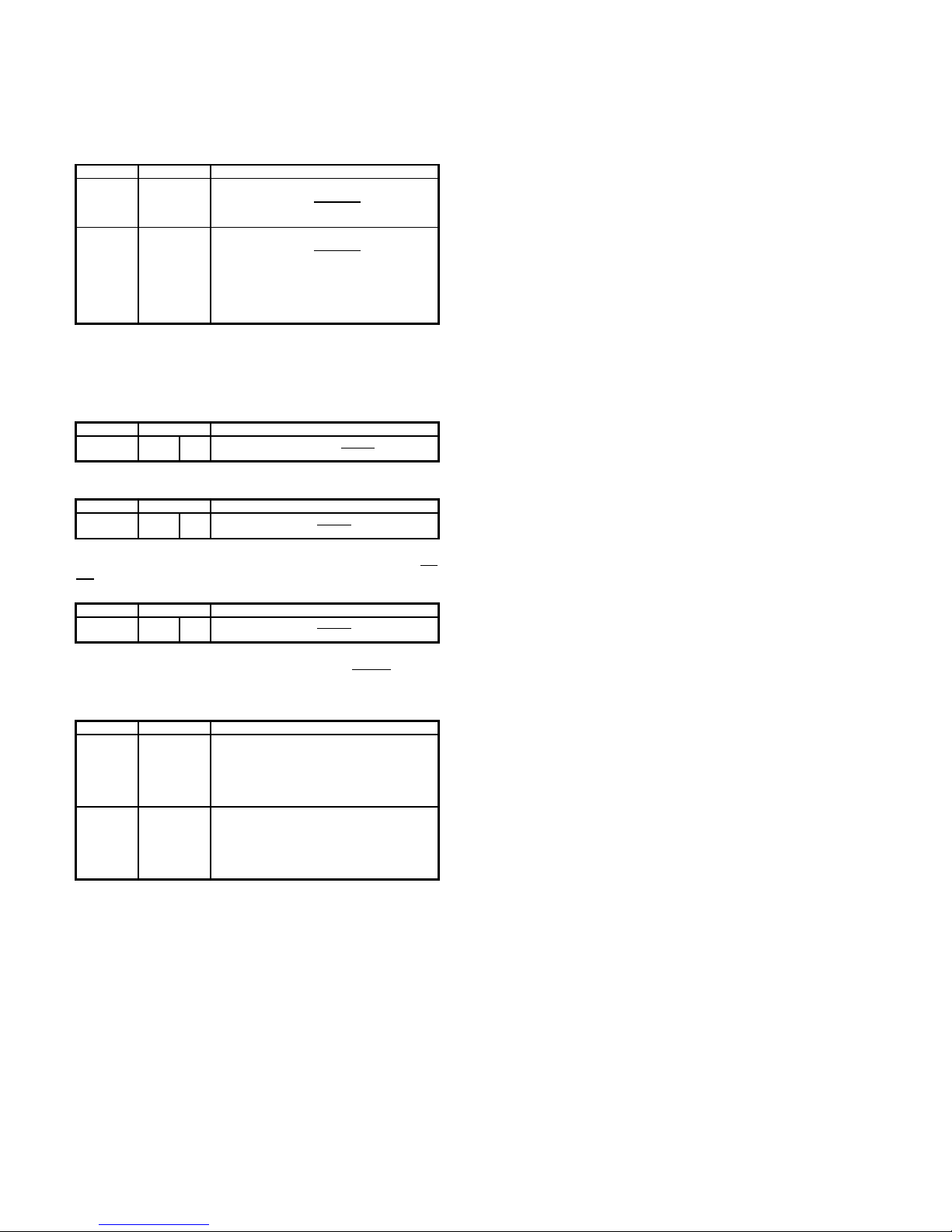

Note: If you only want to connect one SSI encoder, the other SSI

channel has to be disabled in DM m+20, see section Configuring the

Unit via DM for further details.

PNSPO

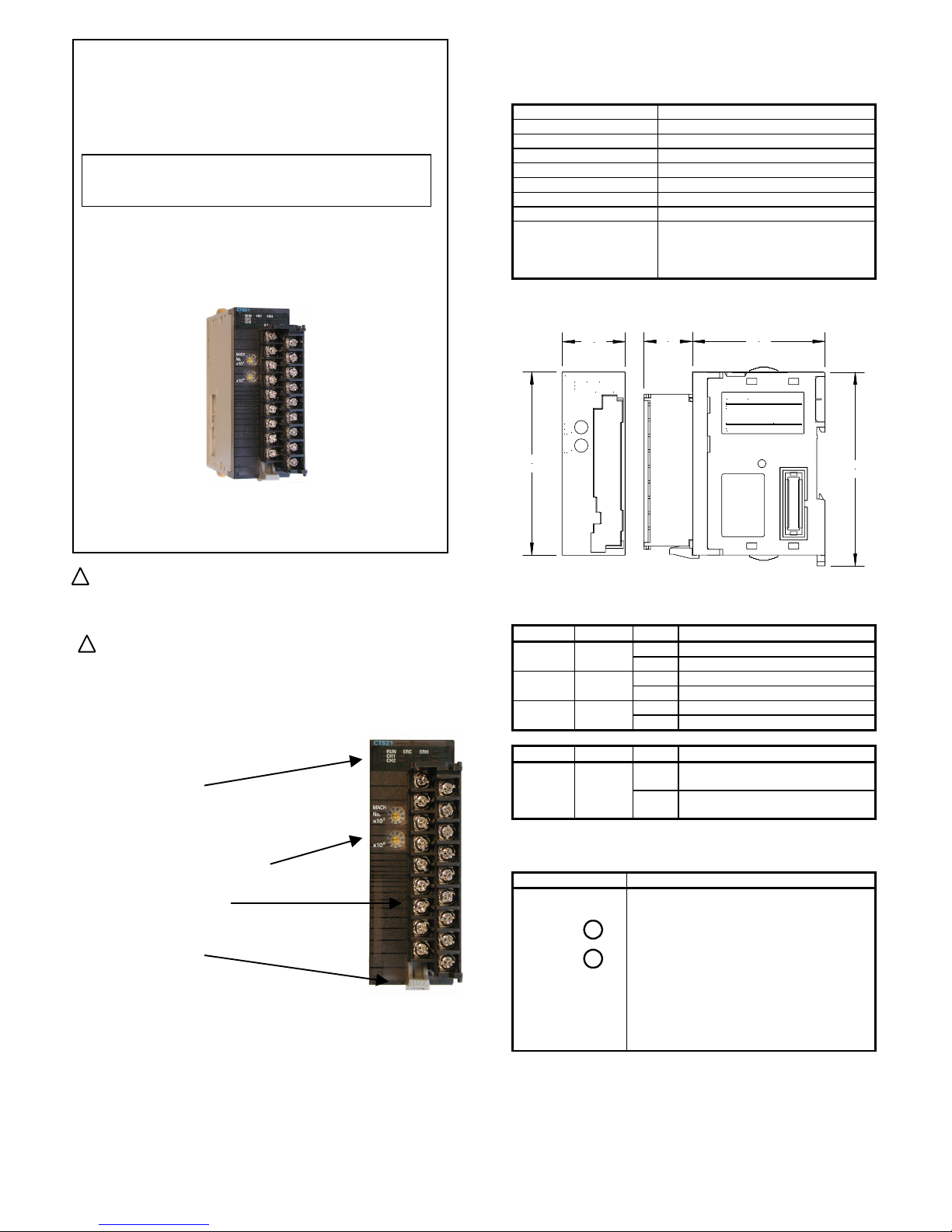

Model

CJ1W-CTS21-E

Synchronous Serial Interface (SSI) Unit

INSTRUCTION SHEET

Thank you for purchasing an OMRON product. Read this

instruction sheet thoroughly and familiarise yourself with the

functions and characteristics of the product before using it. To

ensure safe and correct use of this Unit, also read the following

Operation Manual (Cat. No. W393-E1): SYSMAC CJ1 Series

Programmable Controllers.

Keep this instruction sheet for future reference.

OMRON MANUFACTURING OF THE NETHERLANDS B.V.

OMRON Corporation 2004 All Rights Reserved

1634330-1A

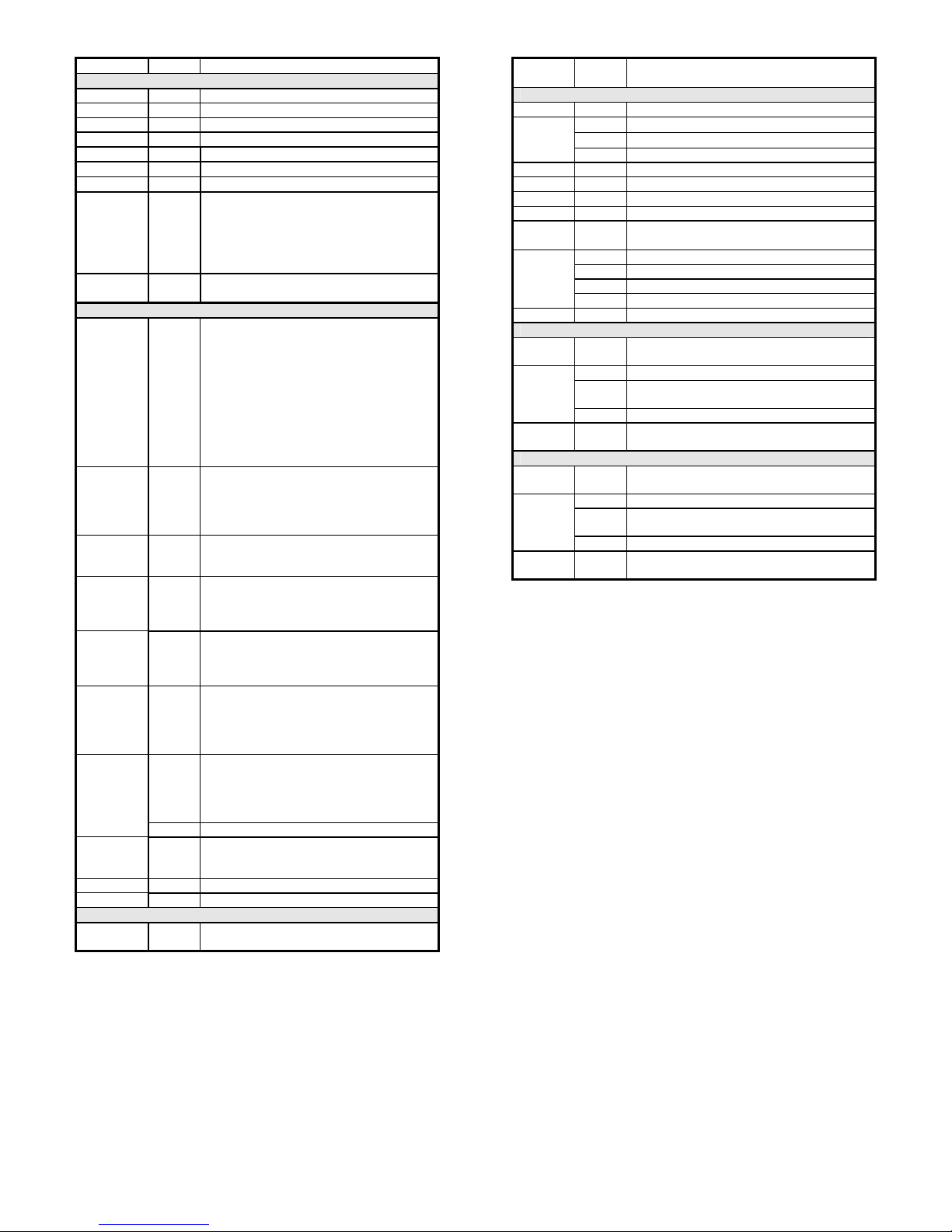

Unit specifications

Unit type CJ1 Special I/O Unit

Applicable PLC models CJ1-series PLCs

Storage temperature -20 to +75 °C

Ambient temperature 0 to +55 °C

Ambient humidity 10 to 90 % (non-condensing)

EMC compliance EN 50081-2, EN 61131-2

Current consumption 300 mA (5V via busconnection)

Weight 200 g (typical)

Number of words

allocated

• 20 CIO-words. First word

allocated = CIO2,000 + (Nx10)

• 30 DM-words. First word

allocated = D20,000 + (Nx100)

Dimensions

EXT.PS FOR ENCODERS: 5-24 V DC, 0.8 A max.

CTS21

10

0

x

10x

1

RUN

CH1

CH2

ERC ERH

B1 A1

MACH

No

CJ1W-CTS21-E

SSI DATA+CLK:RS-422 Line Driver, 1.5 MHz max.

2-CHANNEL SSI UNIT

PNSPO

OMRON MANU FACTURING OF TH E NETHERLAND S B.V.

MADE IN THE NETHERLANDS

Lot No. 000000N0000 Batch No. 000000000

31 65

24

90 95

! DANGER Do not attempt to take the Unit apart and do not

touch any internal parts while the power is being

supplied. Doing either of these may result in

electrical shock, and serious or fatal injury.

! Caution Leave the protective label on top of the Unit as long

as the Unit is not mounted and wired completely, in

order to prevent wire clippings or other materials

from getting inside the Unit. When the mounting and

wiring has been completed, the label must be

removed to allow air circulation and heat radiation.

LED Indicators

Name Colour State Unit status

RUN green On Normal operation

Off Initialisation error

ERC red On Unit error (check CIO n+6, n+7)

Off Unit has no errors

ERH red On CJ1-CPU Unit error

Off CJ1-CPU Unit has no errors

Nomenclature

Unit status indicators

• RUN (green)

• ERC (red)

• ERH (red)

• CH1, CH2 (green)

Machine number rotary switches

Removable Terminal Block

• Connections for SSI-encoders

• Connection for power supply SSI-encoders

Terminal Block latch

• Slide down to remove

Name Colour State Counter channel status

CH1,

CH2

green On Channel configured and is

communicating without errors

Off Channel is not configured or a

communication error has occurred

Machine Number Switch

Name Function

MACHINE No.

Sets the Machine Number (00 – 94).

• Setting Machine Numbers 95-99 will

generate an error.

• Make sure each Machine Number is

used only once per CJ1-CPU.

• The next higher Machine Number should

not be used on any unit, as it would

cause a CIO-data overlap

• Be sure to turn off the power to the Unit

before setting the Machine Number.

x10

x10

1

0

• Slide up to lock

Quick Start

1. Set all DM-settings to 0. The Unit is now configured as follows:

400kHz clock frequency, 24 bit Gray-coded and a 40µs

monoflop time, for both SSI channels.

2. Set Machine Number.

3. Mount and wire the Unit, the two SSI encoders and the

encoders power supply.

4. Turn power on.

5. Create I/O Table.

6. Both green CH1 and CH2 indicators should now turn on.

7. The encoder data can now be read from CIO n+10/11 and CIO

n+15/16.

1