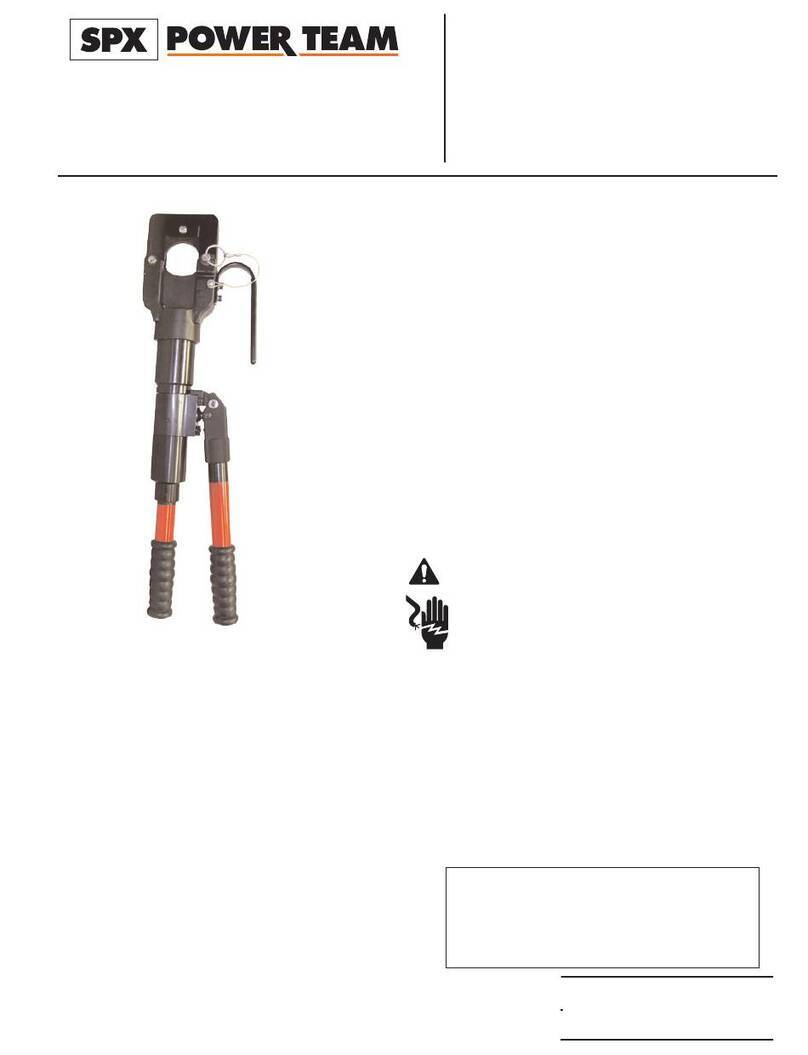

SPX POWER TEAM 6-HCR Use and care manual

Form No. 1000030A

6-HCR-C

Operating Instructions and

Parts List for:

Sheet No. 1 of 4

Rev Date: 11 Feb 2004

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

SPX Corporation

5885 11th Street

Rockford, IL 61109-3699 USA

Internet Address:

http://www.powerteam.com

®

INTRODUCTION

The 6-HCR Hydraulic Cutter Remote is a lightweight,

compact and extremely durable tool that has been designed

for cutting a wide variety of materials.

The Cutter features insert type blades that can be easily

replaced in the field with the use of only a screwdriver. Other

features include a hinged “ Flip Top” Head and a full 360

Degrees of head rotation.

The Cutter can be operated with any suitable hand or power

pump capable of pressure output of 10,000 PSI. No special

control valves are required since the cutter piston is spring

returned.

The 6-HCR is not to be used for hot line work.

SPECIFICATIONS

Blade Opening: 7/8 Inch.

Head Rotation: 360 Degrees

Head Pivot on Hinge: 90 Degrees (Retracted)

Cutting Force: 12,265 lbs. at 10,000 PSI.

Oil required for full stroke: 1-1/2 Cu. In.

To t a l We i g h t : 4 . 6 l b s . ( 2 . 1 k g . )

Mating quick coupler: Power Team Part No 25599

CUTTING CAPACITIES (MAXIMUM

(See Notes)

Wire Rope: 3/4 inch Diameter

Soft Copper Bar: 5/8 inch Diameter

Soft Aluminum Bar: 1/2 inch Diameter

Soft Steel Bolts: 5/8 inch Diameter

Reinforcing Bar: 1/2 inch Diameter

Bare Stranded Copper Wire: 3/4 inch Diameter

Bare Stranded Aluminum Wire 3/4 inch Diameter

ACSR: 3/4 inch Diameter

Stranded Galvanized Steel Wire 5/8 inch Diameter

Underground Power Cable: 3/4 inch Diameter

WARNING

Notes:

Size shown are for stranded bare wires. When

cutting insulated wire, size is over insulation.

Rating for soft steel should not exceed ASTM

1022. Rating for hard drawn steel wire should not

exceed ASTM 1042.

6-HCR

HYDRAULIC CUTTER TOOL

Litho in USA

Operating Instructions and Parts List, Form No. 1000030A, Back sheet 1 of 4

IMPORTANT SAFETY INFORMATION

It is the operators responsibility to read and

understand the following safety statements,

•Onlyqualifiedoperatorsshouldinstall,operate,

adjust, maintain, clean, repair, or transport this

machinery.

•Inspecttoolbeforeuse.Replaceanywornor

damaged parts. Failure to observe these warning

can result in severe injury or death.

Keep hands away from the cutter head

assembly head when cutting.

To help prevent personal injury,

•Alwaysweareyeprotectionwhenever

operating hydraulic equipment.

•Alwayswearhearingprotectionas

required.

•Operation,repair,ormaintenanceofhydraulic

equipment should be performed by a qualified

person who understands the proper function of

hydraulic equipment per local directives and

standards.

•Hydraulicequipmentmustbeassembledcorrectly

and then checked for proper function before use. Use

hydraulic components of the same hydraulic

pressure ratings. An appropriate hydraulic pressure

gauge is recommended to monitor pressure.

• Never place your hands or other body

parts near a hydraulic fluid leak.

Never use your hands or other body parts

to check for a possible leak.

High pressure fluid can be injected under your skin

causing serious injury and/or infection.

•Donotexceedcuttingcapacityofmaterialslistedon

sheet one. Cutting of too large or too hard materials

could cause blades to shatter and cause injury.

• This tool is not insulated. When using this

unit near energized electrical lines, use

proper personal protective equipment.

•Donotcutpianoormusicwire.

•Donotoperatecutterwithtopsupportopen.

•Properlydisposeofallfluids,components,and

assemblies at the end of their useful life.

•Hydraulicfluidshouldbecompatiblewithall

hydraulic components.

IMPORTANT

WARNING

CAUTION

This is the safety alert symbol.

It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death

Denotes an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Denotes a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Denotes a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Caution used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

Denotes an operating or service procedure or condition

considered essential for expedient and efficient

operation and service.

IMPORTANT

CAUTION

CAUTION

WARNING

DANGER

WARNING

WARNING

Sheet No. 2 of 4

Rev Date: 11 Feb 2004

Operating Instructions and Parts List, Form No. 1000030A

OPERATING INSTRUCTIONS

Connect cutter and hose to any suitable hydraulic pump that has pressure

output of 10,000 PSI. The mating half of quick-coupler supplied with cutter is

Power Team Part No. 25599.

Pump should be equipped with 2 or 3-way valve. Put the valve in the retract

position and retract cutter piston fully.

If part to be cut is very long, open cutter head by pulling out pull pin assembly,

slide cutter over part and close head, locking in place with pull pin assembly

fully engaged.

Place valve in advance position and advance piston with pump until lower

blade closes on material. Continue pumping until material is cut and stop

pump when cut is complete to avoid bottoming out piston in cutter and

pumping over relief valve. Although cutter has been designed to overcome

this, repeated bottoming of piston in tool puts unnecessary load on tool and

shortens the life of relief valve.

Retract piston and remove material from cutter.

Note:

After extended use or cutting hard materials, blades will become worn and

pitted. Kit No. 4-1238 is available from the factory for blade replacement.

Replace worn or damaged blades to maintain safe, efficient cutting operations.

Blade Replacement (Kit No. 4-1238)

To r e p l a c e t o p b l a d e, w i t h d r a w p u l l p i n a s s e m bl y a n d o p e n t o p s u p p o r t . R e m o ve s l o t t e d s c r e w a n d t o p bl a d e . I n s e r t

new top blade with flat side facing bottom blade and secure with new slotted screw and lockwasher.

To r e p l a c e b o t t o m b l a d e, a d v a n c e p i s t o n u n t i l b o t t o m bl a d e s c r e w i s ex p o s e d . R e m o v e h ex s o c ke t s c r e w a n d b o t t o m

blade. Insert new bottom blade with flat side facing top blade and secure with new screw.

Close top support and replace pull pin assembly. Cutter is now ready for use.

PERIODIC MAINTENANCE:

Occasionally lubricate pull pins and pivot pins with a molybdenum disulfide grease. The greatest single cause of

failure for hydraulic tools is dirt. Extreme caution should be used to prevent the entry of contaminant's into the unit.

Oil Leaks

A slight weeping of oil from the ram and pump seals is normal and required to keep moving parts lubricated.

Excessive leakage indicates a need for seal replacement.

Seal Replacement

Maintenance and repairs of this type should only be preformed by properly trained personnel in repair shops under

clean conditions. In addition to all parts shown on keyed parts list, 4-1162 Seal Kit is available for this purpose.

6-HCR (Open Position)

Operating Instructions and Parts List, Form No. 1000030A, Back sheet 2 of 4

TROUBLE SHOOTING

If the blade will not extend completely, it will generally be found that there is an insufficient amount of oil in the cutter's

hydraulic system.

If the blade will not retract completely, it will generally be found that there is too much oil in the cutter’s hydraulic

system. Drain enough to permit complete retraction. If the blade will not retract and the oil reservoir is not full, the ram

is likely being held by a deformed washer.

A small amount of leakage is desirable around the ram; to lubricate this part. If enough leakage occurs to cause the

oil to run, the packing should be replaced.

Compatible Hydraulic Fluids:

The use of Amoco Rykon MV oil is recommended. Compatible fluids include:

Mobil DTE 13

Mobil ATF 220

Shell Tellus 32

Arco Dexron III

Citgo AW32

Citgo Dexron III

Other fluids also may be used if they meet or exceed the following specifications:

Viscosity: 180 SSU at 100 degree F.

Flash Point: 350 degree F

Pour Point: -50 degree F

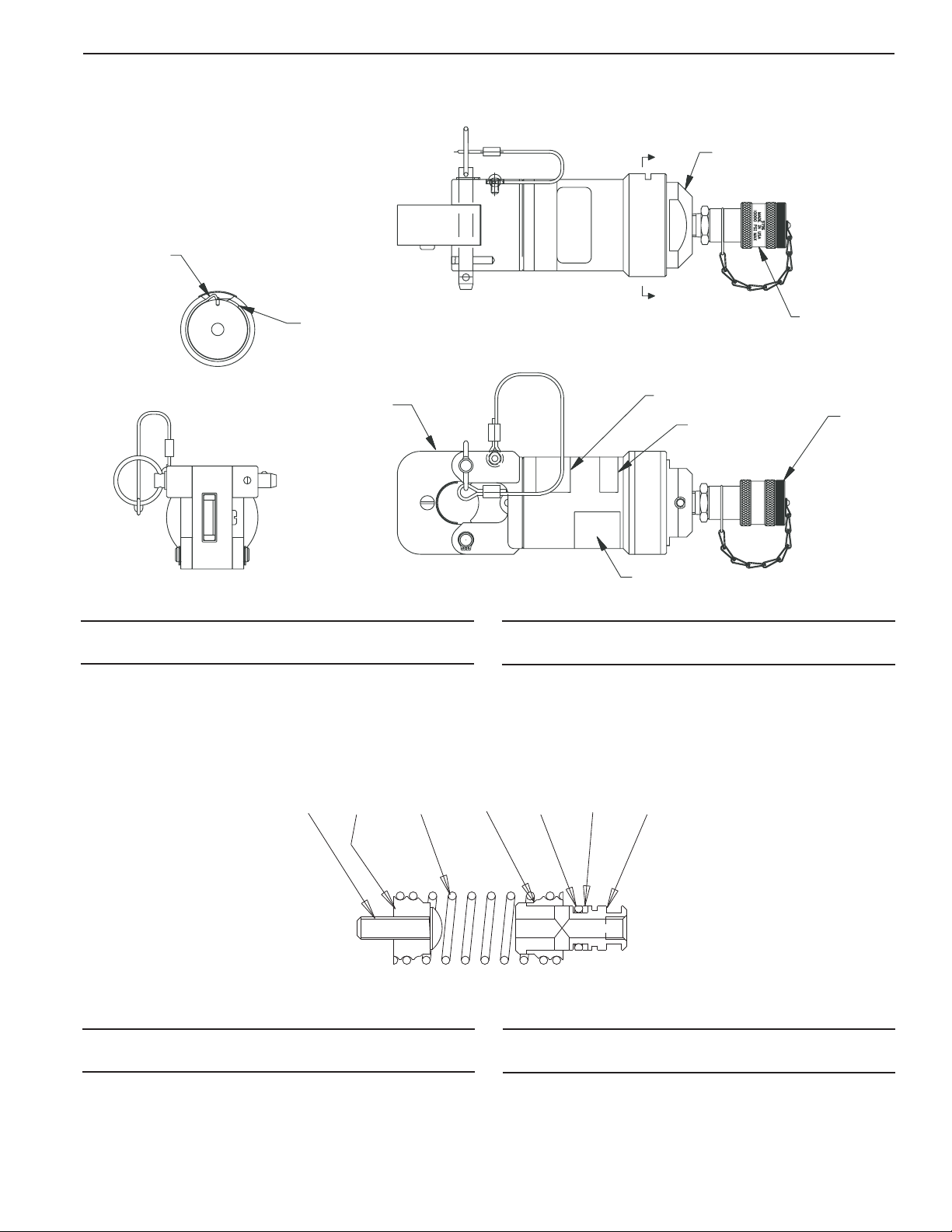

1. Pull Pin Assembly

2. Cutter Head Assembly

3. Adapter

4. Connector

5. Female-coupler

6. Dust-Cap

Illustration

6

5

234

1

Sheet No. 3 of 4

Rev Date: 11 Feb 2004

Operating Instructions and Parts List, Form No. 1000030A

INSTRUCTIONS FOR CONVERSION TO 6-HHC TOOL

1. Fully retract tool ram and make sure all pressure has dissipated. Disconnect tool from hose to pump.

2. Remove adhesive label covering slot in cylinder.

3. Using a thin-bladed screwdriver or punch, pry hooked end of retaining wire out of slot in cylinder.

4. Holding hooked end of wire with pliers, rotate cylinder to force retaining wire out of groove and through slot.

Discard wire.

5. Carefully separate end cap assembly from cylinder assembly.

6. Apply lubricant to groove in pump block and to retaining wire.

7. Insert pump block assembly into back end of cylinder assembly, holding discharge spring in place. Rotate

cylinder assembly until hole in pump block appears in slot in cylinder.

8. Place hooked end of new wire from conversion kit into hole in pump block. Align free length of wire along slot

in cylinder. Rotate cylinder assembly in opposite direction to feed wire through slot and into groove.

9. When wire is fully engaged, hooked end will snap out of hole in end cap to permit full head rotation.

Wedge spring pin in slot in cylinder, allowing wire to move freely beneath. Seal slot with new adhesive label.

10. Purge air from remote tool and pump system using normal fill and bleed procedures.

WIRE SLOT IN CYLINDER

6-HHC TOOL

CUTTER HEAD SUB-ASSEMBLY

(PART NUMBER 4-0866)

PUMP ASSEMBLY

(PART NUMBER 3000089)

CONVERSION ASSEMBLY

(PART NUMBER 4-0766)

1-RETAINING WIRE

1-WRAP AROUND DECAL

®

SPX Corporation, Rockford, IL 61109 USA

http://www.powerteam.com Made in USA

®

SPX Corporation, Rockford, IL 61109 USA

http://www.powerteam.com Made in USA

®

SPX Corporation, Rockford, IL 61109 USA

http://www.powerteam.com Made in USA

Operating Instructions and Parts List, Form No. 1000030A, Back sheet 3 of 4

PARTS LIST

13-9990 1Cap,End

29796 1Coupler,Female(3/8”NPTF)

33-9678 1Wire,Retaining

44-0866 1HeadAssembly,6-TonCutter

51000054 1Decal,Warning

61000056 1Decal,

(Tradename Power Team)

79797 1Plug,Dust

8420691 1Decal,ProductBlank

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

A

A

Apply "White Lube" Lithium Grease (213083)

to groove and wire before assembling.

SECTION A-A

3

1

2

45

67

8

6-HCR

14-1263 1Spring,Tension

24-0697 1Retainer,Fixed

34-0698 1Retainer,Swivel

44-0699 1Tube,Transfer

510266 1O-Ring

65-3880 1Screw,BHSC

75-3245 1Ring,Back-up

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

6213574

SPRING ASSEMBLY 4-0695

Operating Instructions and Parts List, Form No. 1000030A

PARTS LIST

Sheet No. 4 of 4

Rev Date: 11 Feb 2004

13-8682 1Pin,Pivot

23-9008 1CableAssembly

33-9166 1Washer

44-0981 1Wire,Retaining

53-9694 1Blade,Top

63-9695 1Blade,Bottom

73-8672 1Support,Top

84-0691 1Piston

94-0692 1Cylinder

10 4-0694 1Yoke

11 4-0695 1Spring,Assembly,Return

12 10266 1O-Ring

13 10279 1O-Ring

14 251925 2Ring,Retaining

15 19140 1Ring,Back-up

16 5-3245 1Ring,Back-up

17 5-3627 1Screw,Drive

18 5-3678 1Screw,BottomBlade

19 11032 1Ring,Retaining

20 5-3624 1Screw,TopBlade

21 5-3867 1PinAssembly,Pull

22 4-0985 1Bushing

23 5-3868 1Ring,Grip

Item Part No. Item Part No.

No. No. Req’d Description No. No. Req’d Description

AA

21

2

17 3

1

14

20

5

611

18 15

13 19

16 12

SECTION B-B

SECTION A-A

SECTION D-D

B

B

C

C

D

D

SECTION C-C

4

710

22 89

23

Apply "White Lube"

Lithium grease (213083)

to wire and groove

before assembling

HEAD ASSEMBLY 4-0866

This manual suits for next models

1

Table of contents

Other SPX Cutter manuals