5

NOTICE: If the skimmer does not allow you to see the

Yellow Band on the Regulator, the following TEMPORARY

procedure will let you check the suction:

A. Turn off the Pump.

B. Detach the Regulator Valve from the skimmer’s suction

inlet.

C. Insert the Regulator Valve in the joint between the last

and the next to the last sections of hose.

D. Reconnect the hose to the skimmer.

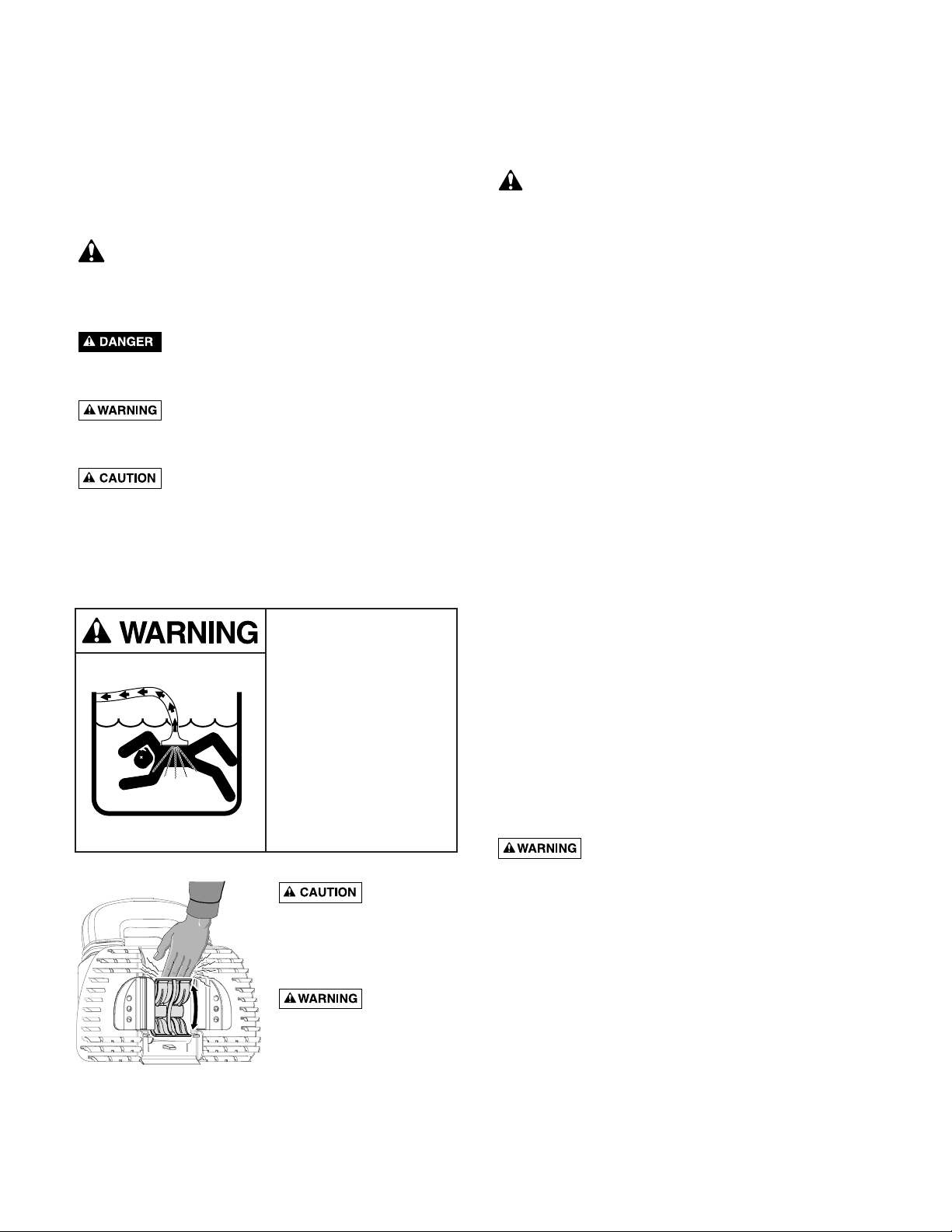

E. While a helper holds the regulator under water (so that

it won’t suck air – see Figure 6), Turn the pump on and

make the valve adjustments described in Steps 2 and 3

(Page 4).

F. When you have finished the valve adjustments, stop

the Pump, reconnect the hoses, and replace the

Regulator in the skimmer.

Do you have enough vacuum on the system for good

operation?

1. If you have not already done so, clean the filtration sys-

tem (including backwashing, if that is appropriate to

your system).

2. If your system is clean and the cleaner still performs

sluggishly, try inserting Regulator Valve #2, which is

designed for use with weaker pumps, longer hose

lengths, or low suction situations.

The installation of Regulator Valve #2 is the same as the

installation of Regulator Valve #1. See “Installation”,

Page 3.

NOTICE: After you have installed Regulator Valve #2, ad-

just the circulation system valves as described in Steps 3

and 4 (Page 4).

Do you have too much vacuum?

You have too much vacuum if the PoolShark sucks air

when it climbs up to the water line. Check to be sure that

you have installed Suction Regulator Valve #1. If not, in-

stall it now. If the PoolShark still climbs out and sucks air,

do the following:

1. If you are connecting the PoolShark to the Skimmer,

slightly open the main drain valve.

2. If you are connecting the PoolShark to the Dedicated

Vacuum Line, slightly open the skimmer intake valve.

3. Check the hose length:

The main circulation pump must be running when you

check the hose length. The hose contracts when the

pump is on and will look longer when the circulation

pump is off or the hose is disconnected from the sys-

tem. Position the PoolShark at the furthest point of the

pool from the skimmer or dedicated suction port. The

hose should be long enough to reach this distance,

with one hose section over.

If your hose is more than one section longer than the

distance to the furthest point of the pool, remove the

extra section(s) from the end of the hose at the vacuum

port or skimmer. Save these extra sections for future use

as replacements.

4. To install the eyeball diverter:

The water flow from the return line can push the

PoolShark’s hose, causing the PoolShark to steer away

from the return line or to remain in one area of the

pool. To correct this, adjust your existing return line di-

verters or install the eyeball diverters supplied with the

PoolShark as follows:

A. Turn off the main circulation pump.

B. Unscrew the lock rings from the pool’s return line

fittings and remove the original eyeball diverters.

C. Replace them with the PoolShark’s eyeball diverters.

D. Replace the lock rings and tighten them. Be sure

that the openings of the eyeball diverters point

down or to the side (9:00 O’clock position), before

fully tightening the rings.

Usually, directing the return line water flow against

the side of the pool (as described above) works

best. However, you may want to try pointing the

flow downward or in different positions to see

which works best in the pool.

After installing the eyeball diverter, turn the circula-

tion pump on. The PoolShark should begin moving

across the pool floor, vacuuming up the debris in its

path.

E. If the PoolShark’s eyeball diverters do not fit your

existing return line fittings, adjust your existing fit-

tings as best you can as described above.

Figure 6: Hold regulator under water to observe sleeve

position.