SST O2I-Flex User manual

© 2010 SST Sensing Ltd 1 www.sstsensing.com

DS0074 Rev 7

FEATURES

Provides the electronics necessary to power

and control SST’s range of dynamic oxygen

sensors

High accuracy linear output

Selectable output measurement ranges:

Standard ranges of 0-25% O2 and

0-100% O2or fully adjustable via RS232 when

configured in 0-100% O2mode

Multiple outputs:

4-20mA, 0-10VDC and RS232 comms

interface

Externally triggered automatic or manual

calibration. Calibration can also be initiated via

an on-board push button switch

Can be calibrated in normal air (20.7% O2) or in

any other known O2 concentration

Cycling 3.3VDC logic output allows direct

monitoring of the O2 sensor pump cycle for

diagnostic purposes

Selectable output filtering allows adaptive, fast

and dynamic or slow and stable output

response

Power and Sensor Operating LEDs

Removable polarised screw terminals for easy

wiring

SPECIFICATIONS

Maximum ratings

Supply voltage 24VDC ± 10%

Current consumption 600mA max

@ 24VDC

4-20mA Load 100-600Ω

Temperature limits

Storage -10 to 70C

Operating -10 to 70C

O2I-Flex

APPLICATIONS

Combustion control including oil, gas and

biomass boiler applications

Composting

Laboratory & building air quality monitoring

including confined space personnel safety

Industrial process control i.e. gas mixing for

welding and steel making

Oxygen generation systems

Medical

Scientific including respiratory studies of a

community or an organism, plants and

animals

Food and beverage packaging

Applications where low oxygen is key

including fermentation, rust and corrosion

prevention, inerting and purging

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 2 www.sstsensing.com

DS0074 Rev 7

DESCRIPTION

The O2I-FLEX Interface provides all necessary

electronics to power and control SST Sensing’s range of

dynamic Oxygen Sensors.

The O2I-FLEX Interface can be user configured to output

measuring ranges of 0-25% O2 and 0-100% O2 . The

entire measurement range is linear in both cases. Factory

default is 0-25% O2. When configured for 0-100% O2 the

user can also customise the analogue output ranges to

suit their application.

The interface outputs the measured values

simultaneously via 4 output channels, 4-20mA, 0-10VDC

and RS232 (Rx and Tx), all outputs are referenced to the

system GND.

A digital 3.3VDC logic output cycles at the same

frequency as the electrochemical pumping action of the

oxygen sensing cell during normal operation, thus

providing a real time sensor health check, if the output

ceases to cycle the sensor has entered a start-up or error

state. This provides fault proof operation. The digital

output is also used during the calibration process to

indicate the interface status.

A green on-board LED mirrors the CYCLE output and can

be used to visually determine the sensor status or during

the calibration process. A red LED indicates the unit has

power applied.

SST’s range of oxygen sensors do not directly measure

the oxygen concentration but instead measure the partial

pressure of oxygen within the measurement gas. In order

to output an oxygen concentration (%) the O2I-FLEX

must be calibrated, or more specifically, re-referenced in

a known gas concentration, typically normal air.

Calibration, or re-referencing, is achieved by connecting

the calibration input to GND or by pressing the on-board

calibration switch and monitoring the status of the digital

cycle output or by visually monitoring the on-board green

LED. During the calibration process the output will either

automatically calibrate to a fixed reference or can be

manually calibrated to any output by way of a PCB

mounted potentiometer. The fixed reference is factory set

to 20.7% O2for calibration in normal air though this value

may be altered via the RS232 interface for calibration

with a reference gas of any known oxygen concentration.

Calibration is stored on power loss.

The auto or manual calibrate function is user

configurable. Regular calibration removes the effects of

application and atmospheric pressure changes and also

eliminates any sensor drift that may occur during the first

few hundred hours of operation.

For more detailed information on the operation

of SST Sensing Oxygen Sensors please refer to

the following application note via our website:

AN0043 Operation Principle and Construction of

Zirconium Dioxide Oxygen Sensor.

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 3 www.sstsensing.com

DS0074 Rev 7

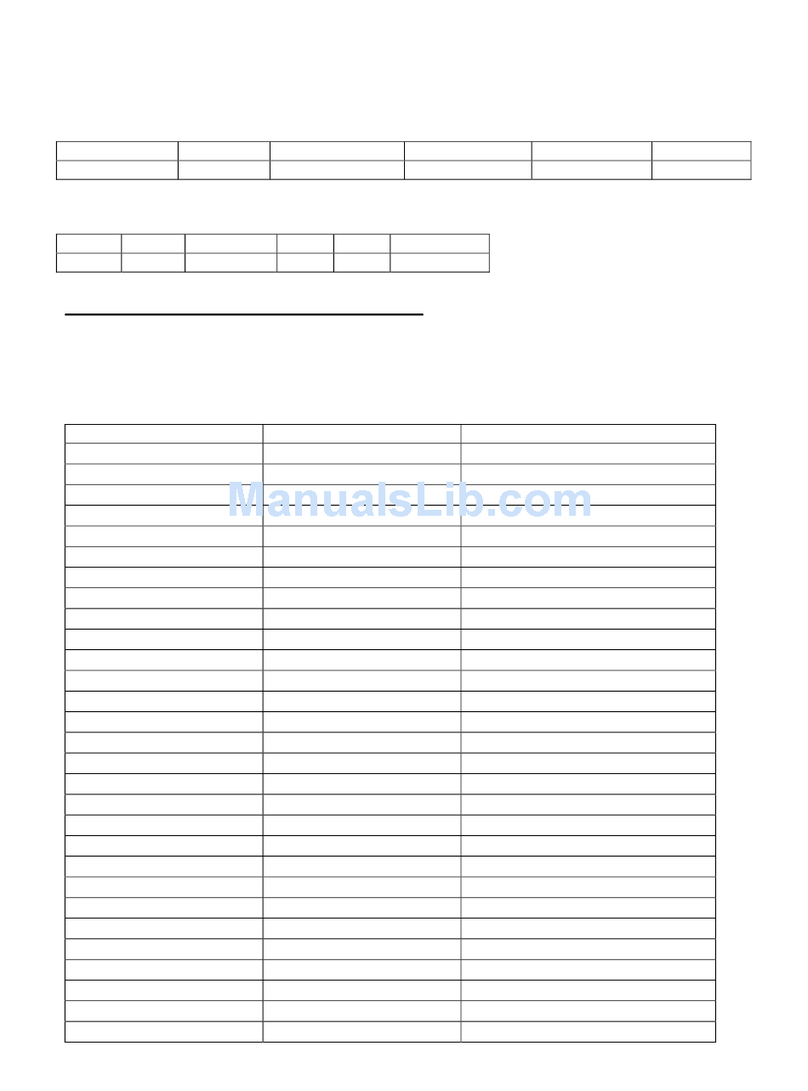

PERFORMANCE CHARACTERISTICS

Characteristics Min. Typ. Max. Unit

Output inactive start up delay (heater warm up) 60 s

Initial warm up time (till stable output) 5 10 min

Measuring ranges

25% Configuration

100% Configuration

0.1 (1)

0.1 (1)

25

100

% O2

Accuracy After Calibration (2) (3) 1 % O2

Repeatability After Calibration (2) 0.5 % O2

0-10 VDC Output Resolution 0.01 V

4-20mA Output Resolution 0.01 mA

RS232 Output Resolution 0.01 % O2

Reaction time (adaptive output filtering in normal air) 1 s

Notes:

(1) Prolonged operation below 0.1% O2can damage the sensing element.

(2) Assuming barometric pressure remains constant.

(3) As the O2 sensor measures the partial pressure of oxygen (PPO2) within the measurement gas deviations in the

Barometric Pressure (BP) from that present during calibration will cause readout errors proportional to the

change. For example if the sensor was reading 21% O2at 1013.25mbar and the BP increased by 1% the sensor

readout would also increase by 1% to 21.21% O2.

OXYGEN SENSOR HEATER ADJUSTMENT

The Oxygen Sensor heater must be adjusted to the correct heater voltage depending on the variant of sensor.

For a sensor with a full porous cap the heater voltage should be adjusted to 4.35VDC measured as close as possible to

the sensor heater connections.

For a sensor with a porous lid the heater voltage should be adjusted to 4.00VDC measured as close as possible to the

sensor heater connections.

The heater voltage is set by adjusting the HEATER VOLTAGE ADJUST pot, highlighted below and on page 4.

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 4 www.sstsensing.com

DS0074 Rev 7

OUTLINE DRAWING AND MOUNTING INFORMATION

60mm

60mm 67mm

67mm

4 x M4 Mounting holes on industry standard 60x60mm pitch

PCB LAYOUT

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 5 www.sstsensing.com

DS0074 Rev 7

ELECTRICAL CONNECTIONS

Output pins 8, 9, 12 & 13 are all referenced to the supply GND (pin 7). Due to high current flow in the supply GND, when

monitoring the 0-10VDC output (pin 9) it is recommended that a separate GND wire for the measurement system is taken

from PIN 7. This removes errors due to voltage drops in the power supply connections.

Every SST oxygen sensor has two heater connections which should be connected to pins 1 & 2 of the O2I-Flex, the

heater coil has no polarity. However when connecting to a sensor where the sensor housing is one of the heater

connections, pin 1 of the O2I-Flex should be connected to the housing.

SYSYEM BLOCK DIAGRAM

PIN Description

1 Sensor Heater GND (Yellow, H)

2 Sensor Heater + (Yellow, H)

3Sensor Sense (Blue, S)

4 Sensor Common (Black, C)

5 Sensor Pump (Red, P)

6 24VDC ± 10%

7 GND

8 4-20mA Output

9 0-10VDC Output

10 Calibrate

11 Cycle

12 RS232 Tx

13 RS232 Rx

6 7 8 9 10 11 12 13

1 2 3 4 5

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 6 www.sstsensing.com

DS0074 Rev 7

RS232 COMMUNICATION SETTINGS

When connecting the O2I-FLEX via the RS232 connections ensure Tx goes to Rx of the PC and Rx goes to Tx of the

PC.

The O2I-Flex communicates via standard COM port settings that are default on most PCs and many other RS232

compatible devices. If however communication problems are occurring use the settings below to configure the PC or

device COM Port.

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 7 www.sstsensing.com

DS0074 Rev 7

CONFIGURATION

The O2I-FLEX may be reconfigured at any time by

adjusting the position of the header pin jumper links on the

interface PCB.

WARNING: Prior to re-configuration the O2I-FLEX MUST

be powered down. The jumper links MUST also be

repositioned correctly and in the correct orientation.

Power down the O2I-FLEX

Adjust the position of the jumper links to the desired

configuration. The diagram below shows the

Interface PCB and the correct orientation of the

Jumper Links. Thin nosed pliers should be used to

remove and replace the Jumper Links. Ensure the

Jumper Links are correctly seated before reapplying

the power

NOTE: Each Jumper Link must be placed in one of the two

positions, either Manual (MANUAL CAL) or Automatic

(AUTO CAL) Calibration and 100% or 25% Measuring

Range.

RS232 OPERATION

With the O2I-FLEX RS232 outputs connected to a PC or

any other RS232 compatible device the user has the

ability to access two modes of operation, continuous data

streaming and the menu screens. Recommended

programs for communicating via PC serial RS232 are

Hyperterminal (windows default), Teraterminal and PuTTY.

A freeware PuTTY link can be found below;

http://the.earth.li/~sgtatham/putty/latest/x86/putty.exe

Continuous Data Streaming

On power up, after the initial 60s heater delay, the O2I-

FLEX will automatically begin outputting the measured O2

concentration and sensor Td as both an averaged and raw

value.

The averaged values give a stable output with the amount

of averaging user variable whilst the raw un-averaged

values allow the user to detect sudden oxygen changes.

The averaged value is the measurement output on both

the 4-20mA and 0-10VDC outputs. The sensor Td value is

the measure of the partial pressure of oxygen in the

measurement gas. The O2concentration (%) is the Td

value scaled by the stored calibration value.

To stop or restart the data streaming ‘s’ (lower or upper

case) should be sent to the unit. Data streaming

automatically ceases during calibration.

Menu Screens

If the O2I-FLEX receives an enter character from the

connected PC or device it automatically enters the menu

password screen and stops outputting O2% and Td

values. After the correct password is entered followed by

the enter character, the menu screens are accessed. The

menu screens are primarily for diagnostics and information

although there are user configurable options that may be

changed. These are the automatic O2calibration %, the

amount of output filtering (averaging) and the analogue

output ranges . All three processes are further described

on Page 7.

The menu access password may also be changed by the

user.

Changing the Menu Access Password

The password is factory set to ‘default’. This however may

be changed to a user specific password.

Connect the O2I-FLEX via the RS232 interface to

the PC.

Press Enter then enter your current security

password. Press Enter to access the menu screen.

In the Configuration menu (menu 2) enter ‘3’ to

access the password menu screen.

Enter the new password then press Enter to save.

The new password is now stored in memory and is

retained on power loss.

.

Pressing ESC returns the screen to the previous menu.

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 8 www.sstsensing.com

DS0074 Rev 7

RS232 USER CONFIGURABLE OPTIONS

Changing the Automatic Calibration Value

The system is factory set to automatically calibrate to

20.7% O2to allow simple calibration in normal air. The

auto calibration value is factory set to 20.7% to take into

account average humidity in the atmosphere. If a

calibration with a gas of a different known O2

concentration is required the factory set value may be

changed via the RS232 interface.

Connect the O2I-FLEX via the RS232 interface to

the PC.

Press Enter then enter your security password.

Press Enter to access the menu screen.

In the Configuration menu (menu 2) enter the auto

calibration value screen (option 1 - Enter

Auto Calib).

The number entered should be the oxygen

concentration (%) of the calibration gas to 2 decimal

places. Press Enter to save.

The new Automatic Calibration value is now stored

in memory. This value is retained on power loss.

If calibration is required with a different gas of known O2

concentration and access to the RS232 menus with a PC

is not available in order to change the calibration

percentage, a manual calibration must be performed.

Variable Output Filtering (Td Averaging)

The O2I-FLEX is factory default to use adaptive output

filtering to give an optimum balance between output

stability and response to oxygen changes. However this

balance may be altered by the customer to suit the needs

of the application.

Connect the O2I-FLEX via the RS232 interface to

the PC.

Press Enter then enter your security password.

Press Enter to access the menu screen.

In the Configuration menu (menu 2) enter the Td

average screen (option 2 - Enter Td Averaging).

The number entered should be between 0 and 200.

0 for adaptive filtering (recommended), 1 for very

fast and dynamic output response but relatively

unstable to 200 for an extremely stable output but

very slow response to oxygen changes.

Press Enter to save.

The new averaging value is now stored in memory.

This value is retained on power loss.

Adjusting the Minimum and Maximum Ranges of the

Analogue Outputs (4-20mA and 0-10VDC)

The O2I-FLEX is factory default to output a range of

0-25% O2via its two analogue outputs. This range can be

expanded to 0-100% O2as described on Page 6. When

the unit is reconfigured to output 0-100% O2the user also

has the option to fully customise the output ranges via

RS232. This is extremely useful in applications where the

O2variation is within a narrow band as it allows the

analogue outputs to be tailored to this limited range.

Ensure the O2I-Flex is configured for 0-100%

operation, see Page 6.

Connect the O2I-FLEX via the RS232 interface to

the PC.

Press Enter then enter your security password.

Press Enter to access the menu screen.

In the Configuration menu (menu 2) enter the

maximum range screen (option 3 - Enter O2 Max

Range).

The number entered should be between 1.00 and

100.00 to represent the maximum output range. The

number must also be greater than the saved

minimum range.

Press Enter to save the ESC to return to the

configuration menu.

Enter the minimum range screen (option 4 - Enter

O2 Min Range).

The number entered should be between 0.00 and

99.00 to represent the minimum output range. The

number must also be less than the saved maximum

range.

Press enter to save.

The new ranges are now stored in memory and are

retained on power loss.

An example of changing the min and max output ranges

would be in an normal air atmosphere where the O2range

is between 20-21%. The user could set the minimum

output range to 19% and the maximum output range to

22% and the outputs would vary linearly in between. The

min and max ranges lock out the outputs at the set limits

so 19% O2or lower would set the analogue outputs to

0VDC/4mA and 22% O2or higher would set the analogue

outputs to 10VDC/20mA.

The min and max range adjustment does not apply to the

RS232 output and is overruled if the unit is reconfigured

for 0-25% operation.

O2I-Flex Oxygen Interface

© 2010 SST Sensing Ltd 9 www.sstsensing.com

DS0074 Rev 7

ERROR CONDITIONS

If the oxygen sensor is not connected up correctly or is

damaged the O2I-Flex will highlight this by blinking the

CYCLE output (pin 11) and green LED in a 3 short blinks 1

long blink pattern or continuously OFF. An error code is

also displayed on the RS232 output and the analogue

outputs will go to 4mA and 0V.

If an error condition occurs the unit should be powered

down and all wiring checked before reapplying the power.

If the error condition remains the O2 sensor is damaged

and should be replaced.

O2I-Flex Oxygen Interface

CALIBRATION PROCEDURES

Automatic Calibration

Ensure the O2I-FLEX is configured for automatic

calibration. See CONFIGURATION on Page 6.

Place the sensor probe in the calibration gas,

typically normal air.

Allow the output to stabilise for at least 5 mins. 10

mins if powering from cold.

Apply GND to the CALIBRATE input (PIN 10) or

press the on-board calibration switch for a

minimum 12s. During the 12s the CYCLE output

(PIN 11) and the green LED will go high/on, blink

rapidly, go high/on, go low/off then return to cycling

normally to indicate normal operation has resumed.

At this point remove GND from PIN 10 or release

the calibration switch.

The output will now track to the correct value for the

calibration gas.

Calibration is complete. Calibration values are

retained on power loss.

Manual Calibration

Ensure the O2I-FLEX is configured for manual

calibration. See CONFIGURATION on Page 6.

Place the sensor probe in the calibration gas,

typically normal air.

Allow the output to stabilise for at least 5 mins. 10

mins if powering from cold.

Apply GND to the CALIBRATE input (PIN 10) or

press the on-board calibration switch for a

minimum 5s or until the CYCLE output and green

LED blink at a steady 1Hz. Remove GND from PIN

10 or release the calibration switch. Manual

Calibration is now initialised.

Adjust the MANUAL CAL POT until the output

equals the correct value of the calibration gas

concentration.

Re-apply GND to PIN 10 or press the calibration

switch for a minimum 5s. During the 5s the CYCLE

output/LED will blink rapidly, go high/on, go low/off

then return to cycling normally to indicate normal

operation has resumed. At this point remove GND

from PIN 10 or release the calibration switch.

The output will now track to the correct value for the

calibration gas.

Calibration is complete. Calibration values are

retained on power loss.

SEE PAGE 4 FOR THE LOCATION OF THE

CALIBRATION SWITCH, SENSOR/POWER LEDs AND

THE MANUAL CAL POT.

© 2010 SST Sensing Ltd 10

DS0074 Rev 7

O2I-Flex Oxygen Interface

SENSOR OPERATING TIPS

To get the best performance from the O2I-Flex interface it is important that the attached oxygen sensor is installed and

maintained in the correct manner. The following two pages outline some useful sensor operating tips and a list of gases

and materials that must be avoided to ensure a long sensor life.

Operating the Sensor in Aggressive Humid Environments:

When operating the sensor in warm, humid environments it is important the sensor remains at a higher temperature

than it’s surroundings, especially if there are corrosive components in the measurement gas. During operation this is not

a problem due the 700°C generated by the heater, but this means when the sensor or application is being powered

down the sensor heater must be the last thing to be turned off after the temperature of the surroundings have suitably

cooled. Ideally the sensor should be left powered at all times in very humid environments.

Failure to adhere to the above will result in condensation forming on the heater and sensing cell as these will be the first

components to cool due to their connections to the outside world. When the sensor is re-powered the condensation will

evaporate, leaving behind corrosive salts which very quickly destroy the heater and cell as illustrated below. Note how

the sensor’s external metalwork looks completely normal.

Protecting from Water Droplets:

In environments where falling water droplets are likely the sensor should be protected from water falling directly onto the

very hot sensor cap as this can cause massive temperature shocks to the cell and heater. Popular methods include a

hood over the sensor cap or for the sensor to be mounted in a larger diameter cylinder.

At a very minimum the sensor cap should be angled downwards in the application as this will deflect any falling moisture

and prevent the sensor cap from filling with water.

Using the Sensor With Silicones:

SST Sensing’s oxygen sensors, like all other Zirconium Dioxide sensors, are damaged by the presence of silicone in the

measurement gas. Vapours (organic silicone compounds) of RTV rubbers and sealants are the main culprits and are

widely used in many applications. These materials which are often applied as a liquid or gel still outgas silicone vapours

into the surrounding atmosphere even after they have cured. When these vapours reach the sensor the organic part of

the compound will be burned at hot sensor parts, leaving behind a very fine divided Silicon Dioxide (SiO2). This SiO2

completely blocks the pores and active parts of the electrodes.

If silicone cannot be avoided in the application we advise using high quality, high temperature cured materials which do

not outgas when subsequently heated. SST can provide guidance if there is concern about use of silicone within the

application.

When installing the sensor do not use any lubricants or grease which may contain silicone.

In addition to silicones other gases which may interfere will the sensor are listed overleaf.

© 2010 SST Sensing Ltd 11

DS0074 Rev 7

O2I-Flex Oxygen Interface

WARNING

Due to the power requirements of the sensor

heater the PCB becomes HOT during operation.

Personal Injury

DO NOT USE these products as safety or

Emergency Stop devices or in any other application

where failure of the product could result in

personal injury.

Failure to comply with these instructions could

result in death or serious injury.

CAUTION

Do not exceed maximum ratings and ensure sensor is

operated in accordance with all requirements of AN0043

Failure to comply with these instructions may result

in product damage.

It is the customer’s responsibility to ensure that this

product is suitable for use in their application. For

technical assistance or advice, please email us:

SENSOR OPERATING TIPS continued

Cross sensitivity with other gases:

Gases or chemicals that will have an influence on the life of the sensor or on the measuring results are:

1. Combustible Gases

Small amounts of combustible gases will be burned at the hot Pt-electrode surfaces or Al2O3filters of the sensor.

In general combustion will be stoichiometric as long as enough oxygen is available, the sensor will measure the

residual oxygen pressure which leads to a measurement error. The sensor is not recommended for use in

applications where there are large amounts of combustible gases present and an accurate O2measurement is

required.

Investigated gases were:

H2(Hydrogen) up to 2%; stoichiometric combustion

CO (Carbon Monoxide) up to 2%; stoichiometric combustion

CH4(Methane) up to 2.5%; stoichiometric combustion

NH3(Ammonia) up to 1500 ppm; stoichiometric combustion

2. Heavy Metals

Vapours of metals like Zn (Zinc), Cd (Cadmium), Pb (Lead), Bi (Bismuth) will have an effect on the catalytic

properties of the Pt–electrodes. Exposure to these metal vapours must be avoided.

3. Halogen and Sulphur Compounds

Small amounts (< 100ppm) of Halogens and/or Sulphur compounds have no effect on the performance of the

oxygen sensor. Higher amounts of these gases will in time cause readout problems or, especially in condensing

atmospheres, corrosion of sensor parts. These gases often outgas from plastic housings and tubes when hot.

Investigated gases were:

Halogens, F2(Flourine), Cl2(Chlorine)

HCL (Hydrogen Chloride), HF (Hydrogen Fluoride)

SO2(Sulphur Dioxide)

H2S (Hydrogen Sulphide)

Freons

CS2(Carbon Disulfide)

4. Reducing Atmospheres

Long time exposure to reducing atmospheres may in time impair the catalytic effect of the Pt-electrodes and has

to be avoided. Reducing atmospheres are defined as an atmosphere with very little free oxygen and where

combustible gases are present. In this type of atmosphere oxygen is consumed as the combustible gases are

burned.

5. Others

Dust. Fine dust (Carbon parts/soot) might cause clogging of the porous stainless steel filter and might

have an effect on the response of the sensor to oxygen changes.

Heavy shocks or vibrations may alter sensor properties resulting in the need for a recalibration.

Table of contents

Other SST Recording Equipment manuals