injury or product or property damage.

Care of Component Materials Votator® II Scraped Surface Heat Exchanger

Page 8 Waukesha Cherry-Burrell®95-03057, 06/2023

Care of Component Materials

NOTE: SPX FLOW recommends the use of an FDA-approved anti-seize compound on all threaded

connections.

WARNING

Failure to comply with the Care of Component Materials could lead to bodily injury.

Stainless Steel Corrosion Corrosion resistance is greatest when a layer of oxide film is

formed on the surface of stainless steel. If film is disturbed or

destroyed, stainless steel becomes much less resistant to corro-

sion and may rust, pit or crack.

Corrosion pitting, rusting and stress cracks may occur due to

chemical attack. Use only cleaning chemicals specified by a repu-

table chemical manufacturer for use with stainless steel. Do not

use excessive concentrations, temperatures or exposure times.

Avoid contact with highly corrosive acids such as hydrofluoric,

hydrochloric or sulfuric. Also avoid prolonged contact with chlo-

ride-containing chemicals, especially in presence of acid. If chlo-

rine-based sanitizers are used, such as sodium hypochlorite

(bleach), do not exceed concentrations of 150 ppm available

chlorine, do not exceed contact time of 20 minutes, and do not

exceed temperatures of 104°F (40°C).

Corrosion discoloration, deposits or pitting may occur under prod-

uct deposits or under gaskets. Keep surfaces clean, including

those under gaskets or in grooves or tight corners. Clean immedi-

ately after use. Do not allow equipment to set idle, exposed to air

with accumulated foreign material on the surface.

Corrosion pitting may occur when stray electrical currents come

in contact with moist stainless steel. Ensure all electrical devices

connected to the equipment are correctly grounded.

Elastomer Seal Replace-

ment Following Passiva-

tion

Passivation chemicals can damage product contact areas of this

equipment. Elastomers (rubber components) are most likely to be

affected. Always inspect all elastomer seals after passivation is

completed. Replace any seals showing signs of chemical attack.

Indications may include swelling, cracks, loss of elasticity or any

other noticeable changes when compared with new components.

Votator® II Scraped Surface Heat Exchanger Introduction

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 9

Introduction

Models and Specifications The Votator II can be furnished for horizontal or vertical installa-

tion, available in the following models:

This manual covers the Horizontal and Vertical Votator II. Special

considerations for the installation and maintenance of each

model are noted.

Cylinder Assembly The cylinder assembly consists of a rotating shaft inside of two

concentric tubes. The outer tube is called the jacket, and contains

working fluid to heat or cool the contents of the inner, product

tube. The product tube provides a heat exchange surface for the

product.

Standard materials of construction for product tubes are:

• Pure nickel with a hard chrome plated interior surface.

• Stainless steel with a hard chrome plated interior surface.

• Stainless steel with no plating.

• Carbon steel with a hard chrome plated interior surface.

• Duplex steel with a hard chrome plated interior surface.

• Duplex steel with no plating

Product Side and Jacket

Pressure Ratings

Check the data plate attached to the cylinder for the exact pres-

sure rating specification of the unit.

Machine Serial Number The machine serial number is stamped on a serial number name-

plate located on the machine side as shown in Figure 1. On verti-

cal units (not shown), the nameplate is on the cylinder. Include

the machine model and serial number with each parts order.

Model Heat Transfer Area Jacket Type

6 x 84 11 ft2 (1.0 m2 ) Steam/Liquid Refrigeration

6 x 72 9 ft2 (0.84 m2 ) Steam/Liquid Refrigeration

6 x 48 6 ft2 (0.56 m2 ) Steam/Liquid Refrigeration

6 x 36 4.2 ft2 (0.39 m2 ) Steam/Liquid Refrigeration

6 x 24 3.0 ft2 (0.28 m2 ) Steam/Liquid Refrigeration

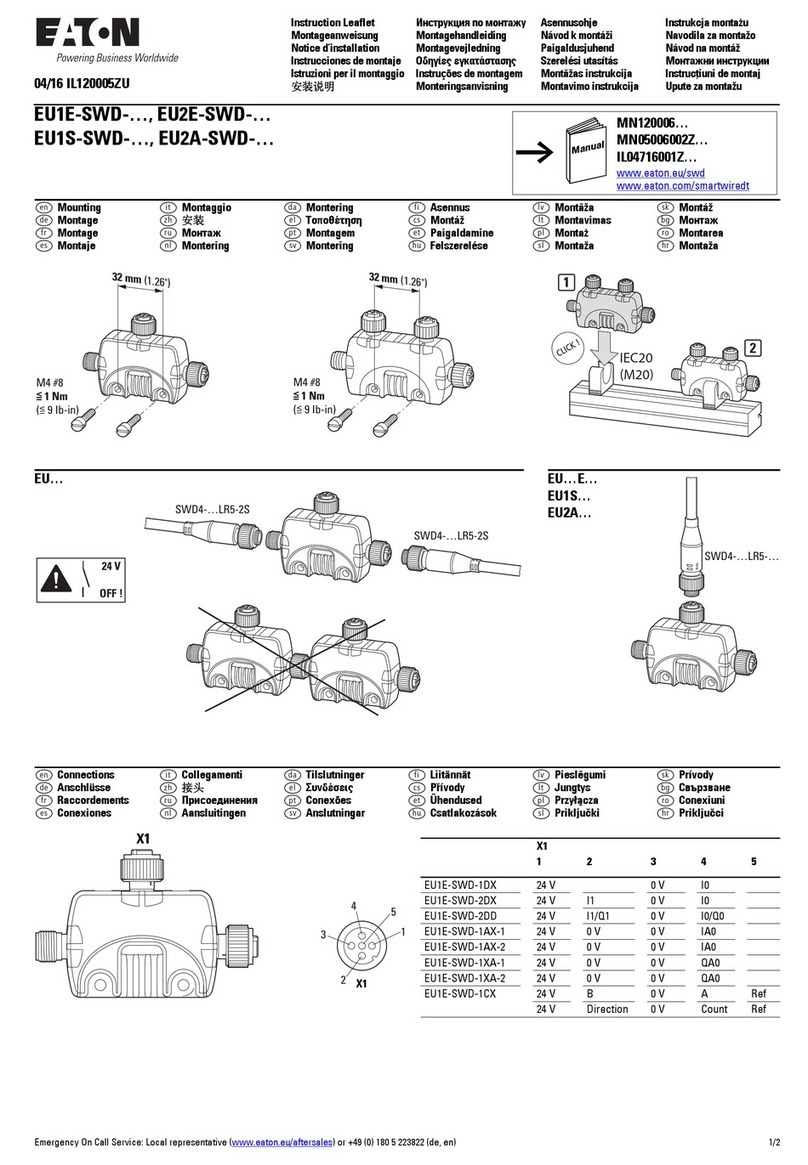

Figure 1 - Machine Serial Number

Location

Introduction Votator® II Scraped Surface Heat Exchanger

Page 10 Waukesha Cherry-Burrell®95-03057, 06/2023

Votator II Media

Configurations

The Votator II is available in the following configurations:

• BWS-Brine/Water/Steam: For liquid and steam heating and

cooling applications.

• LIQUID: For water or glycol.

• VAPOR: For steam or refrigeration.

Special Considerations for

Vertical Votator II

The Vertical Votator II cylinder assembly is shipped for on-site

installation on the mounting pole. When receiving the shipment,

check for the following, shipped separately in their own crate or

crates:

• Scraped Surface Heat Exchanger.

• Frame poles (including attached hydraulic cylinder) with

hydraulic pump & reservoir assembly(s).

• Accumulators, Refrigeration Valves and Piping, if furnished.

• Mount plates, nuts & bolts, and interconnecting product

piping.

Votator® II Scraped Surface Heat Exchanger Installation

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 11

DANGER

Installation

Site Selection

Considerations

Foundation & Drainage

The Votator II should be located on a firm foundation, an

gled to allow liquids to drain away from the unit.

Clearances • The rear and sides of the unit, or unit cluster, should have

adequate clearance to provide easy access for main

tenance.

• The front of the Horizontal unit should have the following

minimum clearances to allow for removal of the mutator

shaft:

6 x 84 Votator II - 102 in (259 cm)

6 x 72 Votator II - 90 in (230 cm)

6 x 48 Votator II - 71 in (180 cm)

6 x 36 Votator II - 59 in (150 cm)

6 x 24 Votator II - 40 in (102 cm)

• The bottom of the Vertical unit should have the following

minimum clearances to allow for removal of the mutator

shaft:

6 x 84 Votator II - 96 in (244 cm)

6 x 72 Votator II - 84 in (214 cm)

6 x 48 Votator II - 66 in (168 cm)

6 x 36 Votator II - 54 in (137 cm)

6 x 24 Votator II - 48 in (122 cm)

Leveling the Unit The Horizontal Votator II should be leveled lengthwise (along the

length of the cylinder) and crosswise by adjusting the feet on the

legs.

For units that will perform CIP, set the level for a forward pitch of

0.3 degrees (1/16 inch per foot).

If CIP is not required, set the level to a pitch that will give the best

drainage for the cylinder.

Electrical Power

Connections

The following electrical components for the Votator II require con-

nection in accordance with the electrical schematics in this man-

ual, tagged vendor specifications, and local regulations:

The Votator II operates with high

voltage. Electrical work should be

performed by a Licensed Electrician in

accordance with local regulations.

• Drive Motor

Each cylinder is furnished with a 3-phase, multi-voltage gear

motor with a horsepower rating per the application:

Standard Votator II accepts 7-1/2 HP (5.5 kW), 10 HP (7.5

kW), 15 HP (11kw) or 20 HP (15 kW); Extra Heavy Duty Vota-

tor II accepts 25 HP (18.8 kW), 30 HP (22.5 kW) or 40 HP (30

kW). The motor is fixed speed and suitable for use with a

variable frequency controller.

• Hydraulic Pump Motor (Vertical units only)

A 1.0 (0.75 kW) horsepower, fixed speed motor. A variable

frequency controller should not be used for this motor. It is

recommended that an emergency shut off switch be installed

for this unit.

Installation Votator® II Scraped Surface Heat Exchanger

Page 12 Waukesha Cherry-Burrell®95-03057, 06/2023

• Refrigeration Valves:

liquid feed solenoid valve

dual pressure regulating valve

level switch

hot gas pressure regulating valve

hot gas solenoid valve

• Freeze Protection Components (if furnished):

current sensing relay

instrument current transformer

digital current indicator

Mutator Rotation Check Correct mutator shaft rotation is counterclockwise when looking

down the unit from the drive end (indicated by a sticker located

near the motor). To check for correct rotation, momentarily start

the drive motor and observe the rotation of the shaft in the back

of the unit.

If the rotation of the shaft is incorrect, the drive motor is wired

incorrectly. Have a Licensed Electrician change the wiring so the

rotation of the shaft is correct.

Mechanical Seals The Votator II is furnished with either a single or double mechani-

cal seal on both ends of the mutator shaft. Units furnished before

2005 were installed with either a single or double mechanical seal

configuration. On page 13, “2005 Mechanical Seal Design”

describes seals for units furnished between 2005 and 2012, and

“2012 Mechanical Seal Design” describes seals for standard

units finished from 2012 to the present. Certain Votator II units

have also been supplied with a special "Ball-lock Mechanical

Seal" or a "Packing Gland" instead. Consult your order documen-

tation to verify the specific seal configuration for each Votator II

unit.

Single Mechanical Seal

The single mechanical seal is normally not flushed, but it can be.

It is shipped with a lip seal (See Figure 2) designed to contain

water or a liquid flush. The spring in the seal must be removed

and the seal reinstalled with the lip in the relief position to allow

flushing. This will minimize any damage to the contact surface on

the stub end of the shaft.

When the single mechanical seal is rotating, there must be prod-

uct or water flow to provide cooling to the rotating surfaces to

avoid permanent damage to the seal assembly.

If the seal is flushed, the fluid flow should be in the range of 5 to

10 gallons per hour and not exceed 5 psig. Piping to seals should

be in the bottom of head and out the top and with parallel flow,

never in series.

Double Mechanical Seal

The double mechanical seal is furnished with a primary seal for

product and a secondary seal to contain a steam or water flush.

Figure 2 - Single Mechanical Seal

Figure 3 - Double Mechanical Seal

Votator® II Scraped Surface Heat Exchanger Installation

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 13

2005 Mechanical Seal Design

Units furnished between 2005 and 2012 have a one-piece

chrome-oxide coated rotating body running against a stationary

ceramic head insert. It can easily be converted to a double

mechanical seal by adding secondary components to contain a

steam or water flush.

2012 Mechanical Seal Design

Standard units furnished starting in 2012 have removable rotary

seal faces in solid carbon, silicon carbide, tungsten carbide, and

narrow-face tungsten carbide materials. The stationary seal faces

are made of solid ceramic or silicon carbide. Like the 2005

design, the 2012 single mechanical seal can be converted to a

double mechanical seal by adding secondary components to con-

tain a water or steam flush.

Figure 4 - Single Mechanical Seal

Figure 5 - Double Mechanical Seal

Figure 6 - 2012 Single Mechanical

Seal

HE100-117

Figure 7 - 2012 Double Mechanical Seal (shown with Narrow-

Face Rotary)

HE100-118

Installation Votator® II Scraped Surface Heat Exchanger

Page 14 Waukesha Cherry-Burrell®95-03057, 06/2023

Flush Fluid Requirements

The double mechanical seal must be flushed using the threaded

flush ports, anytime the mutator shaft is rotated. Failure to do this

will result in rapid seal failure due to excessive contaminate and

heat buildup.

The fluid flow should be in the range of 5 to 10 gallons per hour,

at a typical temperature of 80°F - 120°F (25°C - 49°C). Fluid com-

position and temperature should be selected to dissolve or sus-

pend any product leakage and cool the mechanical seal faces,

and should also be compatible with the sealing O-ring material.

Piping to seal cavities for horizontal units should be in the bottom

of head and out the top, piped with parallel flow, never with multi-

ple seal cavities in series flow.

Piping Guidelines for Piping

Refer to the general assembly drawings in this manual for jacket

connection sizes and locations, and suggested media piping

drawings.

• Support ALL piping independently.

• Provide for line expansion and contraction.

• Install a safety valve to protect jacket.

• Provide temperature indicators on both sides of Votator II

unit.

• Provide pressure gauge on discharge side of pump.

• When using liquid coolant, provide a method to introduce

heating media into the jacket to thaw overcooled product.

• Provide a liquid coolant system bypass line around the unit to

allow the coolant system to be brought down to operating

temperature without circulating coolant through the jacket.

Suggested Media Piping

for Steam

The steam solenoid is opened, which lets pressure-controlled

steam from the boiler into the jacket. A temperature sensor moni-

tors the temperature of the product and regulates the steam flow

to achieve the required temperature. Heating of the product takes

place when the steam condenses into water from the transfer of

heat through the jacket.

CAUTION

The safety valve should be installed on

the discharge side of product pump for

safety and equipment protection.

DANGER

Do not install any positive shutoff

valves downstream of the Votator II

unit.

WARNING

Do not allow a volume of liquid to

become isolated in the jacket without

relief protection. Thermal expansion

created as liquid warms can generate

enough force to crush tube, causing

damage to internal components and

drive system.

Votator® II Scraped Surface Heat Exchanger Installation

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 15

Suggested Media Piping

for Water or Liquid

The media piping should flow counter-current to the product flow,

and should be circulating at a rate of 50 gpm. The suggested

arrangement automates the source flow to the actual heat

exchange requirements to provide maximum control of the pro-

cess.

Table 1: Call Outs For Figure 8

1. Steam IN

2. Strainer

3. By-Pass Line

4. Steam Pressure Regulator

5. Steam Solenoid

6. Temperature Regulator

7. I/P

8. Temperature Control

9. Product OUT

10. Product IN

11. Drain Valve

12. Condensate Trap

Figure 8 - Suggested Media Piping, Steam

S

PI

TC

TY

TE

PI

PI

1

24

3

5

6

7

9

8

10

11 12

HE100-056

Table 2: Call Outs For Figure 9

1. Media IN

2. Product OUT

3. Product IN

4. Temperature Regulator

5. Media OUT

6. I/P

7. Temperature Control

Figure 9 - Suggested Media Piping, Water or Liquid

TC

TY

TE

TI

TI

PI

MS

TI

PI

TI

1

2

3

4

567

HE100-057

Installation Votator® II Scraped Surface Heat Exchanger

Page 16 Waukesha Cherry-Burrell®95-03057, 06/2023

WARNING

CAUTION

DANGER

CAUTION

Refrigeration Piping

Installation

Analyze plant refrigeration load capacity thoroughly. The system

must be sized to adequately support the additional capacity of

this cylinder. All pipes must be clean and free of oil, chips and

sealant residue. Excessive residue in plant piping can foul and

clog cylinder refrigeration valves and components, causing costly

delays in start-up. Refer to the appropriate piping schematic in

this manual for Liquid Overfeed (LOF) (page 19) or Gravity

Refrigeration System (page 20).

Ammonia or Freon lines should be

installed by fully trained and qualified

Refrigeration Piping Specialists.

Liquid Line Installation

The liquid line should be installed to provide a constant and

steady flow of liquid. Check with system requirements and plant

capacities to ensure that refrigeration piping is sized properly.

A suction trap or auxiliary receiver

should be installed in the line to prevent

carry-over back to compressor.

Suction Line Installation

All Votator II refrigeration units operate best when provided with

constant suction pressure. To ensure constant pressure, do the

following:

• Size the suction header for at least 50% above rated capacity

of cylinder.

• Do not connect to a header already in use by other

equipment with widely varying loads.

• Insulate any suction line that passes through a cold room to

prevent condensate formation. Install a trap or auxiliary

receiver in the line.

• Keep the suction pressure at the compressor as low as

possible. (Lower pressure allows greater cooling capacity.)

Hot Gas Line (if required)

Review the following guidelines when connecting a hot gas line to

the system:

• Connection of a hot gas line should be from the compressor

high side of the line past an oil trap or separator, to minimize

drawing in oil.

• DO NOT run line through a cold room or beside a cold

suction line.

• Slope the line away from the equipment at 1/8 inch per foot (1

mm per 100 mm) minimum.

• Install a strainer or filter in addition to the recommended

shutoff valves and pressure gauge.

Never install a shutoff valve on this line.

Never vent or connect relief line back to

suction line.

Pressure Relief Line

The pressure relief line MUST be exhausted to the outside of the

building.

The relief valve is factory set for

appropriate pressure and never needs

adjusting.

Never cap the relief line or tie it back to the suction line.

Votator® II Scraped Surface Heat Exchanger Installation

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 17

Refrigeration Valves Liquid Feed Solenoid Valve

The Liquid Feed Solenoid Valve is for on/off control of liquid

refrigerant flow. The valve is closed when de-energized.

Dual Pressure Regulating Valve

The Dual Pressure Regulating Valve is shipped loose for installa-

tion in the vapor line on the discharge side of the refrigeration pip-

ing. The valve regulates high pressure for internal relief and low

pressure with an on/off solenoid valve for process control. It can

be furnished for manual regulating; pneumatic control with clean,

dry, and oil free air from 0-60 psig; or with a 115 volt motor

mounted on the regulating pilot that responds to a 4-20 milliamp

electrical signal. When using air, a decrease in pressure will

lower the inlet pressure, producing a lower temperature.

Sporlan Level Master Control (LMC) or Level

Switch

Gravity Systems with Accumulator are furnished with a Sporlan

Level Master Control (LMC) or a Level Switch.

The LMC is a thermostatic expansion valve with a 15-watt heater

element. As the level in the accumulator drops, the electrically

added heat increases the pressure within the thermostatic ele-

ment and opens the valve. As the liquid level rises, the electrical

input is balanced by the heat transfer from the bulb to the liquid

refrigerant and modulates or shuts off the liquid flow. Minor

adjustments in the level response can be made by adjusting the

spring tension of the expansion valve seat.

If a refrigerant level float switch is provided (single or double

depending upon specifications), it is used to control the accumu-

lator level by opening or closing a solenoid operated refrigeration

valve. These systems contain that valve and an expansion valve

with a flow indicating scale.

Refrigerant Return Valve

Some Horizontal Votators have a solenoid operated Refrigerant

Return Valve that is in the closed position when the solenoid is

de-energized. This valve is used to stop the cooling process and

is closed if hot gas is applied.

High capacity freon systems have two solenoid valves: one for

hot gas to activate the return valve, the other to bleed the gas to

the suction line.

Installation Votator® II Scraped Surface Heat Exchanger

Page 18 Waukesha Cherry-Burrell®95-03057, 06/2023

DANGER

Flow Control Valves

Liquid Overfeed (LOF) or Pumped Refrigeration Systems have a

manually adjusted Flow Control Valve with setting scale for refrig-

erant flow to each Votator cylinder. This valve maintains a con-

stant flow of liquid to the Votator and can serve as a check valve

to prevent back flow of liquid during hot gas.

The indicator scale on the valve corresponds to the refrigeration

tonnage. The regulator is set by multiplying the tonnage load by

the desired re-circulation rate. For example, if the refrigeration

load is 10 tons and 200% (3:1) overfeed is desired, set the valve

at 30 on the scale reading.

Hot Gas Pressure Regulating Valve

Systems with hot gas include a solenoid-operated Pressure Reg-

ulating Valve for introducing and maintaining constant down-

stream pressure for a hot gas inlet.

Pumped Refrigeration Systems include a solenoid operated Hot

Gas Purge Valve for each Votator hot gas discharge line.

Never install a shutoff valve in a relief

line.

Pressure Relief Valve

This valve is located on the accumulator and should be

exhausted to outside the building. The valve is factory-set to

relieve at the Votator II jacket design pressure, or the accumula-

tor design pressure, if that is lower (some accumulators supplied

in earlier years were only rated for 150 psig).

Votator® II Scraped Surface Heat Exchanger Installation

95-03057, 06/2023 Waukesha Cherry-Burrell®Page 19

Suggested Media Piping

for Liquid Over Feed

Refrigeration

The liquid feed solenoid valve, when opened, allows liquid refrig-

erant to flow into the jacket of the heat exchanger. The flow is

regulated by a manually set flow control valve. Cooling is

achieved when the pressure control valve is opened, causing the

pressure in the jacket to be reduced. This causes the liquid refrig-

erant to change phase, absorbing heat from the heat exchanger

tube and product. The cooling rate is controlled by the back pres-

sure on the system and stops when the valve is closed. Hot gas

is used to push all of the remaining liquid from the system into the

low pressure receiver and quickly warm the system. The low

pressure receiver in the compressor room is designed to sepa-

rate the liquid from the vapor before re-compressing.

Figure 10 - Suggested Media Piping, Liquid Over Feed or Pumped Refrigeration

23

4

5

6

7

8

9

10

11

12

13

13

14

15

16

1

1

17

S

S

PI

S

S

S

HE100-053a

18

or

Table 3: Call Outs For Figure 10 (on page 19)

1. Safety Relief Valve

2. Product IN

3. Product OUT

4. Low Pressure Solenoid Valve, see Item 10

5. Hot Gas

6/7. Electric Control Signal or Instrument Air

Regulated to 60 PSI

8. Low Pressure Regulating Valve, see Item 10

9. High Pressure Regulating Valve, see Item 10.

10. Dual Pressure Regulating Valve (includes Items

4, 8 and 9)

11. To Refrigerant Low Pressure Receiver

12. Hot Gas Purge Valve

13. Flow Control Valve

14. Liquid Feed Solenoid Valve

15. Liquid Refrigerant from Low Pressure Receiver

16. Hot Gas Reducing Valve

17. Hot Gas Solenoid Valve

18. Hot Gas Pressure Regulating Valve

Installation Votator® II Scraped Surface Heat Exchanger

Page 20 Waukesha Cherry-Burrell®95-03057, 06/2023

Suggested Media Piping

for Gravity Refrigeration

Liquid refrigerant from the receiver is stored in a surge drum

located above the Votator II. The level in the surge drum is auto-

matically controlled by the level system provided with the equip-

ment. Gravity forces the refrigerant into the cooling jacket where

it comes into contact with the heat transfer tube. The warm prod-

uct causes a portion of the liquid refrigerant to change phase,

causing the heat transfer tube and the product to be cooled. The

cooling rate is controlled by the refrigerant back pressure, and hot

gas can be used to push the liquid refrigerant from the Votator

cylinder and rapidly warm the system.

NOTE: Set the high pressure regulating valve 5 to 10 psi higher

than the outlet pressure of the hot gas pressure reducing valve

and lower than the relief setting.

Figure 11 - Suggested Media Piping, Gravity Refrigeration - HORIZONTAL

PI

1

10 12

11

11 13

PI

S

S

S

S

PI

5

6

2

3

20

1

7

14

4

15

16

17

13

10 11

12

19

9

18

21

22

HE100-061a

Level Switch Control

OR

Level Master Control

Table of contents