IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the following:

WARNING:

ELECTRIC SHOCK CAN CAUSE SERIOUS

INJURY OR BE FATAL. PLEASE READ THE

FOLLOWING INSTRUCTIONS ON THE USE

AND OPERATIONS OF FLOOR FINISHING

MACHINES.

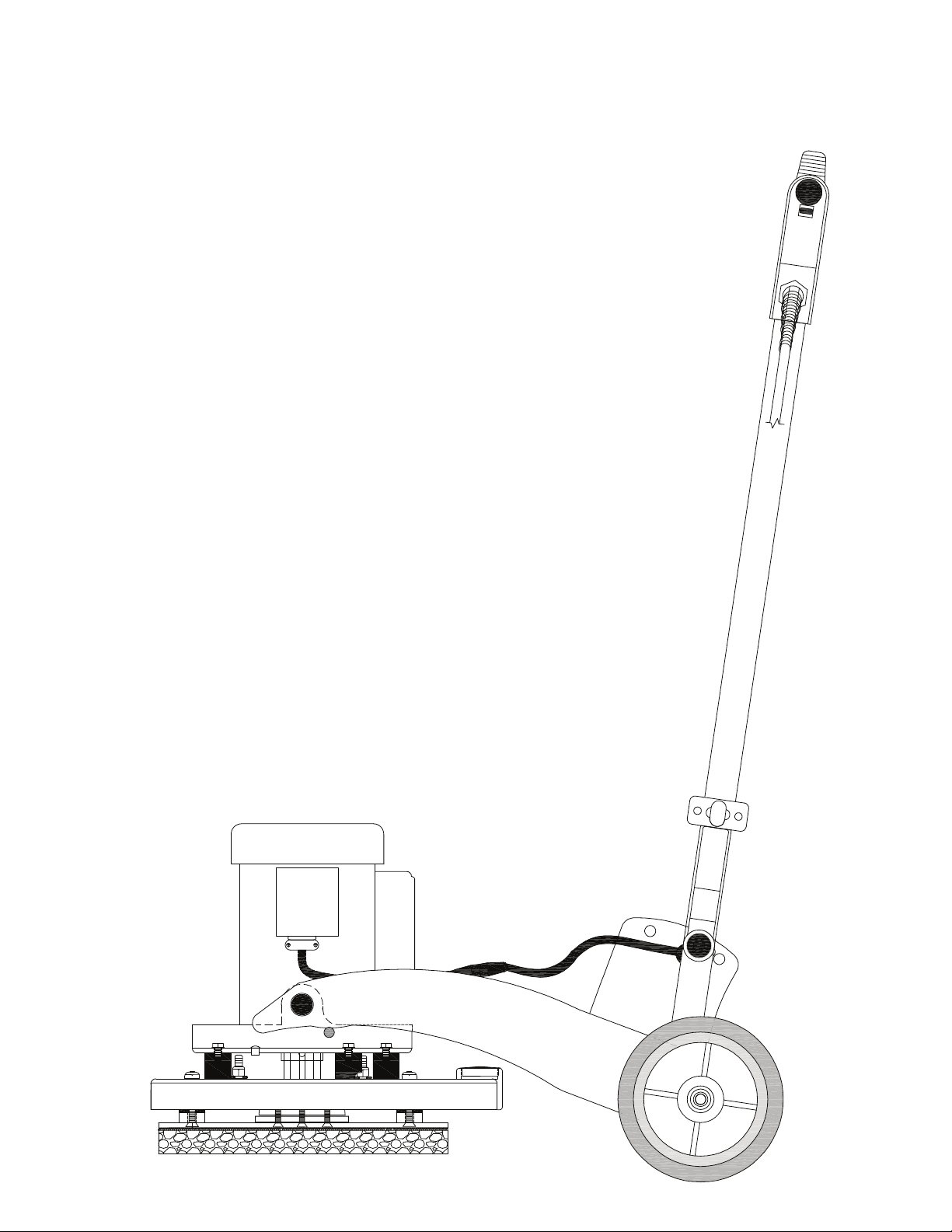

• Your equipped with a safety switch lock and power switch triggers designed for your

safety. Do not attempt to bypass or defeat the safety switch lock. Never use any device

to lock the power switch triggers in the “ON” position.

• Do not leave the unit plugged in. Turn o the switch and unplug the electrical cord

when not in use and before servicing or changing the brushes or pads.

• Do not allow the machine to be used as a toy. Close attention is necessary when used

near children. Do not leave the machine connected to an electrical outlet unattended.

• Use only as described in this manual. Use only manufacturer’s recommended

attachments.

• Do not use with a damaged cord or plug. If the machine is not working as it should, has

been dropped, damaged, or left outdoors, return it to a service center before using.

• Use care to keep the electrical supply cord around sharp edges or corners. Keep the cord

away from the heated surfaces.

• Connect to properly grounded (3-wire) outlet only. Refer to Grounding Instructions,

Page 5-6.

• Do not use extension cords or outlets with inadequate current carrying capacity.

• Turn o all controls before unplugging.

• Do not unplug by pulling on the cord. To unplug, grasp the plug and pull.

• Do not handle the plug or the unit with wet hands.

• Wind the cord no tighter than is necessary to retain it during storage. Refer to Cord

Storage, Page 8.

• Use extra care when working on or near stairs.

• Do not use in conjunction with ammable or combustible liquids such as gasoline, or

use in areas where explosive vapor or dust may be present.

• Store your unit indoors in a cool, dry area.

• Keep your work area well lighted.

• WARNING: To avoid electrical shock, use indoor only.

3