INSTALLATION

NOTICE: Install pump on a hard, level surface (cement,

asphalt, etc.). Never place pump directly on earth, clay or

gravel surfaces.

Piping

Piping must not be smaller than pump discharge.

When installed in a sewage system, pipe must be capable of

handling semi-solids of at least 2" diameter.

When installed in an effluent system, pipe must be capable

of handling semi-solids of at least 3/4" diameter.

The rate of flow in the discharge pipe must keep any solids

present in suspension in the fluid. To meet minimum flow

requirements (2 feet per second in discharge line), size pipe

as follows:

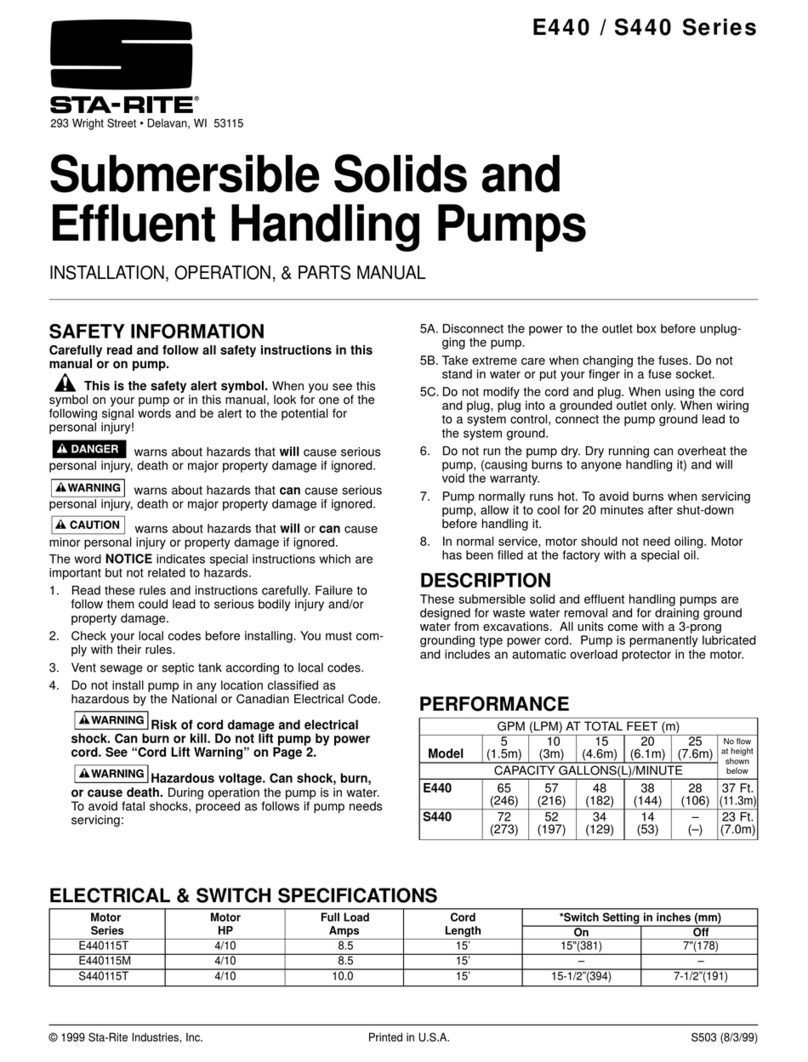

A Pipe Size Of: Will Handle a Flow Rate Of:

1-1/2" 12 GPM

2" 21 GPM

2-1/2" 30 GPM

3" 48 GPM

In a sewage system use a 2" check valve in pump discharge

to prevent backflow of liquid into sump basin. The check

valve should be a free flow valve that will easily pass solids.

Be sure check valve installation complies with local codes.

In an effluent system use a 1-1/2" check valve in pump dis-

charge to prevent backflow of liquid into sump basin. The

check valve should be a free flow valve that will easily pass

solids. Be sure check valve installation complies with local

codes.

NOTICE: For best performance of check valve when han-

dling solids, do not install it with discharge more than 45°

above the horizontal. Do not install check valve in a vertical

position as solids may settle in valve and prevent opening

on startup.

Drill a 3/16" hole in discharge pipe about 1–2" above pump

discharge connection (but below check valve) to prevent air-

locking the pump.

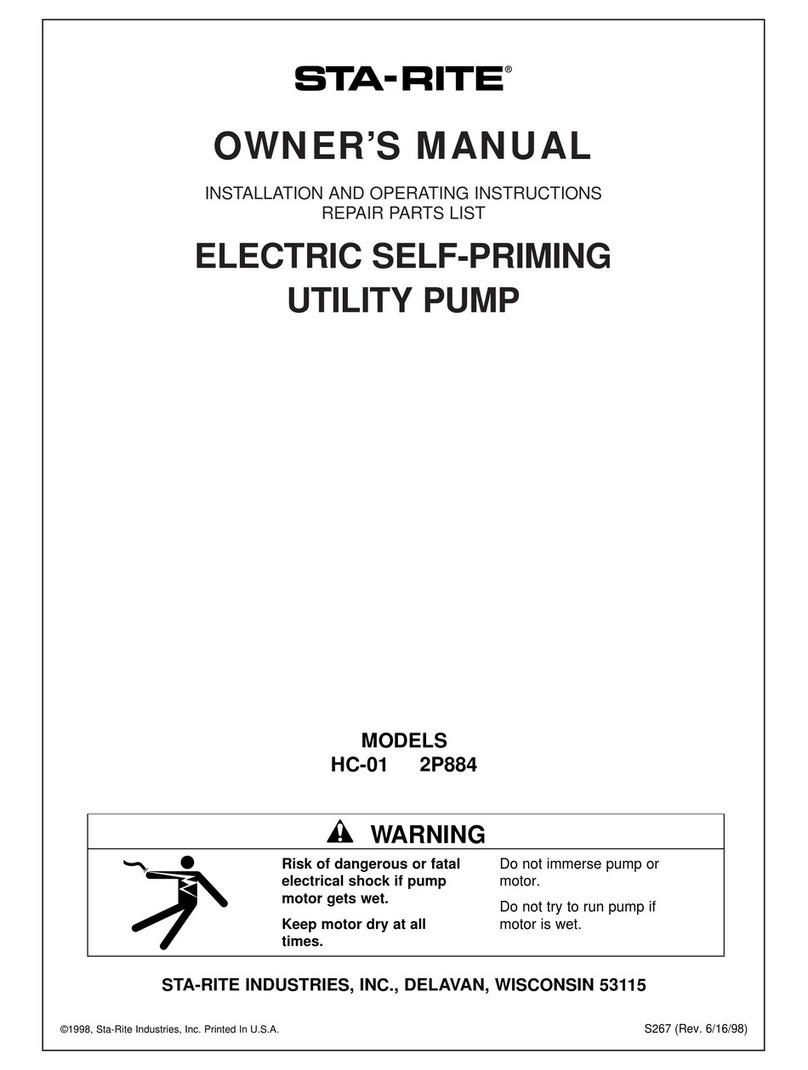

Electrical

Hazardous voltage. Can shock, burn,

or cause death. When installing, operating, or servicing

this pump, follow safety instructions listed below.

1. DO NOT splice the electrical power cord.

2. DO NOT allow electrical cord plug to be submerged.

3. DO NOT use extension cords. They are a fire hazard and

can reduce voltage sufficiently to prevent pumping

and/or damage motor.

4. DO NOT handle or service pump while it is connected to

power supply.

5. DO NOT remove grounding prong from plug or modify

plug. To protect against electrical shock, the power cord

is a three-wire conductor and includes a 3-prong ground-

ed plug. Plug pump into a 3-wire, grounded, grounding-

type receptacle. Connect pump according to NEC and

local codes.

For automatic operation, plug or wire pump into an auto-

matic float switch or duplex controller. Pump will run con-

tinuously when plugged directly into an electrical outlet.

Connect or wire pump to its own circuit with no other out-

lets or equipment in the circuit. Size fuses or circuit break-

ers according to chart below.

Risk of electrical shock and fire. Be

sure that power supply information (Voltage/

Hertz/Phase) on pump motor nameplate matches

incoming power supply exactly. Install pump

according to all electrical codes that apply.

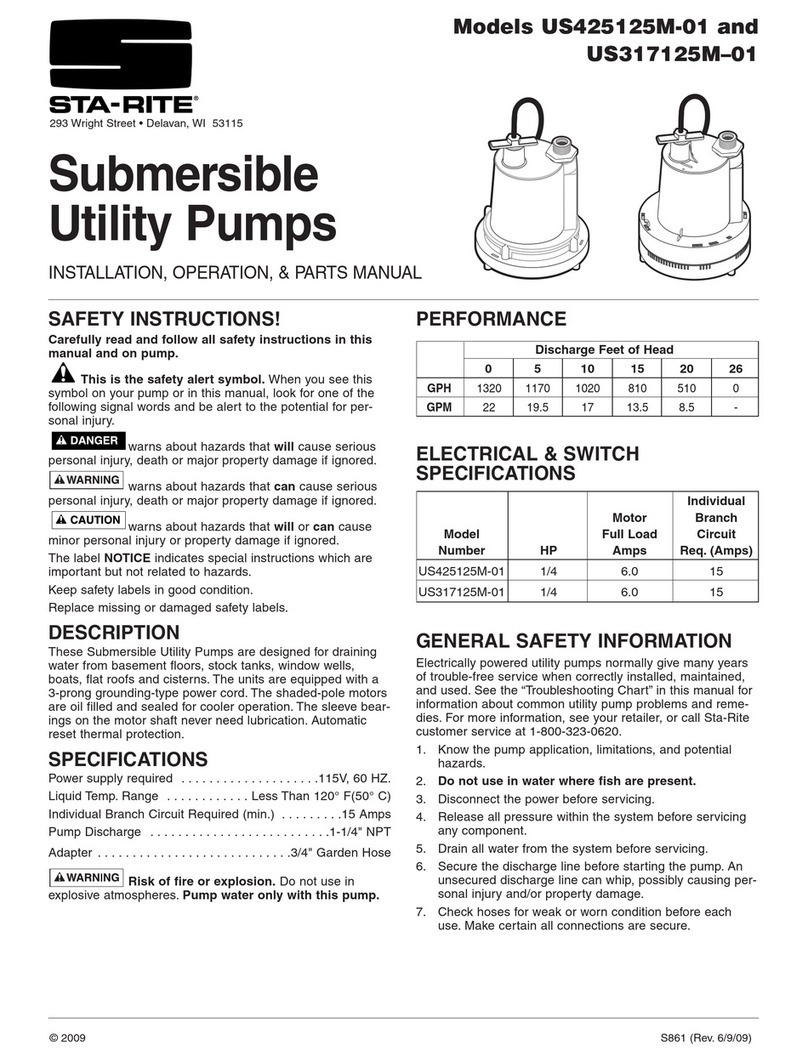

Fuse or Dual Element

Circuit Time Delay

Model HP Voltage Breaker Amps Fuse Amps

300E 1/3 115 20 15

300E 1/3 230 15 10

400E 4/10 115 15 10

500S 4/10 115 20 15

500S 4/10 230 15 10

Operation and Installation

NOTICE: Do not allow pump to run in a dry sump. It will

void the warranty and may damage the pump.

An automatic overload protector in the motor will protect

motor from burning out due to overheating/overloading.

When motor cools down, overload protector will automati-

cally reset and start motor.

If overload trips frequently, check for cause. It could be a

stuck impeller, wrong/low voltage, or electrical failure in

motor. If an electrical failure in the motor is suspected, have

it serviced by a competent repairman.

Pump is permanently lubricated. No oiling or greasing is

required.

2