SPX POWER TEAM PE18 Series User manual

MODE C & D

HIGH SPEED

HYDRAU IC PUMP

Read and carefully follow these instructions. Most problems with new equipment are caused by improper operation or

installation.

SAFETY PRECAUTIONS

WARNING: To help prevent personal injury,

HYDRAU IC HOSE

●Before operating the pump, tighten all hose connections with the proper tools. Do not overtighten.

Connections should only be secure and leak-free. Overtightening can cause premature thread failure or

high pressure fittings to split at pressures lower than their rated capacities.

●Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the pump

and shift the control valve twice to release all pressure. Never attempt to grasp a leaking pressurized

hose with your hands. The force of escaping hydraulic fluid could cause serious injury.

●Do not subject the hose to potential hazard such as fire, sharp surfaces, extreme heat or cold, or heavy

impact. Do not allow the hose to kink, twist, curl, or bend so tightly that the oil flow within the hose is

blocked or reduced. Periodically inspect the hose for wear, because any of these conditions can damage

the hose and result in personal injury.

●Do not use the hose to move attached equipment. Stress can damage the hose and cause personal injury.

●Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must not

come in contact with corrosive materials such as creosote-impregnated objects and some paints.

Consult the manufacturer before painting a hose. Never paint the couplers. Hose deterioration due to

corrosive materials can result in personal injury.

PUMP

●Do not exceed the PSI rating noted on the pump nameplate or tamper with the internal high pressure

relief valve. Creating pressure beyond rated capacities can result in personal injury.

●Before adding oil, retract the system to prevent overfilling the pump reservoir. An overfill can cause

personal injury due to excess reservoir pressure created with cylinders are retracted.

CY INDER

●Do not exceed the rated capacities of the cylinders. Excess pressure can result in personal injury.

●Do not set poorly-balanced or off-center loads on a cylinder. The load can tip and cause personal injury.

POWER SUPP Y

●All electrical work must be done by a qualified electrician.

●Disconnect the power supply before removing the electrical box cover or performing repairs and

maintenance.

●Never use an ungrounded (two-prong) extension cord with this unit.

Form No. 102355

2P-5500

2P-5550

4030

4031

4032

4033

4035

4036

4037

89300-00

201905

D-01023-AA

D-01026-AA

PE18 Series

Y27 Series

Operating Instructions for:

Sheet No. 1 of 4

Rev. 2 Date: 24 August 2009

SPX Hydraulic Technologies

5885 11th Street

Rockford, IL 61109-3699 USA

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Phone: (507) 455-7000

Tech. Services: (800) 533-6127

Fax: (800) 955-8329

Order Entry: (507) 455-1480

Fax: (800) 283-8665

International Sales: (507) 455-7223

Fax: (507) 455-7746

®

®

powerteam.com

© SPX Corporation

Operating Instructions, Form No. 102355, Back sheet 1 of 4

SET-UP

Hose Connections

1. Clean all areas around the oil ports of the pump and cylinder.

2. nspect all threads and fittings for signs of wear and damage. Replace as needed. Clean all hose ends, couplers,

or union ends.

3. Remove thread protectors from hydraulic oil outlets. Connect the hose assembly to the hydraulic oil outlet, and

couple the hose to the cylinder.

IMPORTANT: Seal all pipe connections with an approved thread sealant. Teflon tape can also be used to seal

hydraulic connections if only one layer of tape is used. Apply the tape carefully to prevent it from being

pinched by the coupler and broken off inside the pipe end. Any loose pieces of tape could travel through the

system and obstruct the flow of oil or cause jamming of precision parts.

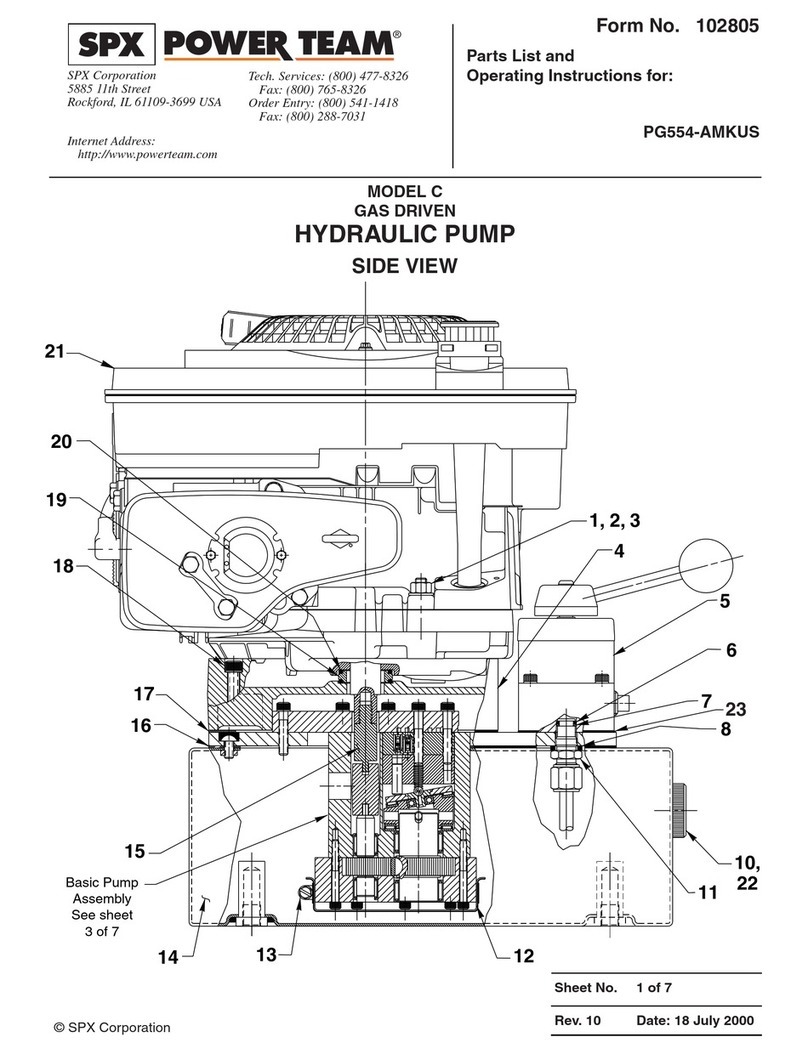

4. Refer to Figure 1.

OPERATION

a. f your pump has a two-way, three-way or automatic

valve, attach one end of the hose to port "C" and the

other end of the hose to advance port "B" of the cylinder.

b. f your pump has a four-way valve for operating double-

acting cylinders, attach one hose between the upper port

"A" on the pump and the return port "D" of the cylinder.

Attach a second hose between the lower port "C" on the

pump and the advance port "B" on the cylinder.

1. Open the filler plug two full turns to vent the reservoir.

2. Place the control valve in the neutral position. (Refer to the

following information about valves.)

3. nsert the power cord into an outlet.

WARNING: To help prevent personal injury, check the

voltage rating on the motor nameplate to be sure the outlet

has the right voltage.

Priming The Pump

1. Back the priming screw out two complete turns. See Figure 2.

2. Jog the pump three times.

3. Tighten the priming screw to 15-25 in. lbs.

Two-Way Valve

(use with single-acting cylinders)

1. Turn the valve handle all the way clockwise. Back the handle

out until it reaches the stop. Always start the pump in this

neutral position.

2. Using the toggle switch, jog the motor several times. Place the

switch on RUN, and let the pump idle for a few minutes.

3. To advance the cylinder, turn the valve handle in all the way

clockwise. See Figure 3.

4. To retract the cylinder, turn the valve handle counterclockwise

until it reaches the stop. See Figure 3.

5. Place the cylinder at a lower level than the pump. Advance

and retract the cylinder several times to remove air from the

hydraulic system.

Figure 2

Figure 3

Figure 1

Operating Instructions Form No. 102355

Figure 4

Figure 5

Automatic Valve

(use with single-acting cylinders only)

NOTE: Pumps with an automatic valve do not have a valve handle. The valve is built into the unit and should

be used only with single-acting cylinders.

1. Place the cylinder lower than the level of the pump.

2. Start the motor to extend the cylinder. When the cylinder reaches the end of its stroke, stop the motor. The

cylinder automatically returns.

3. Extend and return the cylinder several times to remove air from the hydraulic system.

PREVENTIVE MAINTENANCE

WARNING: To help prevent personal injury, disconnect the pump from the power supply before

performing maintenance or repair.

Periodic Cleaning

IMPORTANT: The greatest single cause of failure in hydraulic pumps in dirt. Keep the pump and attached

equipment clean to prevent foreign matter from entering the system.

1. Use only clean hydraulic oil, and change oil after every 300 hours of use.

2. Seal the hydraulic oil outlet and all unused couplers with thread protectors when the pump is not in use.

Three-Way Valve

(use with single-acting cylinders)

1. Place the valve handle in the neutral position as shown in

Figure 4.

2. Jog the motor toggle switch several times. Place the switch

on RUN, and let the pump idle for a few minutes.

3. To advance the cylinder, position the valve handle as shown

in Figure 4. Place the valve handle in neutral again to stop

the cylinder and hold pressure.

4. To retract the cylinder, position the lever as shown in Figure

4. Place the valve handle in neutral to stop the cylinder.

5. Place the cylinder at a lower level than the pump. Advance

and retract the cylinder several times to remove air from the

hydraulic system.

Four-Way Valve

(use with double-acting cylinders)

WARNING: To help prevent personal injury, the

retract port on a double-acting cylinder must be

unrestricted when extending the cylinder.

1. Place the valve handle in the neutral position as shown in

Figure 5.

2. Jog the motor toggle switch several times. Place the switch

on RUN, and let the pump idle for a few minutes.

3. To advance the cylinder, position the valve handle as shown

in Figure 5.

4. To retract the cylinder, position the lever as shown in Figure

4. Place the valve handle in neutral to stop the cylinder.

5. Place the cylinder at a lower level than the pump. Advance

and retract the cylinder several times to remove air from the

hydraulic system.

Sheet No. 2 of 4

Rev. 2 Date: 24 August 2009

Operating Instructions, Form No. 102355, Back sheet 2 of 4

Bleeding Air From The System

Air can accumulate in the hydraulic system during the initial set-up or after prolonged use causing the cylinder to

respond slowly or in an unstable manner. To remove the air:

1. Open the filler plug two full turns.

2. Place the cylinder at a lower level than the pump.

3. Extend and retract the cylinder several times without putting a load on the system. Air will be released through the

pump reservoir.

IMPORTANT: Some spring return cylinders have a capacity in the rod that forms an air pocket. Bleed this

type of cylinder when positioned upside down or lying on its side with the port facing upward.

Hydraulic Fluid evel

1. Check the oil level in the reservoir after every 10 hours of use. The correct level of oil is 1/2" from the top the filler

plug hole with all cylinders retracted.

2. Drain, flush, and fill the reservoir with approved high-grade hydraulic oil after every 300 hours of use. The

frequency of oil changes will depend upon working conditions and the overall amount of use and maintenance

given the pump.

Draining And Flushing The Reservoir

The reservoir should be drained and flushed with a nonflammable flushing fluid after every 300 hours of use.

IMPORTANT: Clean the outside of the pump first to keep dirt from entering the reservoir.

1. Remove the four screws that fasten the pump assembly to the reservoir. Carefully remove the pump assembly

from the reservoir without damaging the gasket, filter, or safety valves.

2. Clean the inside of the reservoir, and fill it with a nonflammable flushing oil. Rinse the filter clean.

3. Place the pump assembly on the reservoir again, and secure it with two of the four screws assembled in opposite

corners of the pump housing.

4. Start the pump and let it idle for several minutes. IMPORTANT: Run the pump with the valve in neutral, or run

the hose back to the reservoir. Do NOT build pressure.

5. Remove the pump assembly from the reservoir again. Drain and clean the reservoir.

6. Fill the reservoir to 1/2" from the top of the filler hole with an approved high-grade hydraulic oil.

7. Place the pump assembly (with gasket) on the reservoir. Assemble the four reservoir screws again and tighten

securely.

Adding Oil To The Reservoir

1. Retract the cylinder, and disconnect the power supply.

2. Clean the area around the filler plug. Remove the filler plug, and insert a clean funnel with a filter.

3. Fill with approved, high-grade hydraulic oil (215 SSU @ 100° F) to 1/2" from top of filler hole.

Checking Brushes on Universal Motors

To help prevent premature failure of the armature

the brushes should be checked periodically.

1. Remove the brush holder caps and brush assemblies.

2. Replace the brush assemblies if they are 1/4" long or less.

See Figure 7.

3. nstall brush assemblies and brush holder caps.

Figure 6

Figure 7

Note: Shaded areas reflect last revision(s) made to this form.

7/8"

(new)

Replace when

1/8" lg. or less

ubrication

To check the level of lubricant in the gear box:

1. Mark the motor housing parts for alignment during reassembly.

2. Remove the four machine screws holding the motor assembly to the pump housing.

See Figure 6. Lift the motor assembly away from the pump housing to uncover the

gear box.

3. f the largest driving gear is not completely covered by oil, add SAE 90 gear

lubricant.

4. Assemble the motor to the pump housing again, aligning the marks made in Step 1.

Operating Instructions Form No. 102355

OPTIONA ACCESSORIES

Pressure Regulating Controls

The pressure range for this pump is from 1000 PS to 10,000 PS . A pressure regulating valve can be adjusted to

bypass oil at a certain pressure setting while the pump continues to run. A pressure switch can be adjusted to stop

the pump motor at a certain pressure setting. Once the pressure falls below the setting, the switch starts the motor

again.

Generally, a pressure switch should be used with a pressure regulating valve. A pressure switch stops the motor at a

selected setting, but the hydraulic pump continues building pressure as it slows to a stop. A pressure regulating valve

bypasses this oil, preventing it from going into the system. As a result, the pressure differential can be held at about

300 PS across the pressure range.

Adjusting The Pressure Switch

NOTE: The pressure regulating valve should be set

first

at the desired maximum pressure.

1. See Figure 7. Loosen the locknut (C) on the pressure switch (B). Slowly turn the adjusting screw (E)clockwise to

increase the pressure setting.

2. Place the control valve in the advance position. Place the motor toggle switch on RUN. With the pump running

and bypassing oil at the desired pressure, slowly turn the adjusting screw (E) counterclockwise, decreasing the

pressure switch setting until the pump motor shuts off. Tighten the locknut (C) again.

3. Release pressure. Move the control valve to advance again, and check the pressure setting and motor cut-out. t

may be necessary to make a second adjustment.

A pressure switch can be used alone for operating other electrical devices (motors, solenoids, relays, etc.) located

elsewhere in the circuit.

Adjusting The Pressure Regulating Valve

NOTE: For easy adjustment of the pressure regulating valve, adjust

pressure by INCREASING to a desired pressure setting.

1. See Figure 8. Loosen the locknut (A) on the pressure regulating valve. Using

a screwdriver, turn the adjusting screw (D) a few turns counterclockwise to

decrease the pressure setting.

2. Connect the pump's power supply, and place the valve in the advance

position. Place the motor control toggle switch on RUN.

3. Slowly turn the adjusting screw (D) clockwise to gradually increase the

pressure setting. When the desired pressure setting is reached, lock the

adjusting screw in position by tightening the locknut (A).

Amperage Draw

This pump can be used with portable generators because of the relatively low

amperage draw of the electric motor. The standard 115 volt motor has a maximum

amperage draw of 12 amps; optional 230 volt motor has a maximum amperage

draw of only six amps.

Hydraulic Gauge

1. Remove the pipe plug from the gauge port located above the

hydraulic outlet port(s). See Figure 9.

2. Apply a small amount of pipe thread sealant or teflon tape on the

gauge threads, and insert the gauge into the port. DO NOT

OVERT GHTEN P PE CONNECT ONS!

Sheet No. 3 of 4

Rev. 2 Date: 24 August 2009

Figure 8

Figure 9

Operating Instructions, Form No. 102355, Back sheet 3 of 4

TROUB E-SHOOTING GUIDE

Depending on the type of pump, it is often best to check for leaks by using a hand pump and applying pressure to the

suspect area without the motor running. Watch for leaking oil and follow it back to its source. (This will not work on an

automatic valve pump, because there won't be any pilot pressure to close the valve.) f there is a crack in the pump

housing, oil can leak into the gear housing and be difficult to find. Always plug the outlet ports of the pump to

eliminate the tool or cylinder as the cause of the leakage.

PROB EM CAUSE SO UTION

WARNING: To help prevent personal injury,

●Trouble-shooting and repair work must be done by

qualified technicians who are familiar with this

equipment.

●Gauges and other equipment used during trouble-

shooting must be rated for 10,000 PSI.

Motor does not run

Motor hums but does not rotate

Hydraulic oil leaking into gear

case under motor

Pump is not delivering oil

1. Pump turned OFF.

2. Pump unplugged.

3. No voltage supply.

4. Broken lead wire or defective

power cord plug.

5. Defective remote switch.

6. Worn brushes.

7. Defective motor.

1. Broken gear has jammed power

train.

1. Damaged oil shaft seal and/or

o-ring seal.

2. Crack in pump body.

1. Oil level too low.

2. Pump is not primed.

3. Loose fitting coupler to cylinder.

4. Vacuum in reservoir.

5. Air in system.

6. Air leak in suction line.

7. Dirt in pump or filter plugged.

8. Oil bypassing through valve or

cylinder.

9. Cold oil or oil is too heavy (of a

higher viscosity than necessary)

1. Turn toggle switch ON.

2. Plug in pump.

3. Check line voltage.

4. Replace defective parts.

5. Check remote switch.

6. Replace brushes.

7. Replace defective parts.

1. Replace broken gear and correct

condition that caused failure.

1. Replace damaged seal(s).

2. Replace pump body.

1. Retract cylinders. Fill reservoir to

1/2" from top of filler hole.

2. Open priming screw - follow

instructions.

3. See if quick disconnect couplings

to cylinders are completely

coupled. Sometimes couplers

have to be replaced, because

the ball check doesn't stay open

due to wear.

4. Open filler plug two turns.

5. Bleed the system.

6. Tighten suction line.

7. Clean filter. Dismantle pump and

clean all parts, if needed.

8. Remove cylinder and see if

pump builds and holds pressure

against coupler at hose ends. f it

does, problem is in the cylinder.

f it doesn't, observe valve drain

line with pump running. f oil is

running out of drain line, problem

is in valve. f not the problem,

disassemble pump and check for

worn or damaged parts.

Conductors North American International

Line............................Black...................Brown

Neutral.......................White ..................Blue

Ground ......................Green ..................Green/Yellow

North American & International Color Codes

Operating Instructions Form No. 102355

PROB EM CAUSE SO UTION

Pump is not delivering oil (cont'd)

Pump delivers only enough oil to

advance cylinder(s) partially or

erratically

Pump builds but does not

maintain pressure

Pump does not build full pressure

10. Relief valve or low pressure

unloading valve set wrong.

11. Motor rotating wrong direction.

12. Defective control valve.

13. Sheared drive shift key.

1. Low oil level.

2. Air in system.

3. Reservoir capacity is too small

for size of cylinder.

1. Defective cylinder.

2. External leaks.

3. nternal leaks: Lift pump from

reservoir, keeping filter in oil.

Remove drain line and look for

leaks from valve.

4. Sheared drive shaft key.

1. Faulty pressure gauge.

2. External leakage.

3. Relief valve set wrong.

4. Cylinder is leaking.

5. Leaking valve.

6. Two-way valve: Valve seat

damaged. ( s oil leaking from

return lin?)

7. Three-/four-way valve: Valve

shear seals or o-rings

damaged. ( s oil leaking from

return line?)

8. Three-/four-way valve: Valve

rotor lapped surface damaged.

10. Adjust as needed.

11. Looking at motor shaft end,

motor must rotate clockwise.

Reverse lead wires to brush

holders, if necessary.

12. nspect all parts and replace, if

needed.

13. Replace key and determine

cause of key failure.

1. Retract cylinder(s). Fill reservoir

to 1/2" from top of filler hole.

2. Bleed air from system.

3. Use smaller cylinder or larger

reservoir.

1. Remove cylinder from pump. f

pump holds pressure, cylinder

is defective.

2. Seal leaking pipe fittings with

pipe sealant.

3. Clean, reseat or replace valve

parts. f needed, dismantle

check valve(s) and repair seat

areas, replace ball and washer.

4. Replace key and determine

cause of key failure.

1. Calibrate gauge.

2. Seal leaking pipe fittings with

pipe sealant.

3. Lift pump from reservoir,

keeping filter in oil. Note

pressure reading when relief

valve begins to open. Adjust if

needed.

4. Remove cylinder from pump. f

pump builds full pressure,

cylinder is defective.

5. Clean and reseat parts.

6. Replace valve seat stem or

reseat pump body.

7. Replace shear seals and/or

o-rings in valve.

8. Lap rotor surface or replace

motor.

Sheet No. 4 of 4

Rev. 2 Date: 24 August 2009

Operating Instructions, Form No. 102355, Back sheet 4 of 4

PROB EM CAUSE SO UTION

Pump does not build full

pressure (cont'd)

Cylinder(s) will not retract

Pump delivers excess oil

pressure

Automatic valve will not allow

pump to build full pressure

Automatic valve will not release

pressure

9. nternal leakage.

10. Sheared drive shaft key.

11. High pressure pump inlet or

outlet ball checks are leaking.

1. Check system pressure. f

pressure is zero, control valve is

releasing pressure and problem

could be in cylinder, linkage to

cylinder, or couplings.

2. Defective valve.

1. Relief valve set wrong.

1. Pilot pressure is too low.

2. Defective or oversize seat in

automatic valve.

3. Short rollers in low pressure

pump. A short roller will make

the pilot pressure erratic,

causing the valve to open

partially and bypass oil into the

reservoir past the ball seat.

1. Piston is sticking.

2. High pressure oil leaking past

the low-to-high pressure check

back to the piston in the

automatic valve, keeping the

piston closed.

9. Look for leaks around entire

inner mechanism. f there are no

visible leaks, the low-to-high

pressure ball check may be

leaking. Remove all parts. Look

for damage to the seat area in

the end plate body. Clean and

reseat, if needed. nspect the

ball for damage; replace if

necessary.

10. Replace key and determine

cause of key failure.

11. Seat or replace valve head.

1. Look for broken return springs in

cylinders. See if couplers are

completely coupled. Sometimes

couplers have to be replaced,

because one check does not

stay open due to wear.

2. nspect and/or replace parts.

1. Adjust relief valve.

1. ncrease pilot pressure.

2. Replace ball and seat.

3. Replace short roller(s).

1. Remove, clean and polish

piston.

2. Seat ball check and carefully

add greater spring force to ball.

(Too much force causes priming

problems.)

This manual suits for next models

14

Table of contents

Other SPX POWER TEAM Water Pump manuals

Popular Water Pump manuals by other brands

Espa

Espa DRAINEX 400 instruction manual

Denison Hydraulics

Denison Hydraulics Goldcup Series Service information

Alarko

Alarko OPTIMA Installation and operating instructions

ALPHA DYNAMIC PUMPS

ALPHA DYNAMIC PUMPS Ruby 040 FDA Installation, operation and maintenance manual

Mistral

Mistral MSP 12 A1 Translation of the original instructions

sauermann

sauermann Si-82 manual