Tatu Marchesan RTA-6 User manual

RTA-6

Tatu Back Hoe

INSTRINSTR

INSTRINSTR

INSTRUCTIONS MANUUCTIONS MANU

UCTIONS MANUUCTIONS MANU

UCTIONS MANUALAL

ALAL

AL

1

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

The Agricultural TATU BACK HOE is of high quality and renders excellent

performance. Its exclusive design offers superior resistance, easy operation and low

maintenance.

It is essential to become completely acquainted with the Tatu Back Hoe before

starting operations or even getting on the tractor.

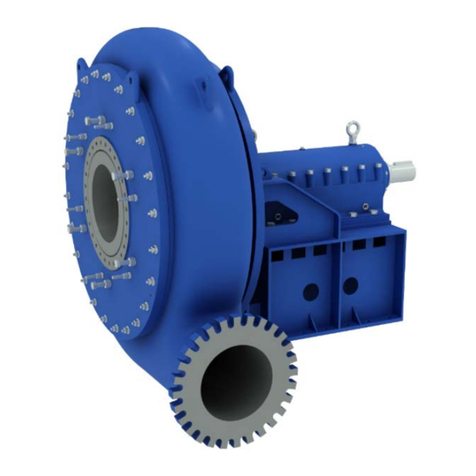

Used with wheeled agricultural tractors (in the range of 60 to 70 CV), the RTA-6

is designed for agricultural use, such as drainage, cleaning canals and digging up

to 3,0 meters deep.

The operator should carefully read the entire operation manual and familiarize

himself with the controls, ways of operation, security aspects and maintenance

procedures in order to obtain maximum performance and maintain the equipment

in optimal condition.

Remember, no one should operate the Tatu Back Hoe without fisrt following the

precautionary safety notices and operating instructions.

2

INDEXINDEX

INDEXINDEX

INDEX

TO THE OWNER .................................................................................................................... 3

TO THE OPERATOR ....................................................................................................... 4 a10

Safety Warnings .................................................................................................... 4 a 6

Transporting on Truck/Trailer ..................................................................................... 6

Safety Stickers ....................................................................................................... 7 a 9

Identification of Controls Levers .............................................................................. 10

TECHNICAL SPECIFICATIONS............................................................................................ 11

General Dimensions .................................................................................................. 11

Bucket Dimensions .................................................................................................... 12

Hydraulic System ....................................................................................................... 12

Cylinders Dimensions ................................................................................................ 12

COMPONENTS .................................................................................................................... 13

ASSEMBLY ............................................................................................................................ 14

SET-UP INSTRUCTIONS ............................................................................................... 15 a 19

Preparing the Tractor................................................................................................ 15

Coupling to Tractor ................................................................................................... 15

Coupling the Shaft .................................................................................................... 16

Longtitudinal Levelling.............................................................................................. 17

Final Adjustments ...................................................................................................... 18

Uncoupling ................................................................................................................. 18

Precautions Prior to Operation ................................................................................ 19

Precautions with the Tractor .................................................................................... 19

Precautions in Transporting ..................................................................................... 19

ADJUSTMENTS AND OPERATIONS.................................................................................... 20

Operation ................................................................................................................... 20

Operating Techniques..................................................................................... 21 a 28

MAINTENANCE ................................................................................................................... 29

Lubrication.................................................................................................................. 29

Hydraulic System .............................................................................................. 30 a 31

General Inspections.................................................................................................. 31

Precautions in Maintaining ...................................................................................... 32

IMPORTANT ......................................................................................................................... 33

3

TO THE OWNERTO THE OWNER

TO THE OWNERTO THE OWNER

TO THE OWNER

IMPORTANT: - ONLY PERSON WHO OWNS A FULL KNOWLEDGE OF THE TRACTOR AND

IMPLEMENT, MUST OPERATE THEM.

- MARCHESAN IS NOT RESPOSABLE FOR ANY DAMAGE CAUSED BY

ACCIDENT ON TRANSPORT, INCORRECT UTILIZATION OR NO ADEQUATE

STORAGE.

- AFTER THE OPERATING SEASON, THOROUGHLY CLEAN YOUR IMPLEMENT

AND INSPECT IT. PREVENTIVE MAINTENANCE PAYS DIVIDENDS.

- YOUR DEALER HAS ORIGINAL EQUIPMENT PARTS WHICH ASSURE PROPER

FIT AND BEST PERFORMANCE.

General Informations

- References to "right side" and "left side" are made looking at the Tatu Back

Hoe from behind.

- When requesting parts or tecnical assistence it is necessary to provide the

information on the identification plate (picture of ID plate).

The acquisition of any TATU product assures to the original pruchaser the following

rights :

- Warranty certificate;

- Instructions manual;

- Technical assistance by the dealer on the equipment delivery.

- The owner has obligation to inspect the conditions of the product on delivery,

as well as knowing the warranty terms.

- Special attention should be given to safety recommendations, operation cares

and maintenance on the product.

- Be sure to read and understand the instructions for adjusting and operating

the equipment as reported in this Manual. Check each item referred to obtain

efficient operation and maximum trouble free performance. Remember, an

equipment which is properly lubricated and adjusted saves you time, labor and fuel.

Note: THE WARRANTY SHALL NOT BE APPLIED TO ANY EQUIPMENT, OR ANY PART THEREOF,

WHICH HAS BEEN ALTERED ELSEWHERE THAN AT THE PLACE OF MANUFACTURE OR

WHICH THE ORIGINAL PRUCHASER THEREOF, AT RETAIL, HAS USED OR ALLOWED

TO BE USED PARTS, NOT MADE OR SUPPLIED BY MARCHESAN S/A.

4

Safety Operation

- ONLY WITH A COMPLETE CO-OPERATION OF IMPLEMENT OPERATOR THE

ACCIDENTS CAN BE PREVENTED.

- THIS SYMBOL IS A WARNING DEVICE WHICH SHOULD BE KEPT IN PLACE,

CLEAN AND VISIBLE WHEN TRANSPORTING THE IMPLEMENT DURING THE DAY

OR NIGHT. USE ACESSORY LIGHTS AND OTHER DEVICES IN ORDER TO GIVE

ADEQUATE WARNING TO OPERATORS OF OTHER VEHICLES.

The Tatu Back Hoe is easy to operate, therefore some basic and indispensable

cares are required on their handling.

- Have always in mind that SAFETY requires CONSTANT ATTENTION, OBSERVATION

AND PRUDENCE during the operation, transport, maintenance and storage of the

machine.

Dear User!

Respect the Ecology.

Do not throw the trash away.

This gesture of goodwill helps to

protect our Environment.

Do not spill combustible oil, battery and filter

residues in the soil. The trash in contact with

the soil reach the sub layer which directely

damage to the Environment. Look for

information to delivery these contaminated

elements to whom knows how to recycle or

re-use them.

Read and

understand the

informations

before realize

adjustments and

maintenance.

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

5

Never use your

hands to check for

hydraulic leaks.

Escaping hydraulic

oil under pressure

can have sufficient

force to penetrate

the skin causing

personal injury.

Be careful when

moving around

steep graders to

avoid overturn.

Be careful with use

of fertilizer or

chemicals.

These products in

contact with skin

could cause

personal injury to

the body.

Never attempt to

change the

adjustments. clean

or lubricate the

implement when in

movement.

Keep the entrances

and places

acessible to

working, clean and

free of the oil and

grease to prevent

accidents.

Use extreme

caution when

circulating with the

implement under

electrical power

lines, any contact

could result in

severe shock, injury

or death.

In order to protect

yourself always

wear adequate

clothes and shoes

during the

operations.

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

Never transport the

implement on

rough roads during

the night. When

operating avoid to

make sharp turns

that may cause tire

to make contact

with implement.

Never allow riders

on the tractor or

implement unless

an additional seat

is available.

Always use the

transport locks

when transporting

the implements.

6

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

- During the operation or transport do not allow riders on the tractor or

implement. Serious personal injuries could result from falling in the path of

the machine while in operation or transport.

- Never allow children playing near the place that you are operating,

transporting or in storage.

- Use individual equipments for your own protection.

- Wear clothes and adequate shoes. Avoid large or loosen clothes that could

twine on the mavable parts.

- Learn about the area before starting the operation. Delimit the dangerous

places or the obstacles.

- Be careful when hitching the implement to the tractor. Hands or fingers can

be injured when caught between the hitch and tractor drawbar.

- When transporting the retro always disconnect the power point and check

to see that the boom clamp is in place.

- Do not drive close to ditches, canals, uneven surfaces, this could result in

slipping.

- Never try to change adjustments, clean or lubricate the retro in moviment.

- Always disconnect the motor before leave the tractor's seat.

- Verify with attention the transport width in narrow places.

- Do not transit on highways or asphalted roads.

- When disconnecting the implement move it to level area, preferably a hard

surface, on the field or at the warehouse. Certify that the machine is properly

parked.

- See the general safety instructions in the back-cover of this Manual.

When Transporting the Implement on Truck or Trailer

To transport the equipment at long distances use a truck or trailer. However,

the safety instructions should be followed carefully:

- Check to see that the boom clamp is in place whenever transporting the

Tatu Back Hoe.

- Use adequate loading dock to load and unload the equipment. Never use

a ditch bank, this practice could result in serious personal injury.

- In the event of lifting up with hoist use appropriate points to hold.

- Use chock blocks and safety chains to secure the implement to the truck or

trailer during the transport.

- After 8 to 10 km transporting, please inspect the condition of the cargo.

Repeat this procedure every 80 to 100 km. Give more attention when

transporting the implement on rough roads, steep graders and other

adverse conditions.

- Be careful with transport height, specially when passing under electrical

power lines. Any contact could result in severe shock, injury or death.

- Observe all laws and regulations as to the height limits and cargo width

while transporting the implement on truck or trailer.. If necessary use

banners, lights and other devices in order to give adequate warning to the

drivers of other vehicles.

7

Safety Stickers

The safety stikers are used to alert you to hazards in the most dangerous parts

in the Retro. Keep the stickers clean and replace them when it is necessary.

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

CACA

CACA

CAUTIONUTION

UTIONUTION

UTION

AA

AA

ATENCIONTENCION

TENCIONTENCION

TENCION

Read the manual before

attempting to work with

the equipment.

Lea el manual antes de

iniciar el uso del equipo.

0503031779

8

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

CUIDCUID

CUIDCUID

CUIDADOSADOS

ADOSADOS

ADOS

ESPECIALESESPECIALES

ESPECIALESESPECIALES

ESPECIALES

ALWAYS ATTEMPT TO THE FOLLOWING INSTRUCTIONS.

- IN DESPITE OF OUR IMPLEMENT HAVING WARRANTY ON

QUALITY, IT'S NECESSARY TO TAKE CARE TO EXTEND

THE USEFUL LIFE AND TO ASSURE ITS EFFICIENCY.

- CHECK THE OIL LEVEL DAILY IN THE RESERVOIR, WITH

ALL THE CYLINDERS ROD RETRACTED (ON TATU

HYDRAULIC SYSTEM).

- MAKE THE PERIODIC OIL REPLACEMENT IN CONFORMITY

WITH “ISO VG 68”.

- IT IS IMPORTANT TO MAKE THE FIRST OIL REPLACEMENT

AFTER THE FIRST 50 OPERATION HOURS.

- AFTER THE FIRST OIL REPLACEMENT ADOPT INTERVALS

OF 250 HOURS (TREEMONTHLY) FOR NEW REPLACEMENT.

- IN CASE OF OPERATING IN DIRTY PLACES OR WITH A

LOT OF POWDER, REPLACE THE OIL MORE FREQUENTLY.

- TO REPLACE THE OIL MAKE THE HYDRAULIC SYSTEM

DRAINAGE, AND DO NOT TURN THE TRACTOR ENGINE ON,

DURING THE OIL DRAINAGE FROM THE RESERVOIR,

OTHERWISE, THE PUMP WOULD BE SERIOUSLY DAMAGED.

- AVOID THE PENETRATION OF IMPURITY IN THE

HYDRAULIC SYSTEM. USE A CLEAN FUNNEL WITH FINE

SCREEN TO INTRODUCE THE OIL IN THE RESERVOIR.

- FOR HYDRAULIC SYSTEMS WITH PUMP IN THE TRACTOR,

CHECK THE OIL LEVEL FOLLOWING THE INSTRUCTIONS

OF THE TRACTOR MANUFACTURER.

- DON’T MIX OILS FROM DIFFERENT BRANDS EVEN WHEN

NEW, BECAUSE THEY AFFECT EACH OTHER AND LOSE THE

QUALITY.

- THE OIL FILTER FROM RETURNING LINE SHOULD BE

REPLACED IN THE FIRST 50 SERVICE HOURS, AND AFTER

EVERY 250 HOURS (THREEMONTHLY).

- STORE THE GREASES IN CLEANED PLACES AND USE A

CLOTH TO CLEAN THE GREASE FITTINGS.

- WHEN SOME HOSES ARE REMOVED, MAKE SURE THAT

THEIR EXTREMITIES DO NOT GET IN TOUCH WITH THE

GROUND.

- EXCESSIVE TIGHTENING DON’T ELIMINATE LEAKS.

CHECK FOR DEFECTS LOOSENING THE NUT ON THE

TERMINAL FITTING.

- DON'T USE YOUR HANDS TO CHECK FOR HYDRAULIC

LEAKS. THE HIGH PRESSURE CAN PROVOKE SERIOUS

LESION; USE CARDBOARD OR OTHER APPROPRIATE

OBJECT.

HAVING DOUBTS CONSULT OUR TECHNICIANS OR CALL ON THE DEALER.

EN CASO DE DUDAS CONSULTE UN TÉCNICO O NUESTRO DISTRIBUIDOR.

ATENCIÓN: LOS APRIETOS CON MAYOR INTENSIDAD

NO RESULTAN EN LA SOLUCIÓN DE LA PÉRDIDA DE

ACEITE.

Marchesan Impls. e Máquinas Agrícolas. Tatu S/A - Av. Marchesan, 1979 - Cx. Postal 131 - MATÃO - SP - Fone: (55) 16 3382-8282

0503030619 - Revisão 0 - 12/02

SPECIAL

PROCEDURES

SIGUEN ABAJO LAS INSTRUCCIONES QUE DEBEN SER

OBSERVADAS.

AUNQUE NUESTRO IMPLEMENTO TENGA CALIDAD

GARANTIZADA SON NECESARIOS CIERTOS CUIDADOS PARA

PROLONGAR LA VIDA UTIL Y GARANTIZAR SU EFICIENCIA.

- VERIFIQUE DIARIAMENTE EL NIVEL DE ACEITE EN EL

RESERVATORIO CON TODOS LOS VÁSTAGOS DE LOS

CILINDROS RECOGIDOS.

- EFECTUE LOS CAMBIOS PERIÓDICOS DE ACEITE,

CONFORME NORMA “ISO VG 68”.

- ES IMPORTANTE QUE EL PRIMER CAMBIO DE ACEITE SEA

A LAS PRIMERAS 50 HORAS DE FUNCIONAMIENTO.

- DESPUÉS DEL PRIMER CAMBIO DE ACEITE, PASE A

ADOPTAR INTERVALOS DE 250 HORAS (1 TRIMESTRE)

PARA NUEVOS CAMBIOS.

- EN CASO DE OPERAR EN LUGARES DE SUCIEDAD O CON

MUCHO POLVO, CAMBIE EL ACEITE CON MÁS FRECUENCIA.

- PARA EL CAMBIO DE ACEITE, DRENE EL SISTEMA

HIDRAULICO Y NO DÉ PARTIDA AL MOTOR DEL TRACTOR

CUANDO EL ACEITE ESTE SIENDO DRENADO DEL

RESERVATORIO, PUES LA BOMBA SERÍA DAMNIFICADA.

- EVITE LA PENETRACIÓN DE IMPUREZAS EN EL SISTEMA

HIDRÁULICO. USE UN EMBUDO LIMPIO CON REJILLA FINA

PARA INTRODUCIR EL ACEITE EN EL RESERVATORIO.

- PARA SISTEMAS HIDRÁULICOS CON BOMBA TRACTOR,

VERIFIQUE EL NIVEL DEL ACEITE DE ACUERDO CON LAS

INSTRUCCIONES DEL FABRICANTE DEL TRACTOR.

- NO MEZCLE ACEITES DE DIFERENTES MARCAS AUNQUE

SEAN NUEVOS, PUES ESTOS SE CONTAMINAN Y PIERDEN

LA CALIDAD.

- EL FILTRO DE RETORNO DEL ACEITE DEBE SER

SUBSTITUIDO A LAS PRIMERAS 50 HORAS DE TRABAJO Y

DESPUÉS A CADA 250 HORAS.

- CONSERVE LAS GRASAS EN LOCALES LIMPIOS Y USE UN

PAÑO PARA LIMPIAR LOS PUNTOS DE LUBRICACIÓN.

- CUANDO ALGUNA MANGUERA SEA RETIRADA, CUIDADO

PARA QUE SUS EXTREMIDADES NO TOQUEN EL SUELO.

- APRIETOS EXCESIVOS NO ELIMINAN FILTRACIONES. VERIFIQUE

EL DEFECTO SOLTANDO LA TUERCA GIRATÓRIA DEL TERMINAL

DE LA CONEXIÓN.

- NO VERIFIQUE FILTRACIONES CON LAS MANOS. LA ALTA

PRESIÓN PUEDE PROVOCAR LESIONES CORPORALES. USE

CARTÓN.

ATTENTION: EXCESSIVE TIGHTENING DON’T

ELIMINATE LEAKS.

9

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

WARNING ADVERTENCIA

0503030768 - Rev. 0 - 12/02

- PRECAUTIONS IN THE BACKHOE OPERATION -

THE OPERATOR SHOULD BE FAMILIAR WITH THE CONTROLS AND GET KNOWLEDGEMENT ON

SAFE OPERATION, BEFORE USING THE BACKHOE.

- ONLY THE OPERATOR CAN OPERATE THE BACKHOE, POSITIONED IN ITS SEAT.

- AT WORKING DO NOTALLOW THEAPPROACH OF PEOPLE NEITHER ANIMALS.

- DON'T CARRY PASSENGERS IN THE TRACTOR OR IN THE BACKHOE.

- INSPECT THEAREA AROUND BEFORE STARTING THE OPERATION. AVOID WORKING CLOSE TO

ELECTRICAL WIRES. TAKE CARE WITH UNDERGROUND PIPES, POSTS, ETC...

- DON'T START WORKING WITHOUT LOWERING THE STABILIZERS PAD PREVIOUSLY.

- NEVER USE THE BACKHOE TO ELEVATE PEOPLE OR ANIMAL. DON'T USE IT TO PUSH THINGS OR

AS PILE DRIVER.

- DON'T FASTEN CABLES OR CHAINS IN THE BACKHOE TO LIFT LOADS.

- ON SLOPES AVOID WORKING WITH THE BACKHOE BUCKETTOTHE DOWNHILLSIDE, THE EQUIPMENT

CAN OVERTURN TO THE FRONT OR TO THE SIDE.

- DON'T DIG VERY CLOSE TO STABILIZERS PAD. THE GROUND COULD COLLAPSE UNDER THE

BACKHOE.

- DON'T USE YOUR HANDS TO CHECK FOR HYDRAULIC LEAKS. THE HIGH PRESSURE CAN PROVOKE

SERIOUS LESION; USE CARDBOARD OR OTHER APPROPRIATE OBJECT.

- THE PRESSURE OF THE HIDRAULIC SYSTEM SHOULD BE RELIEVED BEFORE DISCONNECTINGANY

COMPONENT.

- TO PARK THE TRACTOR OR TO UNCOUPLE THE BACKHOE, CHOOSE ALEVEL AREAAND LOWER

THE STABILIZERS AND BUCKET UNTIL THE GROUND.

- PRECAUTIONS IN THE BACKHOE TRANSPORTATION -

- CHECK FOR THE USE OF THE BOOM LOCK EVERYTIME WHEN TRANSPORTING THE BACKHOE.

- BE ATTEMPT FOR THE BACKHOE HEIGHT. DON'T PASS UNDER LOW ELETRIC WIRES OR AERIAL

OBSTACLES.

- DON'T DRIVE CLOSE TO DITCHES, TRENCHS, PRECIPITOUS, ETC, CAVE IN COULD RESULT.

- ON LONG COURSES AND ON ROADS USE THE SAFETY SIGNS.

- CUIDADOS EN LA OPERACIÓN DE LA RETROEXCAVADORA -

EL OPERADOR DEBE FAMILIARIZARSE CON LOS CONTROLES Y TENER

CONOCIMIENTOS DE SEGURIDAD, ANTES DE USAR LA RETRO.

- APENAS EL OPERADOR PUEDE ACCIONAR LA RETRO, POSICIONADO EN SU ASIENTO.

- NO PERMITA LA APROXIMACIÓN DE PERSONAS Y ANIMALES.

- NO CARGUE PASAJEROS EN EL TRACTOR O EN LA RETRO.

- INSPECIONE EL ÁREA ANTES DE COMENZAR EL TRABAJO, EVITE ÁREAS PRÓXIMAS DE

CONDUCTORES ELÉCTRICOS. CUIDADO CON TUBOS Y CAÑERIAS ENTERRADAS, POSTES, ETC.

- NO COMIENCE EL TRABAJO SIN BAJAR LOS BRAZOS ESTABILIZADORES.

- NUNCA USE LA RETRO PARA LEVANTAR PERSONAS O ANIMALES. NO LA USE PARA EMPUJAR

COSAS O PARA ENTERRAR ESTACAS.

- NO AMARRE CABLES O CADENAS EN LA RETRO PARA LEVANTAR CARGAS.

- EN LOCALES INCLINADOS EVITE TRABAJAR CON EL CUCHARÓN HACIA EL BARRANCO, LA

RETRO PUEDE CAER PARA ADELANTE O AL COSTADO.

- NO EXCAVE PRÓXIMO DE LOS BRAZOS ESTABILIZADORES, EL SUELO PUEDE DESMORONAR

DEBAJO DE LA RETRO.

- NO VERIFIQUE FILTRACIONES CON LAS MANOS, LA ALTA PRESIÓN PUEDE PROVOCAR

LESIONES GRAVES. USE CARTÓN O CUALQUIER OBJETO ADECUADO.

- LA PRESIÓN DEL SISTEMA DEBE SER ALIVIADA ANTES DE DESCONECTAR CUALQUIER

MANGUERA.

- PARA ESTACIONAR EL TRACTOR O PARA DESENGANCHAR LA RETRO, ESCOJA UN LUGAR

PLANO, BAJE LOS BRAZOS ESTABILIZADORES Y EL CUCHARÓN HASTA EL SUELO.

- CUIDADOS EN EL TRANSPORTE DE LA RETROEXCAVADORA -

- VERIFIQUE SI LA TRAVA DE LA LANZA ESTÁ COLOCADA SIEMPRE QUE TRANSPORTE LA RETRO.

- ESTE ATENTO PARA LA ALTURA DE LA RETRO AL PASAR DEBAJO DE CABLES O CUALQUIER

OBSTÁCULO AÉREO.

- NO CONDUZCA CERCA DE ZANJAS, CANALES, TERRENOS ACCIDENTADOS, ETC. PUEDEN

OCURRIR DESLIZAMIENTOS.

- EN TRAYECTOS EXTENSOS Y EN CARRETERAS USE LAS SEÑALES DE ALERTA.

10

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

Identification of control levers

The diagram below shows the functioning of the control levers of the Tatu Back

Hoe and has copies of the decals that are handle of each control.

STABILIZERS: (Levers 1 and 6)

Moving these levers forward lowers the stabilizers and vice versa.

The two stabilizers (shoes) should be fully lowered while in operation.

ARM: (Lever 2)

Moving this lever forward extends the arm and vice versa.

BOOM: (Lever 3)

Moving this lever forward unloads the bucket and vice versa.

BUCKET: (Lever 4)

Moving this lever forward lowers the boom and vice versa.

HORIZONTAL ROTATION: (Lever 5)

Moving this lever forward turns the unit to the left; the oposite action

turns the unit to the right.

Important: NEVER CHANGE THE ADJUSTMENT OF THE PRESSURE OF THE CONTROLS.

Note: "RIGHT SIDE" AND"LEFT SIDE" AS INDICATED ABOVE REFERS TO WHEN THE OPEATOR

IS SEATED ON THE TRACTOR.

123 4 56

0503031328 - Rev. 0 - 12/02

THE MAIN VALVE, IN THE CONTROL VALVE INLET, IT’S CALIBRATED FOR 180 kgf/cm² (2,560 lbs/pol²).

LA VÁLVULA PRINCIPAL, EN LA ENTRADA DEL COMANDO, SE CALIBRA PARA 180 kgf/cm² (2560 lbs/pol²).

170 kgf/cm²

(2,418 lbs/pol²)

170 kgf/cm²

(2,418 lbs/pol²)

170 kgf/cm²

(2,418 lbs/pol²)

100 kgf/cm²

(1,422 lbs/pol²)

170 kgf/cm²

(2,418 lbs/pol²)

170 kgf/cm²

(2,418 lbs/pol²)

100 kgf/cm²

(1,422 lbs/pol²)

100 kgf/cm²

(1,422 lbs/pol²)

11

H

F

G

B

A

E

C

D

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATIONSTIONS

TIONSTIONS

TIONS

General dimensions: (In millimeters)

A - Depth of excavation ...................................................................................3000 mm

B - Angle of horizontal rotation ..................................................................170 Degrees

C - Maximum height for unloading .................................................................2870 mm

D - Reach (from joint) ........................................................................................4400 mm

E - Angle of rotation of buckets ..................................................................... 160 Graus

F - Height in transportation ...............................................................................2650 mm

G - Opening of stabilizers in transportation ....................................................2050 mm

H - Opening of stabilizers in operation............................................................3300 mm

12

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATIONSTIONS

TIONSTIONS

TIONS

Information on scoops (buckets):

Width ..................................... 12" ................ 16" ................ 18" ................ 20".............. 24"

Number of cogs................... 03" ................ 04" ................ 04" ................ 04".............. 05"

Capacity (litres) ................... 51.................. 68 ................. 76 ................. 84 ...............102

Weight (kg) ........................... 50.................. 58 ................. 61 ................. 65 ................. 71

Total weight: (RTA-6 with16" bucket) .................................................................. 1010 kg

Hydraulic system:

Hydraulic pump with flow of 35 litres/minute at 540 rpm

Tank capacity: ........................................................................................................ 55 litros

Hydraulic oil tank, with filter and level indicator

System capacity ..................................................................................................... 65 litros

Hydraulic double action cylinders

Cylinder dimensions: (in millimetres)

Ø Int. Casting Ø Shaft Stroke

Stabilizers (2)............................................... 85,7 .......................... 44,45 ......................320

Horizontal ratation (2) ............................... 85,7 .......................... 44,45 ......................260

Boom .......................................................... 101,6 ......................... 44,45 ......................510

Arm .............................................................. 85,7 .......................... 50,80 ......................755

Bucket ......................................................... 85,7 .......................... 50,80 ......................512

13

07

04

03

01 06

05

02

12"

24"

Four sided bucket

Exclusively for

cleaning gutters

(drains).

14

11

19

12

15

09

16

08

17

18

13

10

16"

18" 20"

COMPONENTSCOMPONENTS

COMPONENTSCOMPONENTS

COMPONENTS

01 - Seat 11 - Mounting rotation support

02 - Controls levers 12 - Plateau

03 - Control support 13 - Hydraulic pump

04 - Arm cylinder 14 - Shoe

05 - Boom 15 - Estabilizing arm

06 - Arm 16 - Foot rest

07 - Bucket cylinder 17 - Axle

08 - Joint link 18 - Oil reserve

09 - Bucket 19 - Oil level

10 - Transportation clamp

14

A

B

C

D

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBLYY

YY

Y

Hydraulic Pump Assembly

Do the assembly of the hydraulic pump as following:

- Couple the pump (A) in the support (B) using the bolts (C), lock washers and

nuts.

- Do the assembly of the shaft (D) in the pump (A).

15

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

The following instructions must be observed carefuly to get the a better

performance at work.

Setting-up the Tractor

The adition of water ballast in the tires, are the ways more used to increase the

traction to the soil and giving a better stability to the tractor. Verify if the tractor is in

full conditions of use.

Coupling to the Tractor

- Do the coupling in a level and firm place in the following manner:

- Fully lower the hydraulic arms of the tractor; maintaining a height of 350 mm

from the ground, until the middle of the joints of the lower arms.

- Pull the upper arm (3rd point) from the tractor.

- Bring the tractor of the Tatu Back Hoe close enough to link with the axle.

- Join the axle to the tractor, securing it with the bolt.

- Start the motor of the tractor and engage the power point, starting in low

rotation.

- Move the levers of the stabilizing arms (shoes) with short and even

movements, raising the Tatu Back Hoe to the coupling level (+/- 350 mm).

- Very carefully work the levers of the arm boom and the bucket until they

are on the ground, leaving the Tatu Back Hoe level in order to facilitate the

coupling.

- Turn off the motor and disconnect the power point.

- Remove the axle from the tractor.

- Couple the Tatu Back Hoe to the tractor, starting with the lower arms. Use

the gaps (holes) in the regulating rod and the guide to facilitate the linking to

the 3rd point. See picture on the next page.

Note: THE COUPLING SEQUENCE DESCRIBED BELOW DOES NOT TAKE INTO ACCOUNT

THE PRESENCE OF FACILITIES SUCH AS CRANES, ETC., FOR RAISING THE TATU BACK

HOE.

Note: FROM THIS POINT ON, BE SURE TO USE OF THE LEVERS AND RESPECTIVE CILYNDERS

CORRECTLY.

Attention: BE CAREFUL NOT TO MOVE THE ROTATION LEVER.

16

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Joining the Shaft to the Power Point

Before starting the operation check the lenth ot the shaft. If necessary, shorten

it by cutting equal parts of the internal and external hoop.

- Join the shaft to the power point, paying attention to the position of the

terminals of the little crosses taking care when taking it apart (see drawing bellow).

Errouneus assembly will cause excessive vibration, which is hamfull to the transmission.

Note: IT IS NECESSARY TO GIVE FINISHING IN THE PARTS CUT (MALE/FEMALE), TO MAKE

THIS USING A FILE, AFTER THAT TAKE OUT THE FILINGS AND LUBRICATE THE MALE

PART WITH A FINE LAYER OF GREASE.

Nota: THE SUPPORTING BAR ASSEMBLING (A) SHOULD BE INSPECTED BEFORE COUPLING

TO THE TRACTOR.

Tractor

TPO Shaft

Cardan Shaft

Pump

Pump

Support

Regulating - Rod

Chassis

Guide

Stabilizer Arm

3rd Point

A

17

3rd Point

Regulating Rod

Pin "A"

Guide Chassis

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Longtitudinal Levelling

The longtitudinal levelling is done by way of the holes in the regulating rod and

the guide in the following manner:

- Fully lower the stabilizing arms (With the Tatu Back Hoe hitched in service

position).

- Rest the bucket on the ground to facilitate manipulation of pin "A".

- Using the levers (except the rotation), level the chassis lengthways, working

again with pin "A".

IMPORTANT: AFTER JOINING THE TATU BACK HOE TO THE TRACTOR THE HYDRAULIC

LIFTING SYSTEM (3 rd POINT) CANNOT BE ACTIVATED; THAT IS, THE RAISING

AND LOWERING LEVERS SHOULD BE KEPT DOWN IN THE DOWN POSITION

DURING EXCAVATION, AS WELL AS WHEN TRANSPORTING.

18

AA

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Final Adjustments (After coupling)

- Pull up the hydraulic cylinders (stabilizers, arms and bucket).

- Proceed with "CENTRALIZATION" of the Tatu Back Hoe with the tractor, verifying

that the distances are equal between the lower arms and the respective tyres of the

tractor (Letters "A" in the drawing below).

- Proceed with transversal levelling by way of the crankshaft of lower right arm.

Uncoupling the RTA-6

- Do the uncoupling in a firm, flat place.

- Lower the stabilizer arms (shoes) resting them on the ground.

- Lower the bucket arm resting it on the ground.

- Still using the controls, remove the coupling bolts from the 3rd point and from

the lower arms.

- Unhitch the axle from the power point of the tractor.

19

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Precautions prior to Operation

- Check the adjustments of the immobilization pieces: screws, bolts and

nuts.

- Check the oil reserve level with the rods pulled out (Arms, Boom, Bucket

and stabilizers raised).

- Lubricate all the grease fittings. Follow the lubricating instructions on page

29.

- Check the general condition of the Retroexcavator and tractor.

Precautions with the tractor

- Inspect the tractor to ensure that it is in good condition.

- The structure and protetion against the capsizing of the tractor, as well

as the other security measures, should be kept in good condition.

- Disconnect the motor before doing any sort of check on it.

- Use hazard signals on long roads or highways.

- Reduce speed on slopes, curves or narrow roads.

- Never leave the tractor motor running without the operator being

present.

- Be careful when hooking up or uncoupling the equipment, especially

with using the power point.

Precautions in transporting the Retroexcavator

- Check to see that the boom clamp is in place whenever transporting

the Tatu Back Hoe.

- Always disconnect the power point.

- Be awere of the height of the Tatu Back Hoe when passing under cables

or any obstacle.

- Do not drive close to ditches, canals, uneven surfaces, etc., as this could

result in slipping.

- Use hazard signals on long roads and highways.

Other manuals for RTA-6

1

Table of contents

Popular Industrial Equipment manuals by other brands

SCHUNK

SCHUNK VERO-S NSE3 138 Assembly and operating manual

Burkert

Burkert MP05 operating instructions

SY-KLONE

SY-KLONE POWERED PRECLEANER XLR Service & Installation

Siemens

Siemens POWER CONTROL Series Operation manual

Index

Index R200 Operating instructions and Maintenance instructions

ABB

ABB HT610533 Operation manual