Tool-Temp TT-13'502 E User manual

Manual TT-13’502 E - 1 -

THE HEATING AND COOLING UNIT

HAS TO BE TRANSPORTED IN AN

UPRIGHT POSITION AND NEVER ON

THE SIDE.

SHOULD THE UNIT BE LAID DOWN TO

THE SIDE DURING TRANSPORT, IT

WILL SUFFER IRREPARABLES

DAMAGES.

Manual TT-13’502 E - 2 -

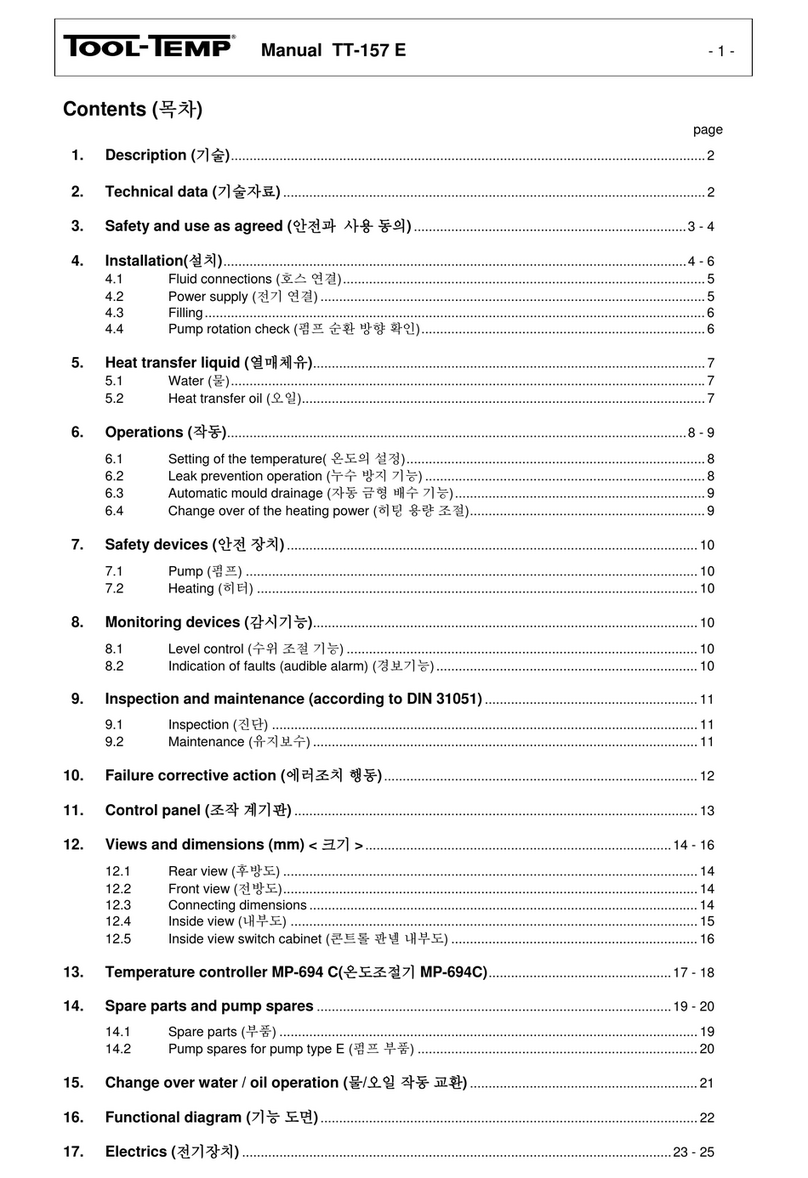

Contents

page

1. Description ..........................................................................................................................................3

2. Technical data.....................................................................................................................................3

3. Safety and use as agreed.................................................................................................................4

4. Installation .....................................................................................................................................5 - 7

4.1 Configuration..........................................................................................................................5

4.2 Water connections..................................................................................................................5

4.3 Power supply..........................................................................................................................6

4.4 Filling......................................................................................................................................6

4.5 Pump rotation check...............................................................................................................7

5. Operation .............................................................................................................................................7

5.1 Setting of temperature............................................................................................................7

5.2 External control ......................................................................................................................7

6. Safety devices.....................................................................................................................................8

6.1 Pump......................................................................................................................................8

6.2 Compressor (circuit 1)............................................................................................................8

6.3 Fan (circuit 1) .........................................................................................................................8

6.4 Heating...................................................................................................................................8

7. Monitoring devices............................................................................................................................9

7.1 Level control...........................................................................................................................9

7.2 Anti-freeze (circuit 1)..............................................................................................................9

7.3 Indications of defaults (audible alarm)....................................................................................9

7.4 Pressure control (circuit 1)......................................................................................................9

8. Inspections and maintenance (according to DIN 31051).......................................................10

8.1 Inspection.............................................................................................................................10

8.2 Maintenance ........................................................................................................................10

9. Failure corrective action .........................................................................................................11 - 13

10. Control panel TT-13’502 E .............................................................................................................14

11. Views and dimensions (in mm).............................................................................................15 - 17

11.1Front view.............................................................................................................................15

11.2 Rear view .............................................................................................................................15

11.3 Dimensions...........................................................................................................................15

11.4 Inside view............................................................................................................................16

11.5 Inside view of control panel .................................................................................................17

12. Temperature controller MP-888.............................................................................................18 - 23

12.1Predefined setups ................................................................................................................19

12.2 Programming MP-888: Heating- and cooling unit TT-13'502 E without flow control......20 - 23

13. Spare parts list...........................................................................................................................24 - 25

14. Datasheet time-lag relay ...............................................................................................................26

15. Electrics ......................................................................................................................................27 - 30

Manual TT-13’502 E - 3 -

1. Description

The heating- and cooling unit TT-13’502 E is operating with antipollution and CFC-free refrigerant agent

The unit has two independent water circuits with two sealless pumps and two stainless steel water tank of

each 25 litres content. Additionally, the unit is equipped with 2 x 6 kW heating capacity. Circuit 2 can only

be cooled when circuit 1 is operating.

The unit corresponds to the harmonized EU norms as EN 292 / EN 60204 as well as to the relevant EU

directives (see EU conformity declaration) and it is provided with the CE sign.

This manual is valid only for this model.

serial equipment:

- 2 self-optimizing temperature controllers with digital display of the set and actual temperature.

Display in 1/10-° range. Switchable from °C to °F.

- horn for default indication

- automatic level control – with pre-warning by too low water level

- automatic or manual water refill

- mechanical safety thermostat and electronic temperature limiter installed in the controller

- with main switch, automatic cutout, transformer and motor protection switch

- with castors

2. Technical data

temperature range

of medium (water)

Circuit 1 for temperatures from +10°C to +40°C

Circuit 2for temperatures from +10°C to +90°C

ambient temperature

min. +2°C / max. +45°C,

use anti-freeze below +2°C in order to protect the heating and cooling unit from

freezing and becoming defective

temperature control

self-optimising microprocessor controller MP-888

refrigerant agent

R-134a

cooling capacity

8 kW for both circuits

heating capacity

approx. 2 x 6 kW

pump capacity

connected load 0,75 kW

pressure mode max. 4,5 bar / max. 75 l/min.

compressor

hermetically sealed

Condenser

air-cooled, air inlet located at the front of the unit, blow out located at the side and

at the rear of the unit.

max.power consumption

approx.. 15 kW

filling amount

approx. 2 x 25 litres

connections

to / from mould R 3/4“ female thread (both circuits)

automatic water refill R 3/8“ female thread

drainage R 3/8“ female thread

dimensions in mm

(LxWxH) incl. castors

Length: 980 mm

Width: 660 mm

Height: 1’300 mm

weight

empty approx. 220 kg

category of protection

IP-44

Electric

in separate switch cabinet, easily accessible from the front

colour

silver grey RAL 7001

noise level (dBA)

66 (distance 3 m)

Manual TT-13’502 E - 4 -

3. Safety and use as agreed

The heating and cooling unit must not be used for other than the described purpose and within the fixed

values for temperature and voltage. Any other use whithout the agreement of the manufacturer is strictly

forbidden. The use of others than the prescribed water (see point 4.4) and/or the use of others than the

admitted spare parts can lead to dangerous operating states and is strictly forbidden. When the unit’s con-

struction state is changed the operating permission and the conformity declaration become unvalid.

Important information in this manual is marked as follows:

remark:

helpful information

CAUTION:

RISKS WHICH CAN LEAD TO MATERIAL DAMAGE

DANGER:

RISKS WHICH CAN LEAD TO HUMAN INJURY

The heating and cooling unit is equipped with the following pictographs (according to DIN 4844) to mark

the remaining dangers (according to EN 1050):

DANGER VOLTAGE

DANGER

-The heating and cooling unit must not be used in hazardous location.

-The heating and cooling unit must not be used in the open air (category of protection IP-44).

-The heating and cooling unit must not be transported in a horizontal position.

Should the unit be laid down to its side during transportation, it will suffer irreparables damages.

-Water is the only permitted medium for the use in the heating and cooling unit (see point 4.4).

Manual TT-13’502 E - 5 -

4. Installation

Before starting the unit the external connections of the hydraulics and of the electric have to be mounted.

CAUTION:

STARTING THE UNIT WITHOUT THE PRESCRIBED

CONNECTIONS CAN DAMAGE IT.

The starting of the unit has to be done in the order of this chapter.

After the proper starting the unit is ready to use.

4.1 Configuration

air inlet: at the front of the unit

air outlet: at the side and at the rear of the unit

ambient temperature: +2°C to +45°C use anti-freeze below +2°C in order to protect the heating

and cooling unit from freezing and becoming defective

CAUTION:

-

AIR INLET AND OUTLET MUST BE OPEN AND ACCESSIBLE IN

ORDER TO GUARANTEE A SUFFICIENT AIR CIRCULATION

SHOULD THE UNIT BE LAID DOWN TO ITS SIDE DURING

TRANSPORTATION, IT WILL SUFFER IRREPARABLE

DAMAGES

CAUTION :

-THE UNIT CAN ONLY BE PLACED IN SUITABLE ROOMS AND

ON PLAIN FLOOR.

-THE ROOM HEIGHT MUST BE AT LEAST 3 M.

-THE UNIT IS NOT JET-PROOFED AND NOT ALLOWED TO BE

OPERATED IN HAZARDOUS LOCATION.

-THE UNIT IS ONLY DESIGNED FOR INSIDE USE AND

CANNOT BE OPERATED OUTSIDE.

4.2 Water connections

We recommend that transparent reinforced hoses should be used so that the cleaness of the water can be

checked. Longer hoses must be insulated.

to- / from mould

R 3/4“ female thread

automatic water refill

R 3/8“ female thread

drainage

R 3/8“ female thread

water filter and automatic water refill

R 3/8“ female thread

Manual TT-13’502 E - 6 -

4.3 Power supply

Main voltage and frequency according to the serial plate.

Pay attention to the local regulations during installation of unit.

CAUTION:

THE CONNECTION TO THE POWER SUPPLY HAS TO BE DONE

BY A QUALIFIED ELECTRICIAN.

Colours of cables:

phases

black / black / black

L1 / L2 / L3

earth

yellow / green

PE

max power consumption: approx. 15 kW

DANGER:

CONNECT THE POWER SUPPLY FIRST WHEN THE HOSES

HAVE BEEN CONNECTED.

4.4 Filling

Manual filling:

Content of approx. 2 x 25 Litres. The manual filling is on the top of the unit (see page 15).

We recommend the use of normal tap water.

CAUTION:

DO NOT USE DISTILLED, DEIONISED OR RAIN WATER.

WATER CONTAINING CHLORID ADDITIVES DESTROYS ON

LONG TERMS THE STRUCTURE OF STAINLESS STEEL. DO

NOT ADD CHLORID TO THE WATER!

Automatic filling

The unit is equipped with an automatic water refill as standard. After switching on the unit the tank will au-

tomatically be filled to the correct level.

Remark:

We recommend that a stop valve is fitted at the water inlet.

This valve should be closed after filling of the tank so that uncon-

trolled refill can be avoided in case of a malfunction.

This unit is not designed to work below +2°C ambient temperature.

If the unit is installed in a production hall with low ambient temperatures, we recommend to add anti-

freeze. The percentage of anti-freeze depends on the lowest ambient temperature.

Manual TT-13’502 E - 7 -

4.5 Pump rotation check

As soon as the unit has been connected to the main supply, hoses connections have been made and the

water has been filled, the sense of rotation of the pump must be checked. This can be done by shortly

switching the unit on. The sense of rotation must be clockwise as shown by the arrow.

In case of anti-clockwise rotation you need to invert two phases on the electrical connection (on the plug or

main supply). This must be done by a qualified electrician only.

Info:

Using a sheet of paper allow if the sense of rotation of the fan is

correct. The sheet of paper must be placed at the rear side of the

unit and should stick to the condenser. Please remove it after test.

If the fan is rotating in the correct direction, the pump is rotating

correctly as well.

The fan runs only if a certain pressure of the refrigerant agent is reached. By too cold air, the fan gets

switched off thanks to a pressure switch (pressostat F42).

5. Operation

For the operating and display elements on the temperature controler see chapter 12 "temperature

controller MP-888."

5.1 Setting of temperature

Temperature range circuit 1: +10°C to +40°C

Temperature range circuit 2: +10°C to +90°C

The required temperature on the temperature controller can be adjusted by pressing the flashes

CAUTION!

PAY ATTENTION TO THE MAXIMUM ALLOWED

TEMPERATURES FOR THE USED HEAT TRANSFER

LIQUID AND HOSES.

The operator can choose the more convenient settings: degree Celsius or degree Fahrenheit.

When the controller gets started, the temperature unit is shown for a short moment.

See instructions „Programming: temperature controller MP-888 for details about function and setting of the

controller (see chapter 12).

5.2 External control

external control of 0-10 V / 4-20 mA is possible. No other interfaces can be used.

Manual TT-13’502 E - 8 -

6. Safety devices

The resetting of the thermal relay can be done by pressing the resetting button on the thermal relay of the

pump motor contactor.

6.1 Pump

The pump motor is protected by a thermal relay – control lamp .

6.2 Compressor (circuit 1)

The compressor is protected by a thermal relay – control lamp .

Info:

The control of the compressor is programmed in a way that a short

on/off is avoided (time-lag of approx. 30 sec.). This guarantees a

long life of the compressor.

6.3 Fan (circuit 1)

The fan is protected by a thermal relay – control lamp .

To guarantee an optimal function of the refrigerating circuit at low ambient temperature, a pressure switch

(ON-/ OFF switch) controls the starting point of the fan.

6.4 Heating

The safety thermostat is set to the maximum allowed temperature. If this temperature is exceeded the red

lamp is lit and the safety thermostat switches the whole unit off.

As soon as the medium temperature falls below the set point the unit automatically switches on again.

Circuit 1:

Circuit 2:

Above +45 °C the whole unit will be

switched off

Within that temperature range the cooling

compressor switches ON/OFF normally

50 °C

40 °C

30 °C

20 °C

10 °C

8 °C

Above +100 °C the whole unit will be

switched off

Within that temperature range the cooling

compressor switches ON/OFF normally

90 °C

80 °C

70 °C

50 °C

40 °C

30°C

20°C

10°C

Manual TT-13’502 E - 9 -

7. Monitoring devices

7.1 Level control

The unit is fitted with two level controls :

yellow lamp on the left is lit: Pre-warning – there is too little water in the tank.

The unit is still working and the horn is activated. Water will

automatically be refilled (see point 4.4). Please also see page 6 –

stop-valve on water inlet.

yellow lamp on the right is lit: The unit stops and the alarm is activated because the level has fallen

below the minimum. The alarm can be switched off by the horn switch

7.2 Anti-freeze (circuit 1)

If the water temperature of the standard unit falls below +8°C the indication lamp is lit and the frost

protection thermostat switches the cooling (compressor) off. It prevents the unit from damages.

7.3Indications of defaults (audible alarm)

During normal operation the horn should be switched on. Any default will then be indicated acoustically.

7.4 Pressure control (circuit 1)

Each unit is equipped with a high- and a low-pressure pressostat with reset button.

-If the ambient temperature exceeds +45 °C or the condenser is not clean, the unit switches off and the

high-pressure lamp HP on the right is lit. (After the failure corrective action the reset button has to be

pushed).

-If not enough refrigerating agent is in the system or the unit is frozen, the low pressure lamp

LP on the left is lit. (After the failure corrective action the reset button has to be pushed).

Manual TT-13’502 E - 10 -

8. Inspection and maintenance (according to DIN 31051)

Inspection and maintenance has to be carried out by instructed staff.

Please contact the manufacturer or your supplier for eventually necessary steps going beyond.

8.1 Inspection

Before starting the heating and cooling unit the following has to be checked:

- condition and tightness of the water connections

- electrical connections

8.2 Maintenance

CAUTION:

DISCONNECT THE UNIT FROM THE POWER SUPPLY

PRIOR TO ANY MANIPULATION ON THE UNIT.

The heating and cooling unit needs periodical checking and cleaning.

Disconnect the unit from the power supply prior to carrying out any work on the unit.

The following service is recommended to grant problem-free operation:

clean fan impeller of pump motor by using compressed air

every 6 months

clean condenser with a soft brush or by using compressed air

every 6 months

CAUTION:

DO NOT USE A METAL BRUSH FOR CLEANING THE

CONDENSER.

These intervals are for standard operation.

For extreme operation these intervals must be shortened accordingly.

Established defects must be repaired.

To guarantee safety the unit must be repaired with original spare parts only.

Manual TT-13’502 E -11 -

9. Failure corrective action

symptom possible cause correction

Green ON/OFF switch and all

lamps are not lit, unit does not work -fuse defective

-possibly transformer or switch

defective

-open the front door

-replace the fuse 5 x 20 mm 1 A

-replace the defective parts

yellow lamp is lit „level control“

left lamp is lit

unit is working

horn sounds :

and can be switch off by the on/off

switch .

right lamp is lit,

unit is not working

horn sounds: - - - - - - - - - - and

can be switch off by the on/off

switch

prewarning – less medium in the

tank, automatic water refill is

defective or not connected

too little water in the tank, automatic

water refill is defective or not

connected.

connect automatic water refill and

open the valve or fill manually

check float, solenoid valve and elec-

trical wiring.

water filter probably needs to be

cleaned.

red lamp „thermal relay pump“

is lit

horn sounds: - - - - - - - - - -

and can be switch off by the on/off

switch

-pump thermal relay has responded

-phase failure (thermal relay)

-pump defective

-pump overheated

-open the front door

-press the blue button on pump

thermal relay

-check electrical wiring

-repair or replace pump

Circuit 1:

red lamp „compressor thermal relay”

is lit -compressor thermal relay has

responded

-phase failure

-motor winding too hot

-open the front door

-press the blue button on

compressor thermal relay

-check electrical wiring

Circuit 1:

red lamp “fan thermal relay”

is lit -fan thermal relay has responded

-phase failure

-open the front door

-press the blue button on fan

thermal relay

-check electrical wiring

Manual TT-13’502 E -12 -

symptom possible cause correction

compressor and pump are not

working; no fault is indicated internal overload relay of the

compressor (thermostat Pilotherm)

has responded.

switch the unit off immediately and

get it checked by a refrigeration

engineer

Circuit 1:

red lamp "LP-HP" is lit Low or high pressure pressostat has

responded If the problem is solved, please

press the reset button on the LP or

HP pressostat

left lamp LP is lit Low pressure

-no water circulation

-too little freon in the system

-expansion valve defective

-running temperature too low

-ambient temperature too low

-water frozen – let the unit thaw

(approx. 1 day), check pump and

circulation

-let the unit be checked by a

refrigeration engineer

-check controller

-check anti-freeze thermostat

- re-site the unit, eventually

contact the supplier.

-add anti-freeze

Circuit 1:

right lamp HP is lit High pressure

-water temperature above +45°C

-ambient temperature too high

-condenser soiled

-fan defective

-fan rotation not correct

-wait until the temperature has

dropped, check capacity of unit

-check fresh air inlet

-clean condenser with soft brush,

do not use metal brush

-repair or exchange fan

-invert 2 phases

(check pump direction,

see point 4.5)

If the problem is solved, please

press the reset button on the LP or

HP pressostat

red lamp „water safety thermostat

is lit -water temperature above +45°C

-ambient temperature above +45°C

-cooling capacity too low – try to

find the cause

-wait until the water temperature

has dropped

- re-site the unit, eventually

contact the supplier.

red lamp „anti-freeze“

is lit As soon as the temperature on the

standard version drops below +8°C

the anti-freeze thermostat responds

in order to protect the unit from

becoming frozen and defective.

-temperature controller defective

-ambient temperature too low

-wrong adjustment on anti-freeze

thermostat

wait until the unit has reached a

higher temperature

do not set the controller below

+10°C

-exchange the controller

-contact the supplier

-check the adjustment on the anti-

freeze thermostat

set temperature cannot be reached - heating not switched on

-controller defective

- heating element defective

-switch on the heating

-exchange the controller

-contact the supplier

Manual TT-13’502 E -13 -

symptom possible cause correction

Lamp „cooling“ is lit no default

simply shows that the cooling is

active.

unit is not cooling anymore but the

compressor is running -loss of refrigerant agent

-unit is working in the fringe range

of the cooling capacity

contact the supplier

CAUTION:

DISCONNECT THE UNIT FROM THE POWER SUPPLY

PRIOR TO ANY MANIPULATION ON THE UNIT.

Manual TT-13’502 E -14 -

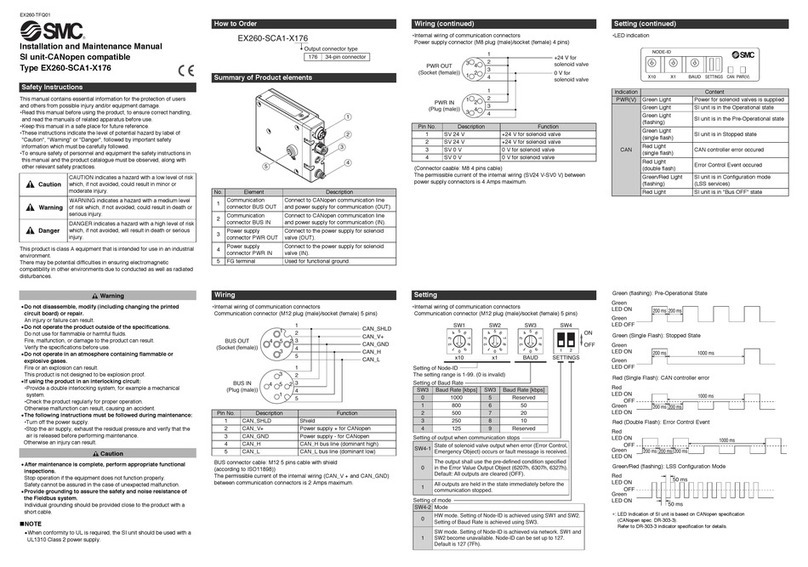

10. Control panel TT-13’502 E

9. Control lamp

overload relay

compressor

10.Control lamp overload

relay fan

1. ON/OFF switch unit

8. Indication lamp (green):

cooling active

11.Lamp pressure control:

LP: low pressure

5. Control lamp

overload relay pump

Circuit 1

7. Control lamp

water temperature in

the tank too low

4. Level control lamp:

dropping below the

minimum level

-Unit switches off

13.ON/OFF switch

horn: ON means that in

case of a defect the

horn will be activated

3. Level control lamp: pre-

warning, not enough

liquid in the unit

2. ON/OFF switch

heating

see„Temperature

controller MP-888 /

programming“

Circuit 2

6. Control lamp

water temperature in

the tank too high

1

2

3

4

5

6

8

1

2

3

4

5

6

8

7

11

12

9

10

13

13

12.Lamp pressure control:

HP: high pressure

Manual TT-13‘502 E -15 -

11. Views and dimensions (in mm)

11.1 Front view

Main switch

Air outlet

Circuit 1:

From mould R 3/4“

female thread

Circuit 2:

Drainage R 3/8“

female thread

Autom. refill

R 3/8“ female

thread

Air outlet

Circuit 1:

To mould R 3/4“

female thread

Control panel

11.2 Rear view

11.3 Dimensions

660

980

1180

1300

120

Manual fill

Overlfow

Air inlet

Air outlet

Circuit 1:

Drainage R 3/8“

female thread

Circuit 2:

From mould R 3/4“

female thread

Circuit 2:

To mould R 3/4“

female thread

Manual TT-13‘502 E -16 -

11.4 Inside view

Compressor

Expansion valve

Electrical cabinet

Pump with motor

(Circuit 2)

Pressostat LP/HP

Float with

microswitch

(circuit 2)

Drier

Solenoid valve

freon

Fan with motor

Freon collector

Tank

(circuit 2)

Condenser

Sight glass

freon indicator

Plate heat exchanger

autom. refill

Pressostat fan

Pump with motor

(Circuit 1)

Float with

micorswitch

(Circuit 1)

Tank

(Circuit 1)

Manual TT-13'502 E -17 -

11.5 Inside view of control panel

temperature controller

MP-888 (N1, N2)

horn (H15)

thermal relay

pump (F1, F2)

thermal relay

compressor (F3)

auxiliary relay start-delayed

(K23) with RR 900

contactor pump motor (K1, K2)

max. and min.

thermostat

(F13, F14, F42)

main switch(Q1)

contactor

compressor (K5)

contactor heating

(K3, K4)

control fuse

primary voltage (F7)

control fuse

secondary volt. (F8)

transformer (T1)

thermal relay

fan (F4)

automatic cut off

(F22, F20)

contactor fan (K6)

auxiliary relay

(K25-/2/3/4/5)

Manual TT-13'502 E -18 -

12.Temperature controller MP-888

cooling switched on

heating switched on

sensor failure

controller is triggered from

external source with a signal of

0-10 V - or 4-20 mA

electronic safety

thermostat

automatic temperature

monitoring / upper and

lower limit contact

programming key:

press the button for

3 sec.

Program steps:

P01 maximum temperature

0-400 °C

(set value +50 °C)

P02 temperature monitoring

limit +/- 20 °C

(set value +/- 5 °C)

set point

actual value

connections 26 - 28

for external analogue set point

0-10 V oder 4-20 mA

heating

cooling

possible supply voltages –

factory adjusted

current supply

temperature monitoring

(extreme value)

possible heat sensor –

factory adjusted

program version

of the controller

heat sensor connection

set point:

adjustment of the

required temperature

flow control – actual flow value

flow control finger tip (reset)

flow control –

minimum flow

flow control

connections 29 + 30

for external analouge actual value

0-10 V

Manual TT-13'502 E -19 -

12.1 Predefined setups

Temperature controller circuit 1 (10 – 40°C):

The temperature controller must be set on the program P12.

Temperature controller circuit 2 (10 – 90°C):

The temperature controller must be set on the program P41 and the following parameters has to be changed.

- P1: Set max. temperature to 90°C

-P21: Set the temperature sensor to Pt 100 2-Draht

The controller finally indicates the program P100 (specialprogramming).

Table of contents

Other Tool-Temp Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT613304 Operation manual

ABB

ABB HT572706 Operation manual

MUSASHI ENGINEERING

MUSASHI ENGINEERING SHOTMASTER QX Series SHOTMASTER SX Series instruction manual

Graco

Graco ProBell instructions

CHART

CHART Trifecta XPro Series product manual

Tractel Group

Tractel Group Dynasafe HF 32 Operating and maintenance manual